A manufacturing process of double-socket nodular cast iron pipe

A technology of ductile iron pipe and manufacturing process, which is applied in the field of manufacturing process of double socket ductile iron pipe, can solve the problems of damage to quality, affect the quality of socket casting, single working surface of core mold, etc., and achieve the effect of strong earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

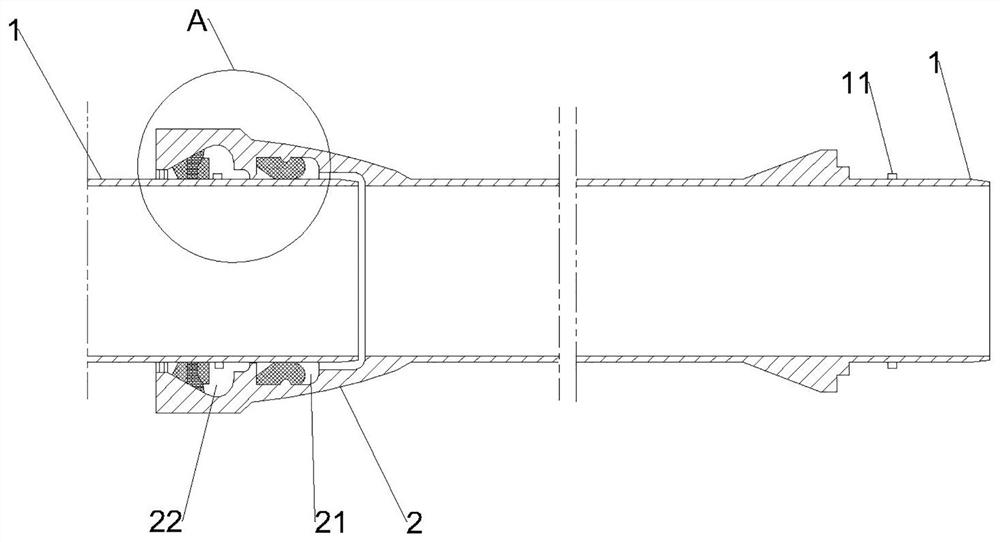

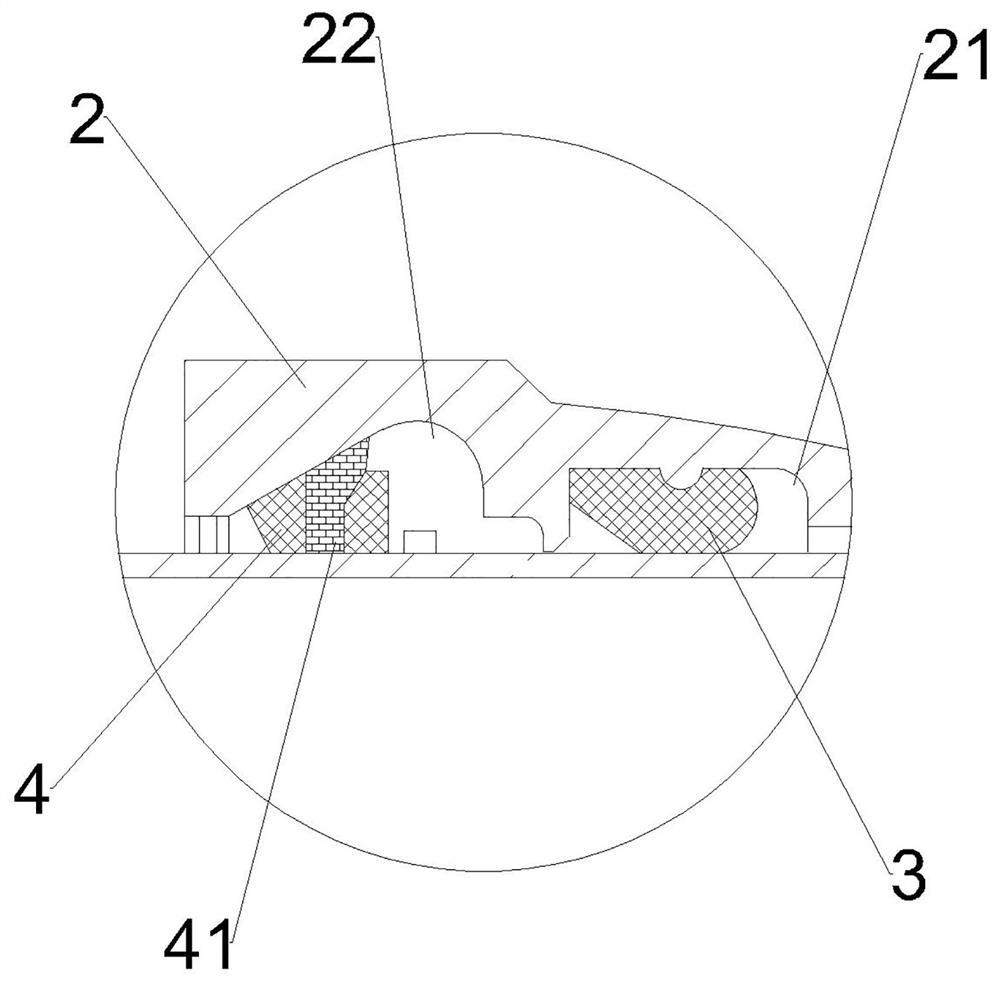

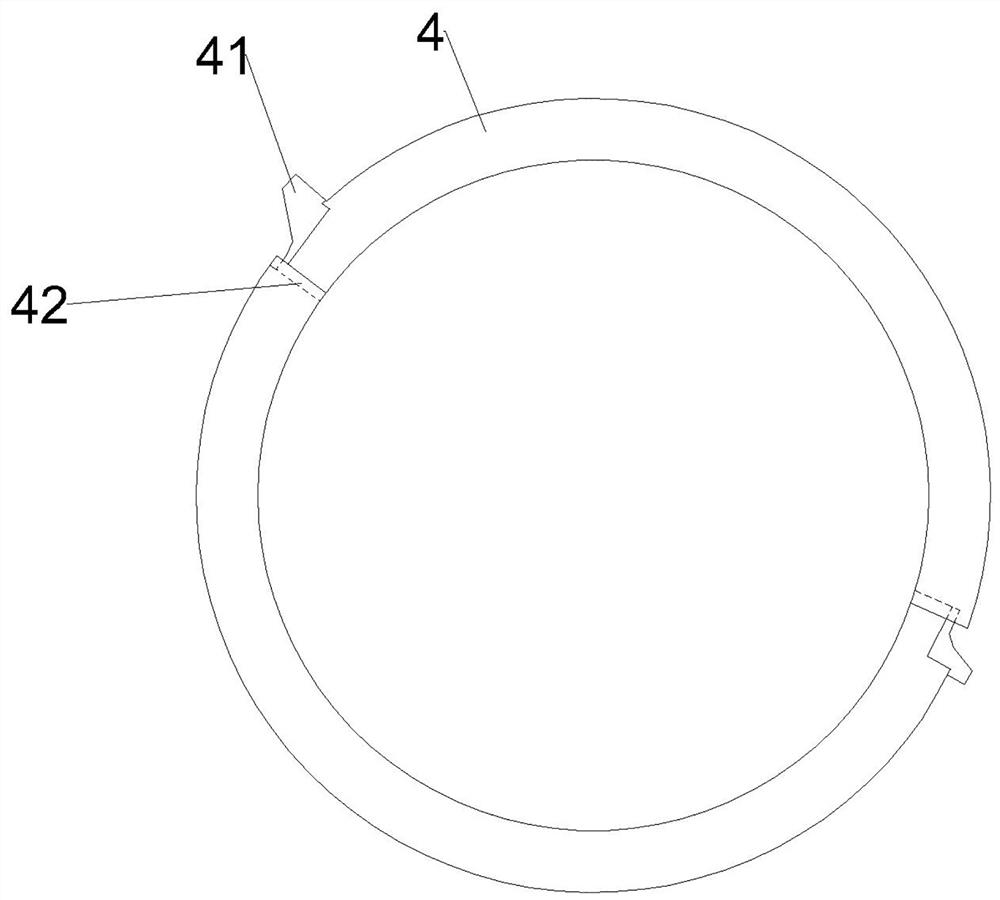

[0031] Such as Figure 1-6 The shown double-socket ductile iron pipe includes a pipe body and a socket 2 and a socket 1 arranged at both ends of the pipe body. The socket 2 is provided with a sealing cavity 21 and an anti-loosening cavity 22 from the outside to the inside. The invention provides a manufacturing process for a ductile iron pipe with double sockets, which specifically includes the following steps:

[0032] 1. Put the dotted pouring mold into the centrifugal pipe casting machine, pour cooling water into the outer wall of the pouring mold for cooling; install the prepared sand mold core 6 on the cast steel core frame, and install the cast steel core frame to the bearing of the pouring mold Mouth. Among them, the specific material for making the pouring mold is 21CrMo10; the arc surface section of the casting mold and the sand core 6 socket end of the anti-snap cavity sand mold part is dotted, and the diameter of the dots after dots is 1.5-4mm, the dot spacing is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com