Environment-friendly aluminum alloy refractory material and preparation method thereof

A technology of refractory materials and aluminum alloys, applied in the field of refractory materials, can solve the problems of high temperature of metal oxide itself, increase of material tensile stress, affecting use, etc., and achieve the effect of not easy to be deformed by heat, strong polarity, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

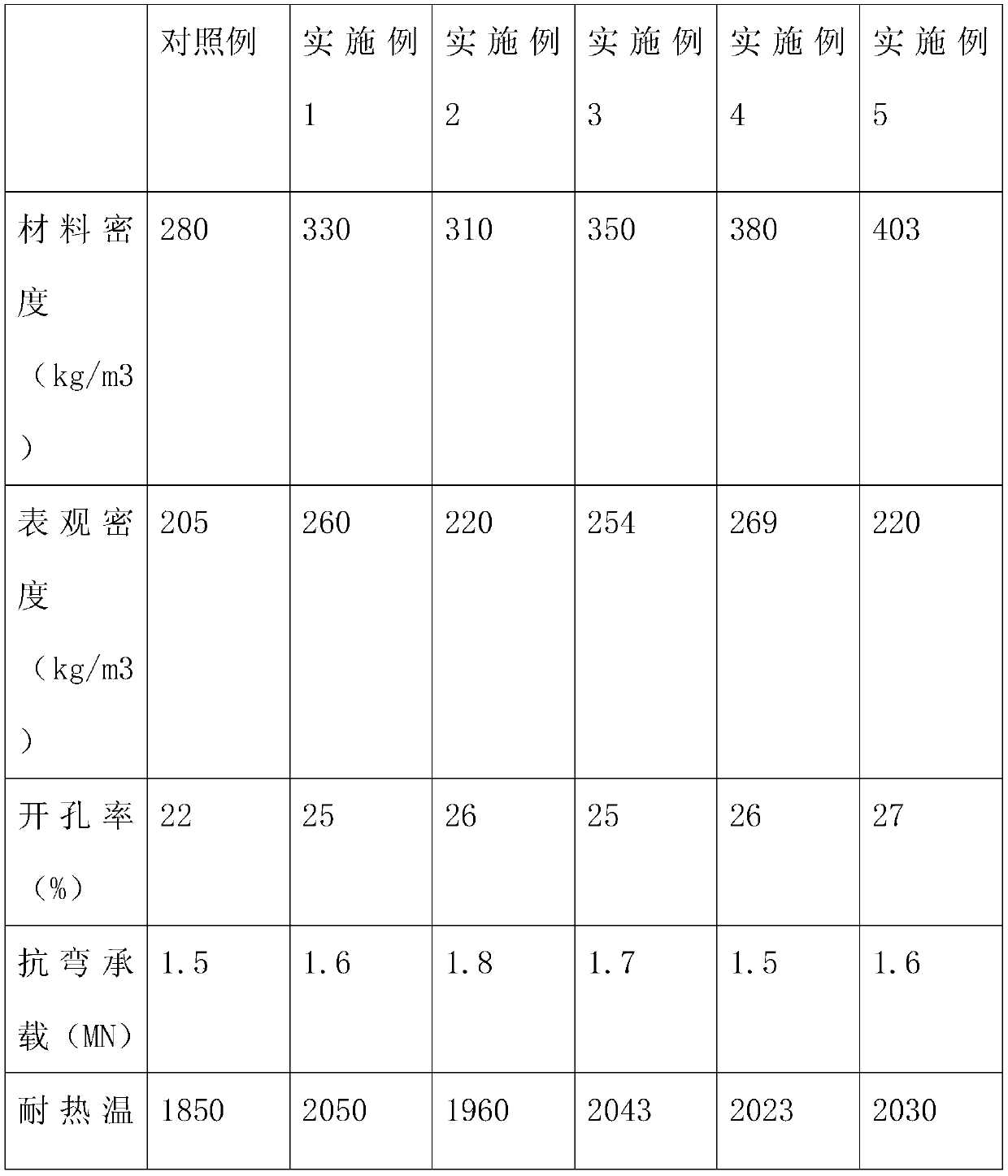

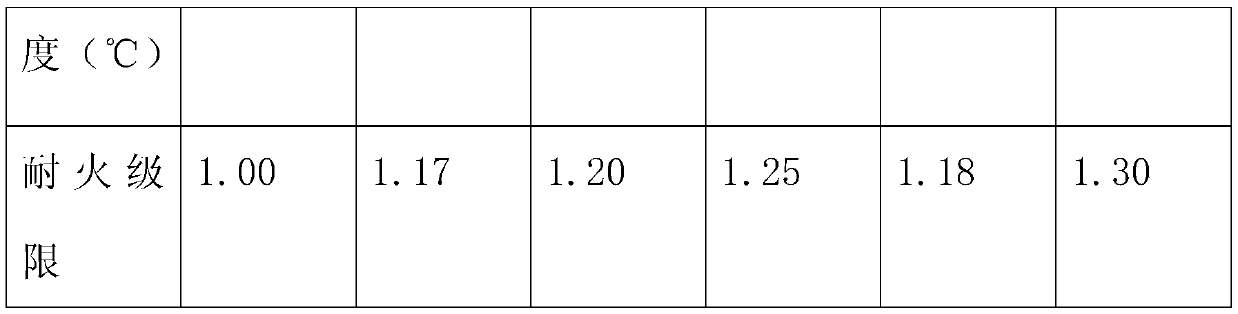

Examples

Embodiment 1

[0029] This embodiment provides an environment-friendly aluminum alloy refractory material, including the following components in parts by weight: 20 parts of aluminum alloy, 20 parts of aluminum oxide, 10 parts of silicon nitride, 10 parts of boron nitride, and 10 parts of zirconia , 15 parts of sodium silicate, 5 parts of hydrochloric acid, 10 parts of ammonia monohydrate, 5 parts of epoxy toughness modifier, 5 parts of curing agent, and 6 parts of modified carboxy-terminated nitrile rubber.

[0030] The curing agent includes the following components in parts by weight: 50 parts of methyltrichlorosilane, 20 parts of anhydrous methanol, 10 parts of petroleum ether, and 6 parts of sodium methoxide.

[0031] The modified carboxyl-terminated nitrile rubber is prepared by mixing carboxylated nitrile rubber and epoxy resin E51 in a ratio of 3:1.

[0032] A preparation method of an environment-friendly aluminum alloy refractory material, specifically comprising the following steps:...

Embodiment 2

