Patents

Literature

57results about How to "Difficult to expand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fabric multifunctional foaming material and preparation method and application thereof

ActiveCN101892590AImprove sleep qualityImprove microcirculationFibre treatmentScreen printingAntibiosis

The invention relates to a fabric multifunctional foaming material with the functions of magnetism, far infrared, anion, traditional Chinese medicine, aroma, antibiosis, adsorption and the like. The invention mainly solves the technical problems that the conventional fabric products have single function, have side effect on a human body and the like. The fabric multifunctional foaming material is prepared by mixing NdFeB powder microcapsules, nano silver powder microcapsules, tourmaline powder microcapsules, Chinese medicinal powder microcapsules, plant essential oil microcapsules, a foaming base material, a wetting agent and a diluent. The preparation method comprises the step of uniformly mixing the raw materials according to a certain proportion. The fabric multifunctional foaming material can be applied to slurry for screen printing of fabrics. The foaming material is applied to the fabrics, so the fabrics have the functions of magnetism, far infrared, anion, traditional Chinese medicine, aroma, antibiosis, adsorption and the like, have no harm to a human body and improve the quality of life of people.

Owner:太原伦嘉生物科技股份有限公司

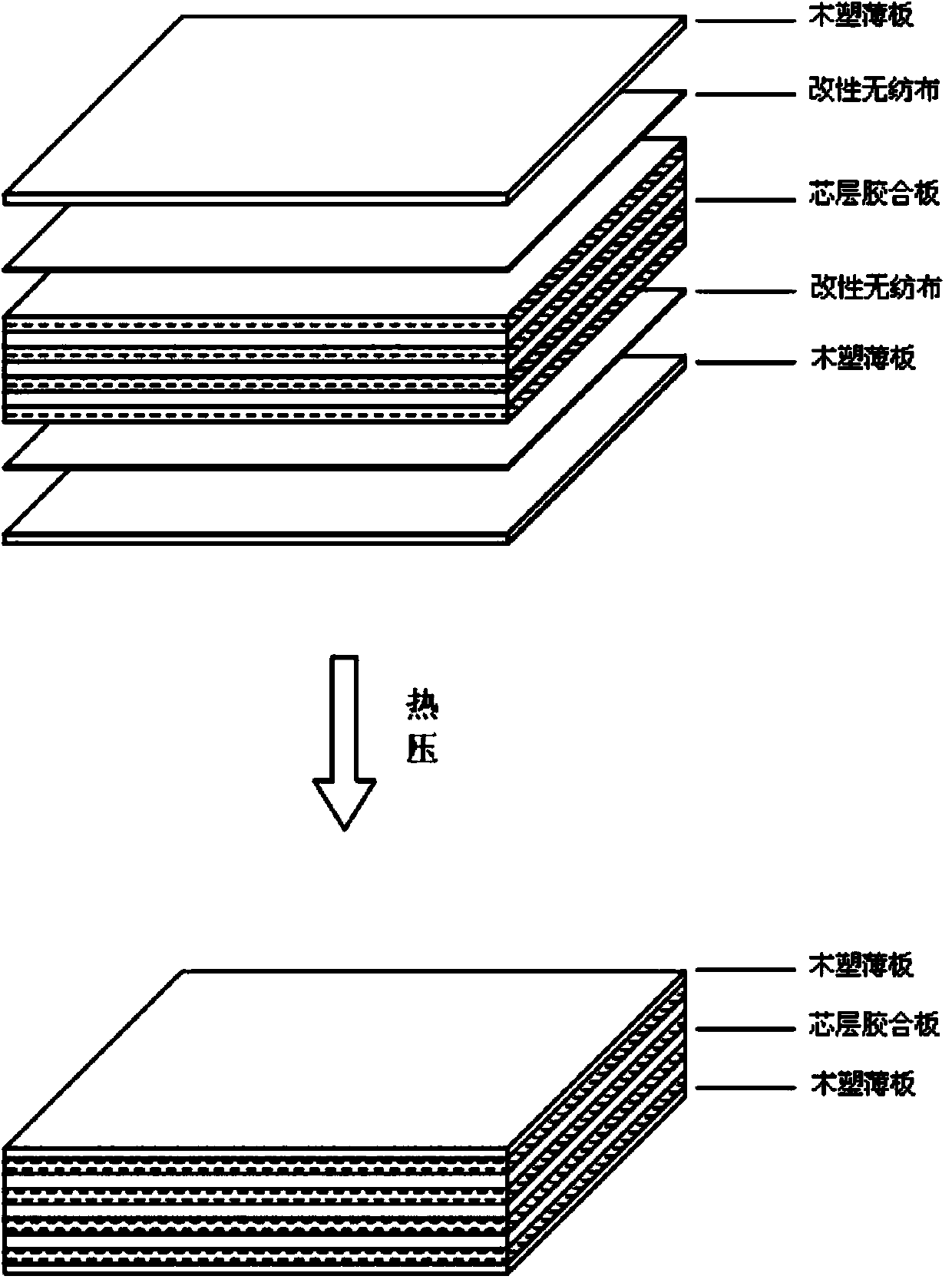

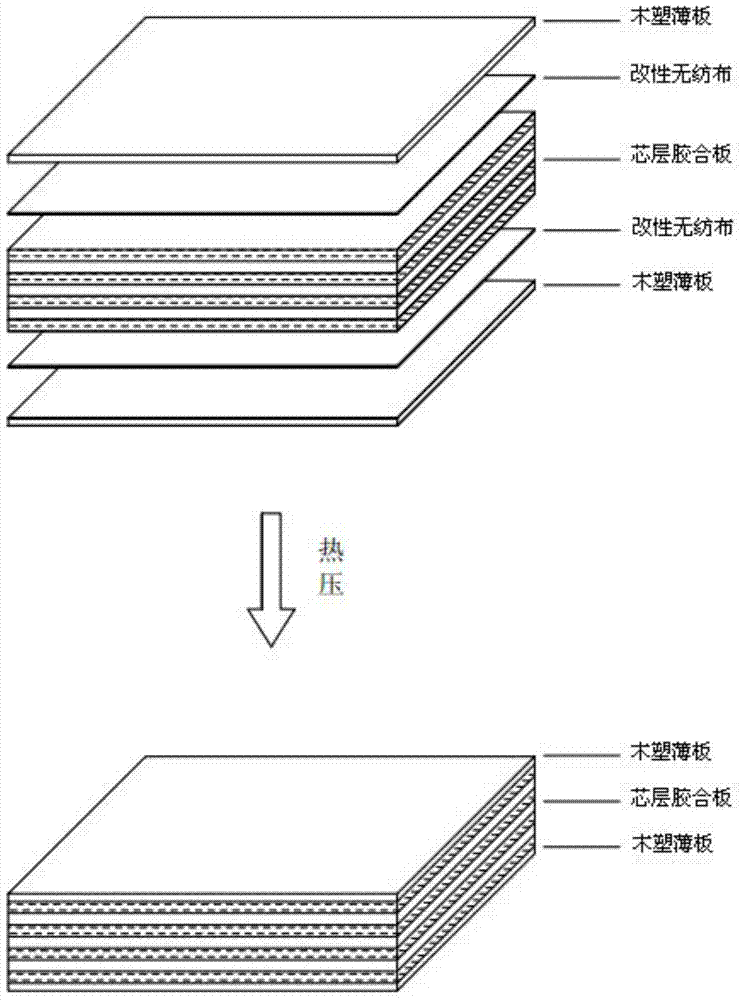

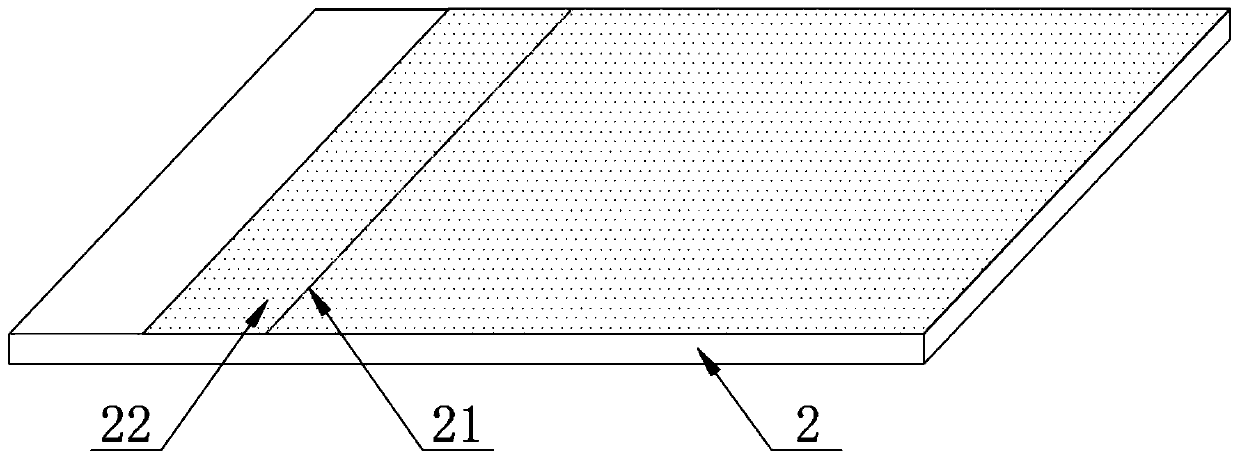

Wood plastic composite material cladding plywood formwork and manufacturing method thereof

ActiveCN103758340AReduced flatness errorGood dimensional stabilityFibre treatmentSynthetic resin layered productsPlastic filmToughness

The invention relates to a plywood formwork and a manufacturing method of the plywood formwork, in particular to a wood plastic composite material cladding plywood formwork and a manufacturing method of the wood plastic composite material cladding plywood formwork. The wood plastic composite material cladding plywood formwork aims to solves the problems that a wood plywood formwork manufactured in the prior art is low in intensity and poor in durability. The wood plastic composite material cladding plywood formwork is formed by a wood plastic sheet, an improved non-woven fabric and core-layer plywood in a manufactured mode. The manufacturing method comprises the steps that the wood plastic sheet is manufactured; the non-woven fabric is improved; the core-layer plywood is manufactured; pavement is carried out; the formwork is formed. The wood plastic composite material cladding plywood formwork is low in manufacturing cost, high in intensity, good in toughness, long in service life, resistant to moisture and corrosion, stainless, bright, clean and flat in surface, light in weight, and convenient to transport and construct, a die does not swell easily, and the die is released easily. The wood plastic composite material cladding plywood formwork is used as a building formwork.

Owner:NORTHEAST FORESTRY UNIVERSITY

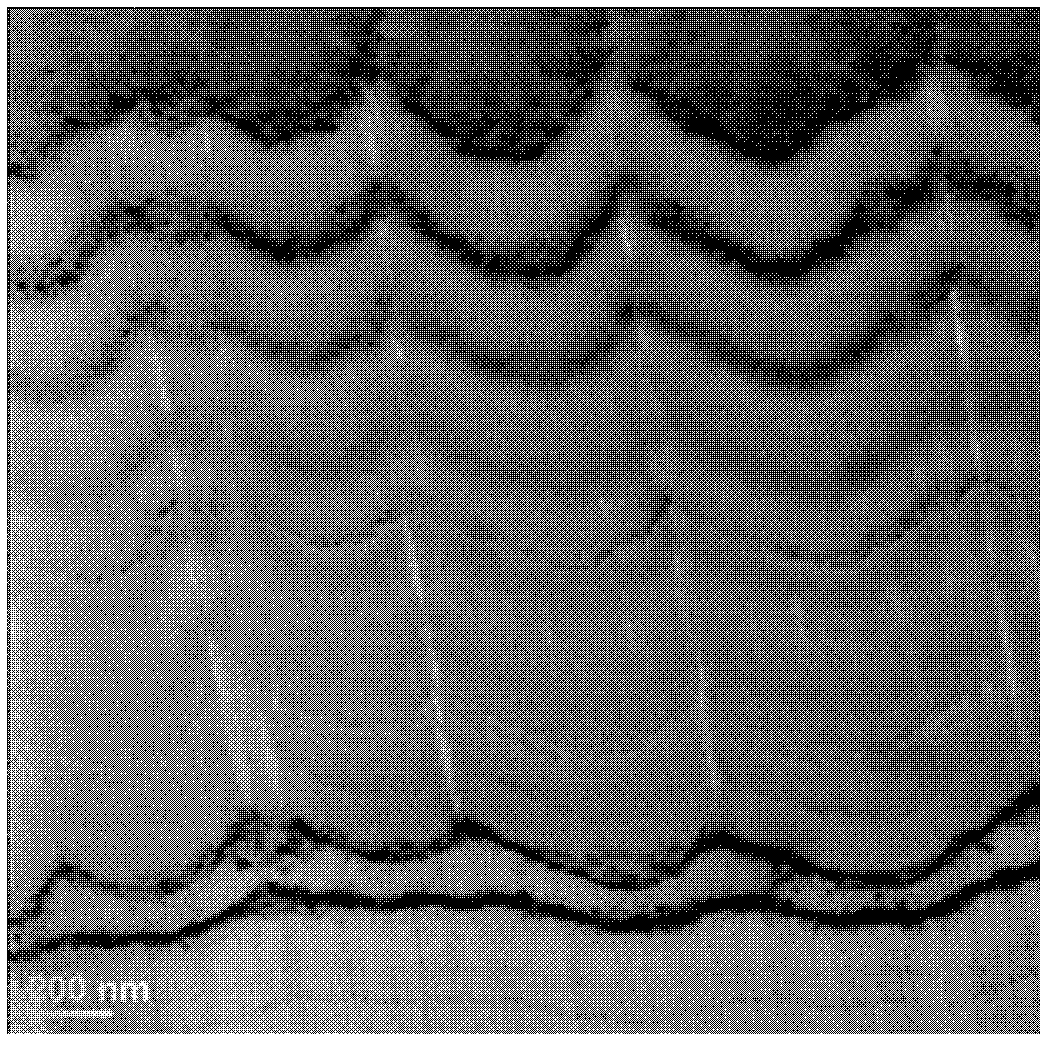

Dental pulp marrow similar cells (DPMSC) and methods of isolating and using

InactiveUS20110158962A1Effective to ameliorateImprove isolationBiocideMetabolism disorderCD44Isolated population

The invention provides for isolated population of pulp marrow similar cells (DPMSCs) and methods for isolating and using these cells. The population of DPMSCs are highly homogenous for CD1O, CD29, CD13, CD44, CD49a, CD49d, CD59, CD73, CDw90, CD105, Oct-4 Isoform A and B, Nanog, Sox-2, and SSEA-4.

Owner:FOUND OF TRANSLATIONAL SCI +1

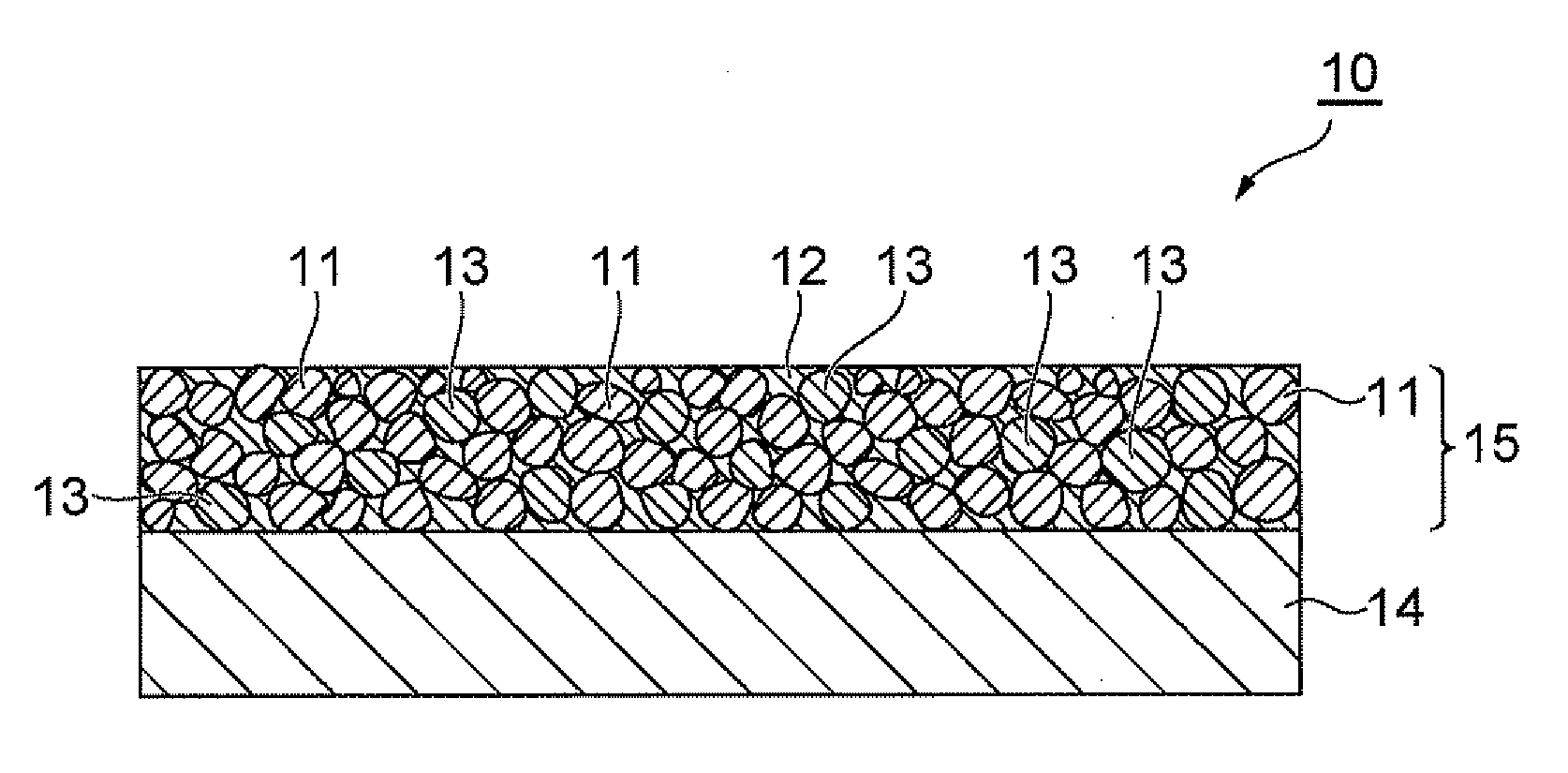

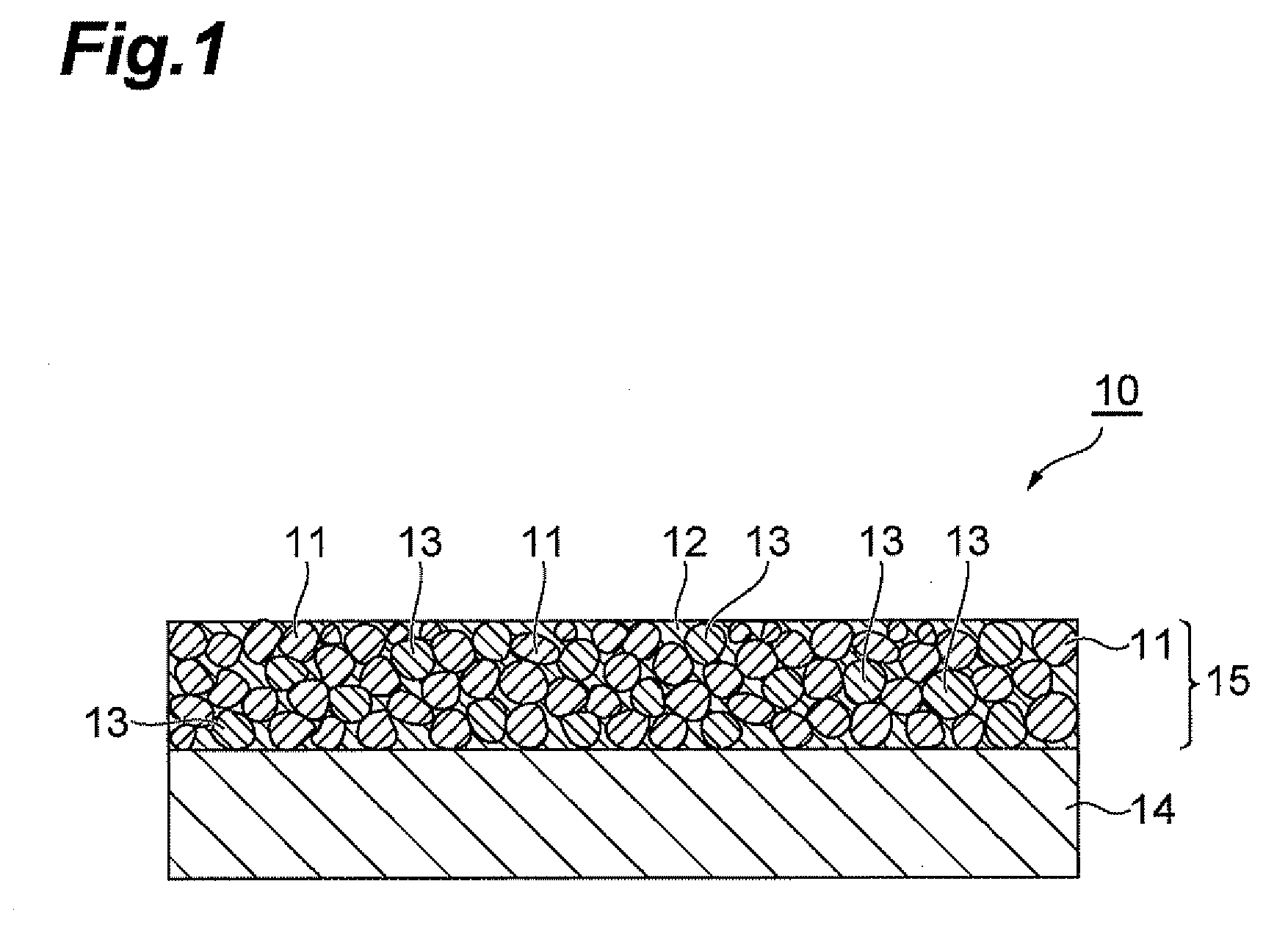

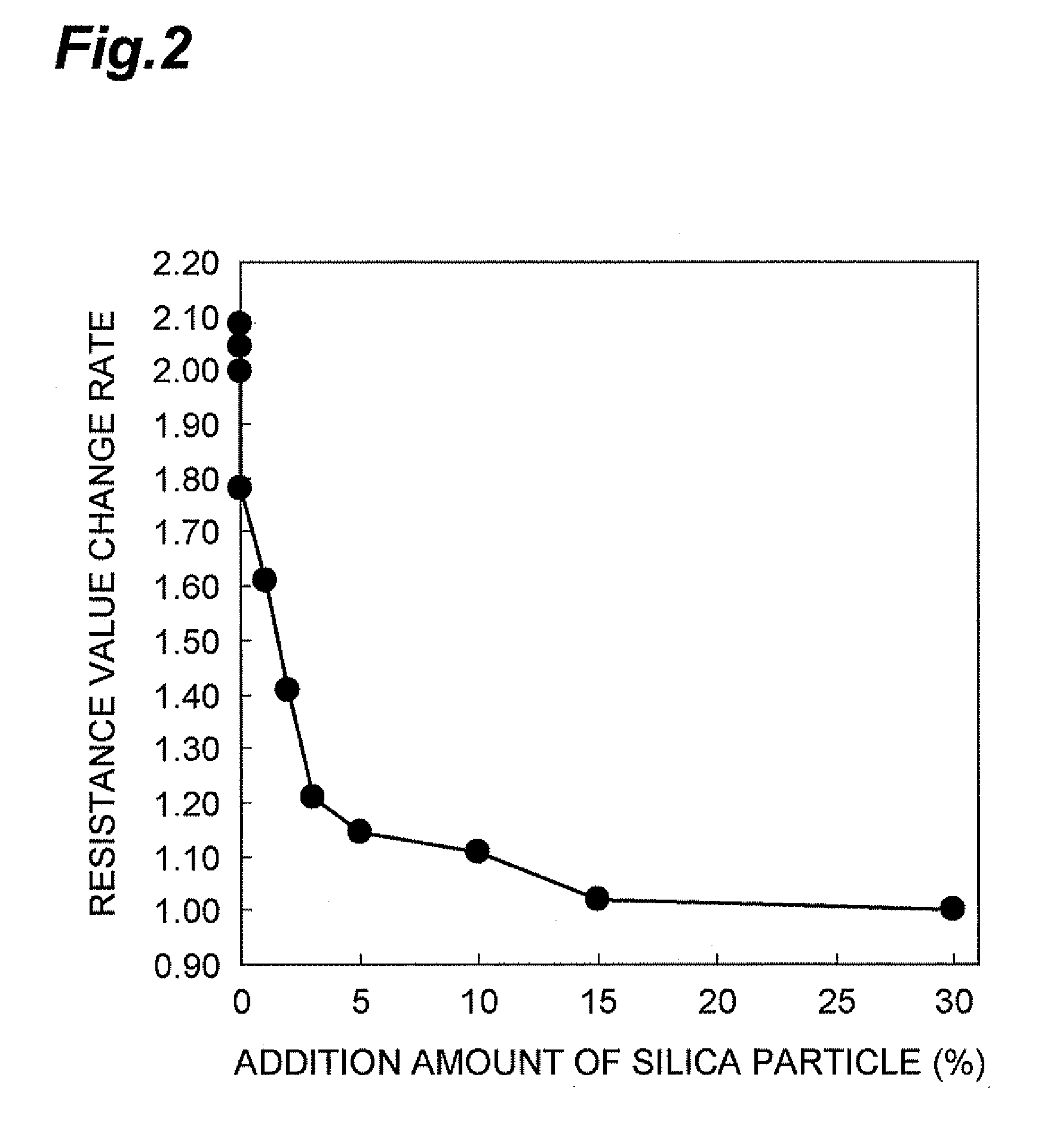

Transparent conductive material and transparent conductor

InactiveUS20090140218A1Excellent transparent conductivityPoor transparencyNon-metal conductorsConductive materialSilica particleTransparent conducting film

The present invention provides a transparent conductive material with little change in electric resistance under influence of temperature or humidity and a transparent conductive membrane using the same.The transparent conductive material of the present invention includes a resin, a transparent conductive particle, a silica material containing at least either of a silica particle or a precursor of silica particle, and a silane coupling agent.

