A kind of manufacturing method of bn ion gate and manufacturing substrate

A manufacturing method and ion gate technology, which are used in the manufacture of electronic/ion optical devices, particle separation tubes, and non-light-emitting electrodes, can solve the problems of long assembly time, complex manufacturing process, harsh manufacturing conditions, etc., and achieve batch processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

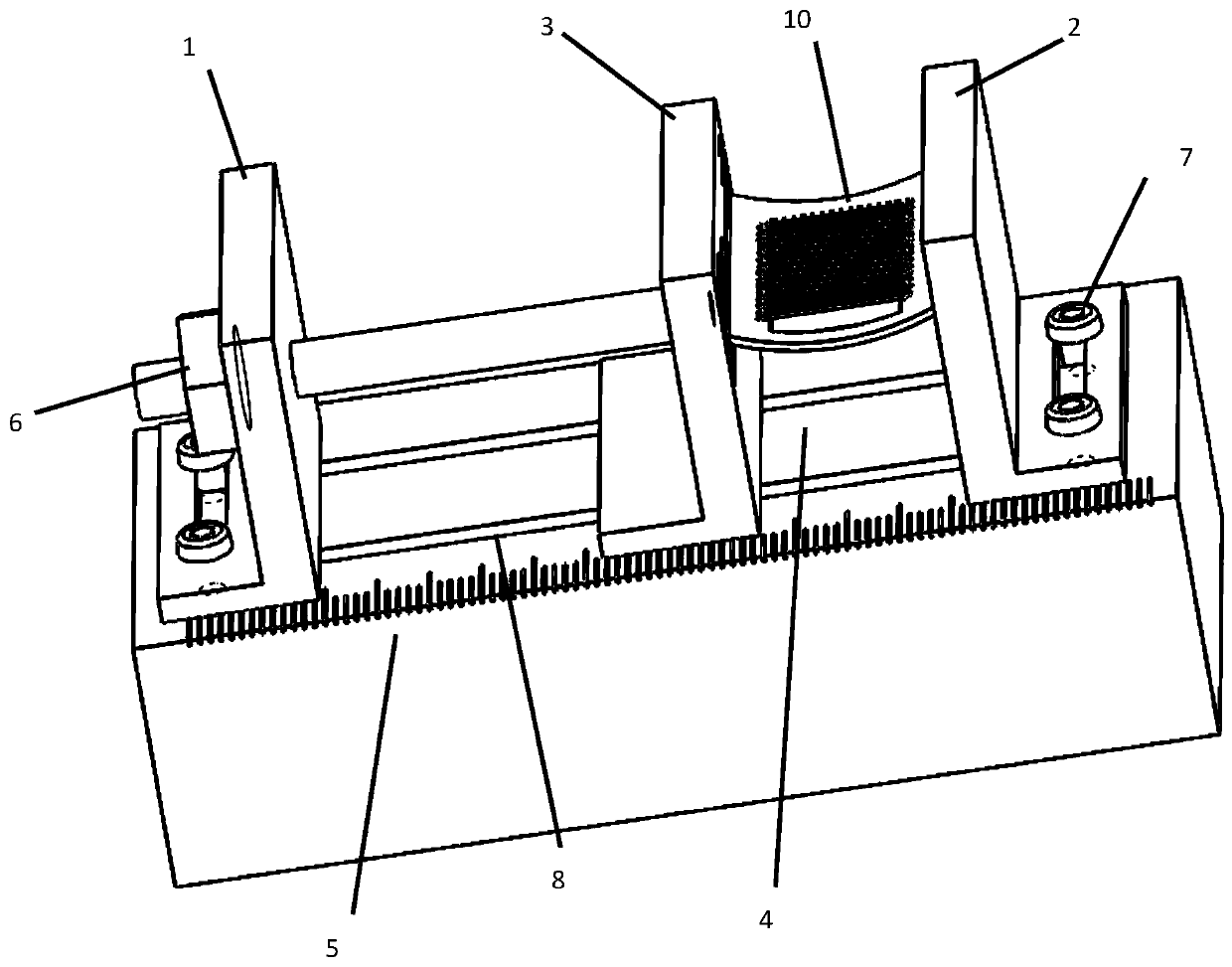

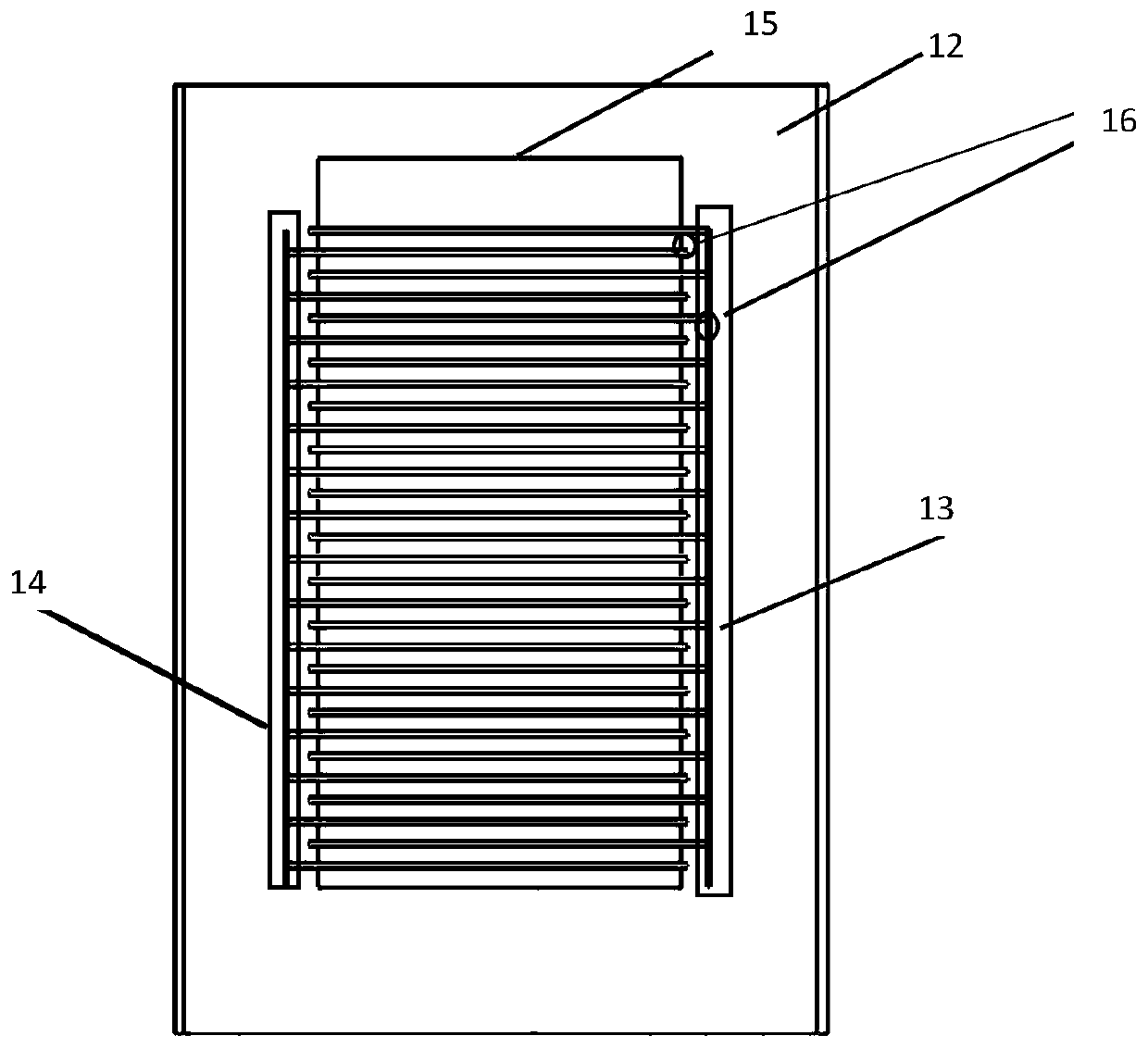

[0018] figure 1 It is a schematic diagram of the insulating substrate of this embodiment when the metal wire is bent and fixed on the jig, figure 2 is a schematic diagram of a curved BN ion gate, image 3 It is a schematic diagram after straightening. Wherein the fixture has a first fixed block 1, a second fixed block 2, a sliding block 3, a third fixed block 4, a scale 5, a positioning screw 6, a positioning screw 7, and a fixing groove 8.

[0019] 10 of them are BN ion gates in production, such as figure 2 , 3 As shown, it includes a substrate 12 and a wire 11 .

[0020] Figure 4 Shown in the bottom surface of the groove 31 sliding feet 32 for fixing the sliding block 3 of the curved ion gate.

[0021] The substrate 12 is a PCB board with a thickness of 0.8 mm to 1.6 mm, the outer frame is a square frame, and the center is a rectangular through hole 15 . Two sets of mutually insulated first copper-clad regions 13 and second copper-clad regions 14 are distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com