One-step synthesis of one-dimensional indium oxide/indium sulfide composite semiconductor nanofibers

A compound semiconductor and nanofiber technology, applied in the direction of carbon monoxide, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of large electrostatic repulsion, simple and time-saving methods, and high product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

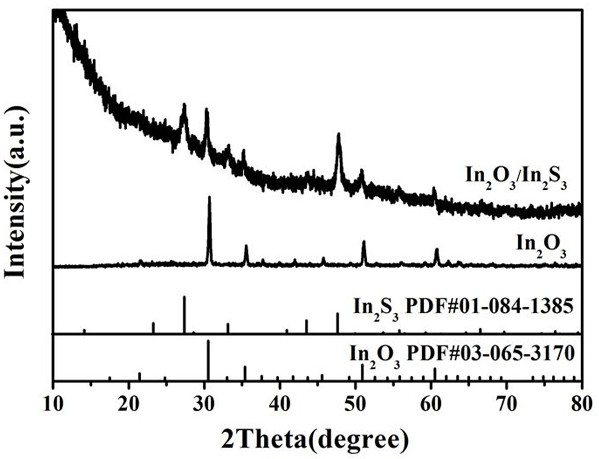

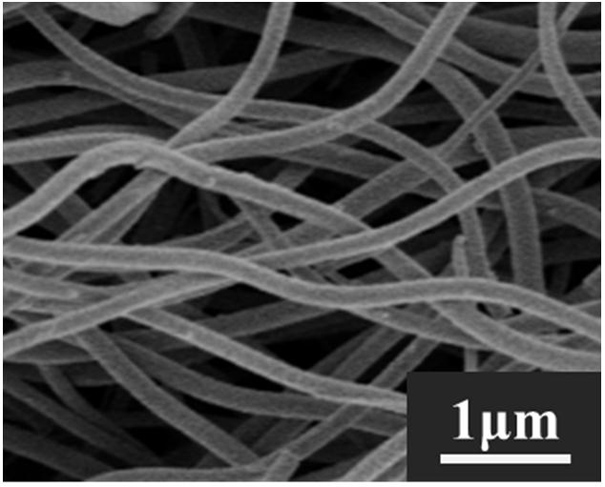

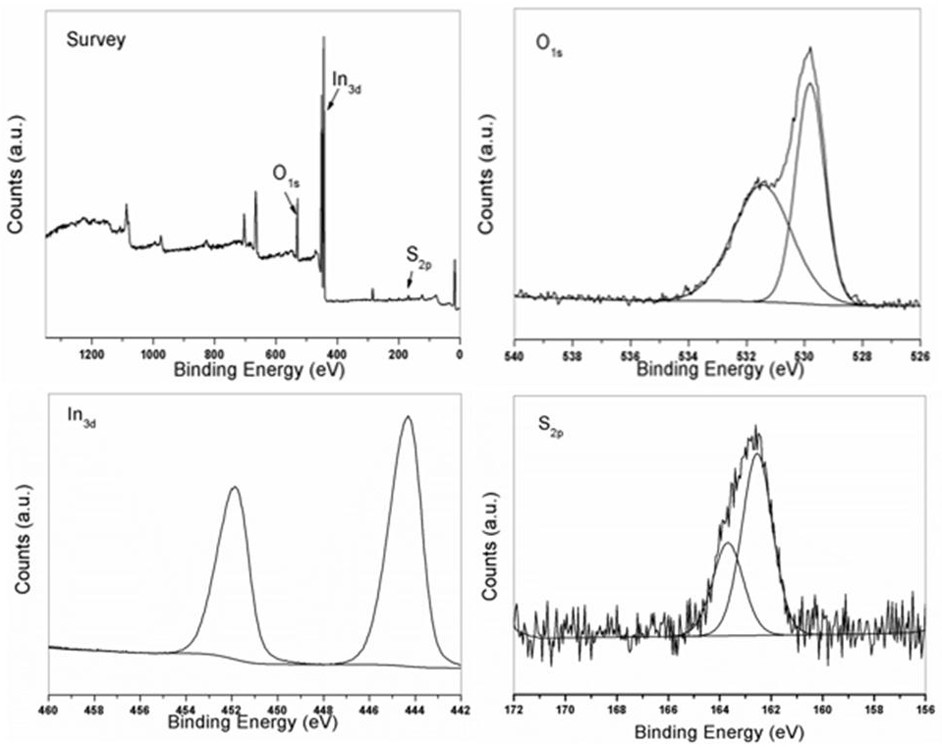

[0024] 0.5 g of indium trichloride tetrahydrate (InCl 3 4H 2 O) and 0.2 g of thioacetamide were sequentially added to a mixed solution of 10 mL of absolute ethanol, ethylene glycol and N,N-dimethylformamide (volume ratio 2:1:2), and stirred evenly; 1 g polyvinylpyrrolidone was added to the above solution to obtain a homogeneous precursor spinning solution, which was jet-spun in an electrospinning device with a spinneret aperture of 0.5 mm; the receiving distance was 15 cm, and the voltage was 10 kV. The speed was 0.1 mm / min; the prepared precursor fibers were placed in a tube furnace and calcined at 400 °C for 2 h under an Ar atmosphere with a heating rate of 2 °C / min to obtain one-dimensional In 2 o 3 / In 2 S 3 Composite semiconducting nanofibers with a diameter of 250-300 nm.

Embodiment 2

[0026] 0.5 g of indium trichloride tetrahydrate (InCl 3 4H 2 O) and 0.4 g of thioacetamide were sequentially added to a mixed solution of 10 mL of absolute ethanol, ethylene glycol and N,N-dimethylformamide (volume ratio 2:1:2), and stirred evenly; 0.9 g of polyvinylpyrrolidone was added to the above solution to obtain a homogeneous precursor spinning solution, which was jet-spun in an electrospinning device with a spinneret aperture of 0.5 mm; the receiving distance was 15 cm, and the voltage was 15 kV. The speed was 0.15 mm / min; the prepared precursor fibers were placed in a tube furnace and calcined at 500 °C for 2 h under an Ar atmosphere with a heating rate of 2 °C / min to obtain one-dimensional In 2 o 3 / In 2 S 3 Composite semiconducting nanofibers with a diameter of 200-250 nm.

Embodiment 3

[0028] 0.5 g of indium trichloride tetrahydrate (InCl 3 4H 2 O) and 0.6 g of thioacetamide were sequentially added to a mixed solution of 10 mL of absolute ethanol, ethylene glycol and N,N-dimethylformamide (volume ratio 2:1:2), and stirred evenly; 1.1 g of polyvinylpyrrolidone was added to the above solution to obtain a homogeneous precursor spinning solution, which was jet-spun in an electrospinning equipment with a spinneret aperture of 0.5 mm; the receiving distance was 15 cm, and the voltage was 13 kV. The speed was 0.2 mm / min; the prepared precursor fibers were placed in a tube furnace and calcined at 600 °C for 2 h under an Ar atmosphere with a heating rate of 2 °C / min to obtain one-dimensional In 2 o 3 / In 2 S 3 Composite semiconducting nanofibers with a diameter of 270-320 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com