Metal hose

A technology of metal hoses and hoses, applied in the mechanical field, can solve problems such as property loss, lack of airtight methods, hidden dangers to life safety, etc., and achieve good wear resistance and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

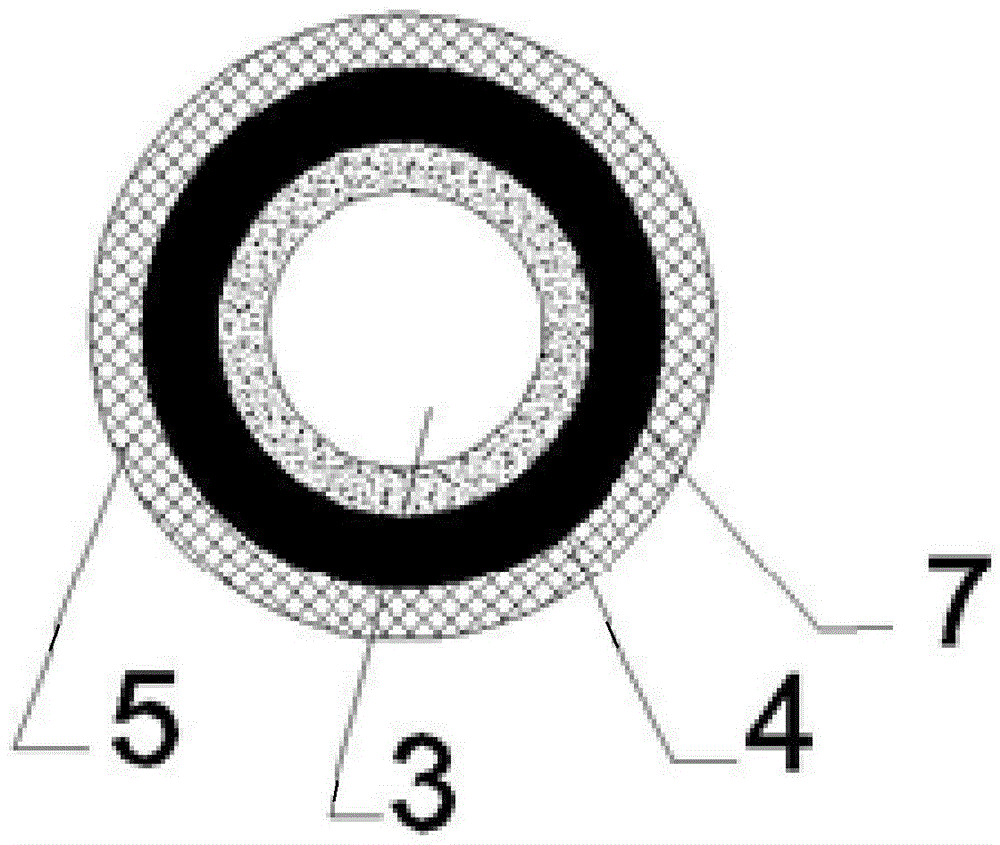

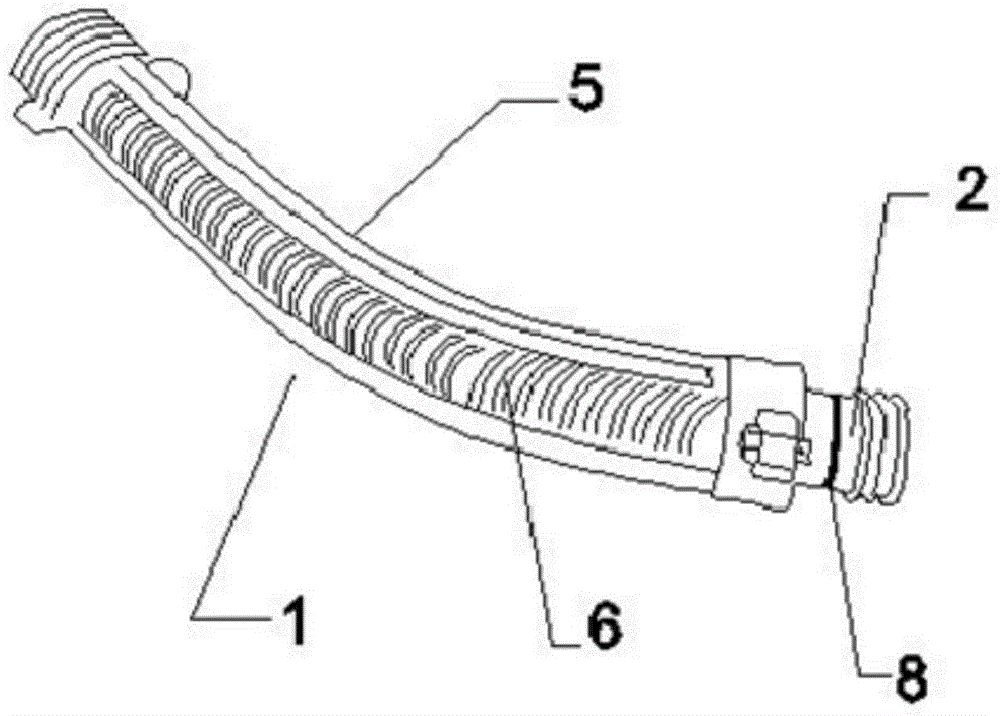

[0013] like figure 1 As shown, a metal hose includes a hose body 1 and joints 2 fixed at both ends. The hose body is provided with an inner tube 3, a bellows 4 and a metal mesh 5. The inner tube is arranged on the Inside, the metal mesh is set 5 on the outside of the corrugated pipe 4; the inner pipe 3 is formed by lapping a plurality of manganese steel rings 6 steel pipes sequentially, and a heat-resistant material is arranged between the corrugated pipe 4 and the inner pipe 3 7. The inner tube 3 is a P3-type metal hose, and a linear piece of fireproof cotton is wound around the groove of the P3-type metal hose. There is a joint with an internal thread and a joint with an external thread. Because in the existing technology, flat-coated plastic metal hoses generally include (P3 type) metal hoses and outer plastic coatings. In the application process of modern society In the event of a fire due to the aging of the middle circuit or other reasons, on the one hand, it will cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com