Valve with guide vanes for coolant for internal combustion engines

A technology for guide vanes and cooling valves, applied in valve heating/cooling devices, internal combustion piston engines, combustion engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

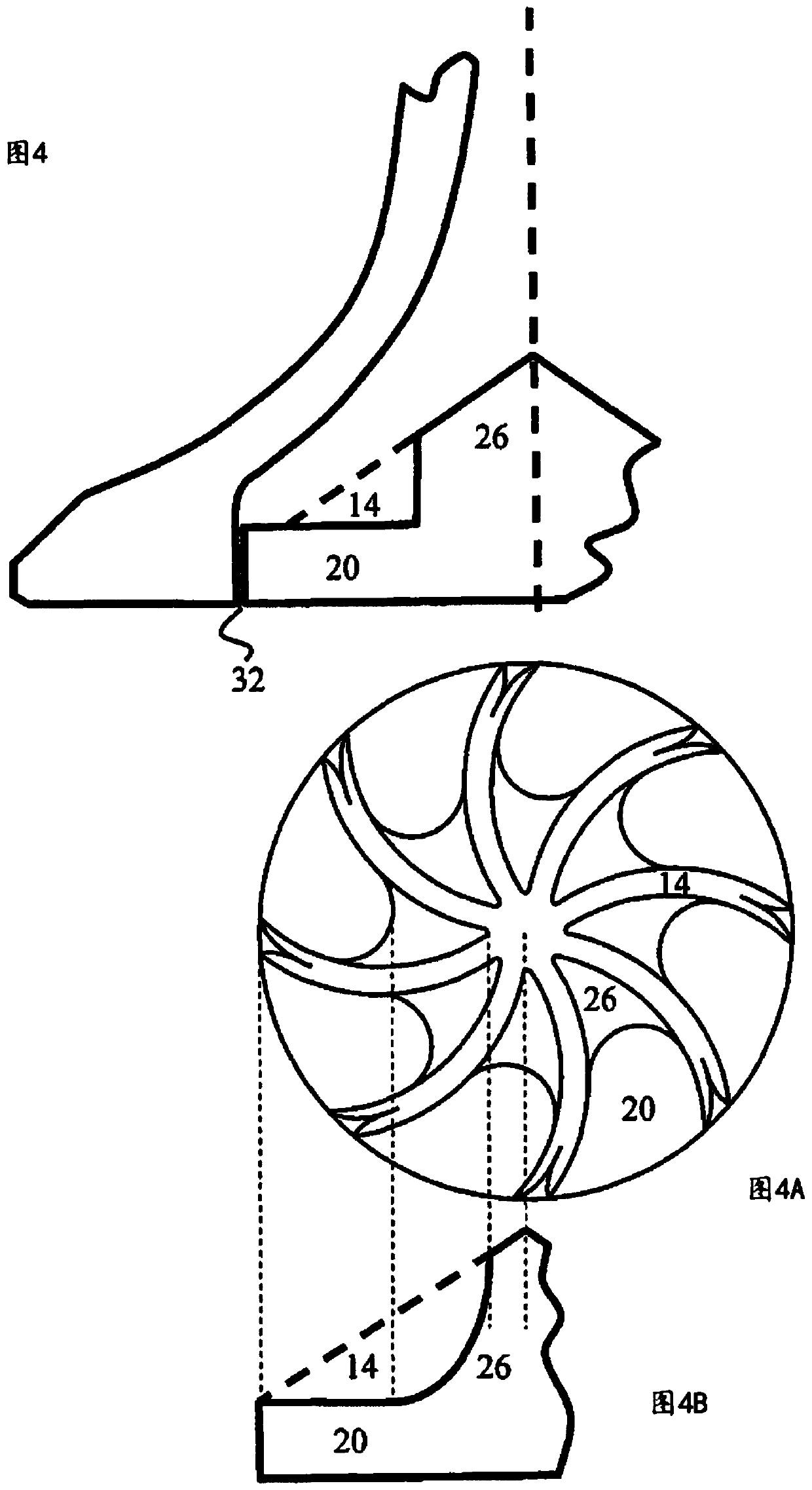