Owner:TDK CORPARATION

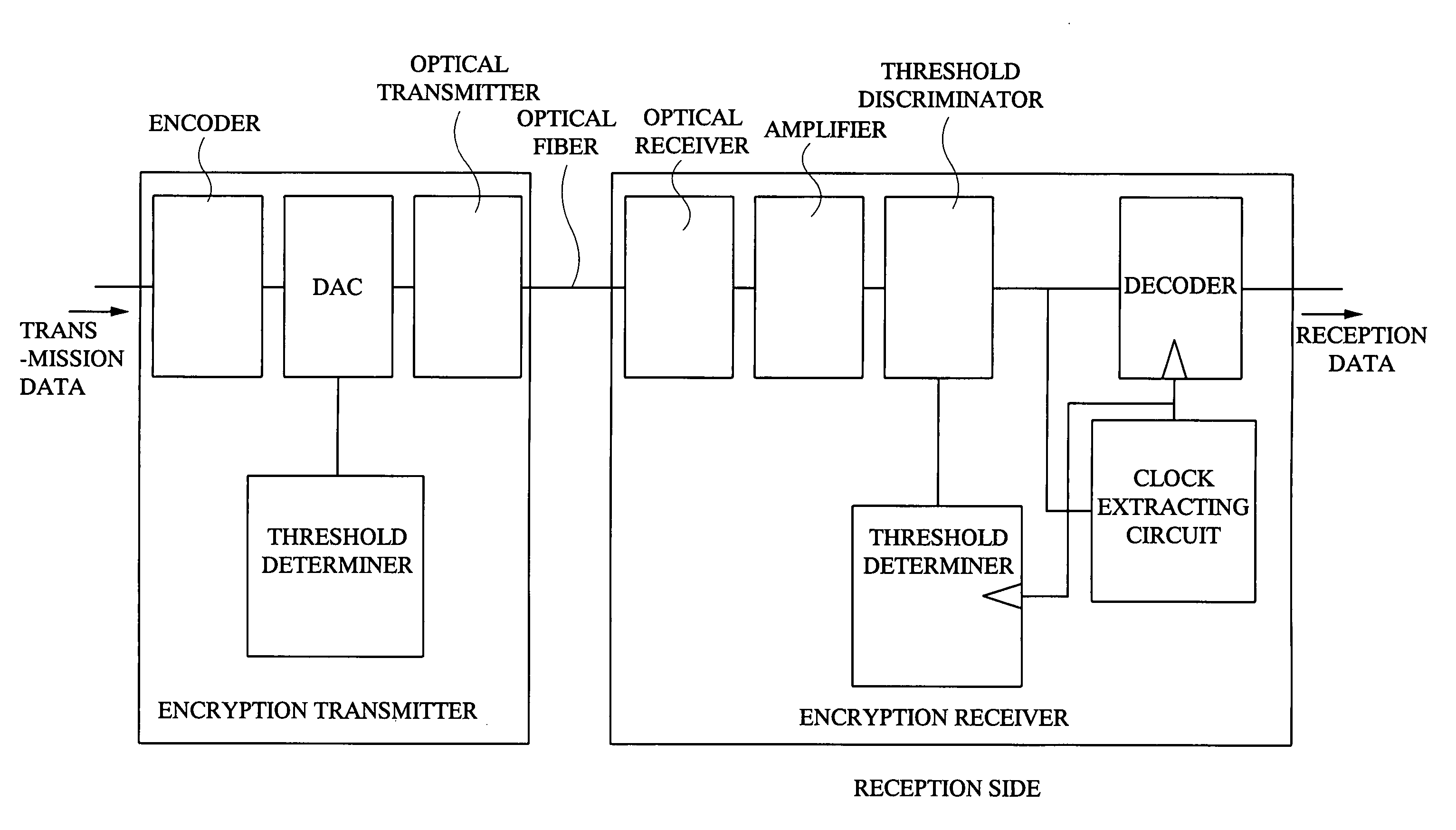

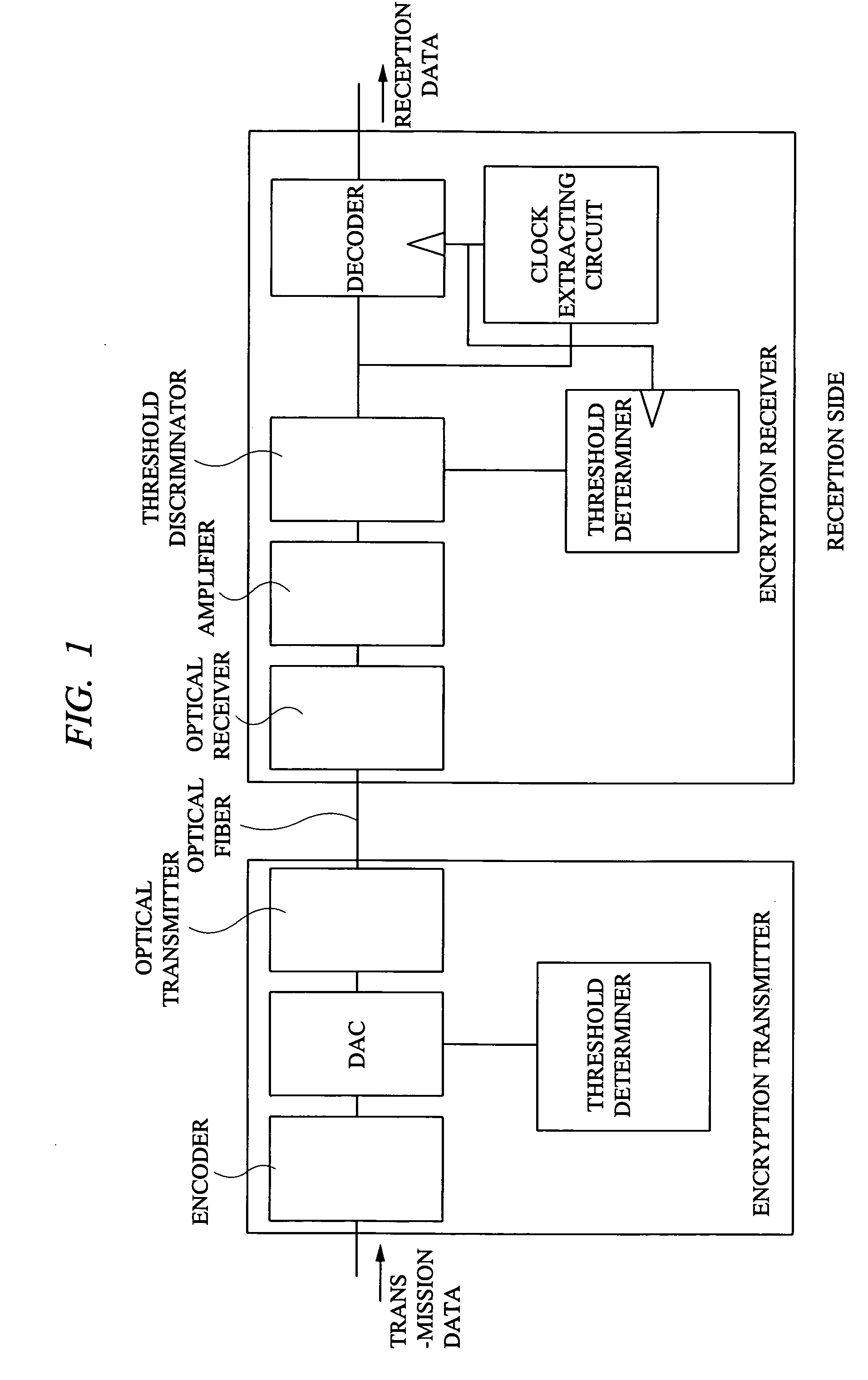

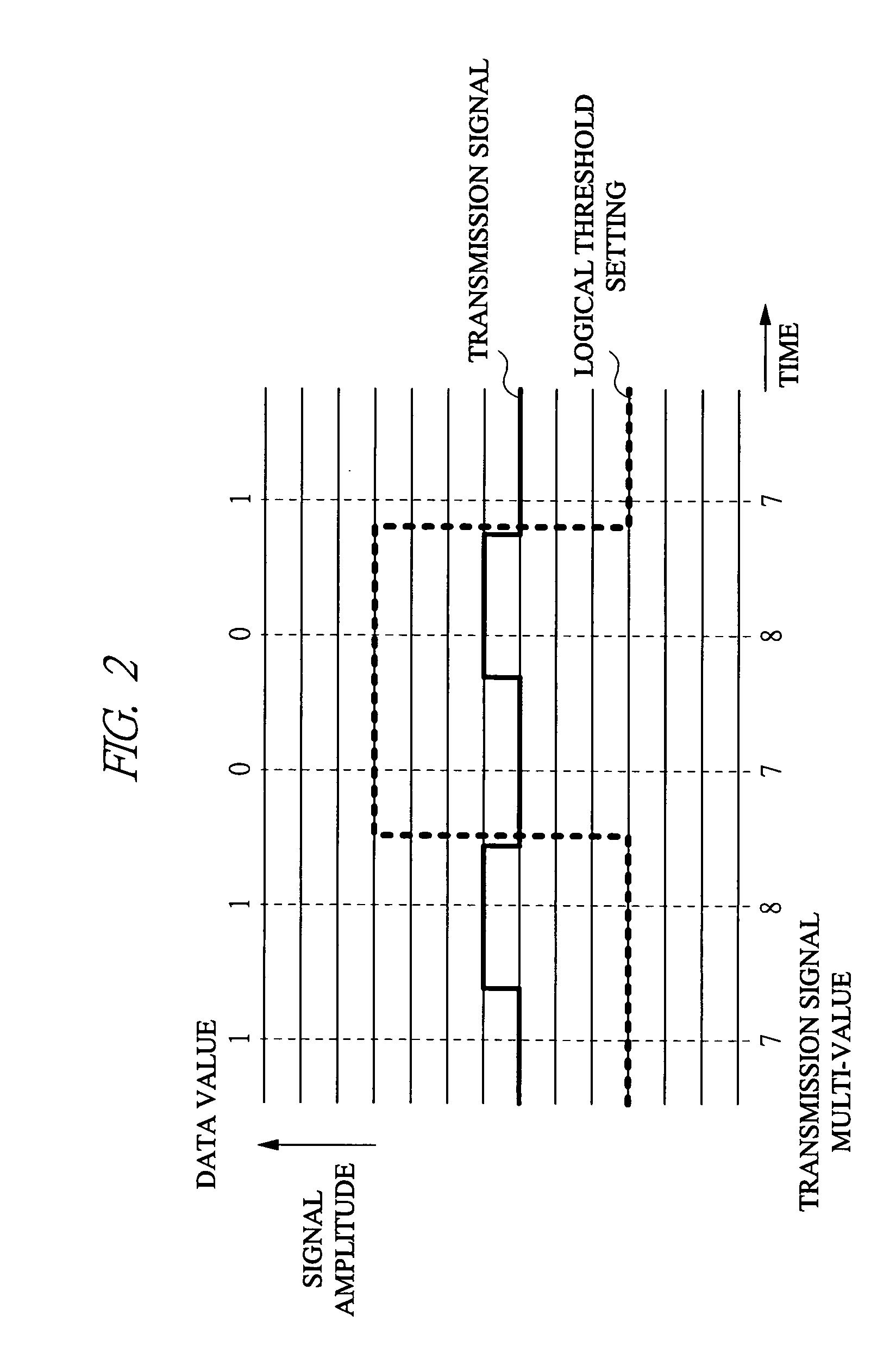

Optical signal communication apparatus

InactiveUS20060072753A1Low costImprove transmission qualityKey distribution for secure communicationElectromagnetic transmission optical aspectsTransfer systemData signal

In encryption transmission employing a conventional optical transmission apparatus, since a dedicated hardware unit to be used executes a complicated signal process, there are the problems that a high-speed transmission speed is difficult to realize and an entirety of a transmission system employing encryption becomes high in cost. An optical signal transmitter for encryption and an optical signal receiver for encryption, employing optical multi-value transmission which is high in cost and in which an effective improvement of transmission speed is difficult, are used only for exchanging an encryption key and data to be actually transmitted is transmitted by another line. A data signal is transmitted by using: the exchanged encryption key after communication of the encryption key is executed by using the transmitter and receiver for encryption transmission prior to the data transmission; and another system of high-speed signal transmission line in an encryption transmission circuit.

Owner:HITACHI LTD

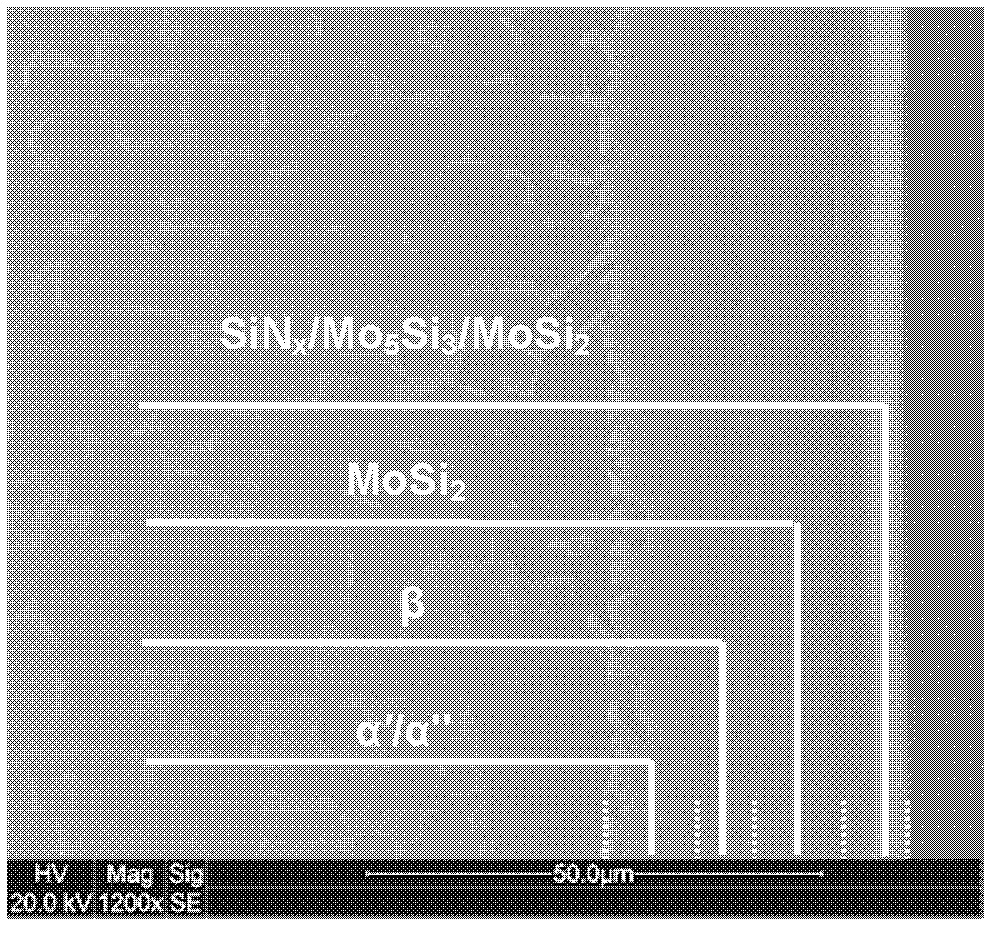

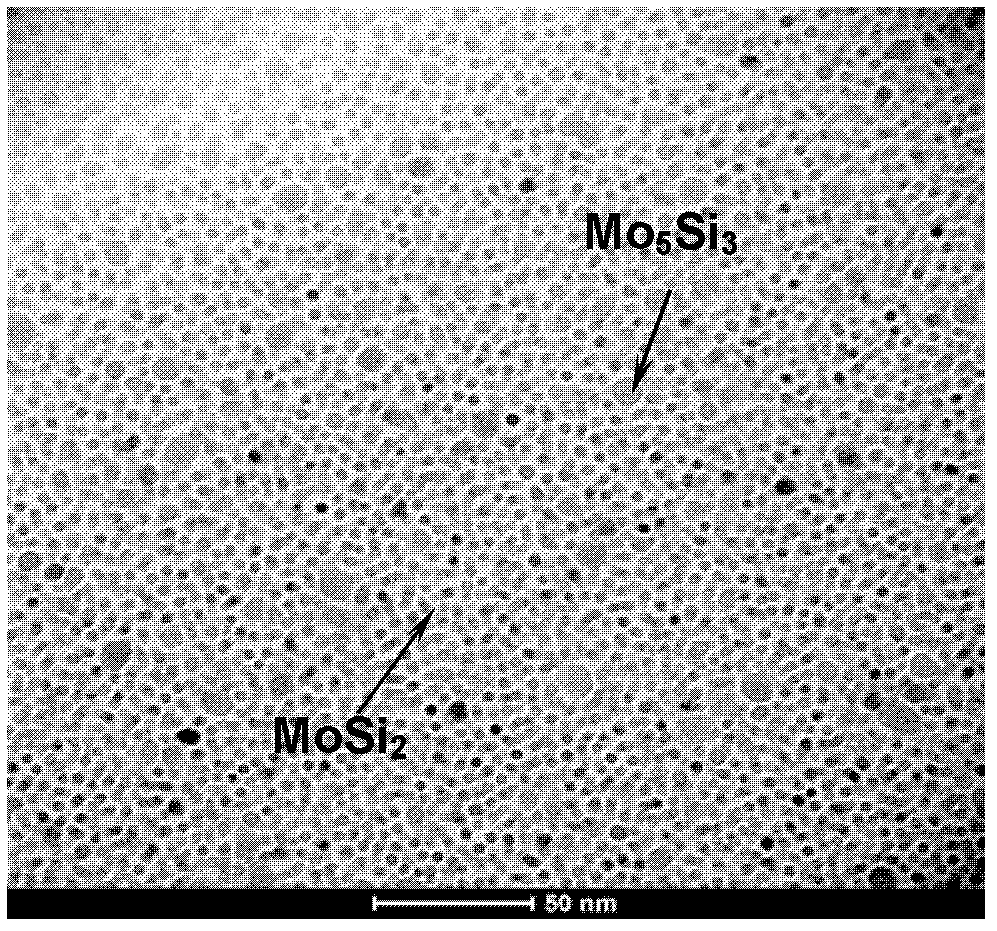

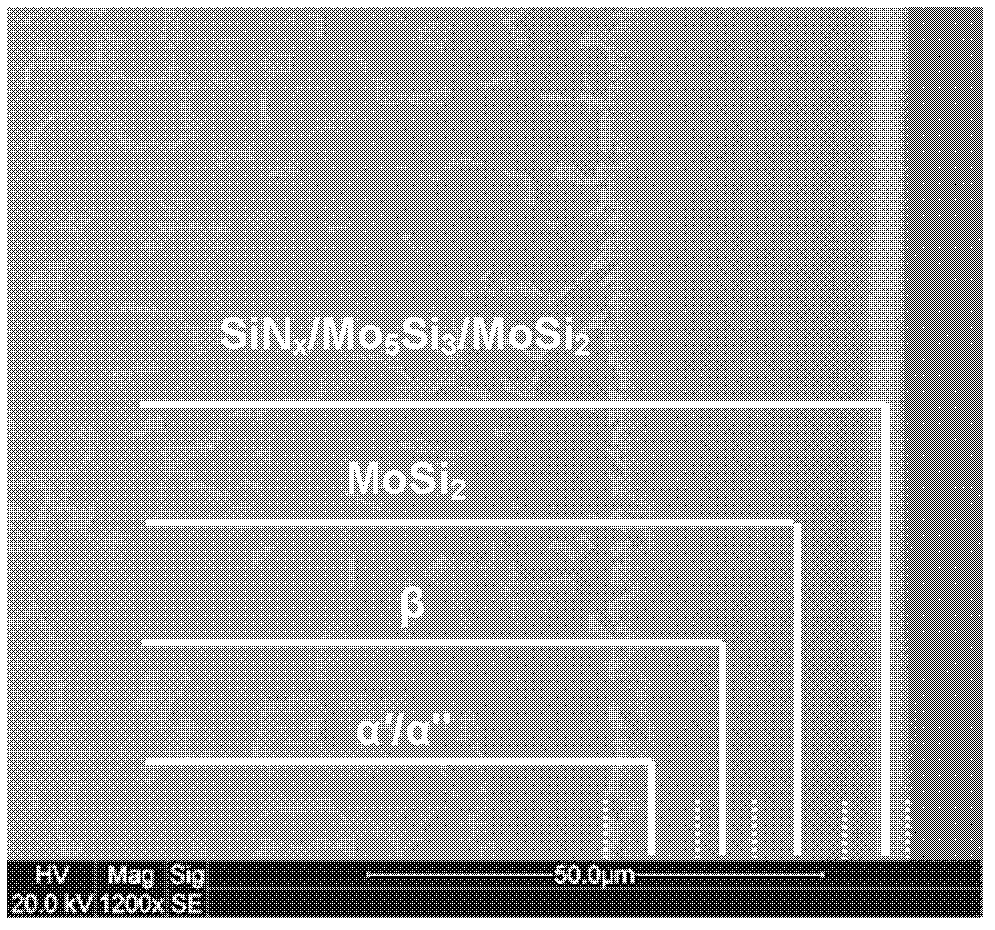

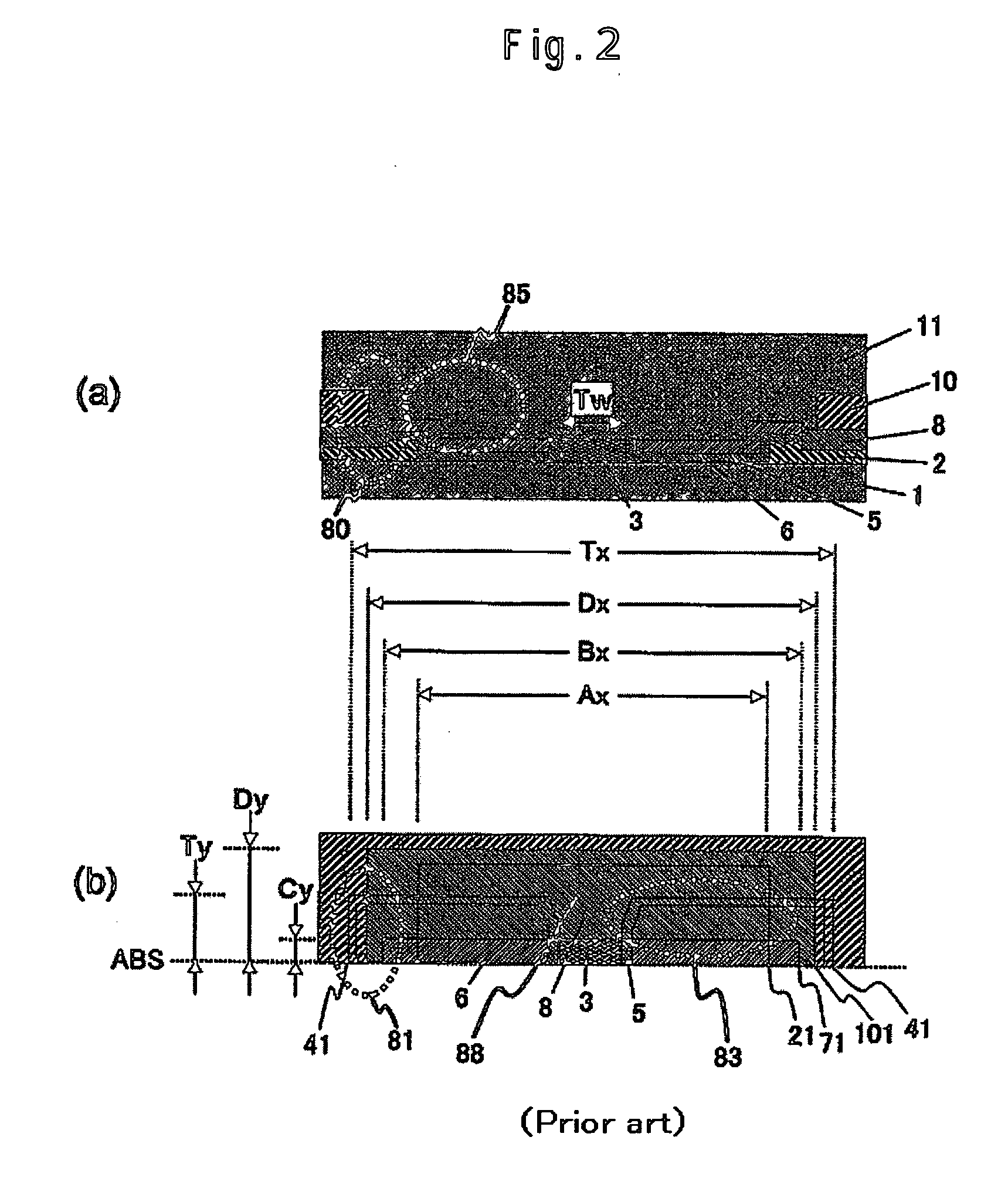

Composite surface treatment process for preparing amorphous-nanocrystalline molybdenum disilicide base abrasion resistant and corrosion resistant coatings on titanium alloy surfaces

