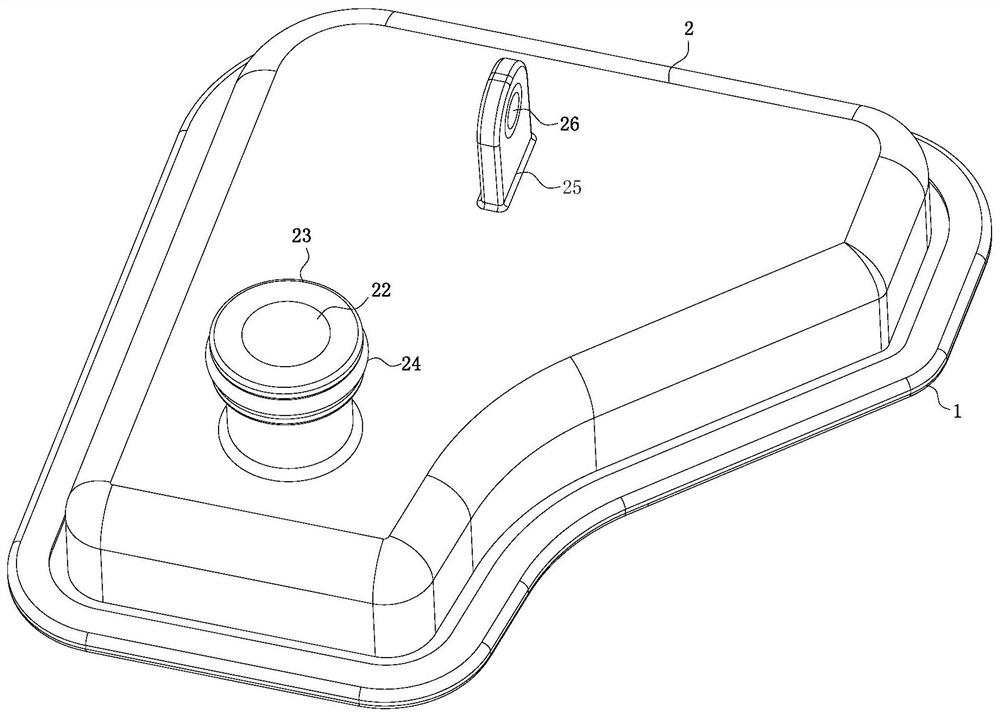

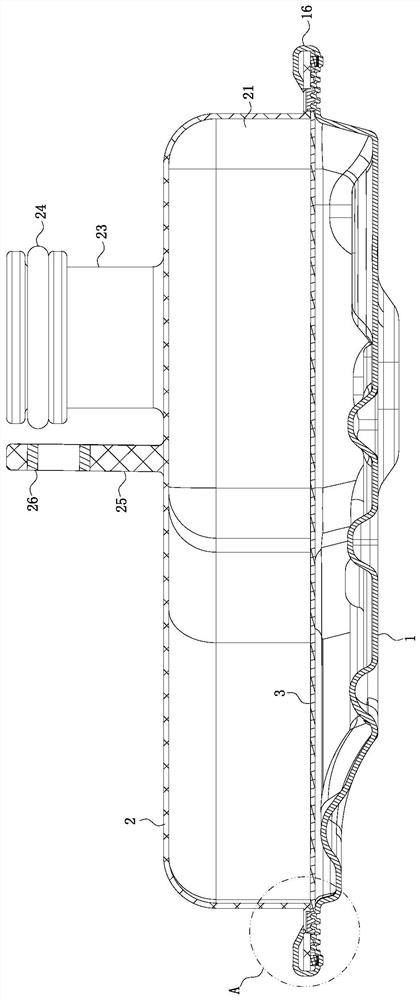

A metal stamping part

A technology of stamping parts and hardware, which is applied in the field of metal stamping parts, can solve the problems of full-plastic oil filter toothing, transmission gear or oil filter damage, etc., and achieves heat-resistant deformation, long service life, and equipment investment saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