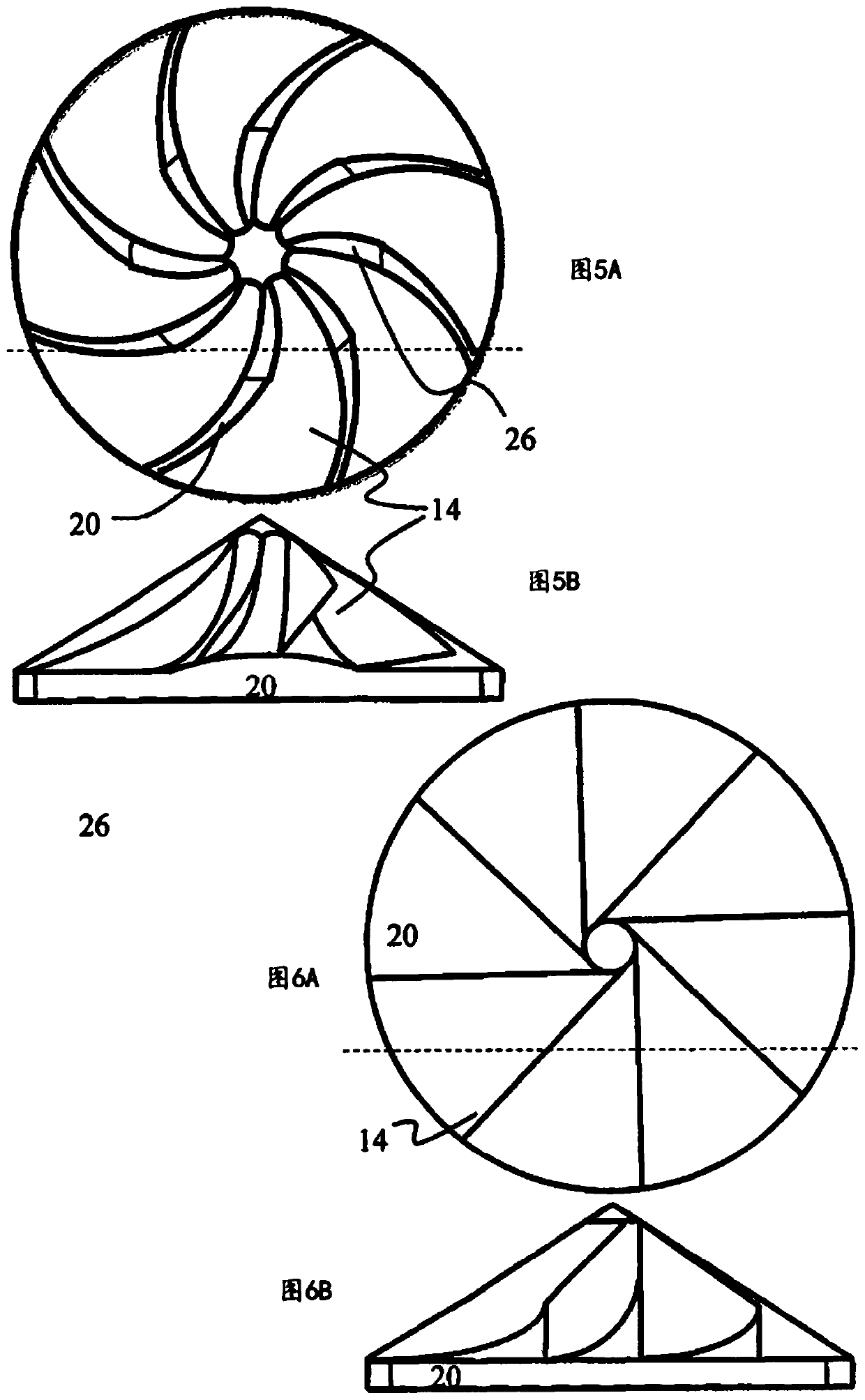

[0036] In the specification and in the drawings, the same or similar reference numerals are used to refer to the same or similar parts and elements. In order to avoid an excessively long description, elements already described in one figure are not individually mentioned in another figure.

