Automobile door plate injection mold

An injection mold and door panel technology, which is applied in the field of auto parts, can solve the problems of glass fiber being easily softened, damaged, wrinkled and deformed in the structure of the fixture, and achieves the effects of not easily deformed by heat, stable in fixation, and easier to process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] First of all, the original intention of the design of the present invention is explained, because the quality requirements for door panels are getting higher and higher, and the conventional glass fiber processing is to design a special fixture, and then fix the glass fiber to be pre-embedded on it and then heat it Then carry out injection molding to form the car door panel. Firstly, the fixture cannot fix the glass fiber when it is fixed. The glass fiber is easily deformed when heated, and because the fixture is heated together during the heating process, the fixture is not protected at this time, which is easy to be damaged. The fixture structure itself is harmful, and the present invention provides a device capable of stably improving the above problems, which is convenient for people to use.

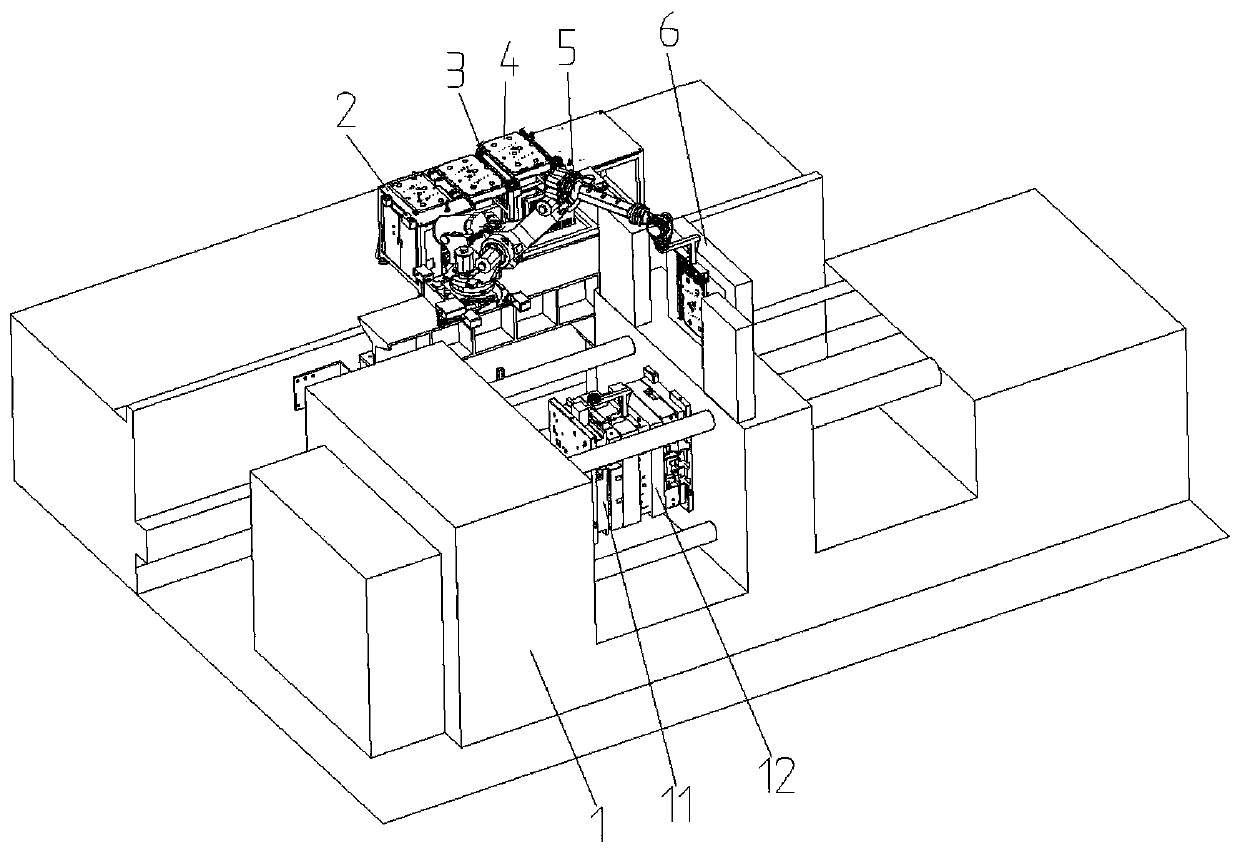

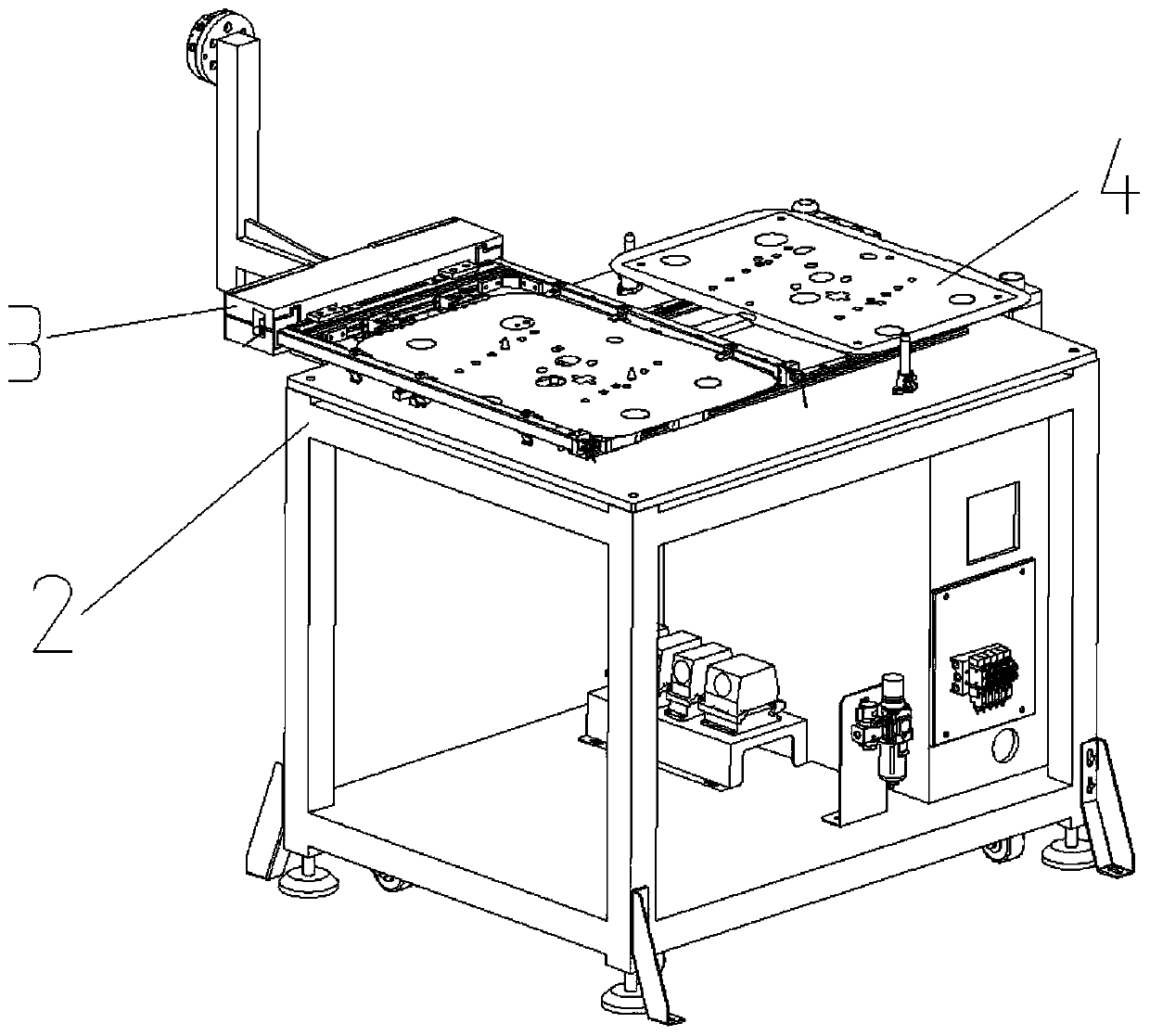

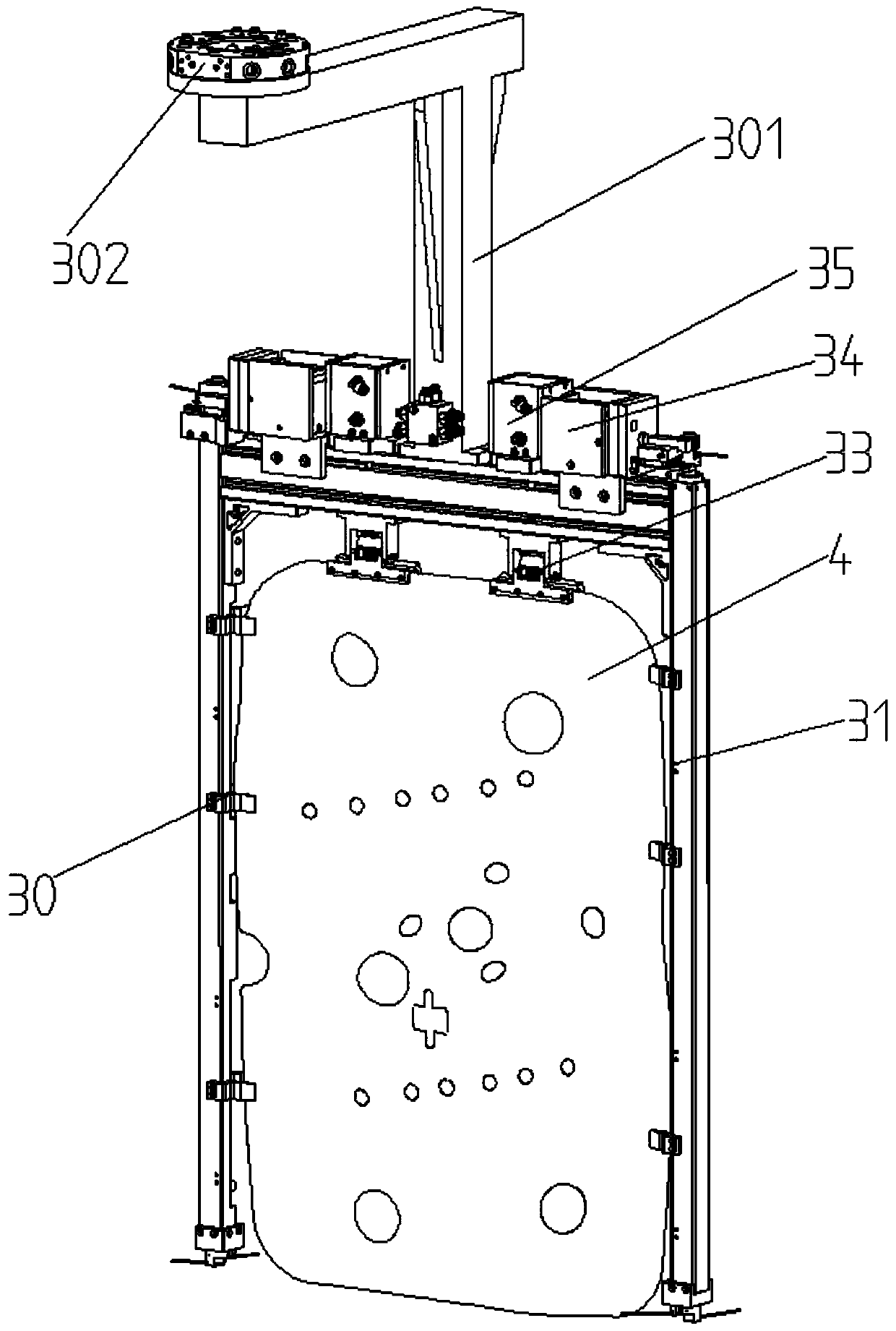

[0029] The present invention includes a general mechanism on a conventional injection mold, and involves an injection molding machine 1, a fixture table 2 arranged on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com