InactiveCN102644054AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingDeposition temperatureOxidation resistant

The main preparing process of a composite surface treatment process of preparing amorphous-nanocrystalline molybdenum disilicide base abrasion resistant and corrosion resistant coatings on titanium alloy surfaces includes that double cathode plasma sputtering deposition is conducted, technological parameters include that the target material voltage is 500 V to 1000 V, the workpiece voltage is 300 V to 450 V, the distance between the target material and the workpiece is 10 mm to 30 mm, the working air pressure is 20 Pa to 45 Pa, and the deposition temperature is 450 DEG C to 850 DEG C; the kind of the sputtered target material is Mo 0.1-0.3 (Si 0.90, Al 10.10) 0.9-0.7; and the kind of the workpiece material is titanium alloy. The composite amorphous-nanocrystalline silicide layer has the advantages of high toughness, high hardness and good corrosion resistance, abrasion resistance and oxidation resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

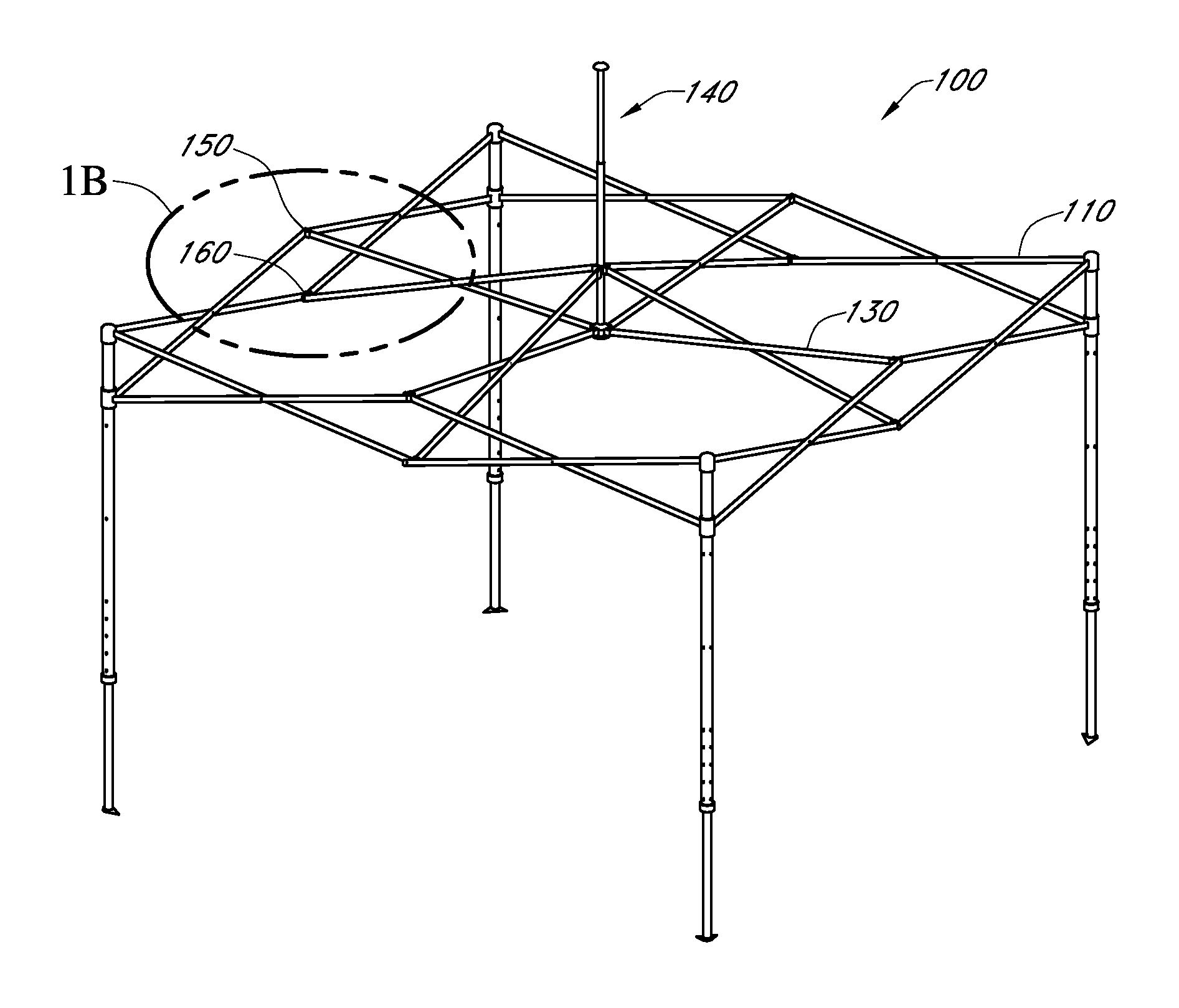

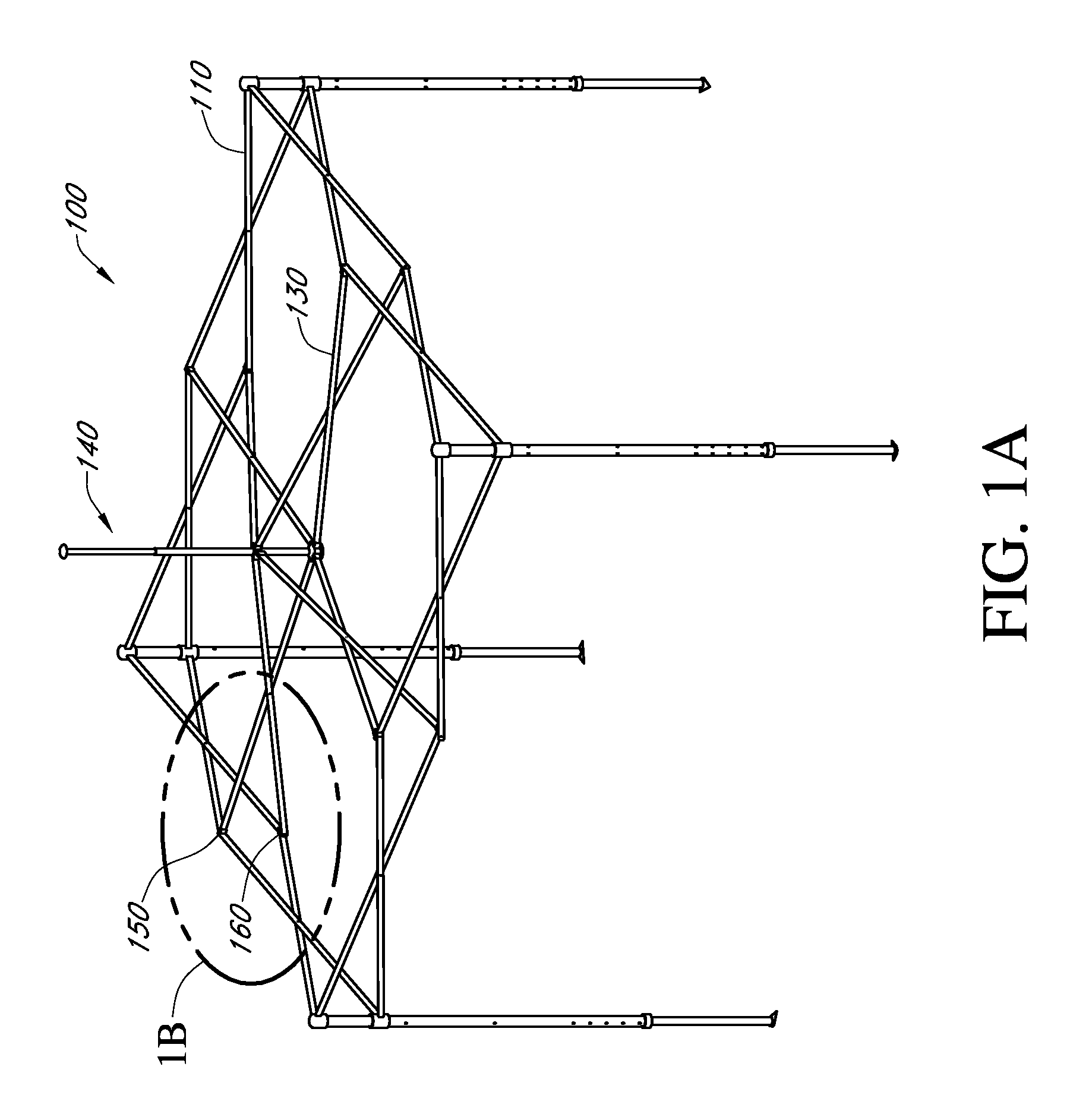

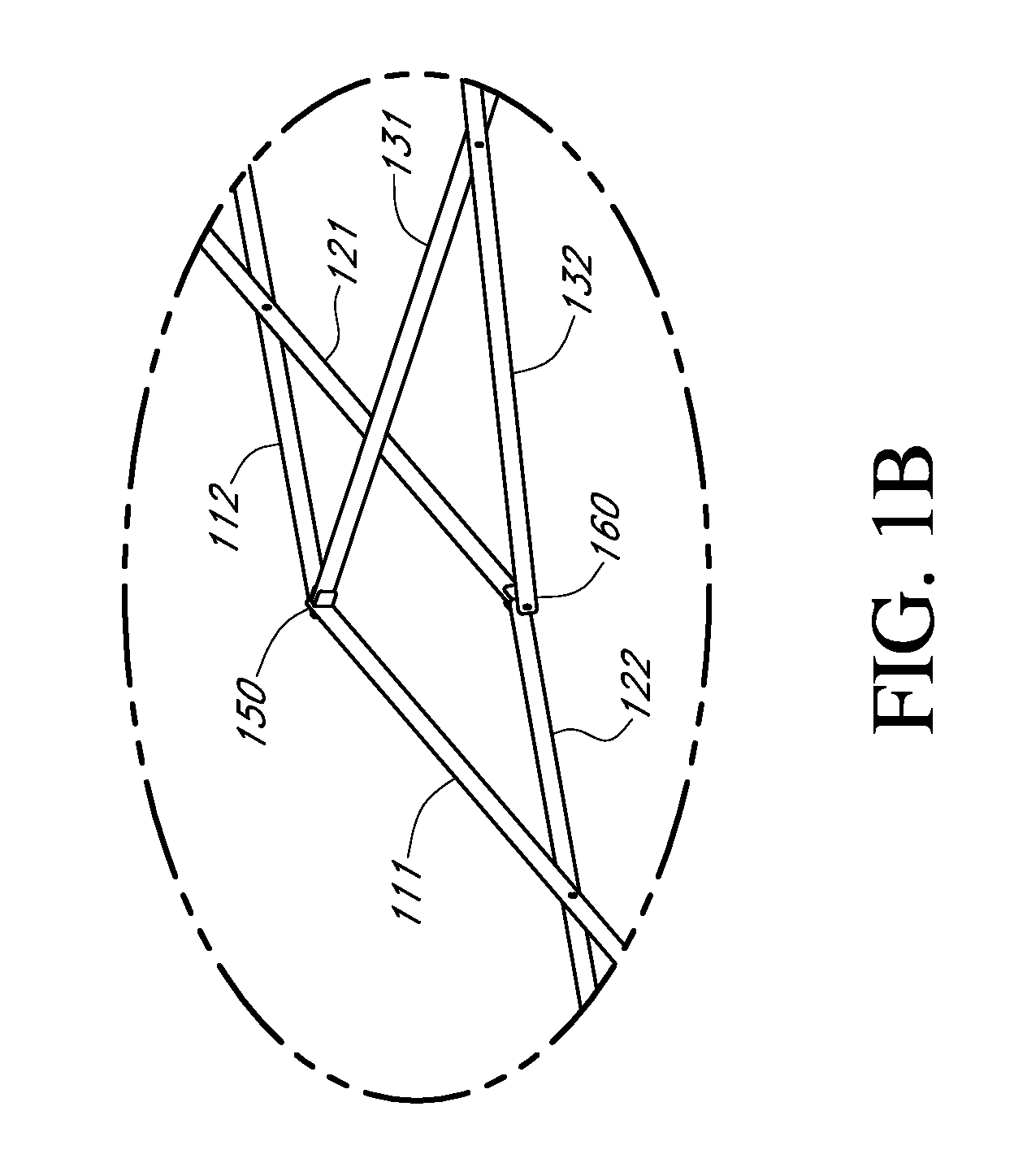

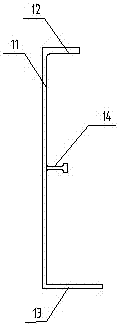

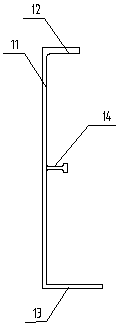

Canopy shelter brackets

A canopy shelter bracket for increased structural integrity. The canopy shelter bracket can include an inner portion, an intermediate portion, a first outer portion, and a second outer portion integrally connected to form a generally “F” shape or an “S” shape. The inner portion, first outer portion, and / or the second outer portion can include holes for receiving a fastener therethrough to fasten the brackets to cross members. A single fastener can be used to fasten multiple cross members to the bracket. The first and / or second outer portions can additionally serve to space apart a first cross member from a second cross member.

Owner:SHELTERLOGIC

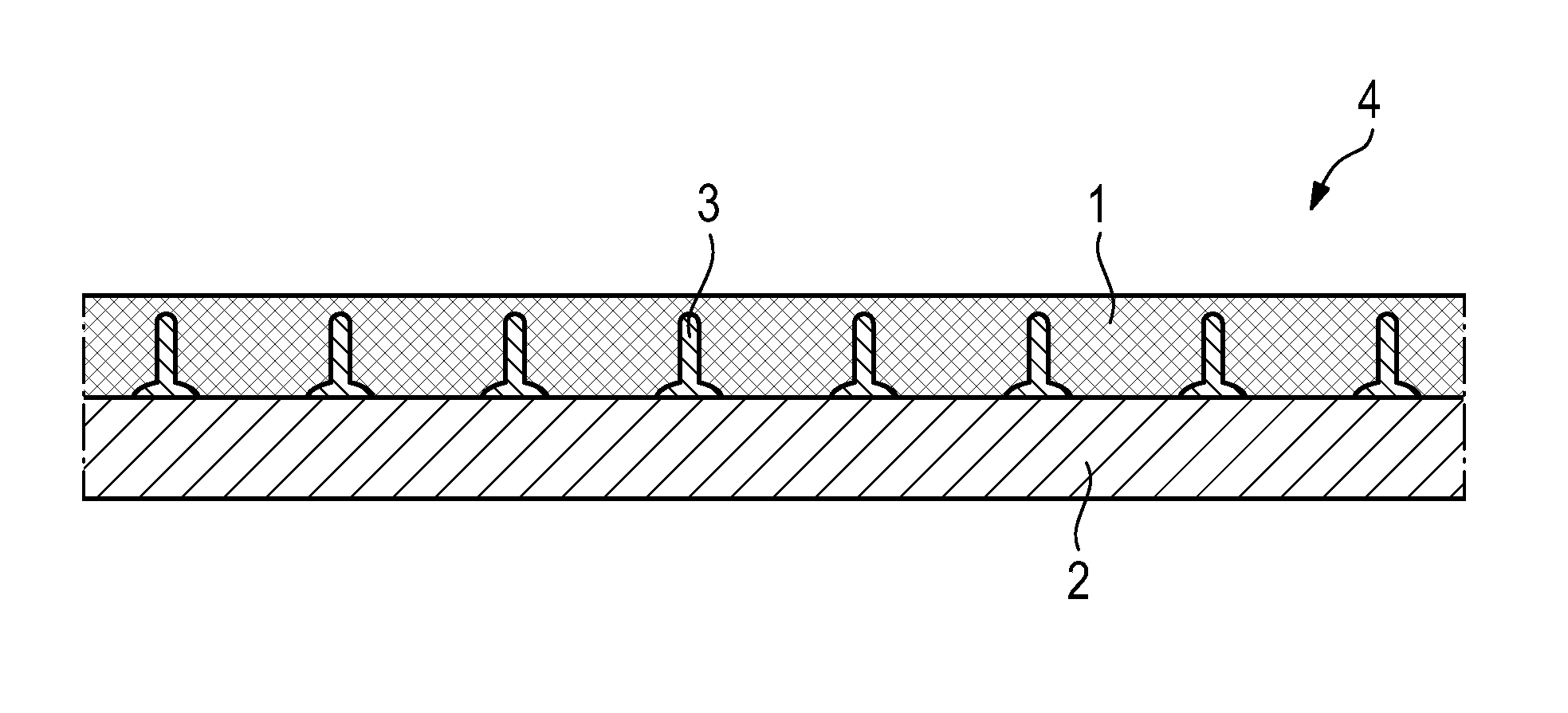

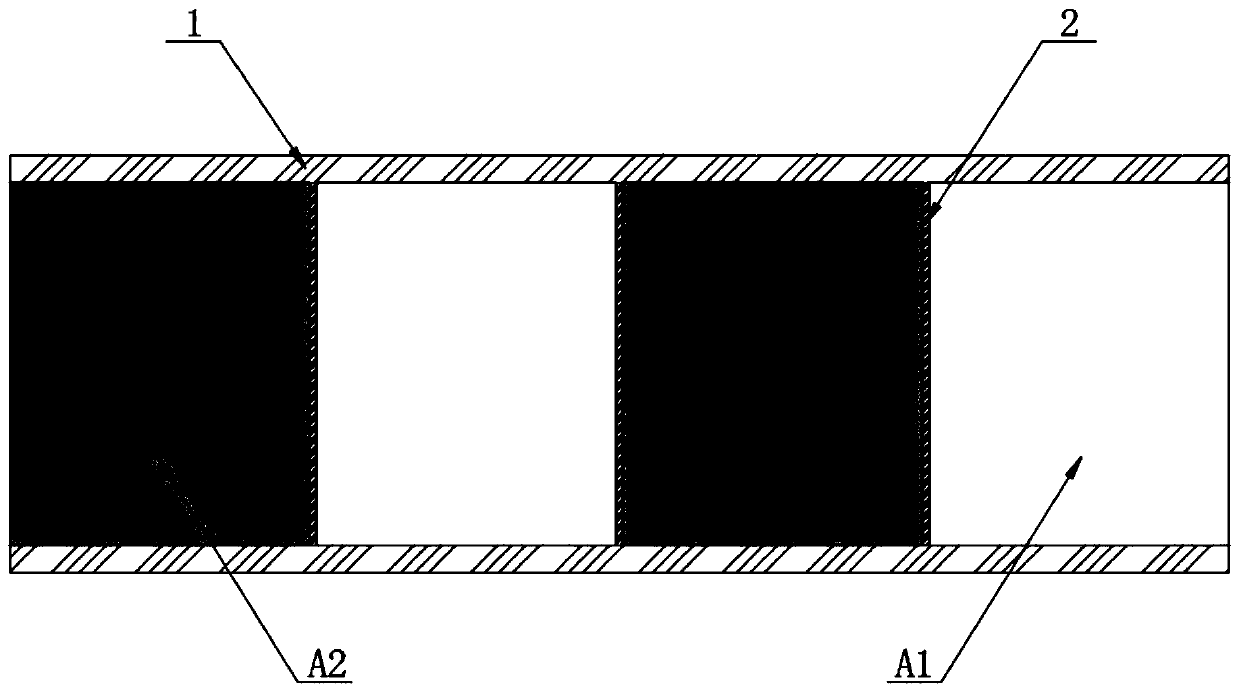

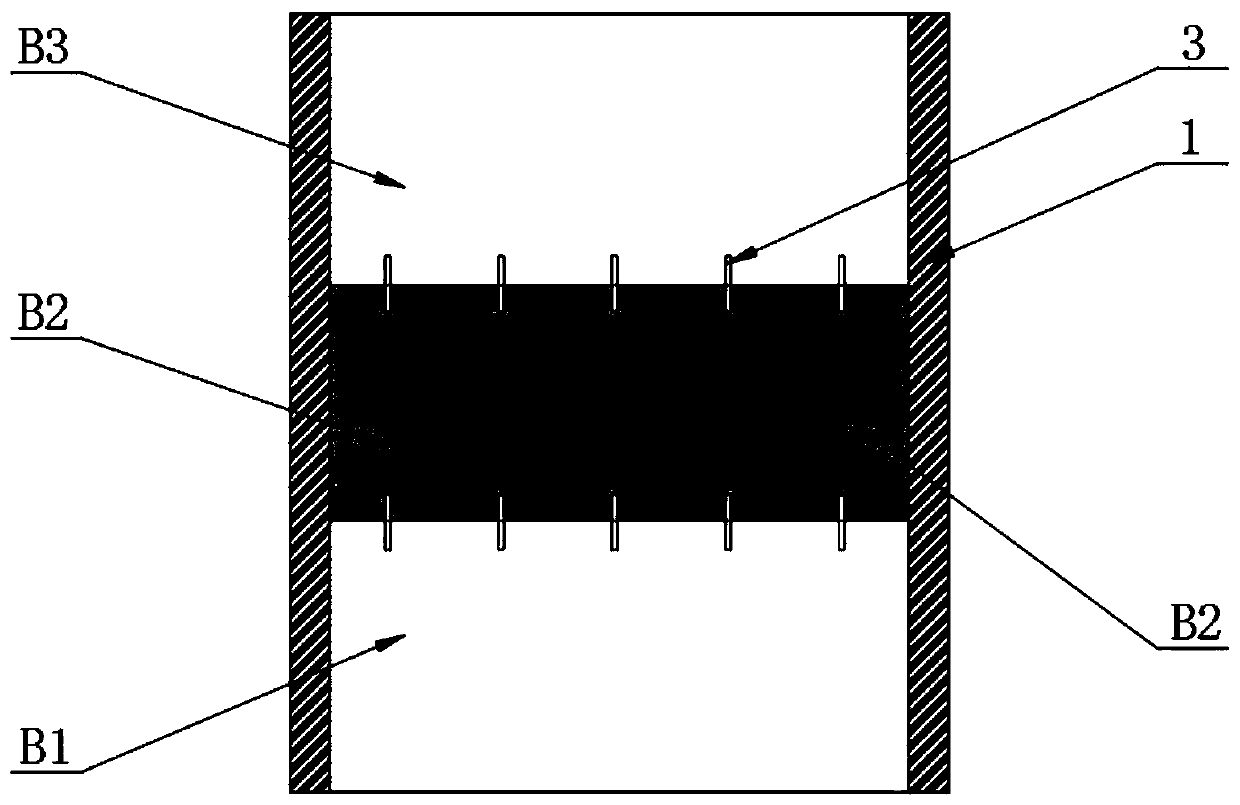

Composite component

ActiveUS20150343742A1Improve mechanical propertiesImprove temperature resistanceSynthetic resin layered productsVehicle componentsRoom temperatureMetal

A composite component has a continuous-filament reinforced thermoplastic material (1) and a metallic insert (2), which is obtainable in that (a) a metallic insert (2) having pin structures (3) attached to the surface is provided, (b) firstly the pinned metallic insert (2) is inserted into a forming tool, (c) subsequently an optionally pre-heated organic sheet (1) manufactured from the continuous-filament reinforced thermoplastic (1) is disposed thereon, (d) the forming tool is closed and subsequent to a dwell time is optionally cooled to room temperature, and finally (e) the composite component (4) thus obtained is removed, is proposed.