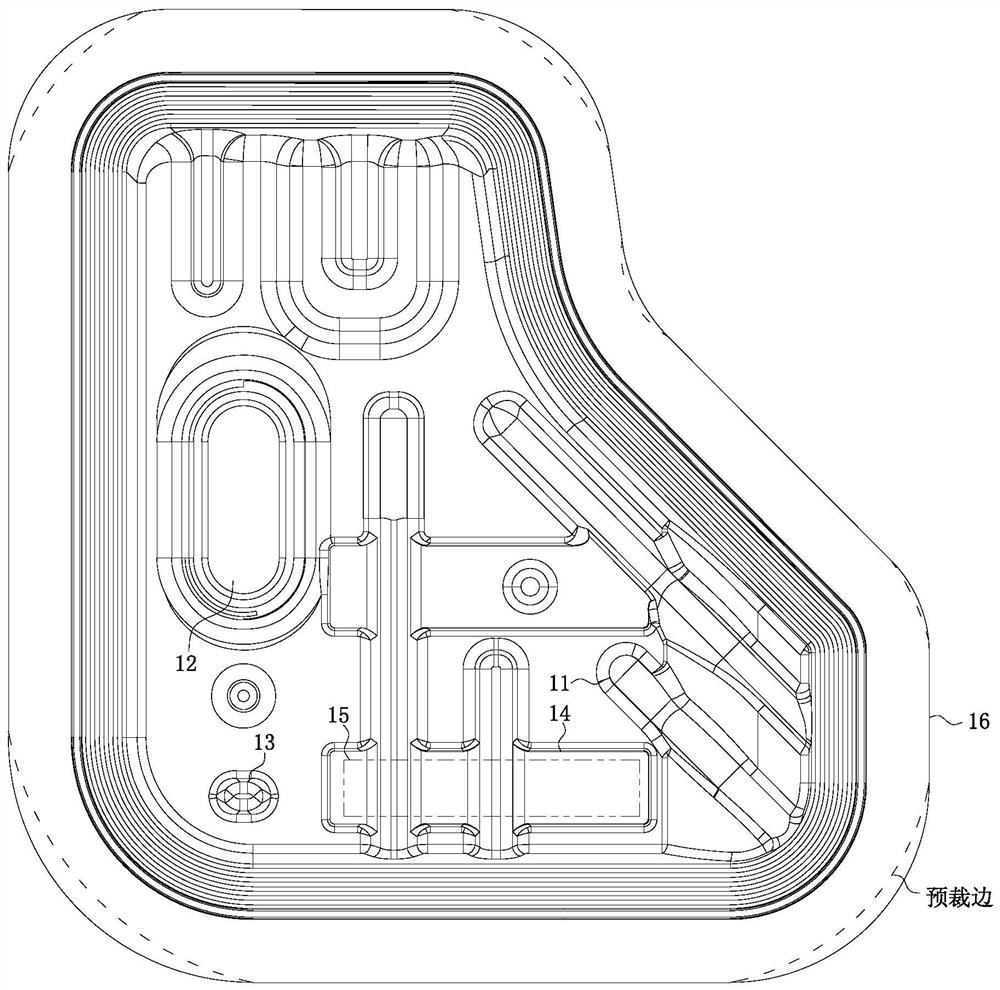

[0025] As an embodiment of the present invention, the cover plate 1 is punched with uniformly arranged pressing bosses 31 on one side of the housing 2, and the pressing bosses 31 are located near the bending position of the flange 16 The pressing boss 31 is designed with a trapezoidal ring structure; during work, since the connection position of the cover plate 1 and the opposite side of the housing 2 are planes, the filter paper 3 is pressed on the cover plate 1 and the housing 2 In between, the pulling force is difficult to control, and the pulling force of the filter paper 3 may be insufficient in some cases. However, since the filter paper 3 is located in the cavity 21 between the cover plate 1 and the housing 2, batch testing cannot be realized, and the testing process It will also cause damage to the filter paper 3, so the pulling force and quality of the filter paper 3 are unstable. By stamping the side of the cover plate 1 relative to the housing 2, there are evenly arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com