Sealing element, manufacturing method thereof and battery

A technology for sealing parts and batteries, applied in sealing materials, battery pack components, circuits, etc., can solve problems such as poor battery safety, and achieve the effects of improving safety, reducing manufacturing costs, and being less susceptible to thermal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

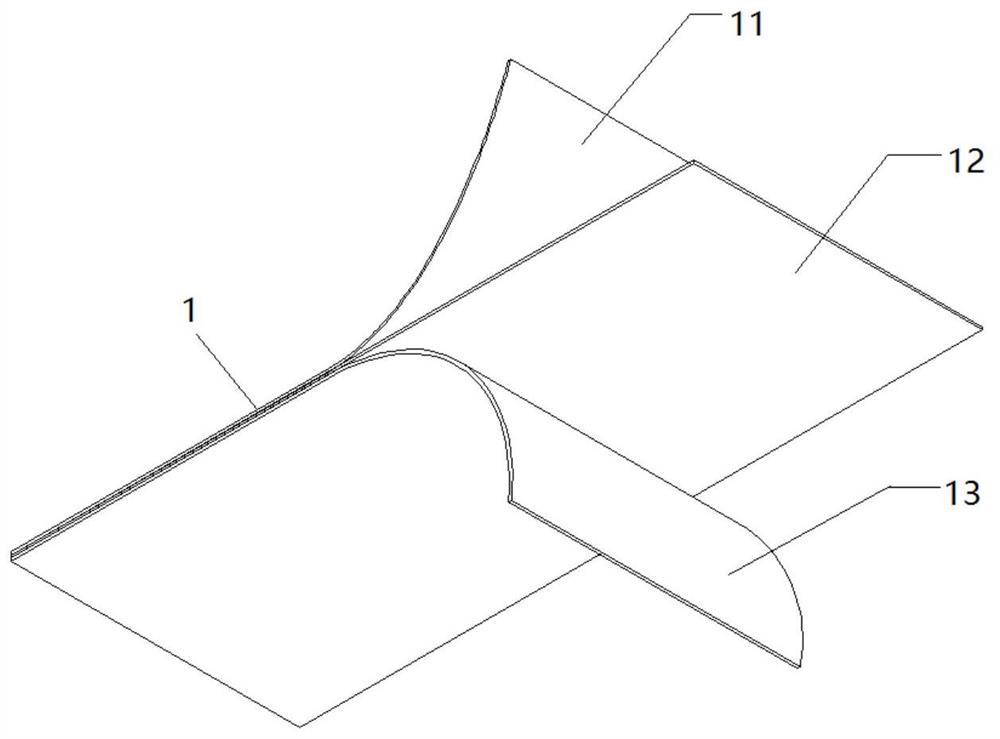

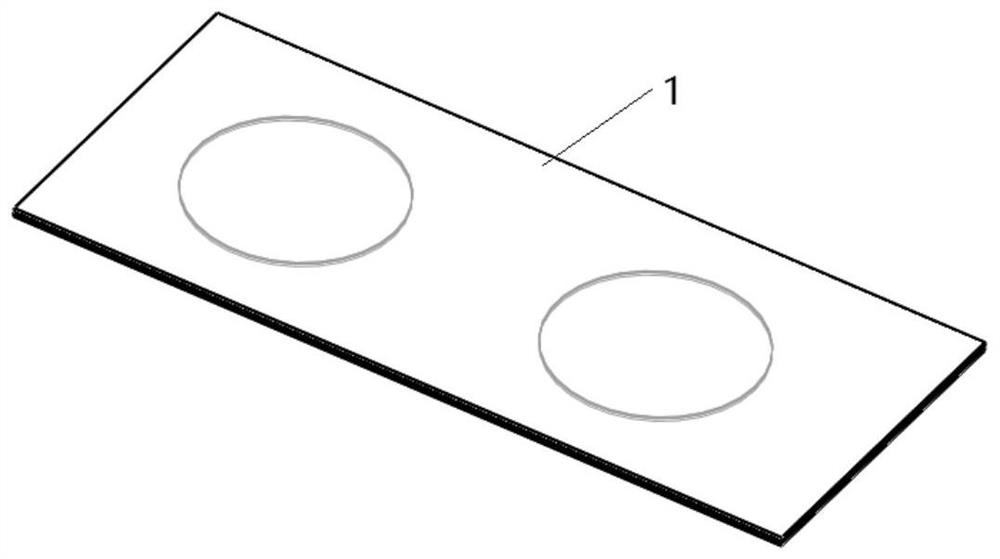

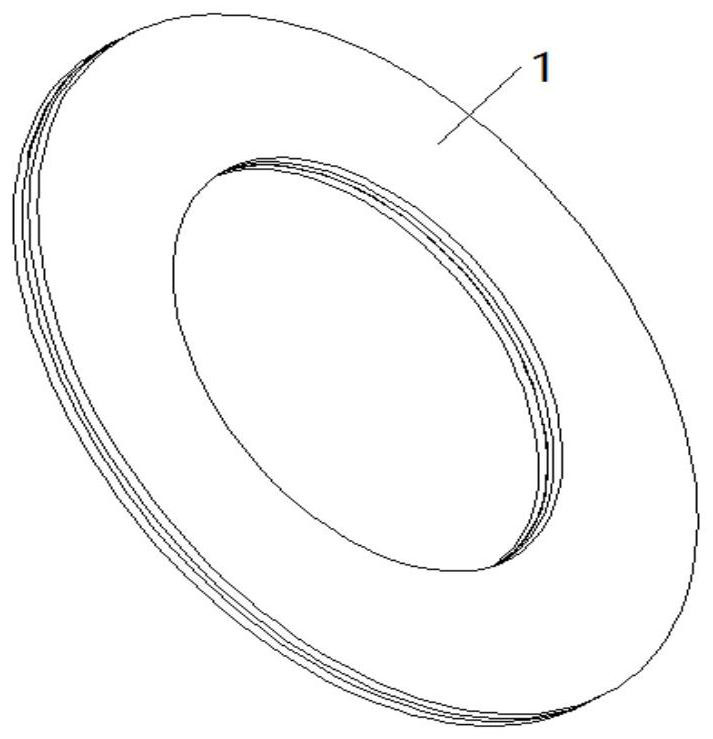

[0036] One aspect of the present invention provides a seal, such as figure 1 As shown, it includes: a first metal layer 11 , a sealing insulating layer 12 and a second metal layer 13 which are sequentially stacked. The present invention arranges metal layers on both sides of the sealing insulating layer, so that the two surfaces of the sealing member have good consistency, avoiding the risk of liquid leakage after the sealing member encapsulates the battery, has good sealing performance and service life, and is beneficial to Improve the quality of battery safety, cycle and service life.

[0037] In the present invention, the sealing member can be used especially between the positive electrode cover and the housing of the battery to realize the sealed and insulating connection between the positive electrode cover and the housing. The positive electrode cover and the housing are generally made of metal. Therefore, the sealing member of the present invention has two sides The me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com