Owner:DR ING H C F PORSCHE AG

Edible mushroom ice temperature fresh-keeping method

InactiveCN1631240AExtended shelf lifeReduce the amount requiredFood preservationFood preparationBiological propertyEdible mushroom

The invention provides an edible mushroom ice temperature fresh-keeping method, which comprises the following parts, edible mushroom ice temperature fresh-keeping collection and raw material standard, edible mushroom ice temperature processing technology, ddible mushroom ice temperature processing key technology, and edible mushroom ice temperature fresh-keeping standard, wherein the process comprises collection, precooling, repairing, ice temperature modifier disposing, airing, sorting, packaging, ice temperature storing, and ice temperature transporting.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

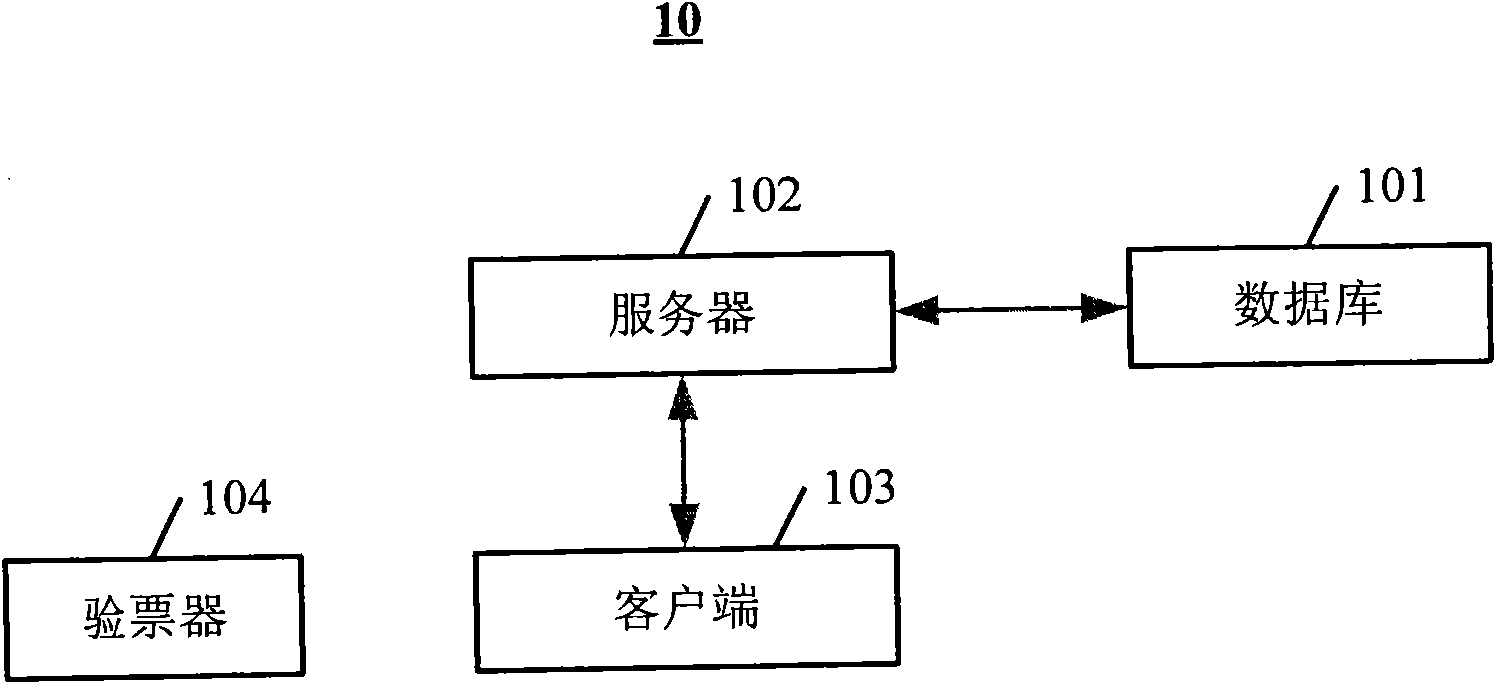

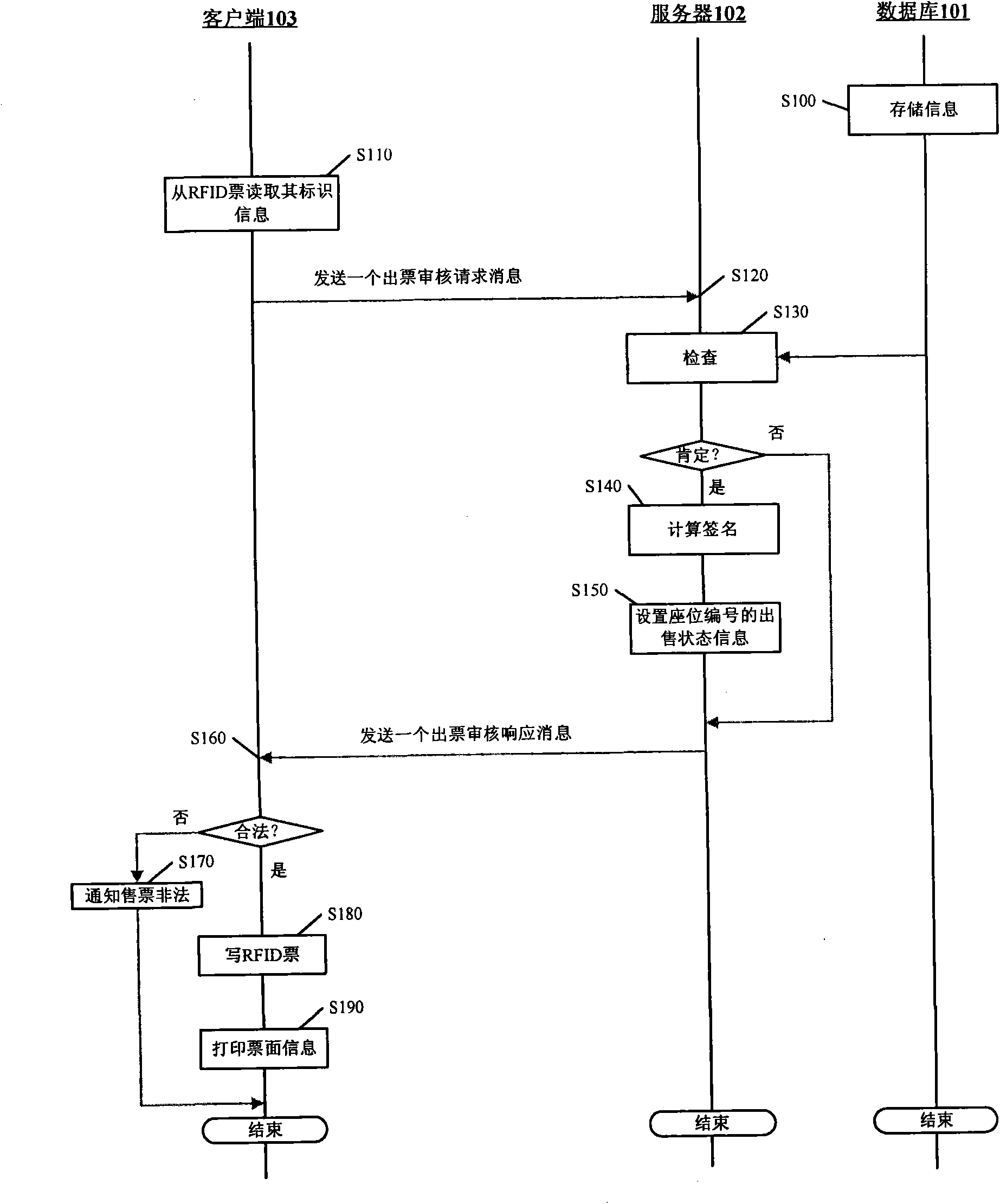

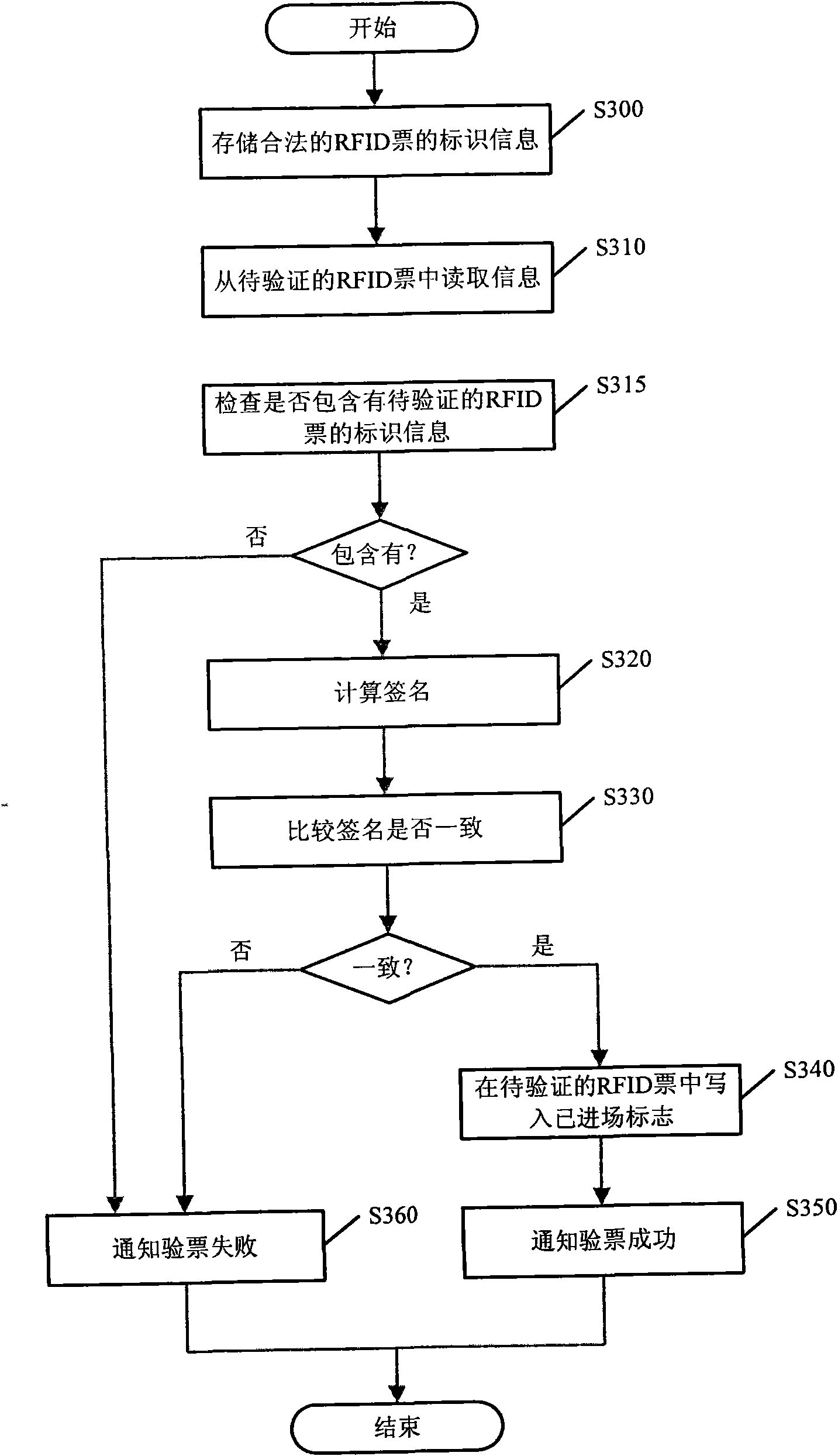

Multiple anti-fake electronic ticket business system based on RFID technology

The invention relates to a multiple anti-fake electronic ticket business system based on an RFID technology. A server of the system comprises a receiving module, a checking module, a calculating module and a sending module, wherein the receiving module is used for receiving an output ticket checking request message sent by a client terminal and used for requesting the server to check whether a ticket sold by a concrete seller is legal or not; the checking module is used for checking whether the concrete ticket sold by the concrete seller is legal or not according to the information which is stored in advance and relevant to the checking of the ticket to be sold and the received output ticket checking request message; the calculating module is used for calculating a signature by using a preset signature arithmetic when a checking result shows that the concrete seller selling the legal concrete ticket; and the sending module is used for sending an output ticket checking response message for showing that the concrete seller is legal for selling the concrete ticket and the calculated signature to the client terminal. The difficulty for faking the ticket is greatly improved by utilizing the system.

Owner:BRITISH VIRGIN ISLANDS RCG HLDG

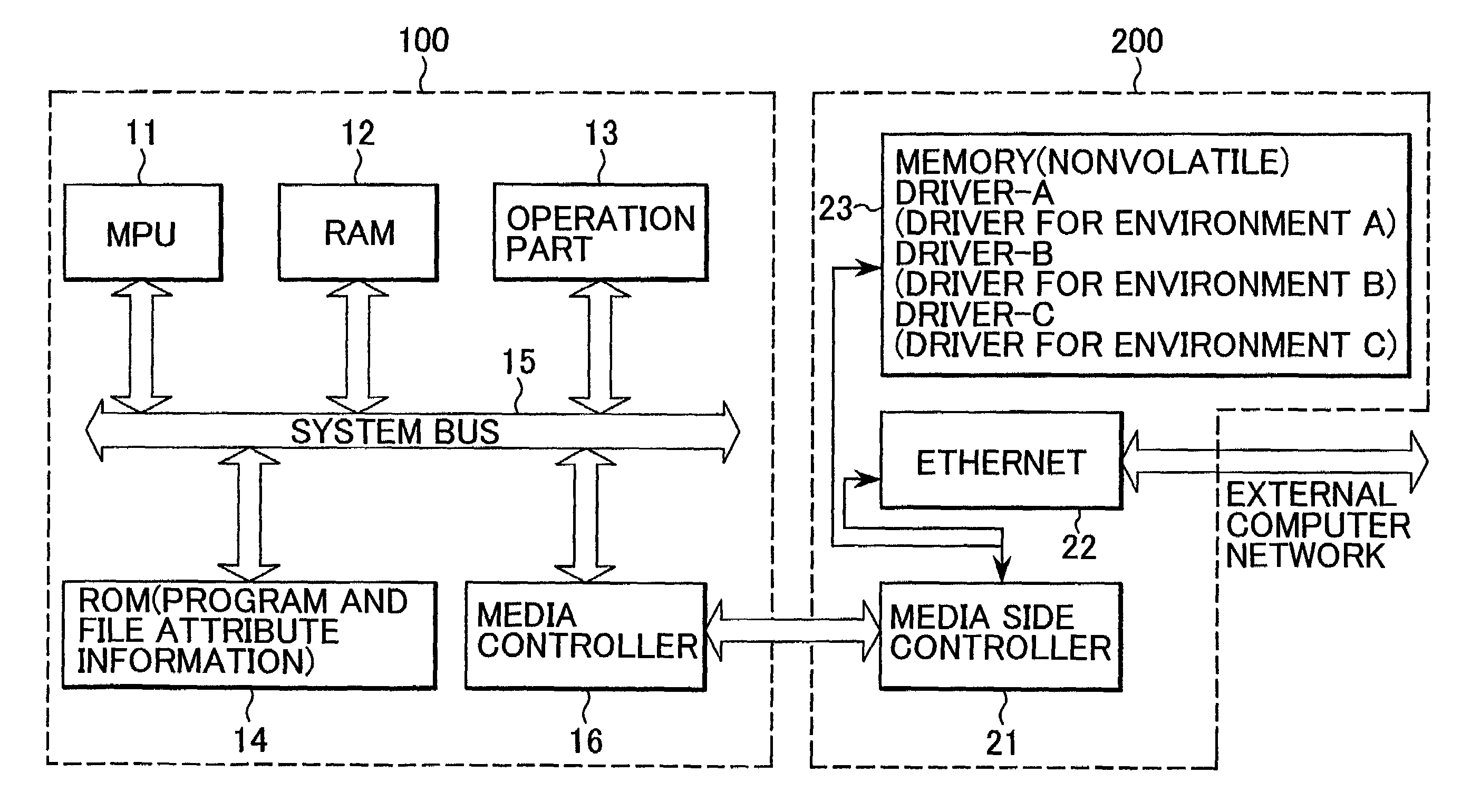

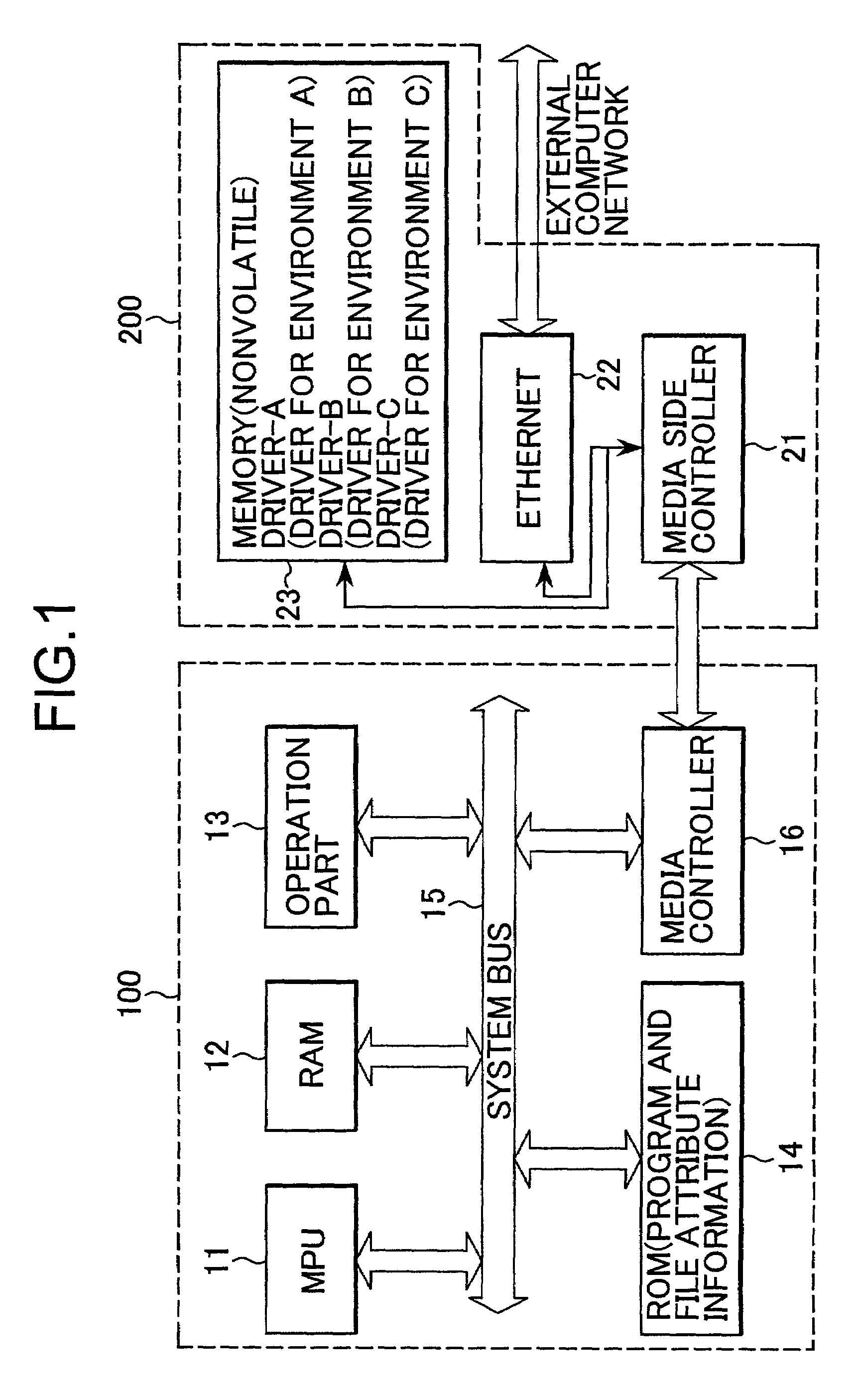

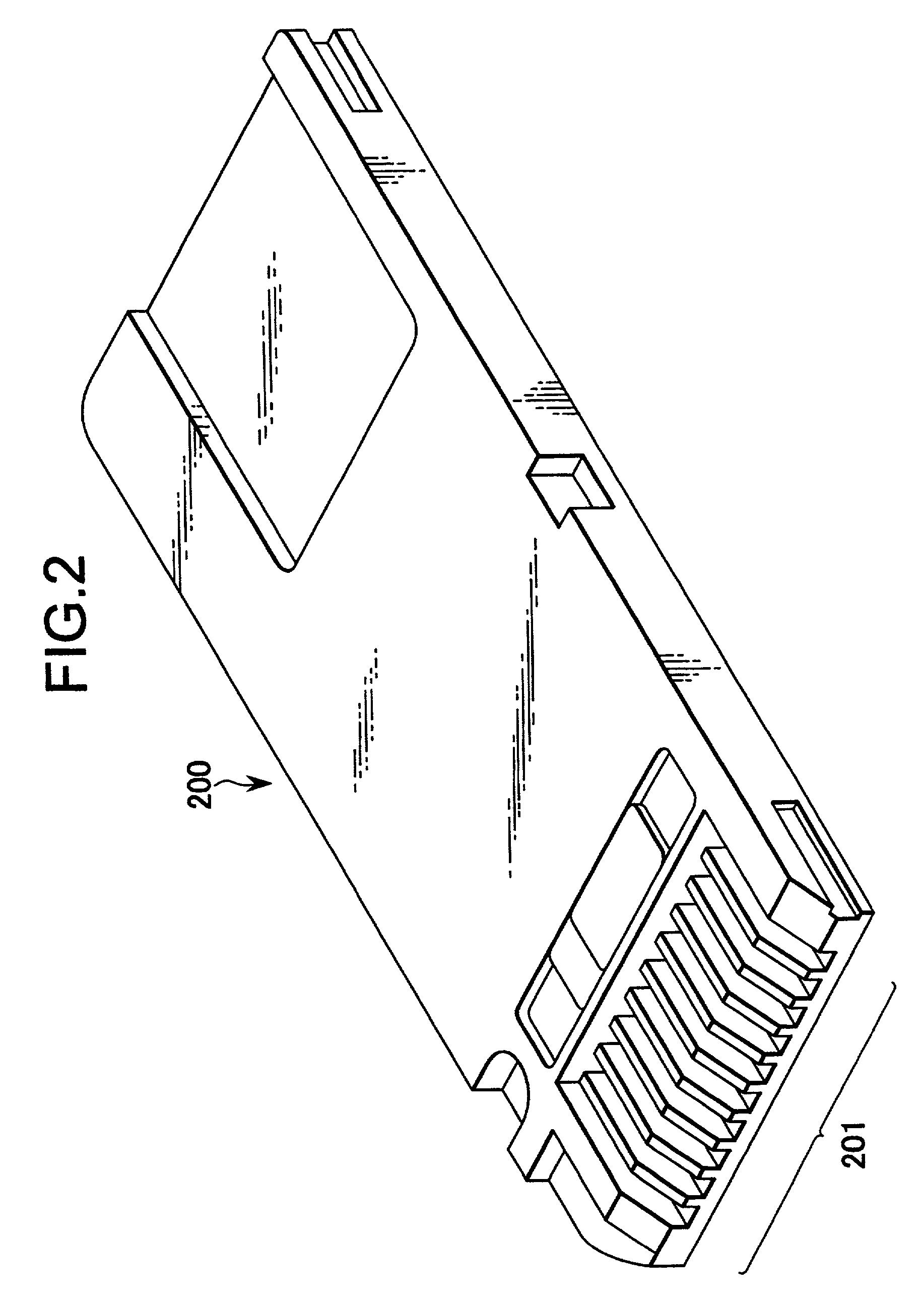

Electronic device, apparatus using the same, and method of reading out data

InactiveUS7325236B2Difficult to expandEasy to resolveComponent plug-in assemblagesProgram loading/initiatingExternal storageRandom access memory

A device, an apparatus using the device, and a method designed for performing operations such as automatic installation of driver software facilitate expansion of the existing functions of the apparatus. A microprocessing unit, a random access memory, an operation part, a read only memory or the like are mutually connected via a system bus and mounted in main equipment which is made up of a personal computer. A media controller is connected to the system bus of the main equipment. An electronic device is connected to the media controller as a medium for executing external memory, expanding the existing function or the like, the electronic device being provided with an Ethernet providing connection to external computer networks via a media side controller and a nonvolatile memory in which driver software data driving the Ethernet under respective environments is stored.

