Automatic bottle blowing machine

A technology of a blow molding machine and a blow molding mechanism, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of unstable chain connection and product heating quality, and achieve the effect of reducing power, easy control, and reducing wear rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

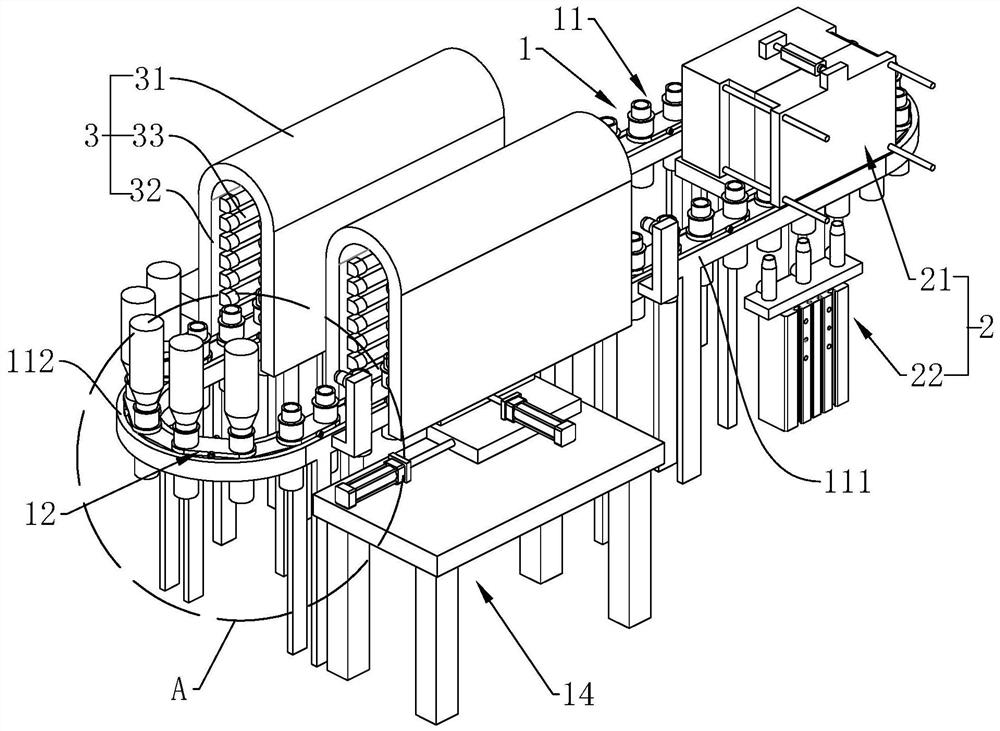

[0036] The following is attached Figure 1-4 The application is described in further detail.