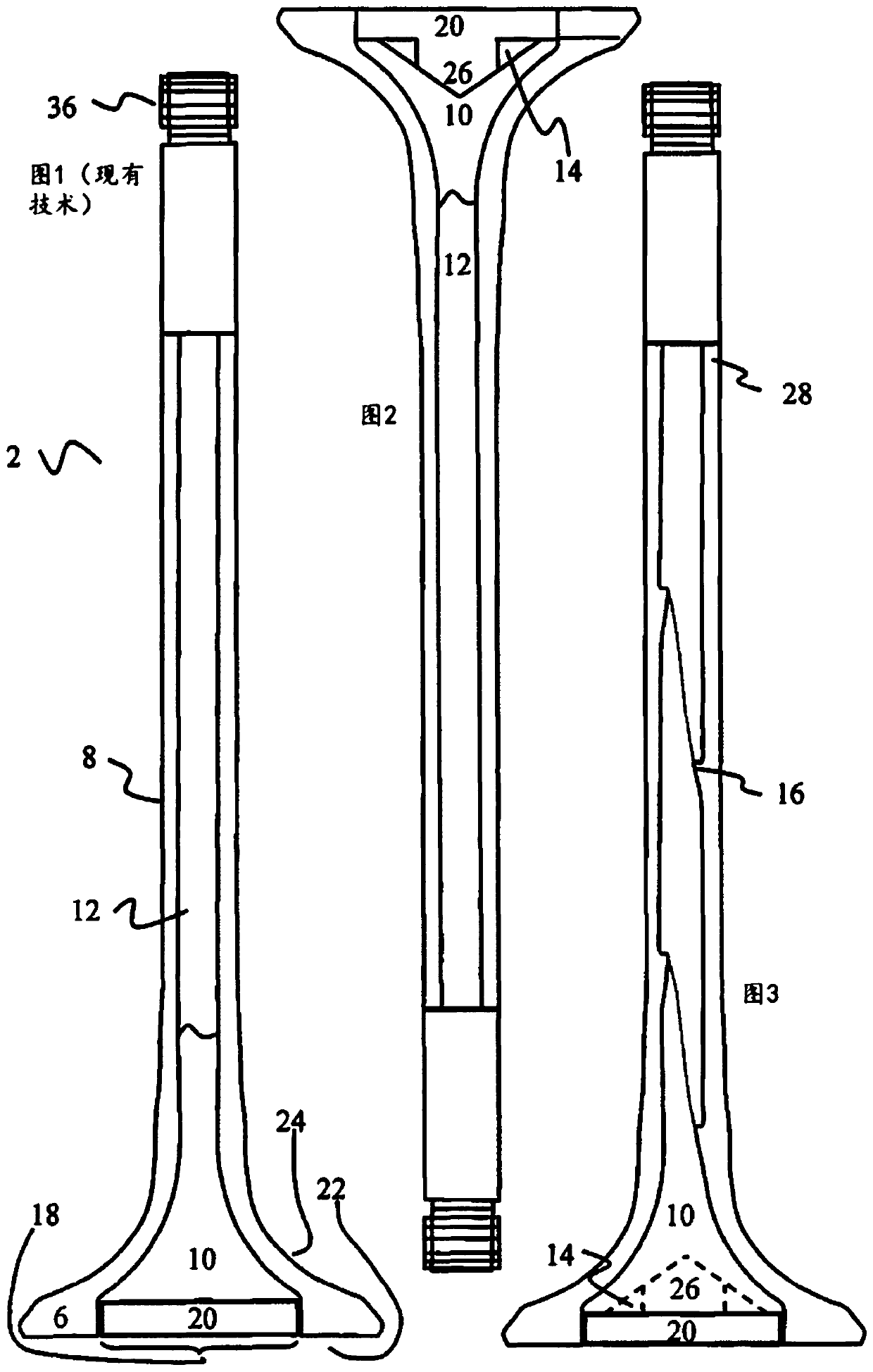

[0037] figure 1 A conventional internally cooled valve 2 is shown with a valve stem 8 , which terminates at a lower end in a valve disk 6 . The valve stem 8 ends at the top at a rod end 36 where the valve is normally controlled. The valve is internally provided with a cavity 10 filled with coolant 12 . Sodium, which is liquid at the operating temperature of the internal combustion engine, is usually used as a coolant. Typically, not the entire cavity, but only 2 / 3 to 3 / 4 of the cavity of the valve is filled with sodium. During operation, the sodium moves up and down in the valve stem 8 or in the cavity 10 of the valve stem 8 and in the process transports heat from the valve disk 6 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com