Owner:SONY CORP

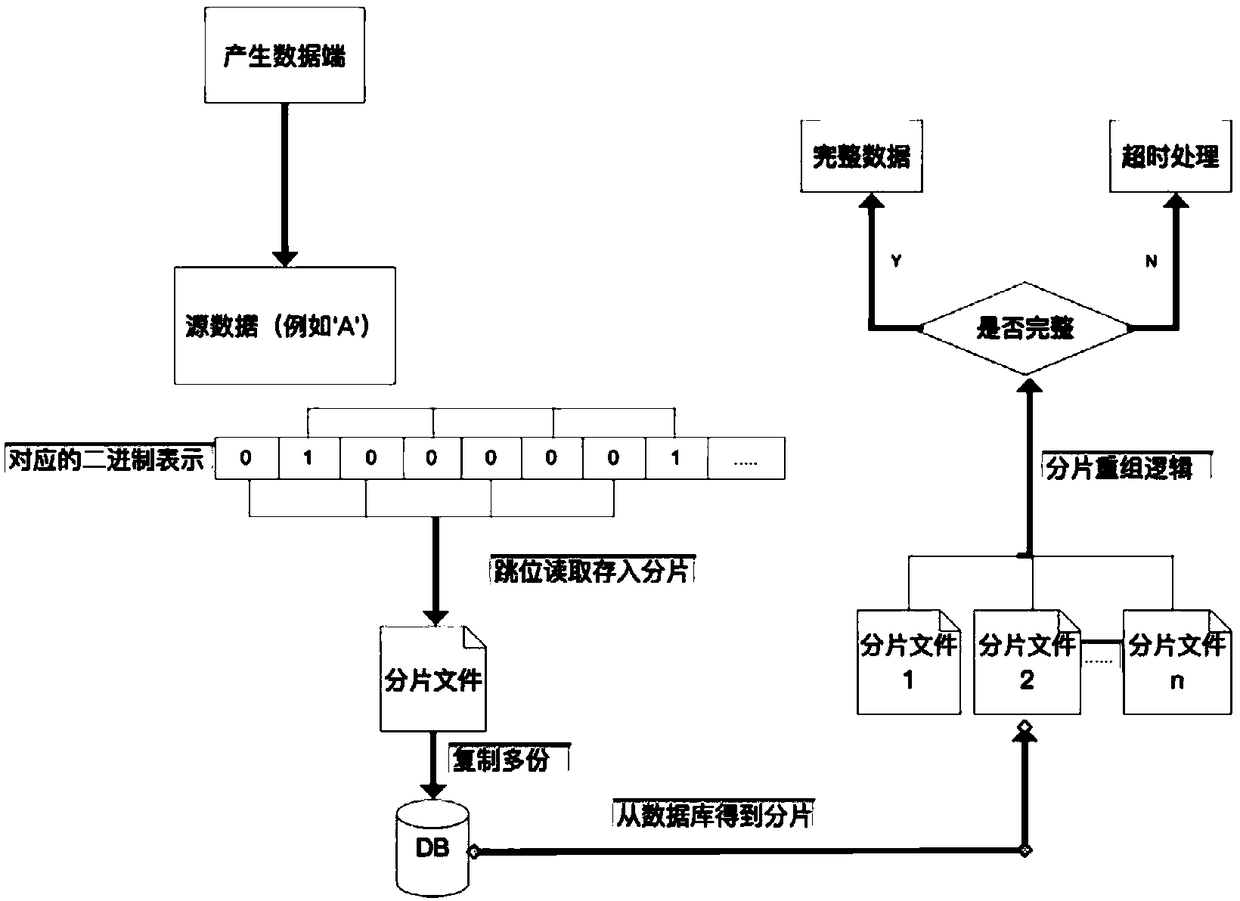

Method for realizing data security storage based on fragment recombination technology

InactiveCN108710702ADifficult to expandEnsure safetySpecial data processing applicationsStorage securityArray data structure

The invention discloses a method for realizing data security storage based on a fragment recombination technology, and relates to the technical field of data storage, wherein source data are first analyzed into a binary array; then, a plurality of fragment files are obtained in a manner of jump reading and stored in a plurality of databases; finally, the source data are obtained by finding all thefragment files and recombining. Such a data security storage method fragments data and stores the fragmented data into multiple databases in a distributed manner, which breaks the thinking formula ofdata encryption commonly used in the prior art, and makes it difficult for a hacker to find the data again, thereby ensuring data storage security.

Owner:吴卓航 +3

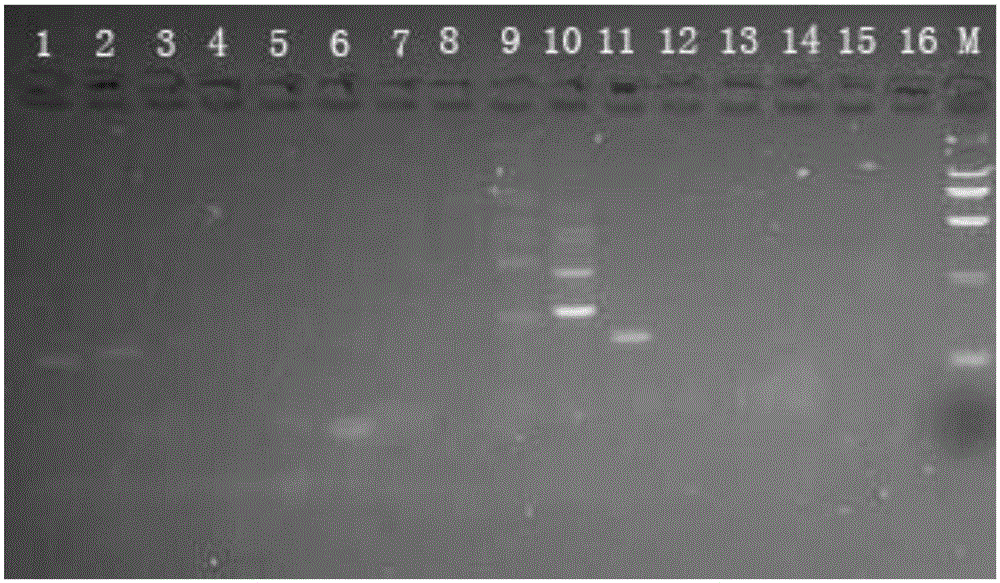

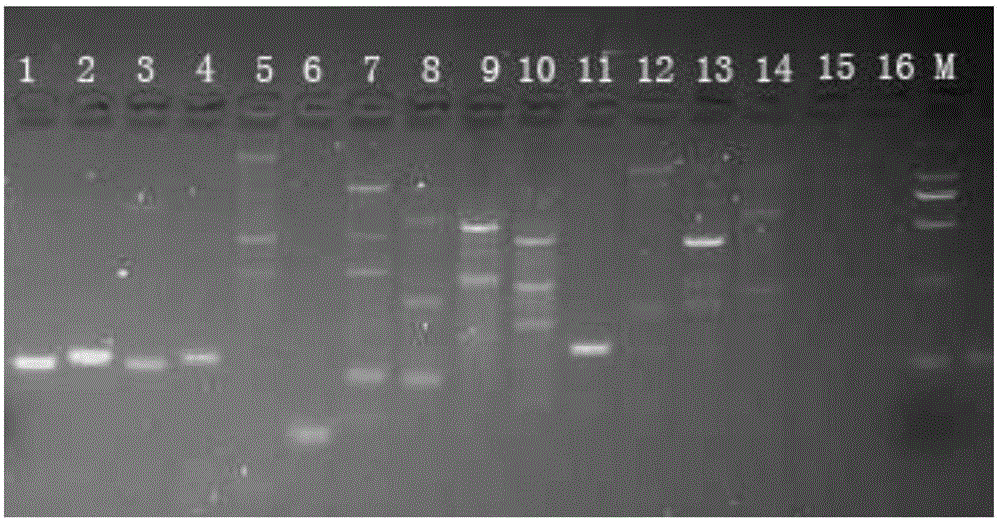

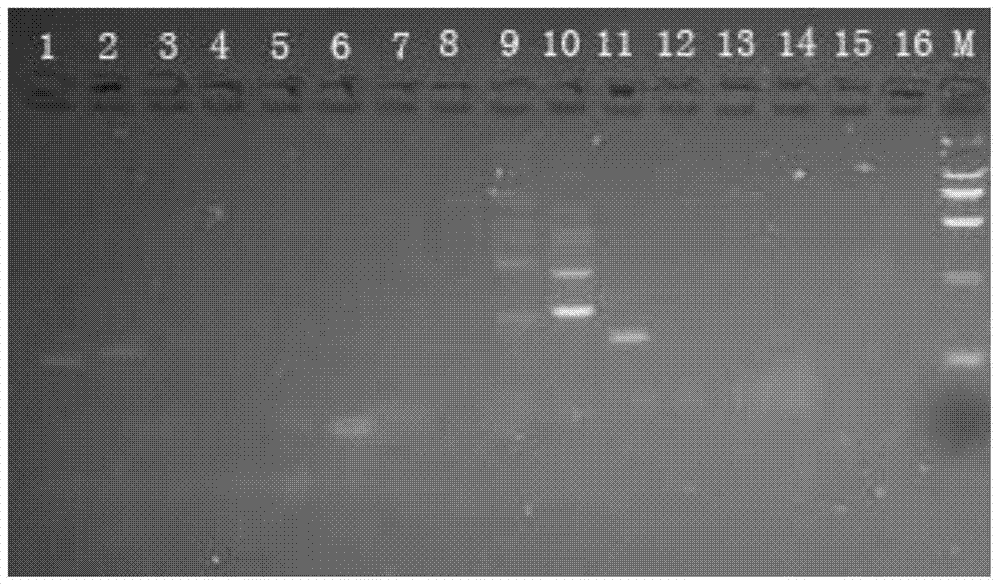

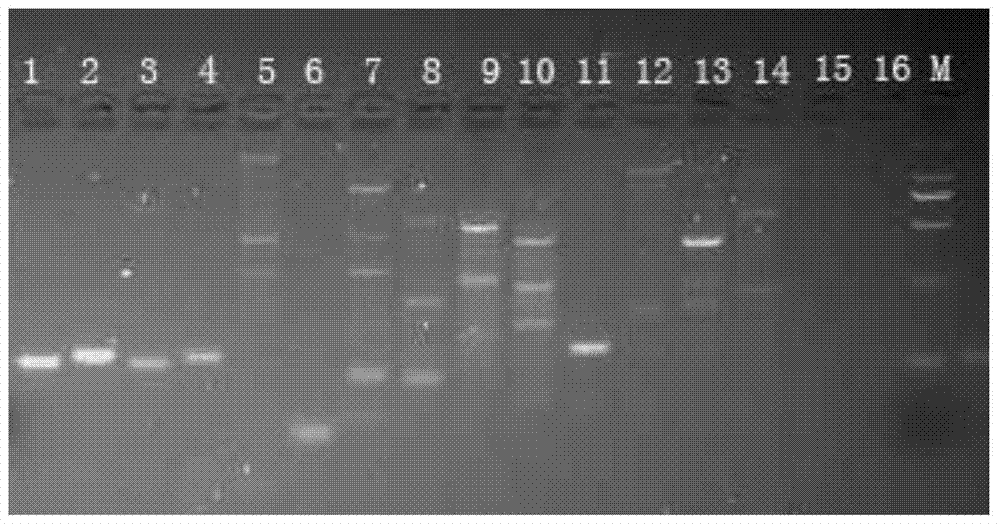

Functional marker for paddy thermo-sensitive male sterile gene tms 5 and application of functional marker

ActiveCN105002176ADifficult to expandGood effectMicrobiological testing/measurementDNA/RNA fragmentationGeneticsFalse-positive result

The invention provides a functional marker for a paddy thermo-sensitive male sterile gene tms5, a method of testing whether a sample contains a tms5 gene or not by using the functional marker, a method of judging the seed purity of two-line thermo-sensitive paddy by using the functional marker, and the application of the functional marker in cultivating a sterile line. According to a mutation site sequence of the paddy tms5 gene, a mismatched base is introduced into a PCR primer, so that a paddy PCR amplification product containing a tms5 gene (mutation type) generates an enzyme cutting site of a restriction enzyme Rsa I, while a paddy PCR product not containing a tms5 gene (wild type) does not have the enzyme digestion site. The PCR product is subjected to enzyme digestion by the Rsa I, and the paddy PCR amplification product containing the tms5 gene is turned into two segments by enzyme digestion; but the paddy PCR product not containing the tms5 gene cannot be digested; thus distinguishing can be performed. By adopting the design that the tms5 amplification product is directly subjected to enzyme digestion, compared with the prior art, on one hand, the detection process is simplified, and on the other hand, the occurrence of a false positive result is avoided.

Owner:RICE RES ISTITUTE ANHUI ACAD OF AGRI SCI

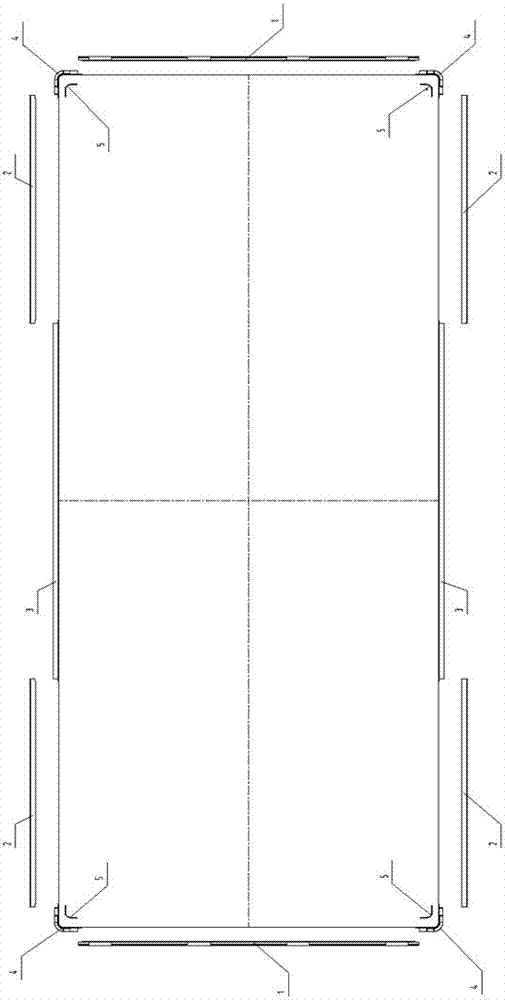

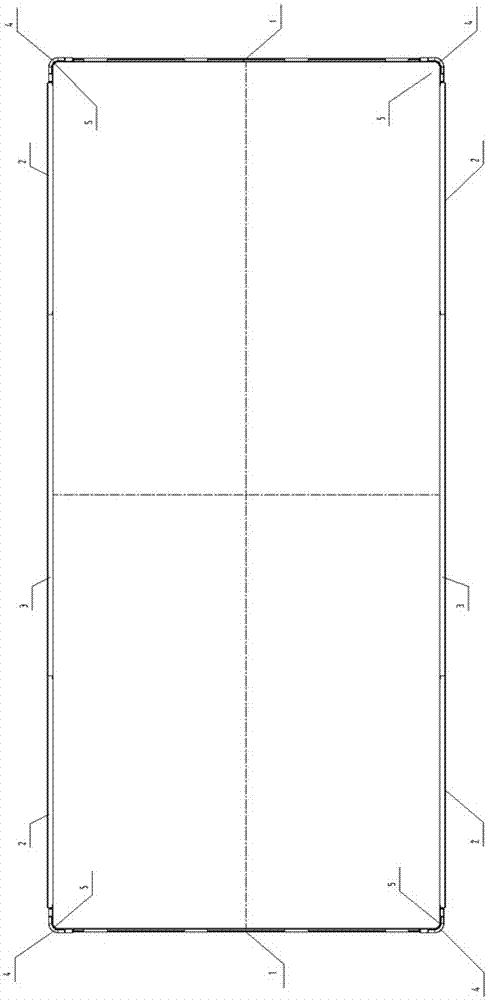

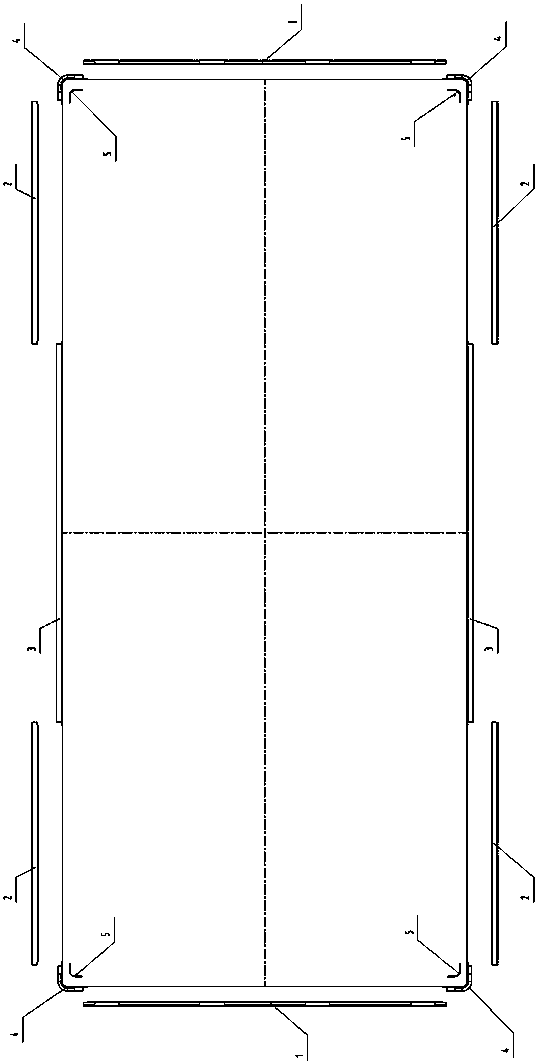

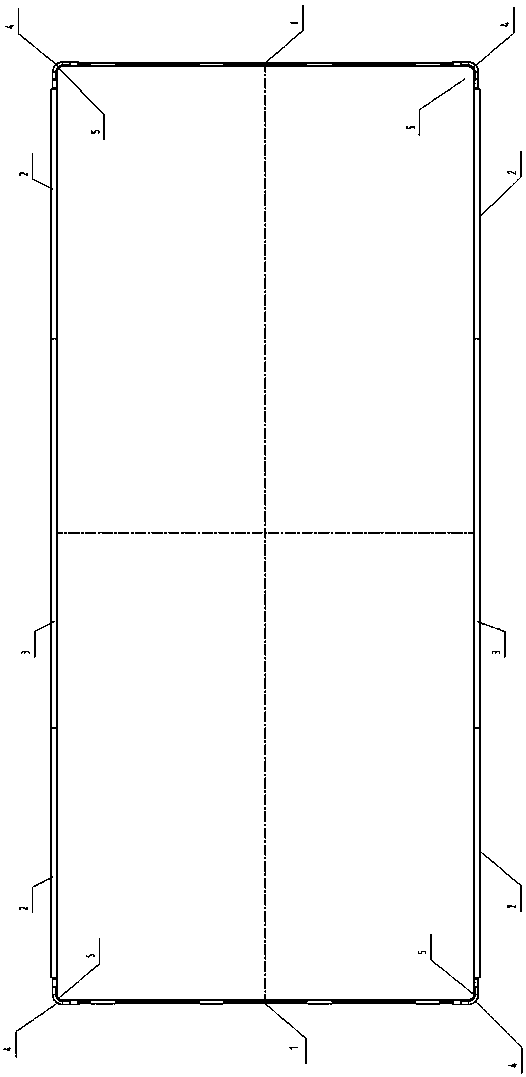

Self-compacting concrete aluminum alloy edge-sealing formwork for ballastless track

ActiveCN106948229AUnbroken strengthImprove bearing capacityBallastwayRailway track constructionCorner angleEdge banding

The invention relates to a self-compacting concrete aluminum alloy edge-sealing formwork for a ballastless track. The self-compacting concrete aluminum alloy edge-sealing formwork for the ballastless track comprises two end molds, four standard side molds, two adjusting side blocks, four corner formworks, and four inserting boards, which are symmetrically assembled into the quadrilateral self-compacting edge-sealing formwork, wherein the end mold comprises a panel and upper and lower frame plates, a reinforcing rib is arranged in the middle part of the panel to form a groove shape, and the end mold is integrally molded by extrusion once through an aluminum profile extrusion device; the standard side molds and the adjusting side molds are made of square tube aluminum profiles, and are molded by extrusion once through the extrusion equipment, the corner formworks and the inserting boards are made of arc-shaped aluminum profiles, and are molded by extrusion once through extrusion equipment. The self-compacting concrete aluminum alloy edge-sealing formwork for the ballastless track provided by the invention solves the problems of slow turnover of the formwork, fewer use times, easy deformation, easy rusting, formwork swelling and mortar leakage of self-compacting concrete, poor exhaust effect, uneasy installation, great waste of human resources and the like under construction.

