Reinforced diffusion plate and manufacturing method thereof

A manufacturing method and diffusion plate technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of reduced structural strength, increased cost of consumables, bending deformation, etc., to reduce the cost of consumables and reduce downtime The frequency of maintenance and the effect of improving coating productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings.

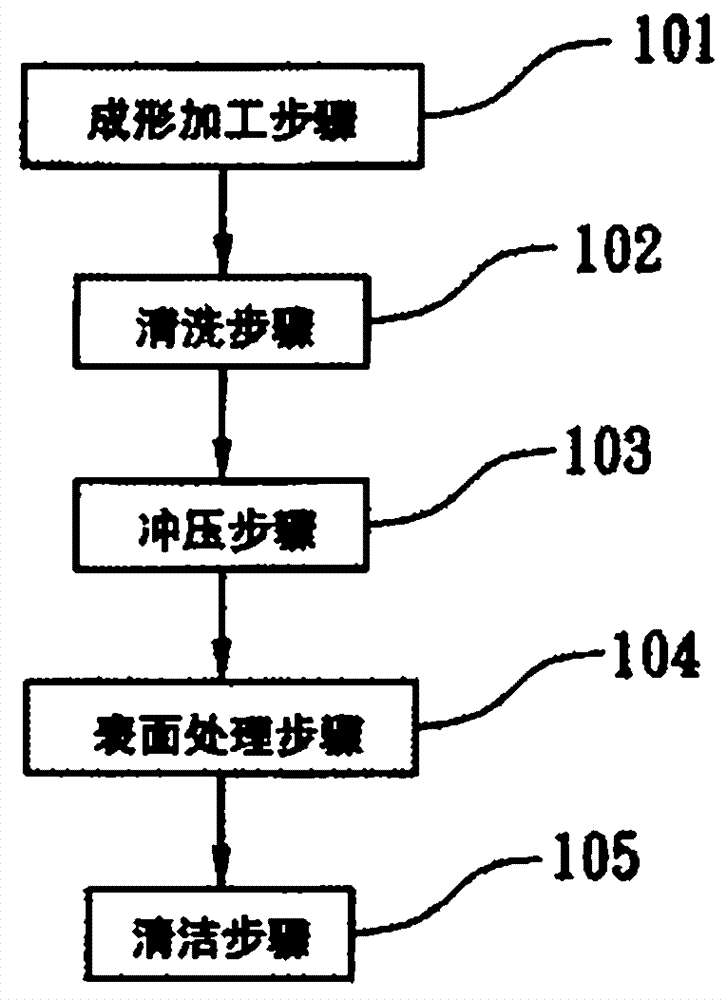

[0050] refer to image 3 , is a preferred embodiment of the manufacturing method of the reinforced diffuser plate of the present invention, the manufacturing method includes a forming step 101, a cleaning step 102, a stamping step 103, a surface treatment step 104 and a cleaning step 105.

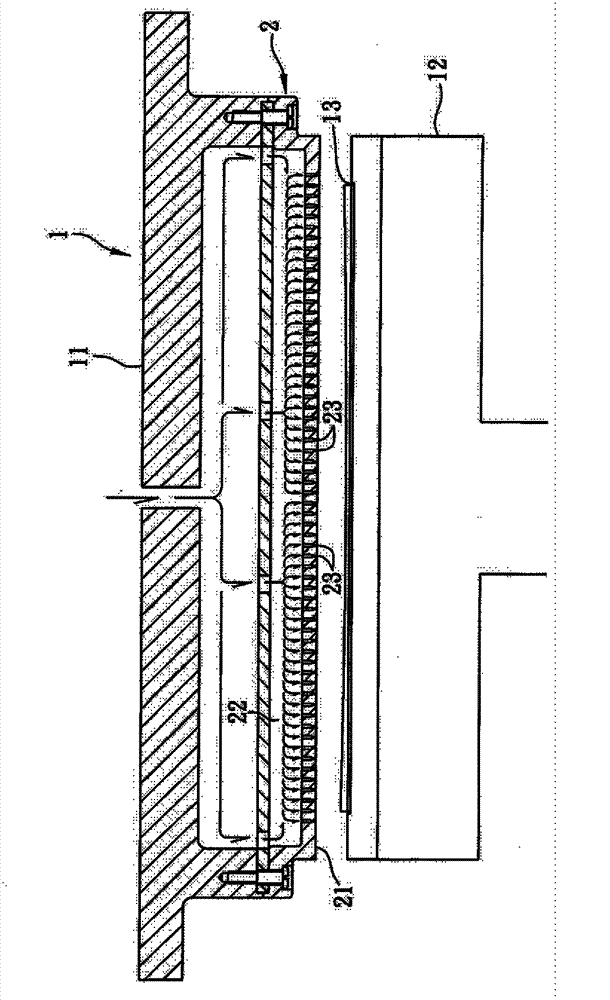

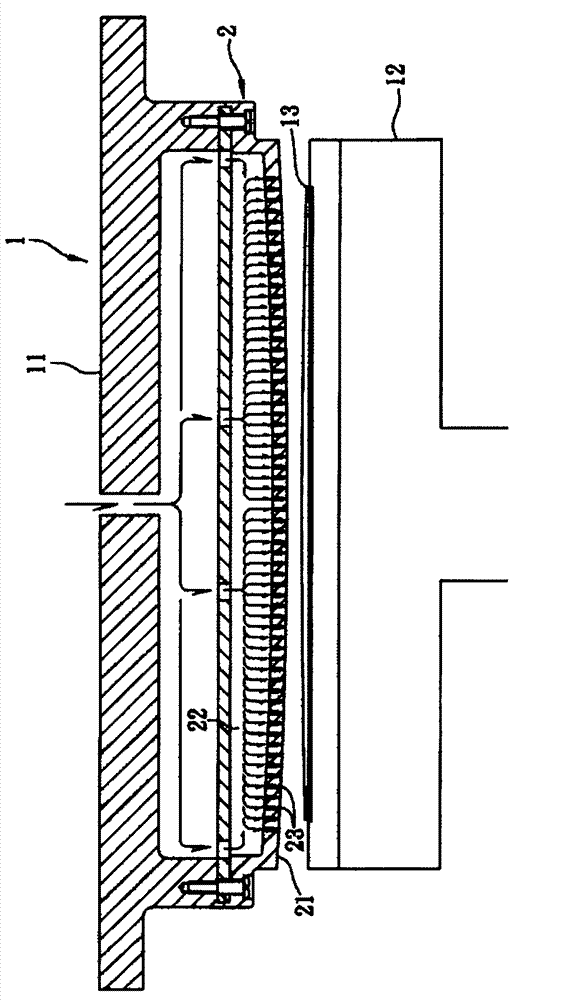

[0051] refer to image 3 and Figure 4 , firstly, the forming step 101 is carried out, and a piece of material is turned into a blank by turning operation, and the blank includes a connecting portion 4, a bending portion 6 connecting the connecting portion 4, and a bending portion connecting the bending The bottom plate portion 5 of the part 6, and the bottom plate portion 5, the connecting portion 4, and the bending portion 6 jointly define a shunt chamber 7, and ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com