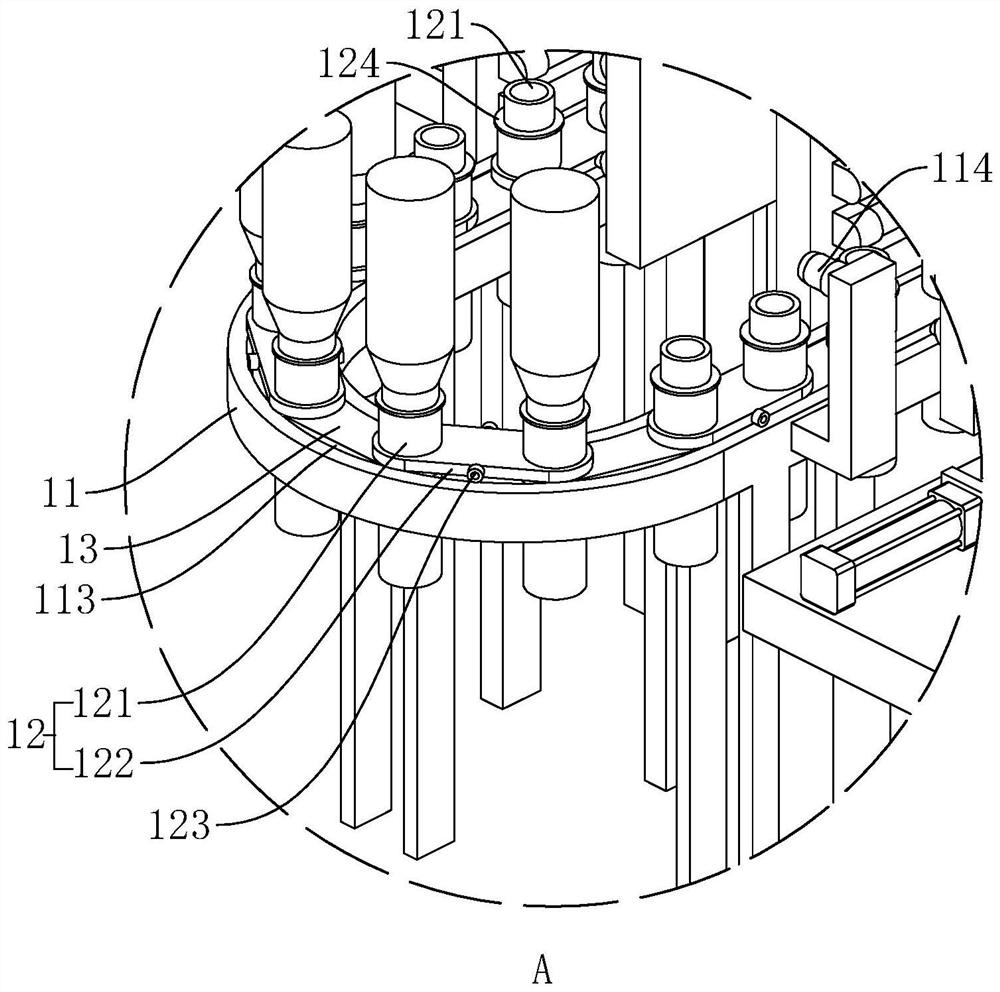

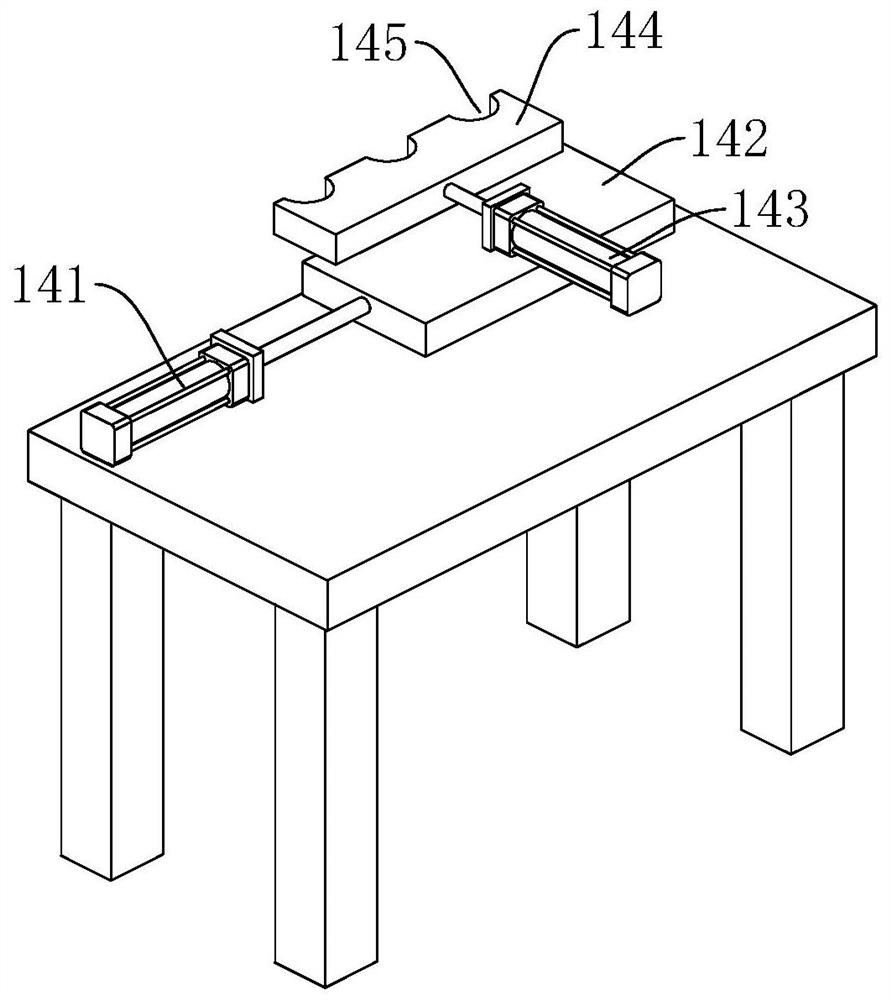

[0037] The embodiment of the present application discloses an automatic bottle blowing machine. refer tofigure 1 , including a conveying mechanism 1 for conveying the preform, a heating mechanism 3 for heating the preform, and a blow molding mechanism 2 for blow molding the preform. Both the heating mechanism 3 and the blow molding mechanism 2 are located above the conveying mechanism 1. The conveying mechanism 1 transports the semi-finished preforms to the heating mechanism 3 for heating, and then sends the heated preforms to the blow molding mechanism 2 for blow molding process.

[0038] refer to figure 1 with figure 2 , the conveying mechanism 1 includes a circular conveying track 11 and a plurality of preform conveying assemblies 12 slidably arranged on the circular conveying track 11 . The preform conveying assembly 12 includes a fixing plate 122 and two cylindrical bottle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com