Owner:湖南天象建筑科技有限公司

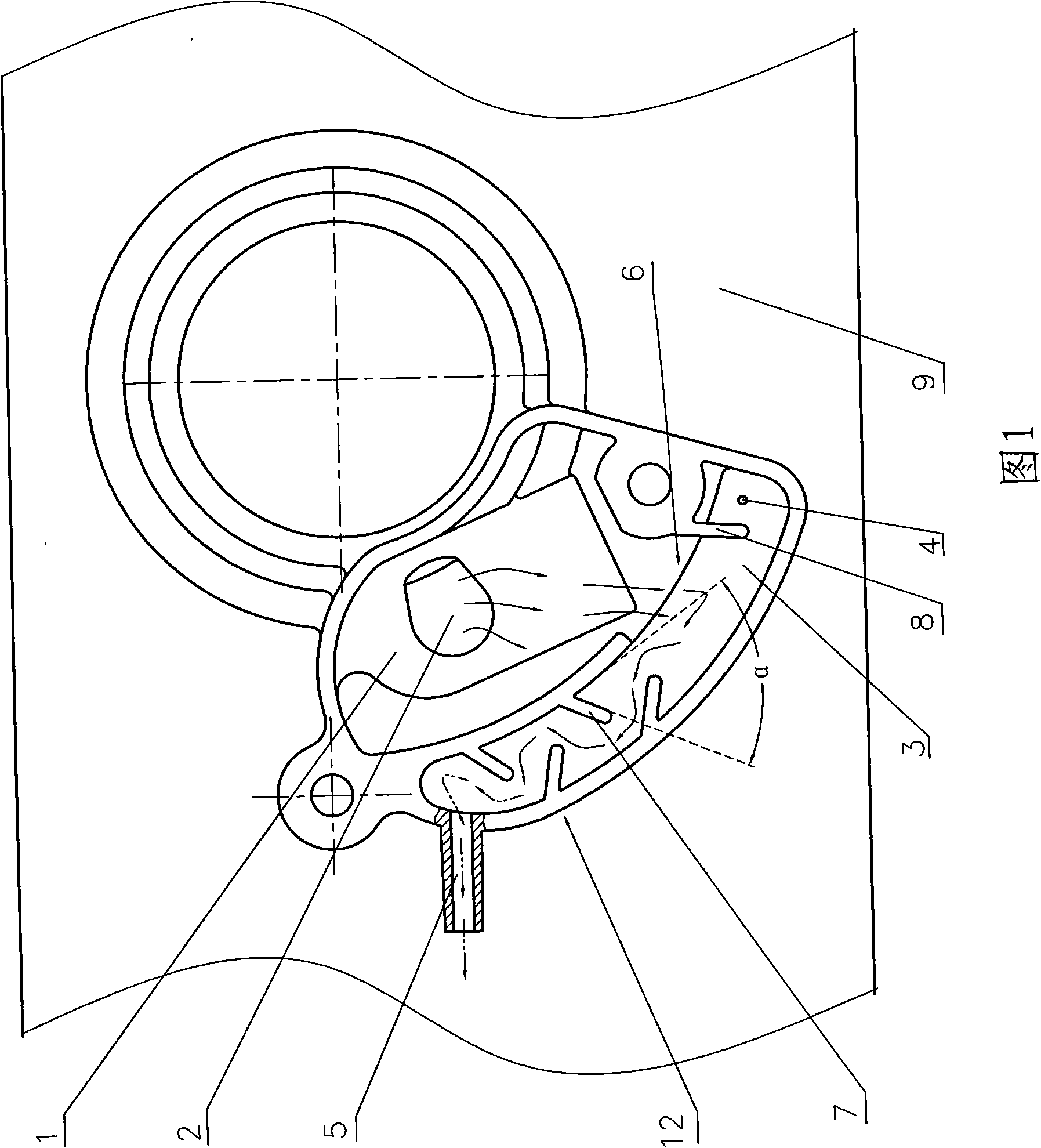

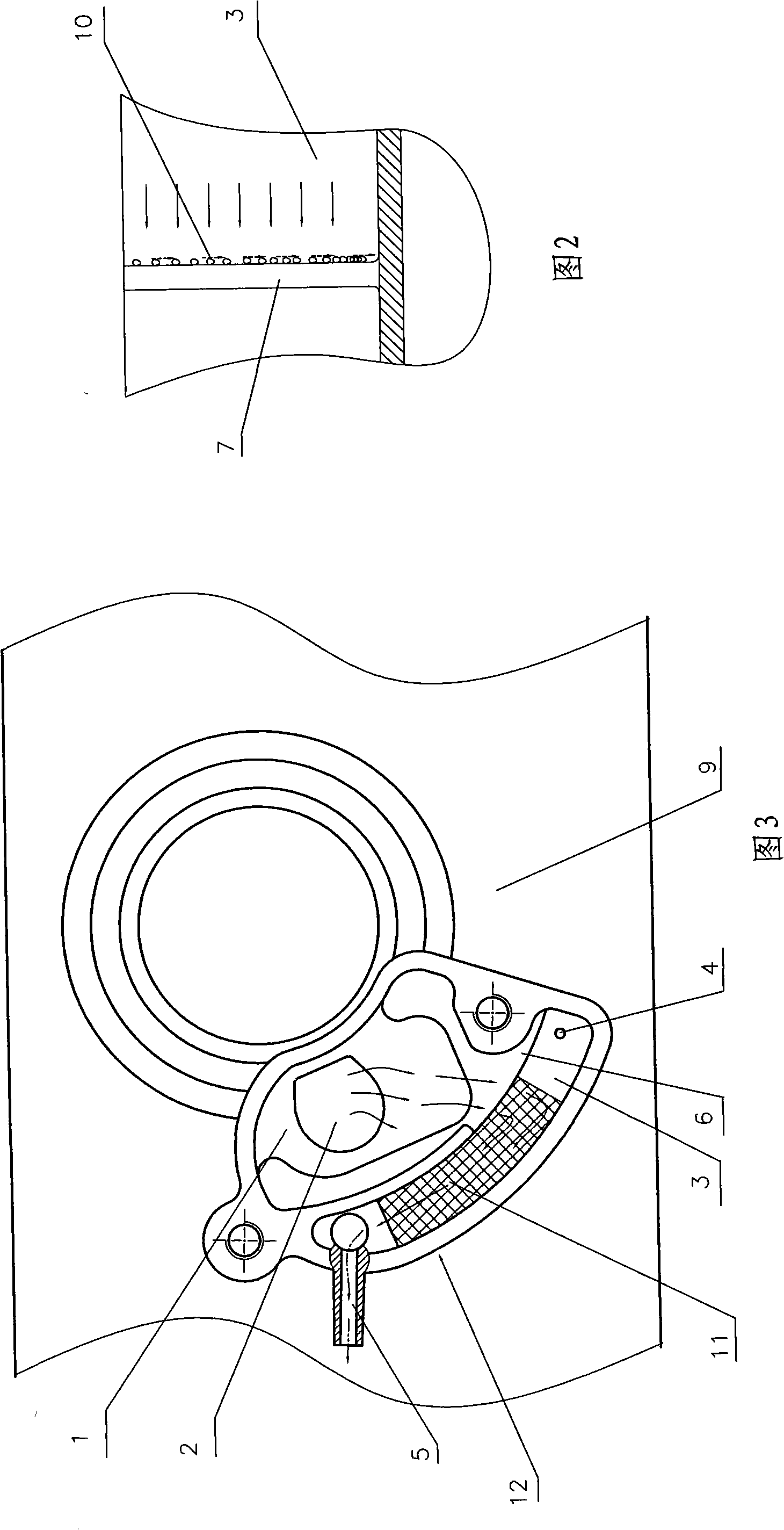

Oil-gas separating device of general-purpose petrol engine crankshaft case waste gases

InactiveCN101280705AReduce carbon depositionEnsure performanceMachines/enginesCrankcase ventillationGeneral purposeCombustion chamber

The invention discloses an oil gas separation device for crankcase waste gas of a general gasoline engine, which comprises an intake buffering cavity and an oil gas separation cavity; the gas inlet of the oil gas separation device is in communication with the inside of the crankcase; the upstream inlet of the oil gas separation cavity is positioned between an oil return hole and an outgassing mouth and is communicated with the intake buffering cavity; the outgassing mouth of the oil gas separation device is arranged at the lower steam of the oil gas separation cavity; the lower part of the oil gas separation cavity is provided with the oil return hole communicated with the inside of the crankcase; walls at the two sides of the oil gas separation cavity are respectively provided with a plurality of structures which stretch from the wall at the side to the opposite slanchwise to prevent gas flow from passing directly; the structures on the walls at the two sides used to prevent gas flow from passing directly are in staggered arrangement at intervals and the extension length of each structure used to prevent gas flow from passing directly is less than the width of the oil gas separation cavity and more than one second of the width of the oil gas separation cavity, and the extension end declines to the upstream direction. The device does not adopt fillers and can effectively separate the oil and gas from the waste gas and avoid oil droplets from being taken into the combustion chamber.

Owner:LONCIN MOTOR

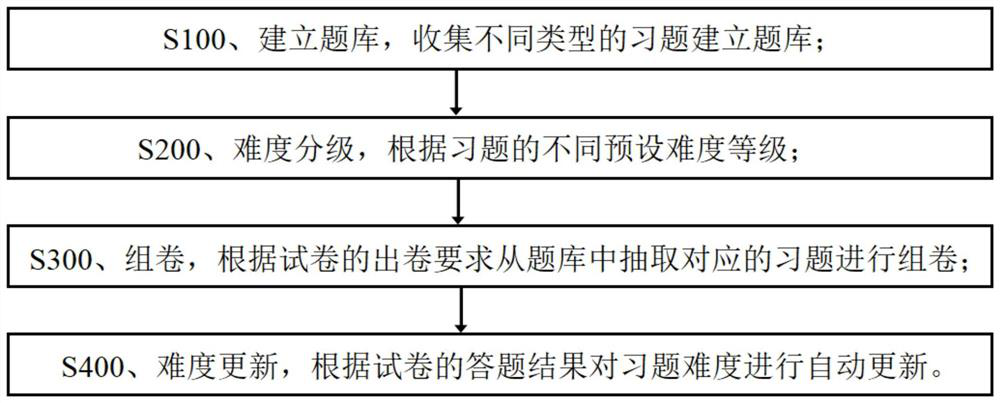

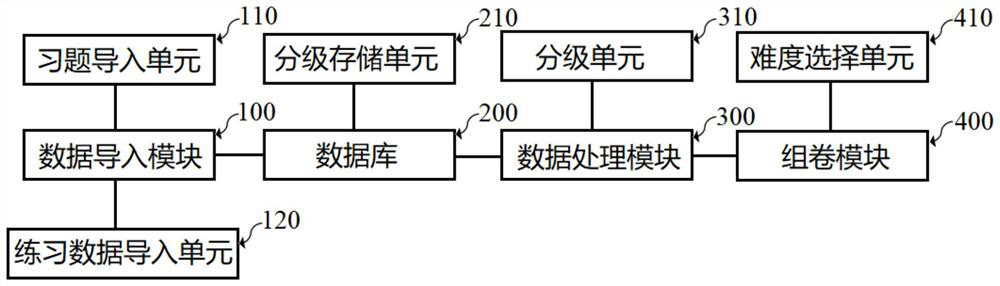

Automatic question bank question forming and difficulty real-time updating method

PendingCN112364123ADifficult to expandEasy to controlData processing applicationsText database indexingQuestion answerOperations research

The invention relates to an automatic question bank question forming and difficulty real-time updating method, comprising the steps: collecting exercises; performing difficulty grading; creating a question bank; when test paper needs to be output, extracting the exercises from the question bank according to the question types and difficulty in test paper and generating the test paper; updating thedifficulty of the exercises in the question bank according to the question answering situation of the test paper, wherein the difficulty grading comprises preset difficulty grading during exercise collection and automatic difficulty grading according to exercise test paper and accuracy; when a preset difficulty grading result is different from an automatic difficulty grading result, performing variance calculation between the preset difficulty grading result and the automatic difficulty grading result, and selecting a difficulty interval with the minimum variance as a result. According to themethod, difficulty setting and real-time updating are carried out on the test exercises in the question bank, so that the difficulty of the exercises can be controlled in the test paper composition process, and the control on the overall difficulty of the test paper is improved.

Owner:上海凌立健康管理股份有限公司

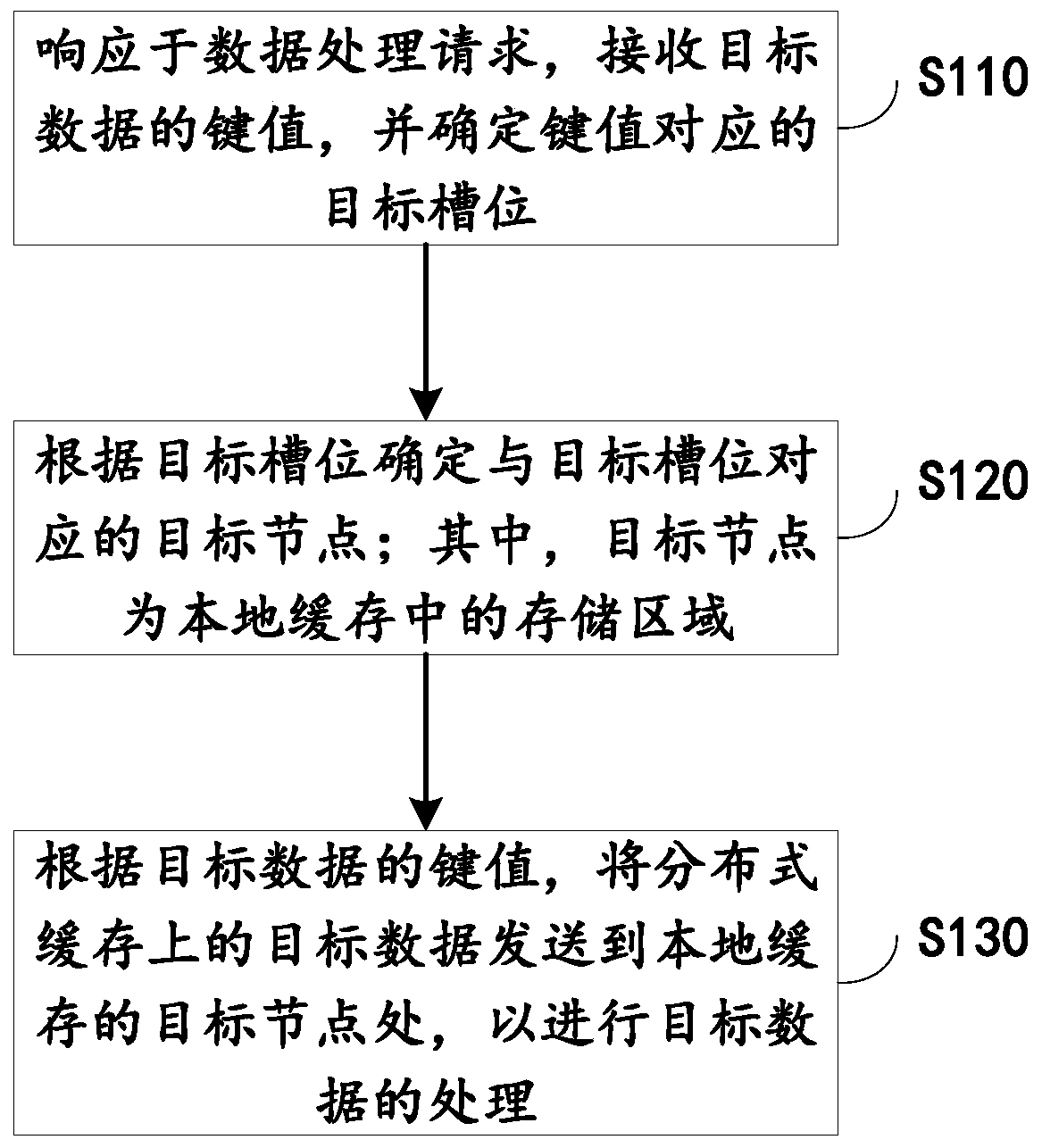

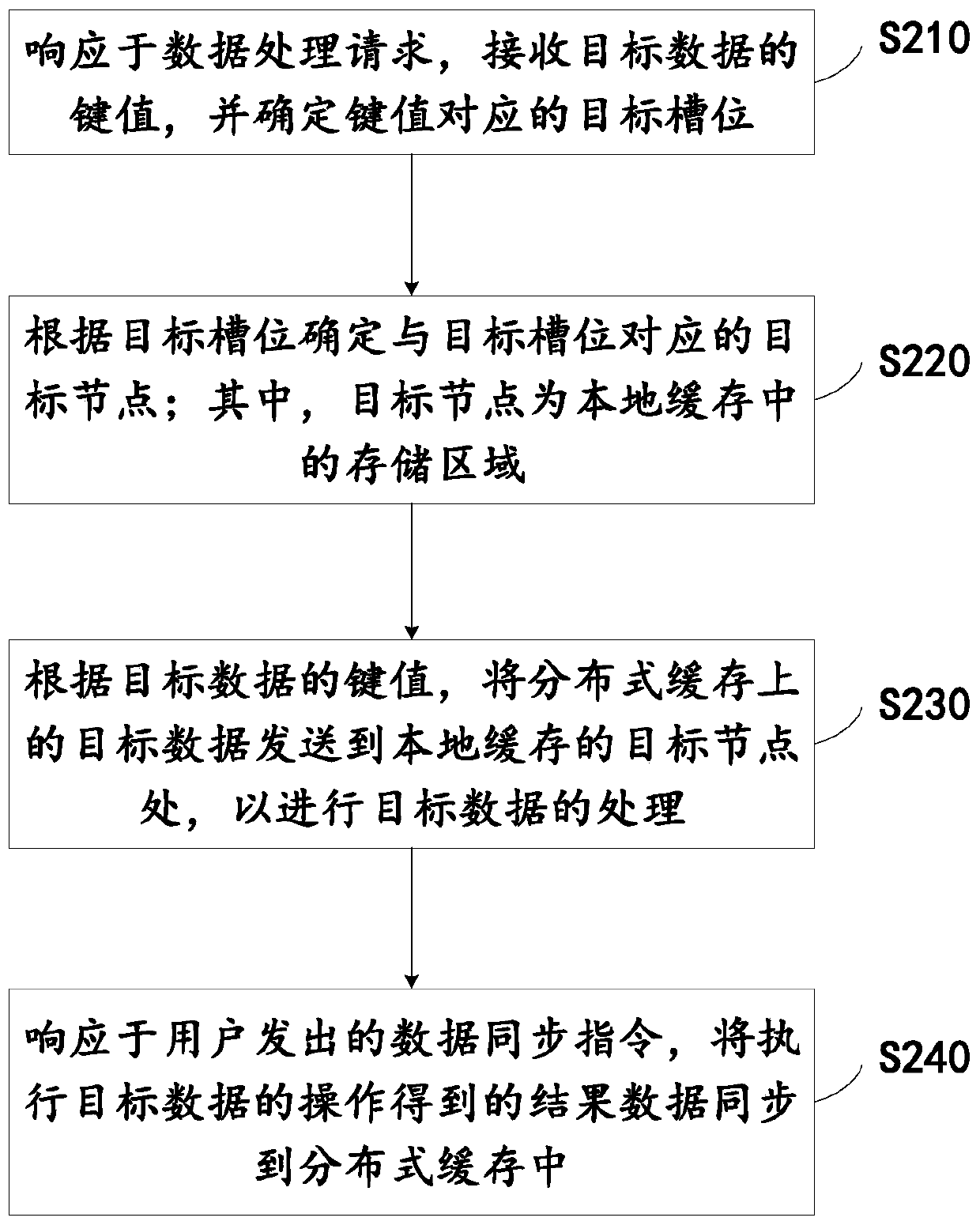

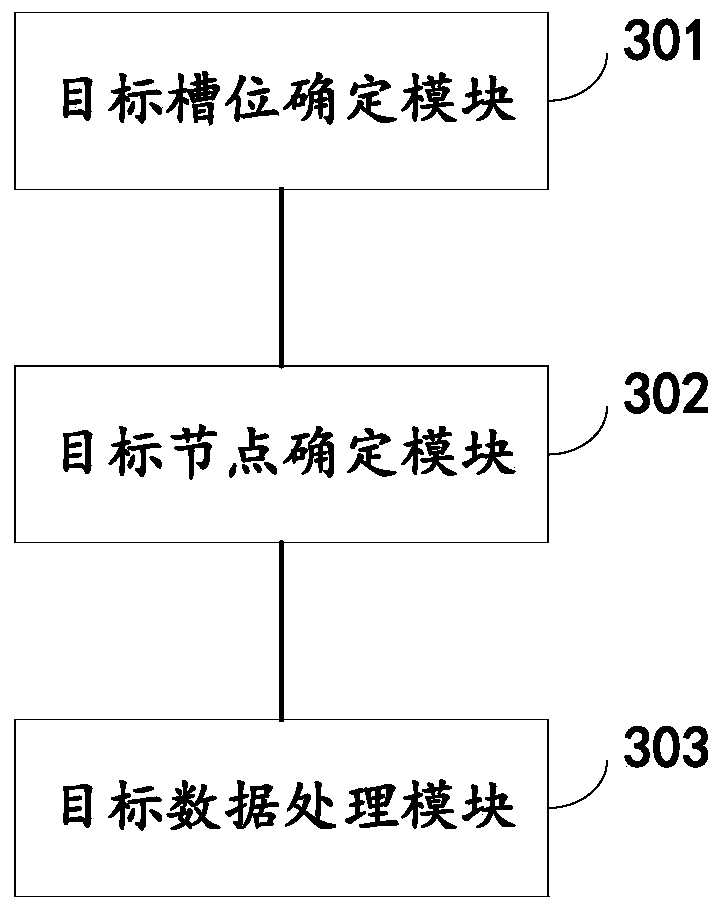

Cache data processing method, device and equipment and storage medium

ActiveCN111078147ADifficult to expandSolve the problem of low concurrencyInput/output to record carriersComputer networkDistributed cache

The embodiment of the invention discloses a cache data processing method and device, equipment and a storage medium. The method is executed by a client, the client acquires computing node and local cache cluster information, and the method comprises the following steps: receiving a key value of target data in response to a data processing request, and determining a target slot position corresponding to the key value; determining a target node corresponding to the target slot position according to the target slot position, wherein the target node is a storage area in a local cache; and sendingthe target data on the distributed cache to a target node of a local cache according to the key value of the target data so as to process the target data. According to the embodiment of the invention,the target node of the local cache is determined, and the data of the distributed cache is sent to the local cache to be processed, so that the problems that the local cache is difficult to expand and the distributed cache is low in concurrency are solved, and the data processing efficiency is improved.

Owner:NANJING LINGXING TECH CO LTD

Automobile fender

InactiveCN108001546ATimely cleaningDifficult to expandSuperstructure subunitsVehicle cleaningSludgeEngineering

The invention discloses an automobile fender which comprises a fender body, a baffle and an installation shell. A body of the fender body is the baffle. A flow division blade is arranged below the baffle. A groove is formed in the rear side of the bottom of the baffle. Protruding points are arranged in the groove and connected with springs on the inner side of the baffle. A cleaning brush is arranged on the side, close to the baffle, below the protruding points. The bottom of the cleaning brush is a conic head. An acoustic panel is installed on the inner side of the baffle. The rear side of the baffle is the installation shell. The automobile fender is environment-friendly, noise is reduced, the cleaning brush is arranged below the fender, sludge generated in the automobile traveling process can be cleaned away in time, the sludge which is iced and is difficult to dispose can be knocked through the conic head firstly, and the cleaning easiness is improved.