[0041] This embodiment provides an environment-friendly aluminum alloy refractory material, including the following components in parts by weight: 22 parts of aluminum alloy, 25 parts of aluminum oxide, 12 parts of silicon nitride, 11 parts of boron nitride, and 11 parts of zirconia , 16 parts of sodium silicate, 6 parts of hydrochloric acid, 11 parts of ammonia monohydrate, 6 parts of epoxy toughness modifier, 6 parts of curing agent, and 8 parts of modified carboxy-terminated nitrile rubber.

[0042] The curing agent includes the following components in parts by weight: 52 parts of methyltrichlorosilane, 22 parts of anhydrous methanol, 12 parts of petroleum ether, and 7 parts of sodium methoxide.

[0043] The modified carboxyl-terminated nitrile rubber is prepared by mixing carboxylated nitrile rubber and epoxy resin E51 in a ratio of 4:1.

[0044] A preparation method of an environment-friendly aluminum alloy refractory material, specifically comprising the following steps:...

Embodiment 3

[0053] This embodiment provides an environment-friendly aluminum alloy refractory material, including the following components in parts by weight: 25 parts of aluminum alloy, 30 parts of aluminum oxide, 15 parts of silicon nitride, 13 parts of boron nitride, and 13 parts of zirconia , 17 parts of sodium silicate, 8 parts of hydrochloric acid, 13 parts of ammonia monohydrate, 8 parts of epoxy toughness modifier, 8 parts of curing agent, and 9 parts of modified carboxy-terminated nitrile rubber.

[0054] The curing agent includes the following components in parts by weight: 55 parts of methyltrichlorosilane, 25 parts of anhydrous methanol, 15 parts of petroleum ether, and 7 parts of sodium methoxide.

[0055] The modified carboxyl-terminated nitrile rubber is prepared by mixing carboxyl-terminated nitrile rubber and epoxy resin E51 in a ratio of 5:2.

[0056] A preparation method of an environment-friendly aluminum alloy refractory material, specifically comprising the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com