Method for manufacturing flexible circuit board

A technology of flexible circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, printed circuits, printed circuits, etc. It can solve the problems of low line fineness, difficulty in attaching intact, unstable lines and hole yields, etc., and achieve glass light transmission Good resistance, not easy to be deformed by heat, and the effect of improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The flexible circuit board of this embodiment is made of a substrate with a copper film on at least one surface through complicated operations. It has a plurality of holes and circuits on the surface of the substrate. The holes are generally made of copper formed on the copper film. Pores and film pores formed in the substrate. Wherein the material of the substrate can be polyimide, polyester, Teflon, polymethyl methacrylate or carbonate and the like.

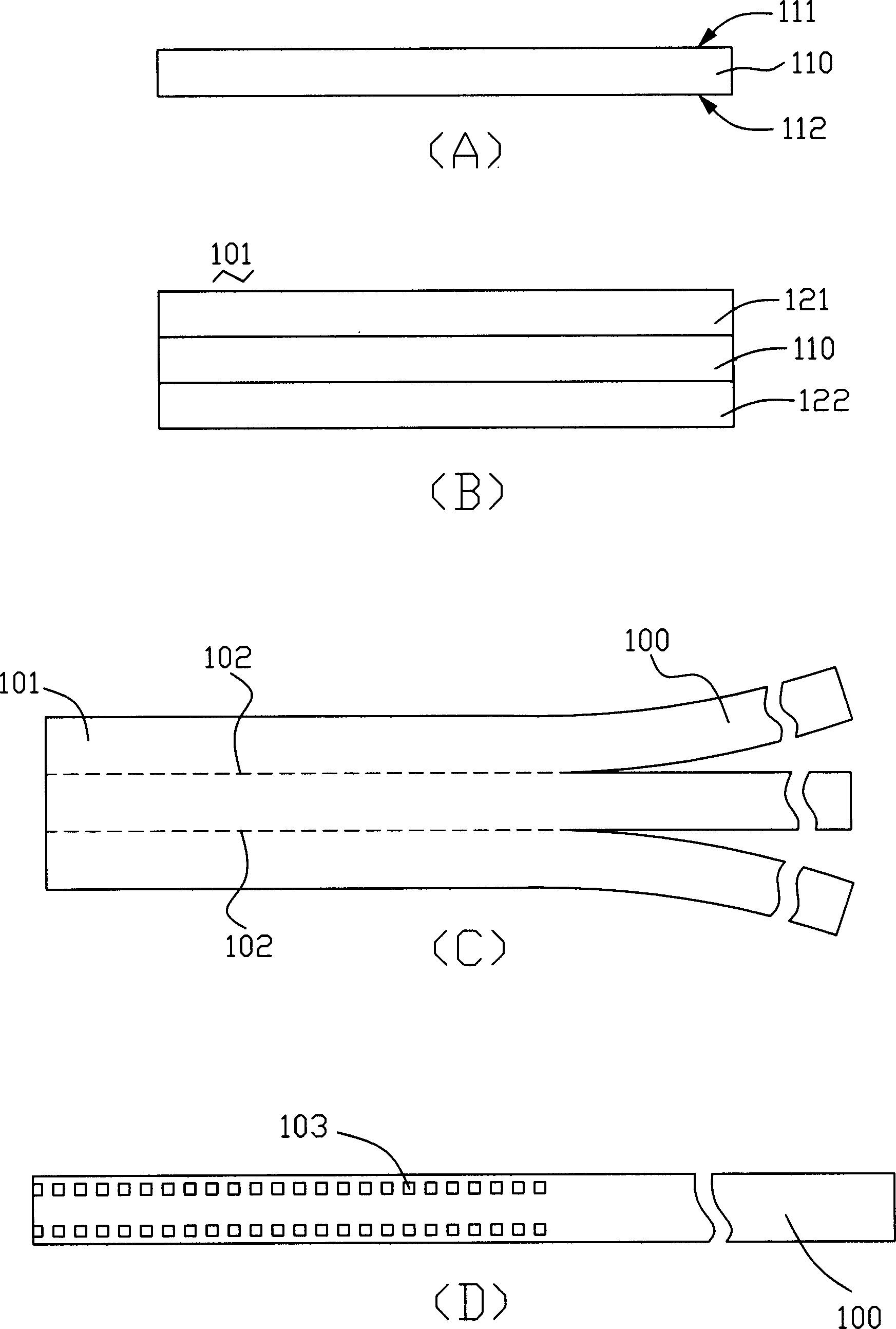

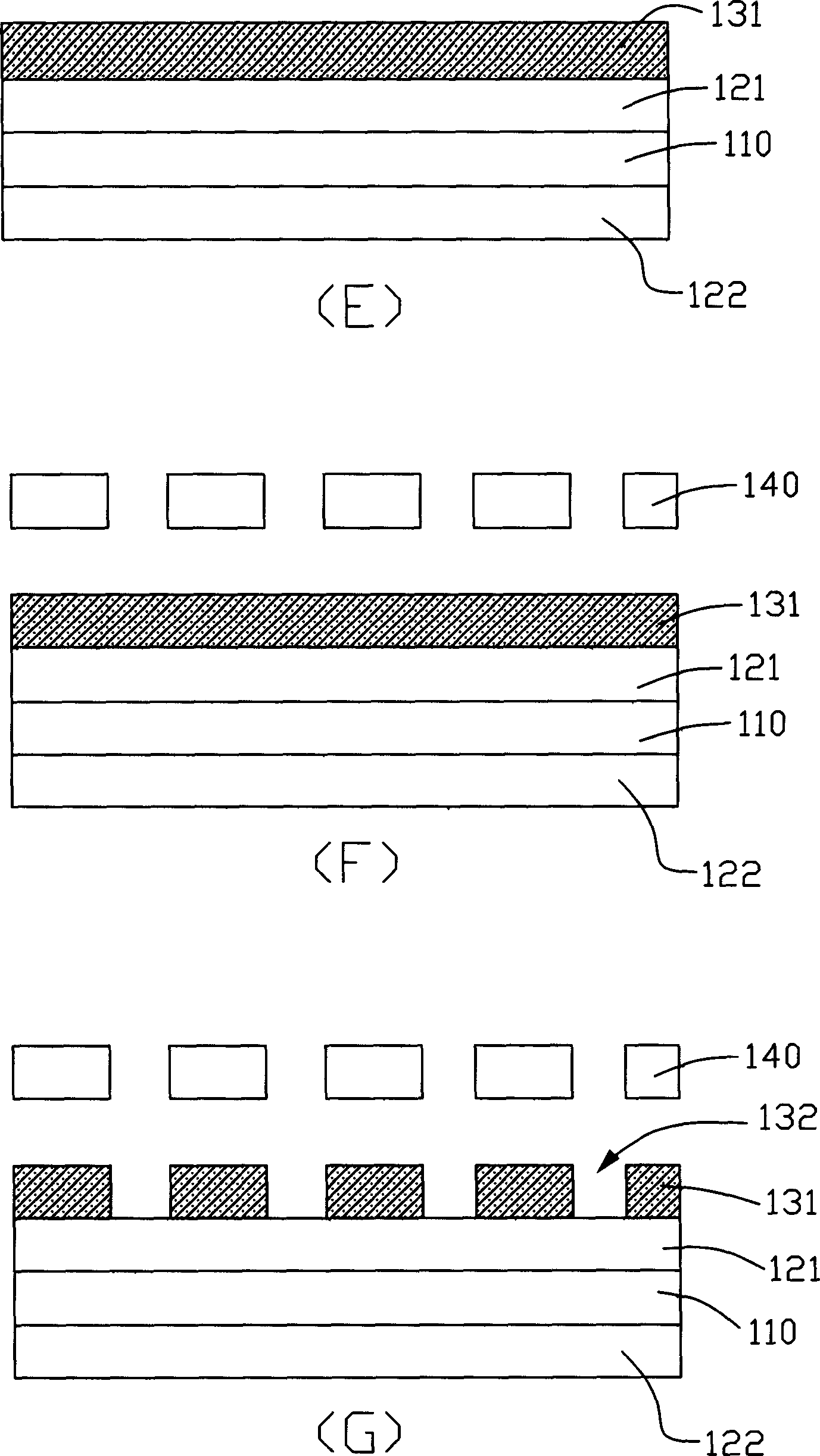

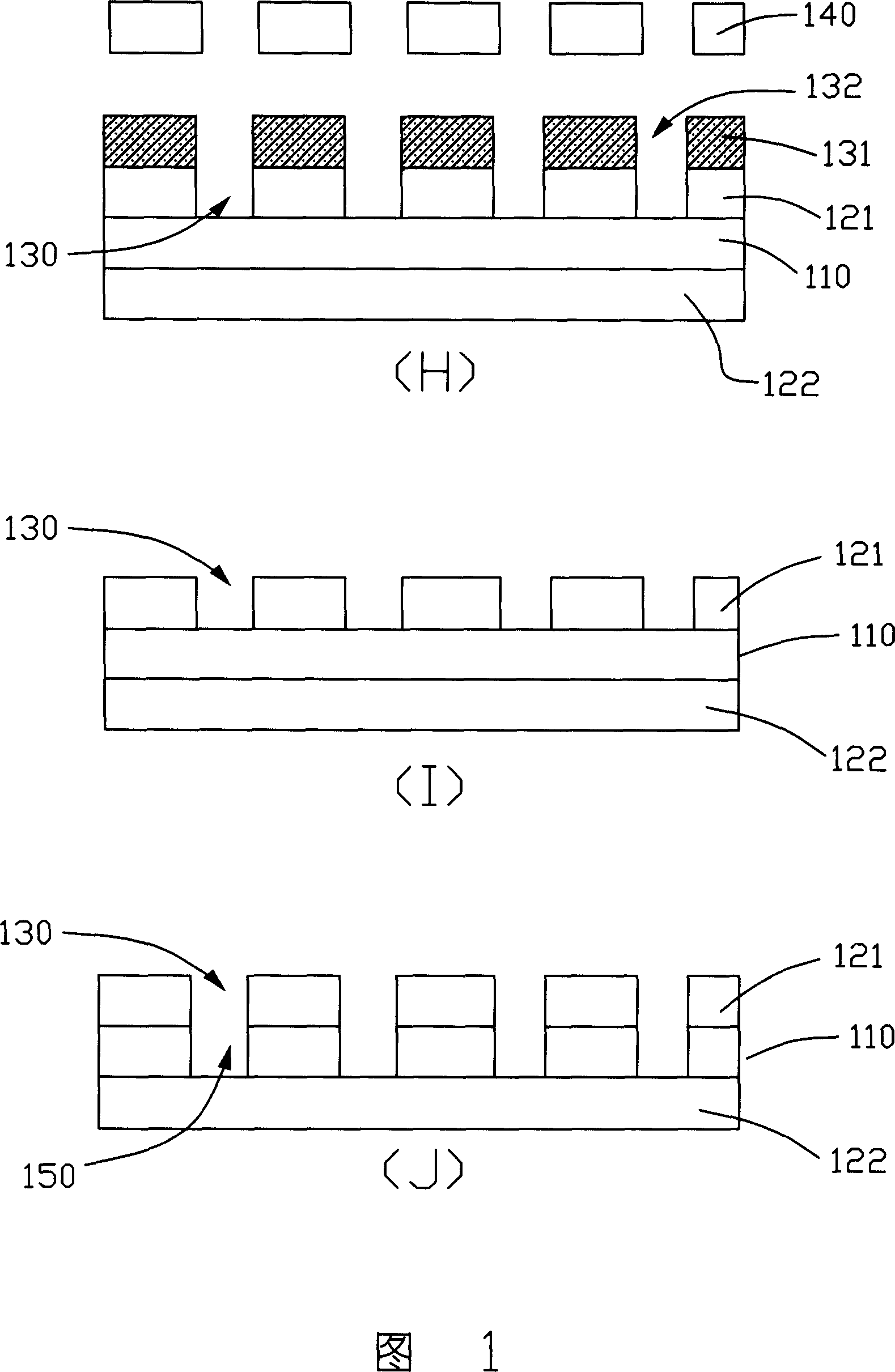

[0037] Please refer to FIG. 2 and FIG. 3 together, which are schematic diagrams of the manufacturing process and method of the flexible circuit board in this embodiment. This embodiment comprises the steps:

[0038] (1) As shown in Fig. 3 (A), at first provide a substrate 210, it has a first surface 211 and an opposite second surface 212, and its material is polyimide, also can be polyester etc.;

[0039] (2) As shown in Fig. 3 (B) (being cross-sectional view), form a first copper film 221 on this first surface 211, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com