Owner:天津丽明津科技有限公司

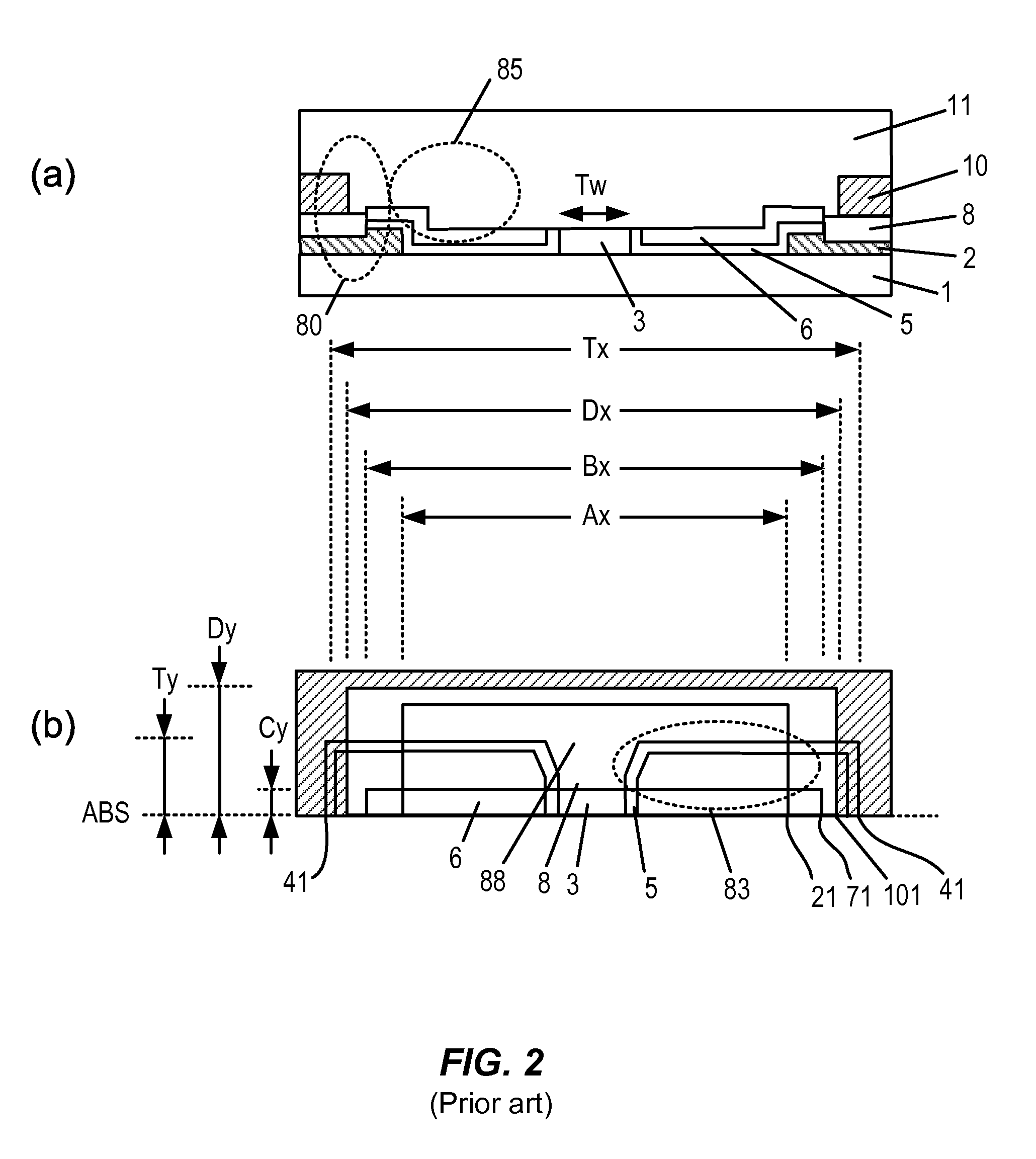

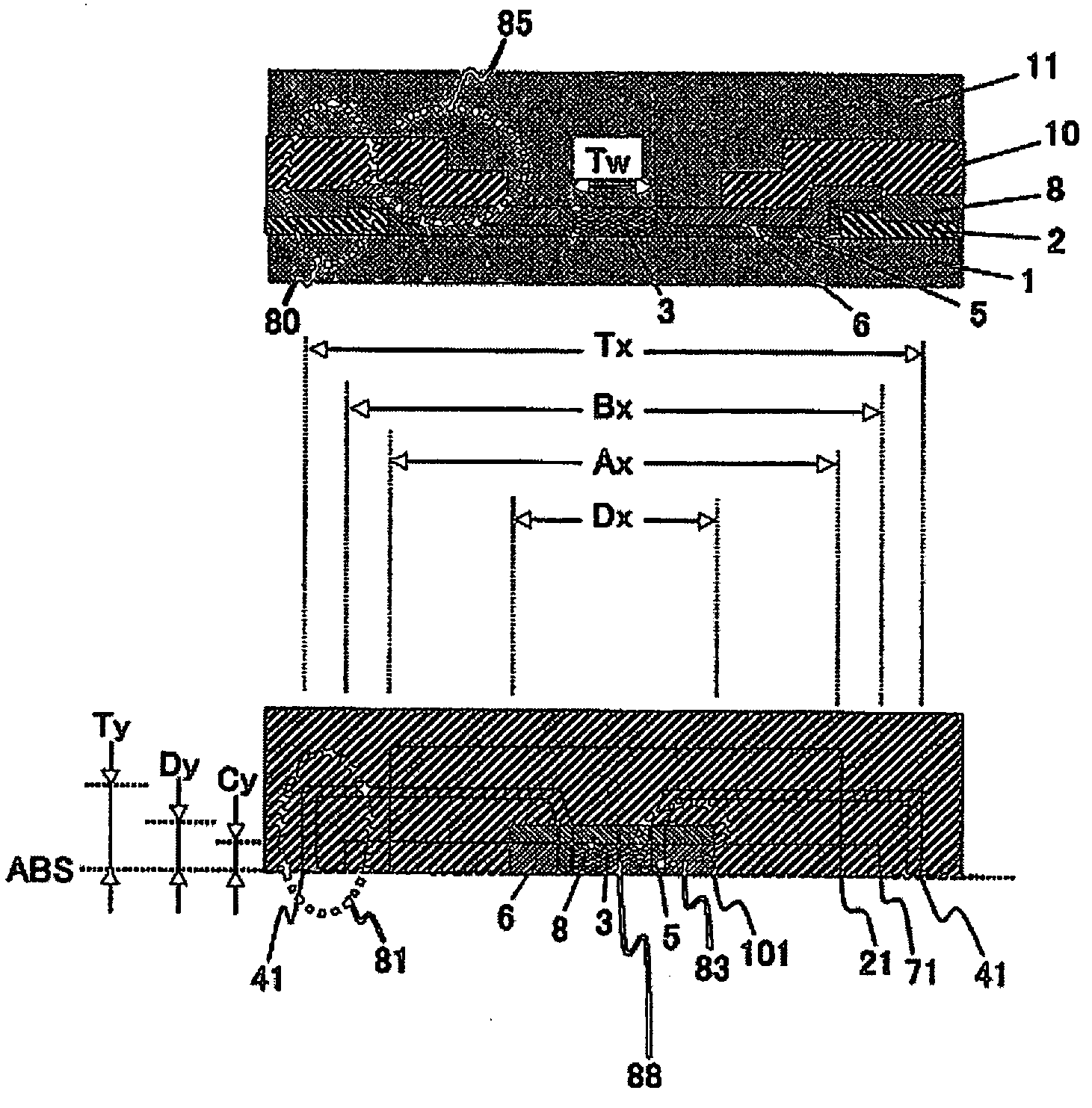

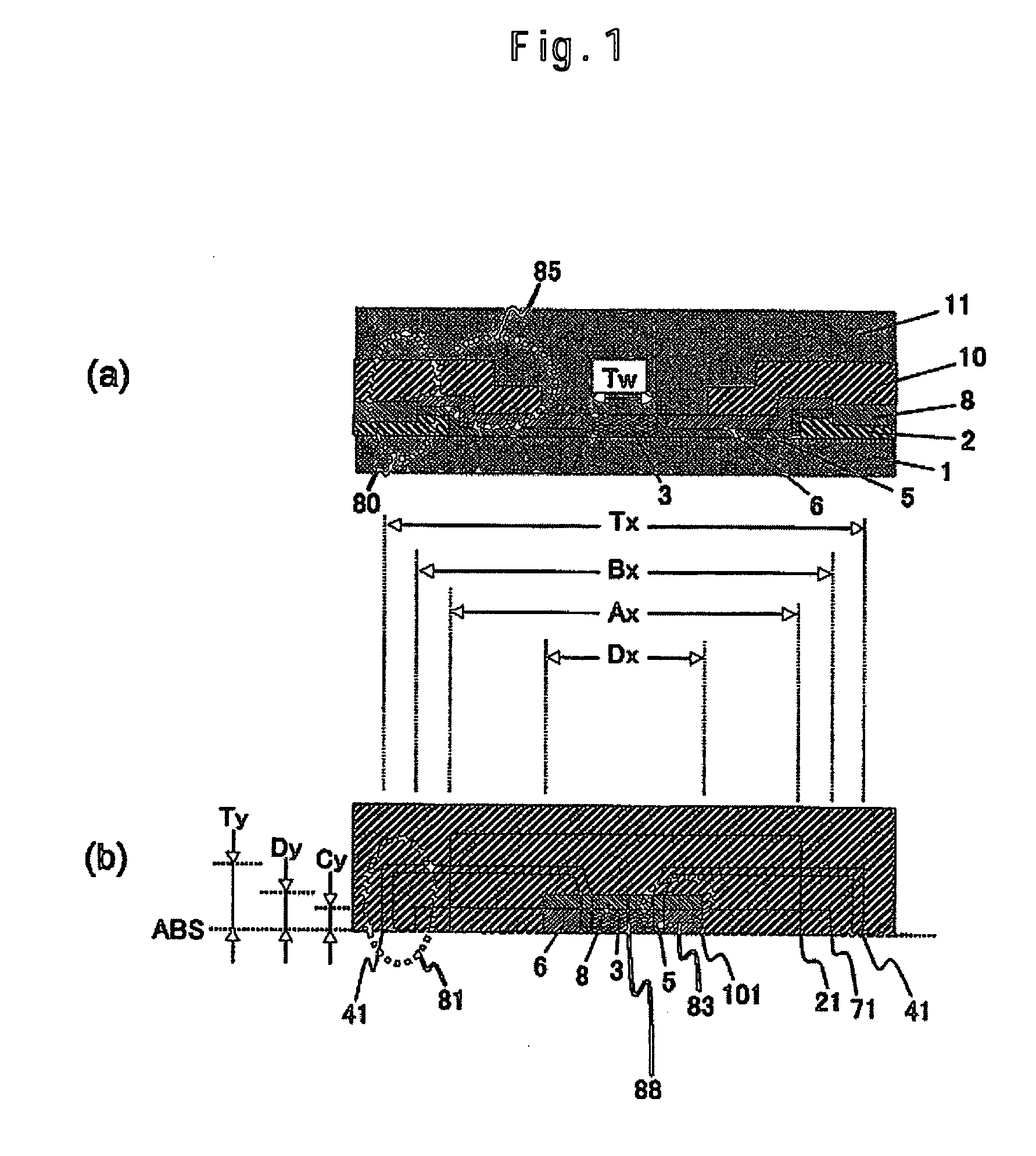

Thin film magnetic head and fabrication process for preventing short-circuit failure in a narrow track width and narrow gap length

InactiveUS7522387B2Reduce outputImprove insulation voltageRecord information storageManufacture of flux-sensitive headsManufacturing technologyShort circuit fault

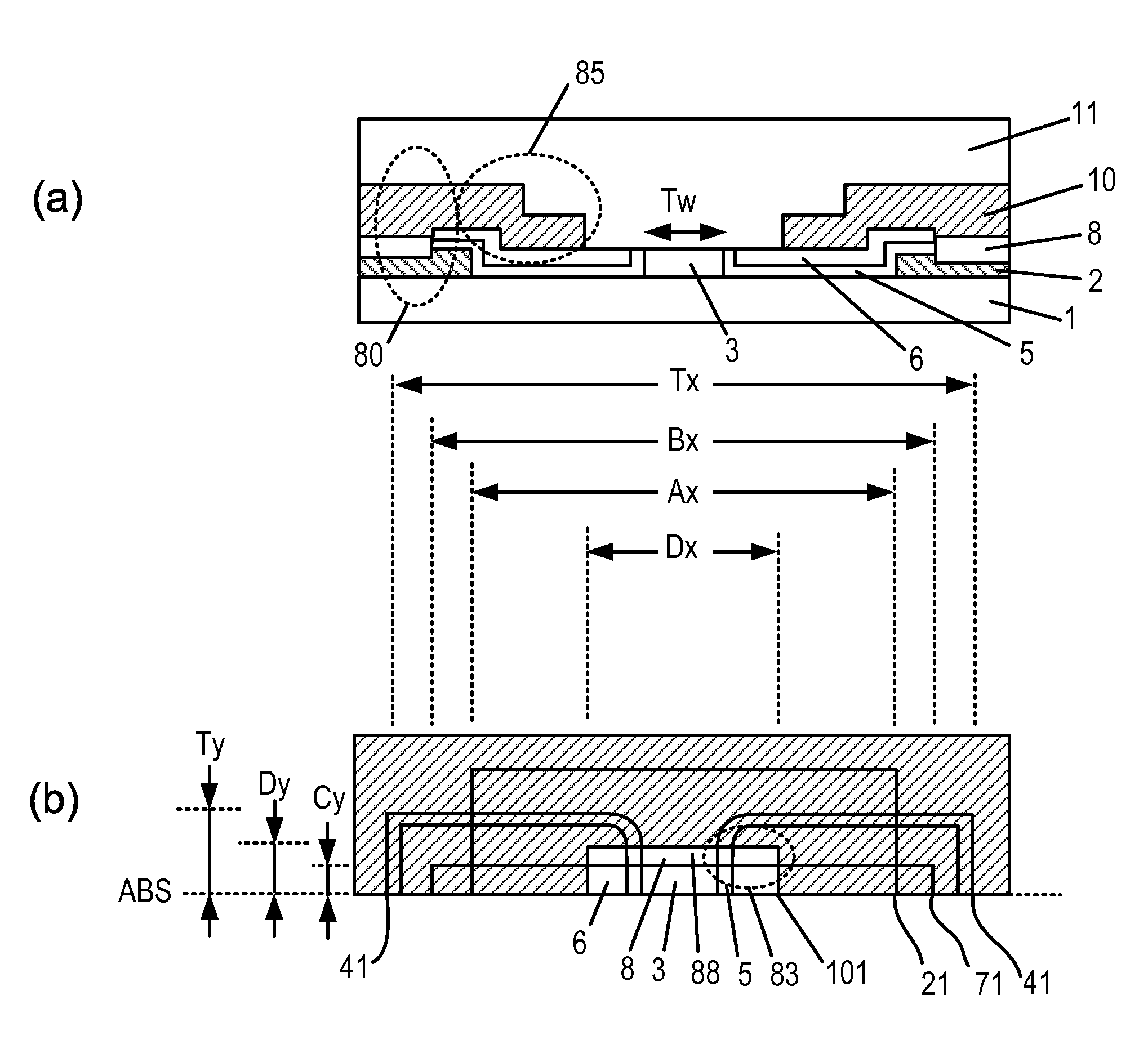

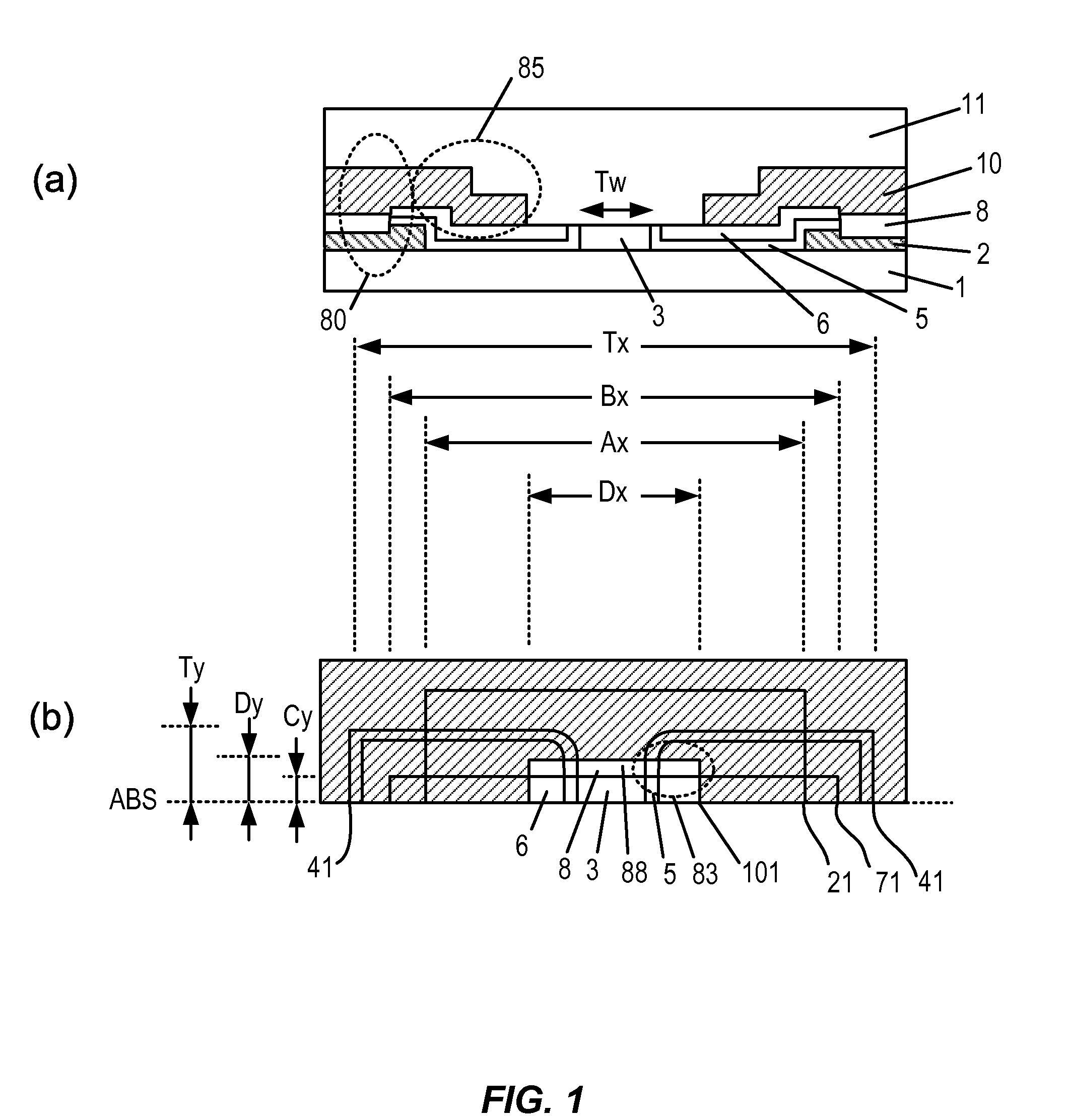

Embodiments of the invention relate to preventing short-circuit failure even in the narrow track width and narrow gap length, resulting in improved yield. In one embodiment, die sensor heads are placed on both sides of the track direction of the sensor film. The sensor heads comprise the first insulating film with at least a part connected to the track direction wall surface of the sensor film and the third insulating film formed between the upper shield and the first insulating film, and have the relationship being Tw<Dx<Bx where the distance between edges of the first insulating film connected to the track direction wall surface of the sensor film is Tw, the distance between outside edges of the first insulating film along the track direction Bx, and the distance of inside edges of the third insulating film along the track direction Dx.

Owner:WESTERN DIGITAL TECH INC

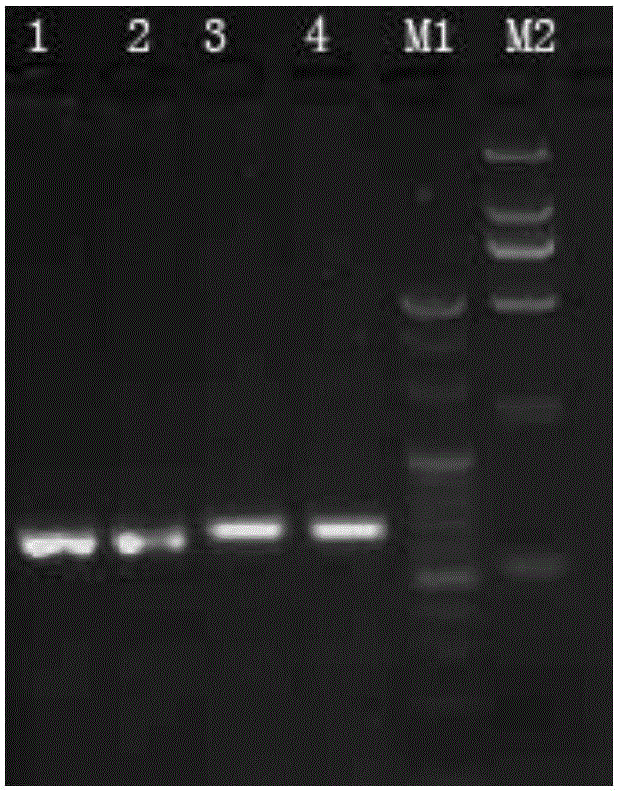

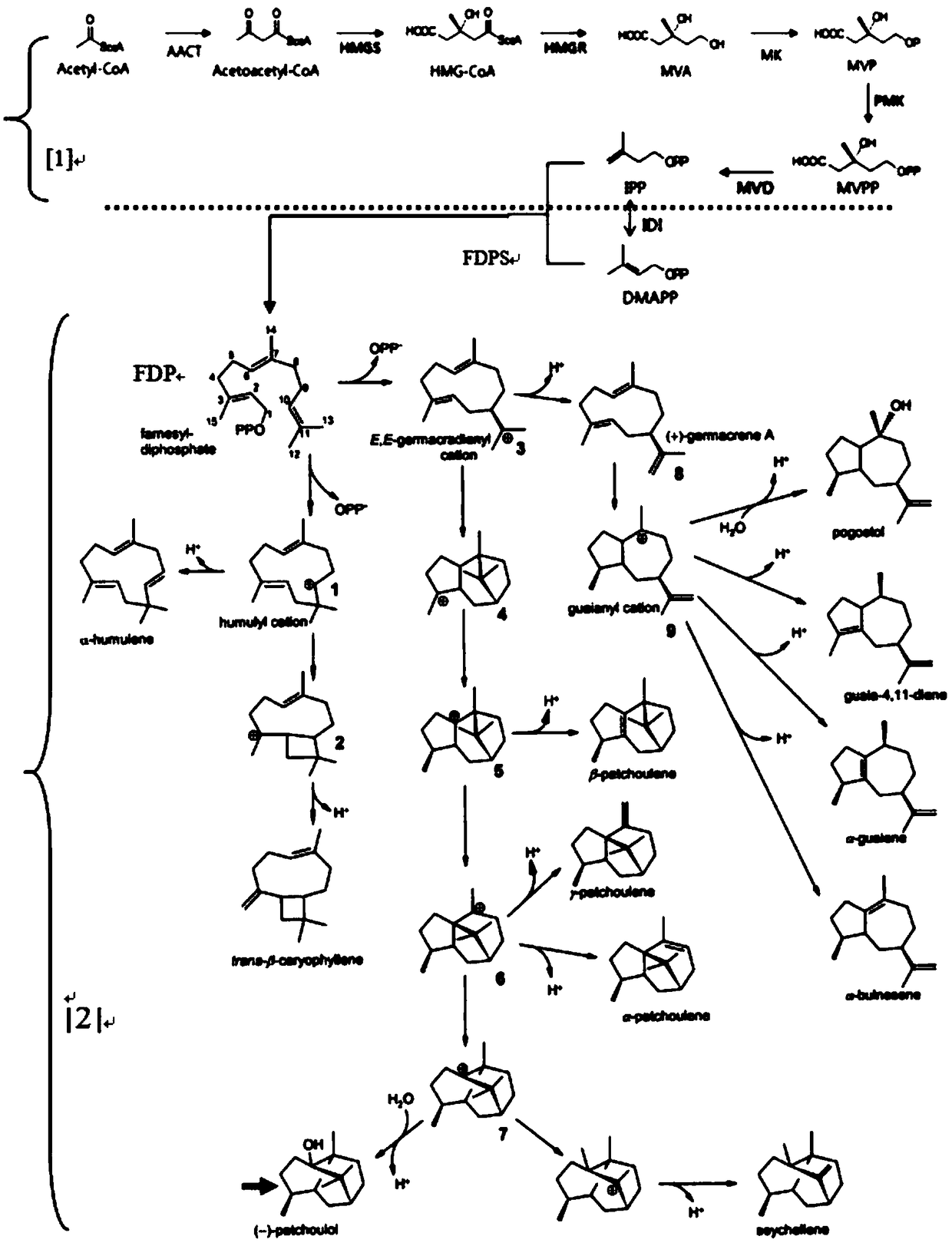

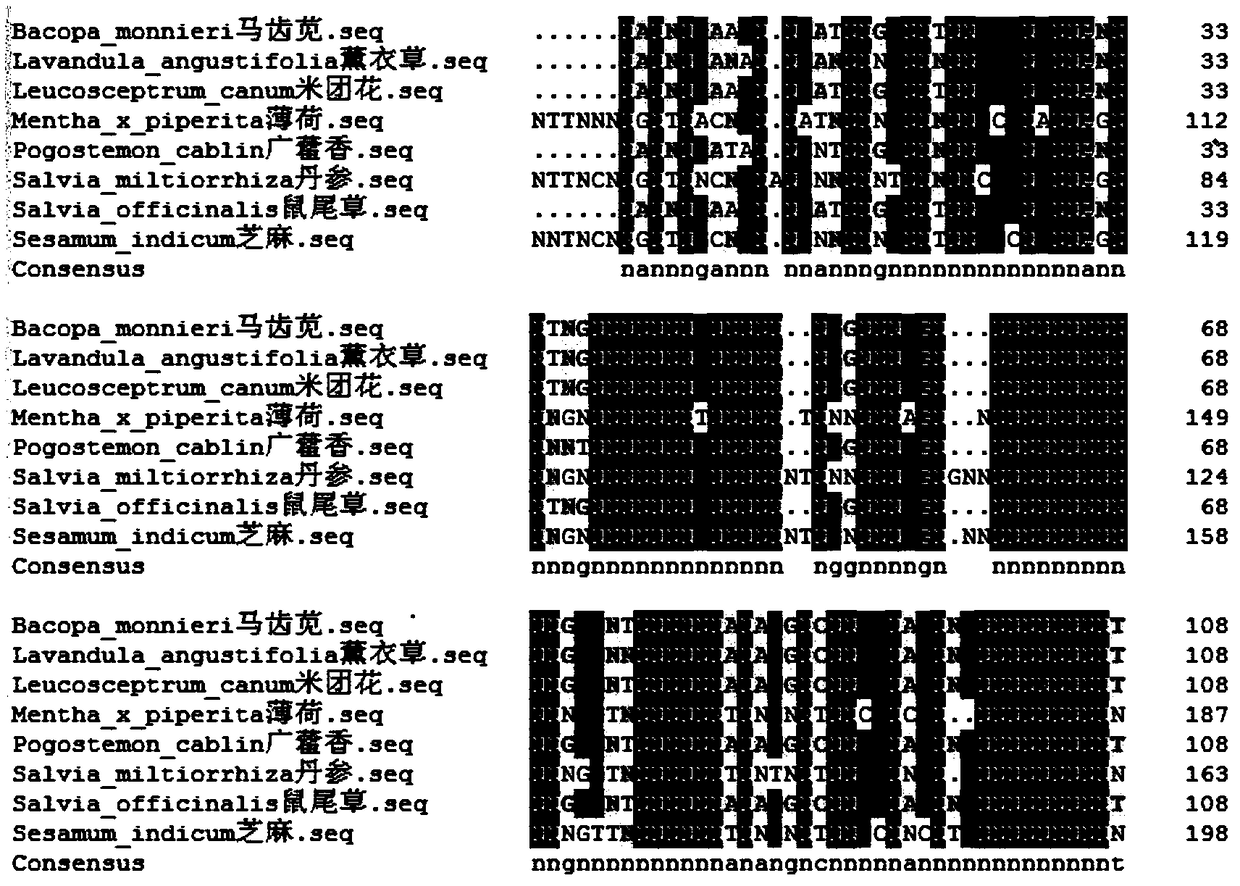

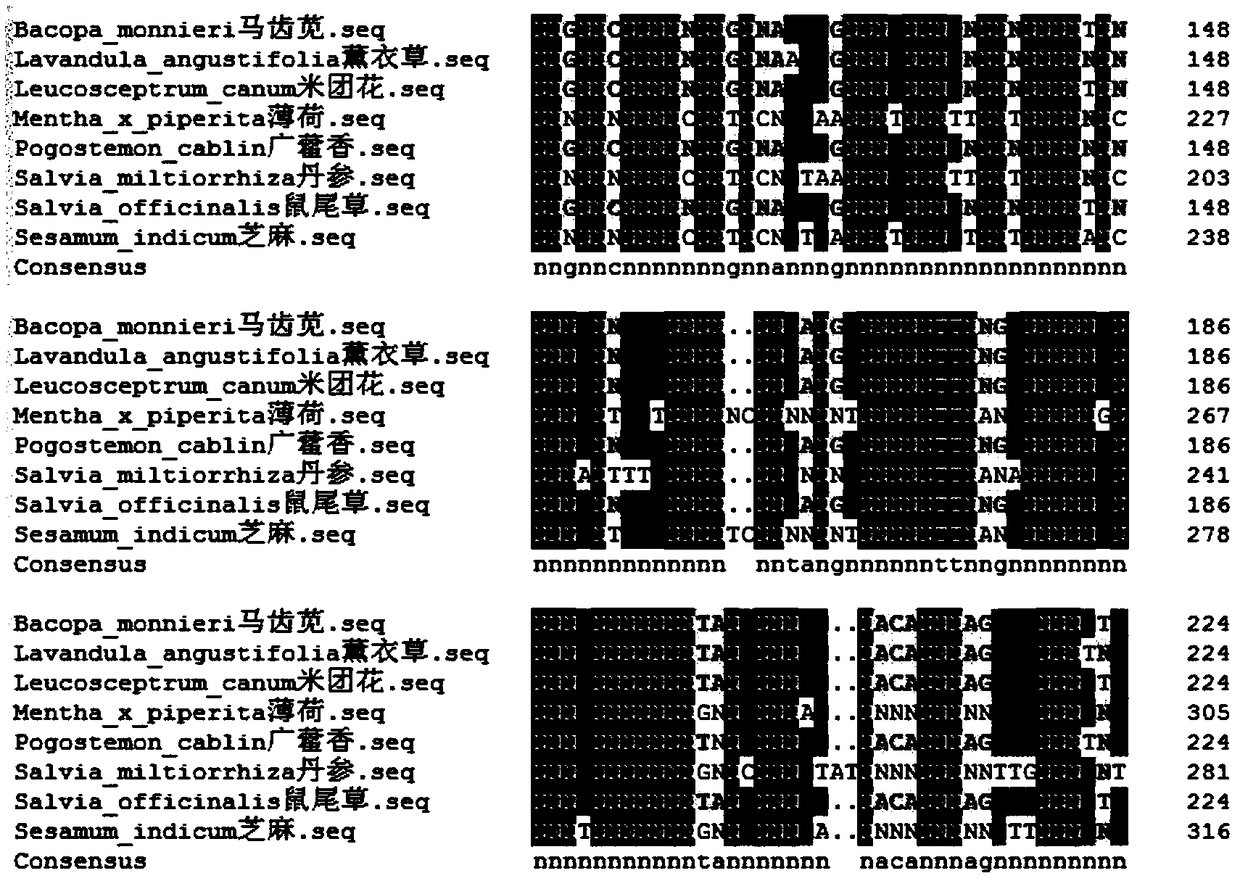

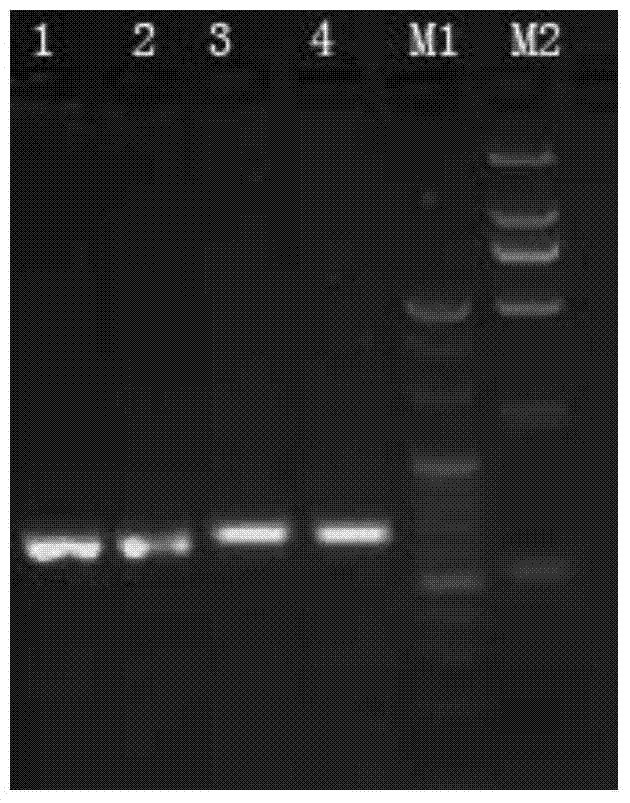

PcFPS gene primer pair and application of gene amplified by primer pair to increase of content of patchouli alcohol in pogostemon cablin

ActiveCN109371020ADifficult to expandStrong specificityMicrobiological testing/measurementTransferasesAlcoholAgricultural science

The invention provides a PcFPS gene primer pair and an application of a gene amplified by the primer pair to increase of the content of patchouli alcohol in pogostemon cablin, and relates to the technical field of gene engineering. The nucleotide sequences of an upstream primer and a downstream primer of the PcFPS gene primer pair are as shown in SEQ ID No. 3 and SEQ ID No. 4. The primer pair canspecifically amplify the FPS gene related to patchouli alcohol synthesis, and is high in specificity and does not easily amplify non-specific strips as compared with other primers. The invention further provides an application of the PcFPS gene and the primer pair thereof to increase of the content of the patchouli alcohol in the pogostemon cablin. The PcFPS gene primer pair can perform specific amplification to obtain the PcFPS gene, the PcFPS gene is transferred into the pogostemon cablin to construct transgenic pogostemon cablin, patchouli alcohol synthesis can be effectively improved by over-expression of the PcFPS gene, and the content of the patchouli alcohol in the transgenic pogostemon cablin is increased.

Owner:HAINAN UNIVERSITY

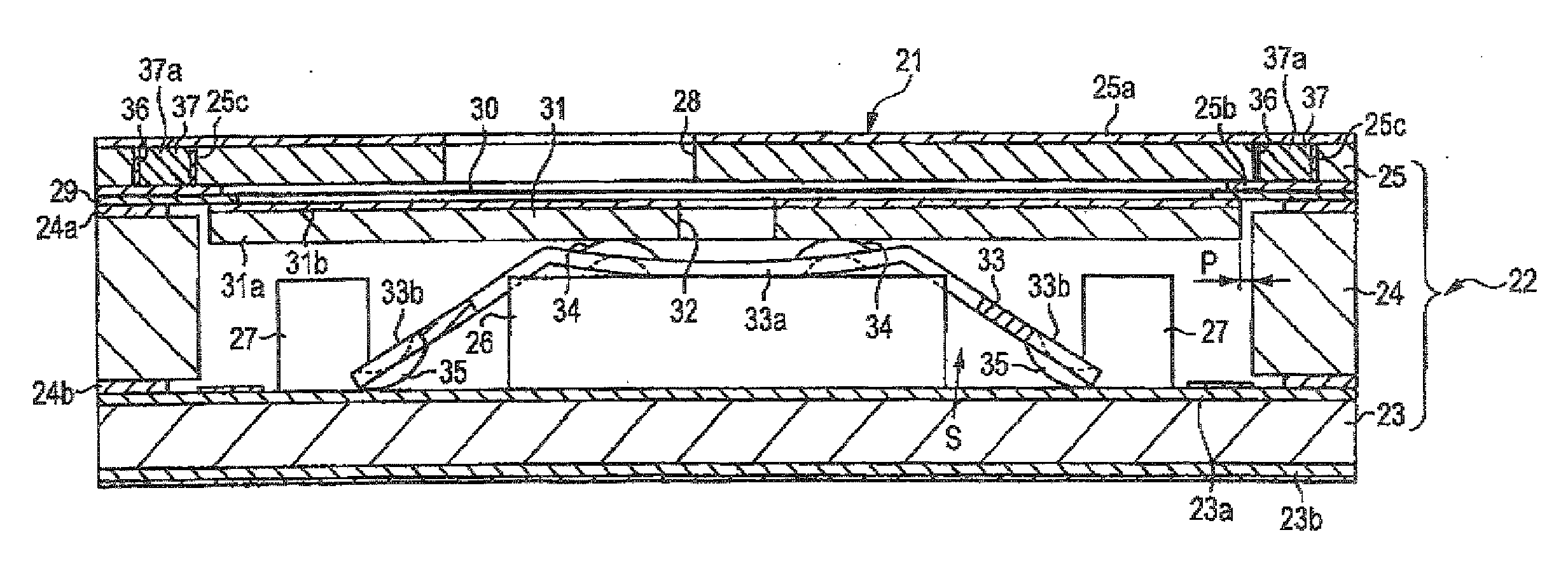

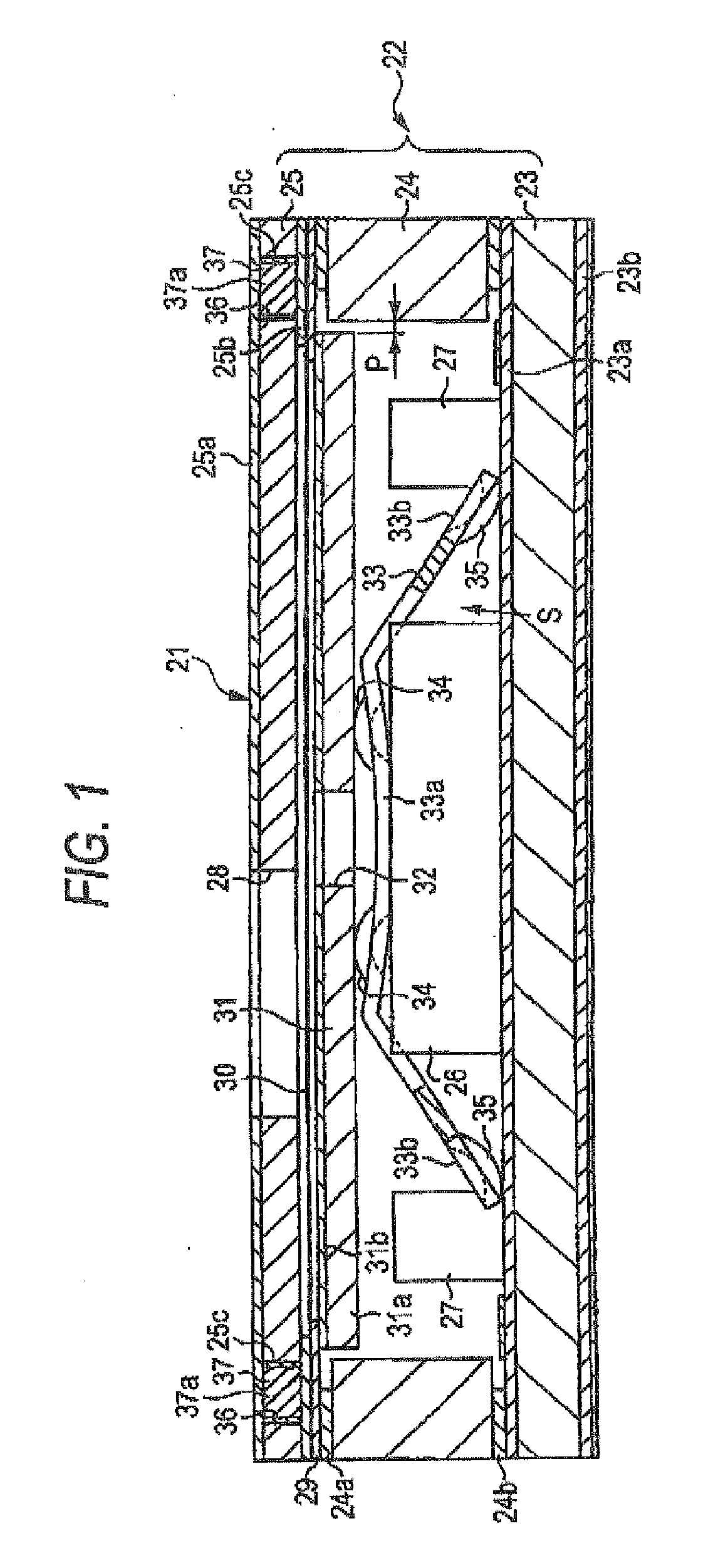

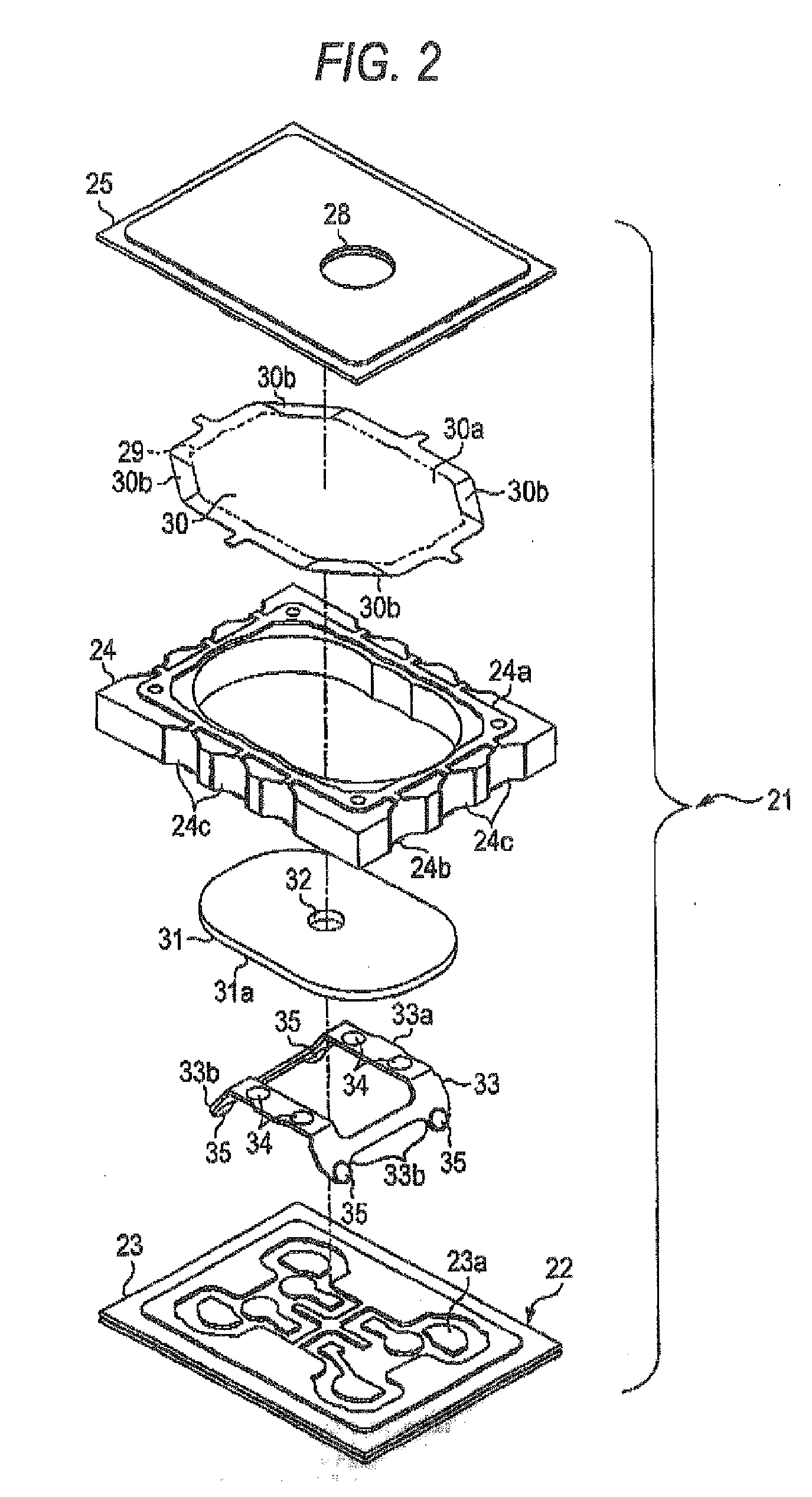

Condenser microphone

InactiveUS20080267439A1Difficult to expandDifficult to contractPiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesCapacitanceEngineering

A condenser microphone includes: a casing including a sound hole; a vibration film disposed in the casing so as to face the sound hole; a back plate disposed opposed to the vibration film; a spacer disposed between the vibration film and the back plate; and a hold member including a spring member. The back plate has an outer peripheral shape that is smaller than an inner peripheral shape of the casing so as to provide a clearance between an outer peripheral surface of the back plate and an inner peripheral surface of the casing. The back plate is held by the hold member from an opposite side of the vibration fills.

Owner:STAR MICRONICS

Thin film magnetic head and fabrication process

InactiveUS20060012923A1Increase productionReduce capacitanceRecord information storageManufacture of flux-sensitive headsManufacturing technologyShort circuit fault

Embodiments of the invention relate to keeping the insulation voltage between the upper and lower leads and preventing short-circuit failure even in the narrow track width and narrow gap length, resulting in improved yield. In one embodiment, the sensor heads are placed on both sides of the track direction of the sensor film at the side of the sensor film, upper shield, lower shield, and air bearing surface. The sensor heads comprise the first insulating film with at least a part connected to the track direction wall surface of the aforementioned sensor film and the third insulating film formed between the upper shield and the first insulating film, and have the relationship being Tw<Dx<Bx where the distance between edges of the first insulating film connected to the track direction wall surface of the sensor film is Tw, the distance between outside edges of the first insulating film along the track direction Bx, and the distance of inside edges of the third insulating film along the track direction Dx.

Owner:WESTERN DIGITAL TECH INC

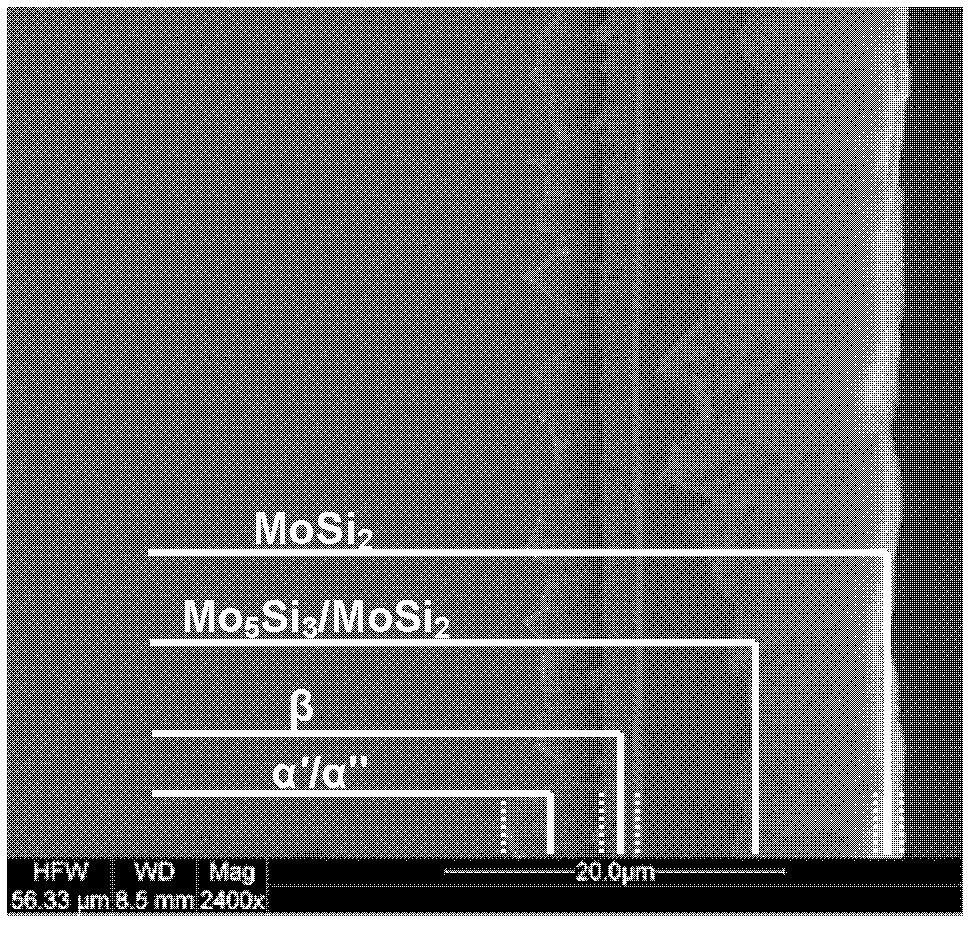

Preparing technology for bionic molybdenum silicide gradient laminate compositing nanometer coatings

InactiveCN102644048AImprove toughnessDifficult to expandVacuum evaporation coatingSputtering coatingOxidation resistantTitanium alloy

Disclosed is a preparing technology for bionic molybdenum silicide gradient laminate compositing nanometer coatings. A double cathode plasma sputtering deposition method is used, a dense nanometer crystal silicide layer is formed on the surface of a titanium alloy workpiece, wherein double cathode plasma sputtering technological parameters are selected, and the type of sputtered target material is powder metallurgy sintered plate with an ingredient ratio of Mo of 0.35-55 (Si 0.95, Al 0.05) 0.65-45; and the type of workpiece material is titanium alloy. The gradient compositing nanometer crystal silicide layer has the advantages of having high toughness, high hardness and good corrosion resistance, and being capable of obviously improving abrasion resistance, corrosion resistance and oxidation resistance of the titanium alloy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A functional marker of rice temperature-sensitive sterile gene tms5 and its application

ActiveCN105002176BDifficult to expandGood effectMicrobiological testing/measurementDNA/RNA fragmentationEnzyme digestionWild type

The invention provides a functional marker for the temperature-sensitive sterile gene tms5 of rice, a method for checking whether a sample contains the tms5 gene by using the functional marker, a method for judging the seed purity of two lines of temperature-sensitive rice by using the functional marker gene, and Its application in breeding sterile lines. According to the rice tms5 gene mutation site sequence, the present invention introduces mismatched bases into the PCR primers, so that a restriction endonuclease Rsa I enzyme cutting site appears in the rice PCR amplification product containing the tms5 gene (mutant type), Rice PCR products that do not contain the tms5 gene (wild type) do not have this restriction site. By cutting the PCR product with Rsa I, the rice PCR amplification product containing the tms5 gene can be enzymatically cut into two fragments, while the one not contained cannot be cut, so as to distinguish them. The present invention adopts the design of directly digesting the tms5 amplification product. Compared with the predecessors, on the one hand, it simplifies the detection process, and on the other hand, it also avoids the occurrence of false positive results.

Owner:RICE RES ISTITUTE ANHUI ACAD OF AGRI SCI

Dental pulp marrow similar cells (DPMSC) and methods of isolating and using

ActiveUS20160244724A1Improve isolationEasy to expand in cultureMetabolism disorderDigestive systemCD29Isolated population

Owner:UNIV DEGLI STUDI DI UDINE UNIV OF UDINE +1

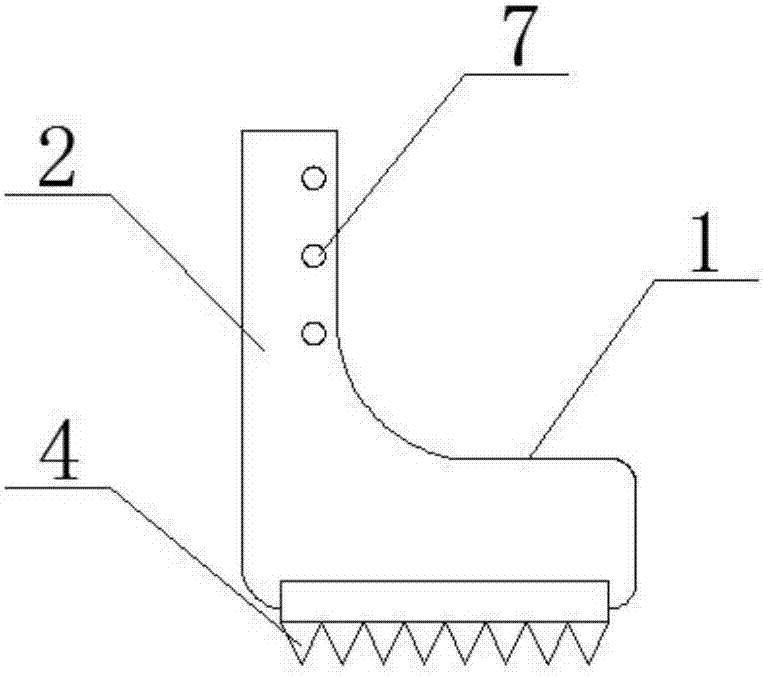

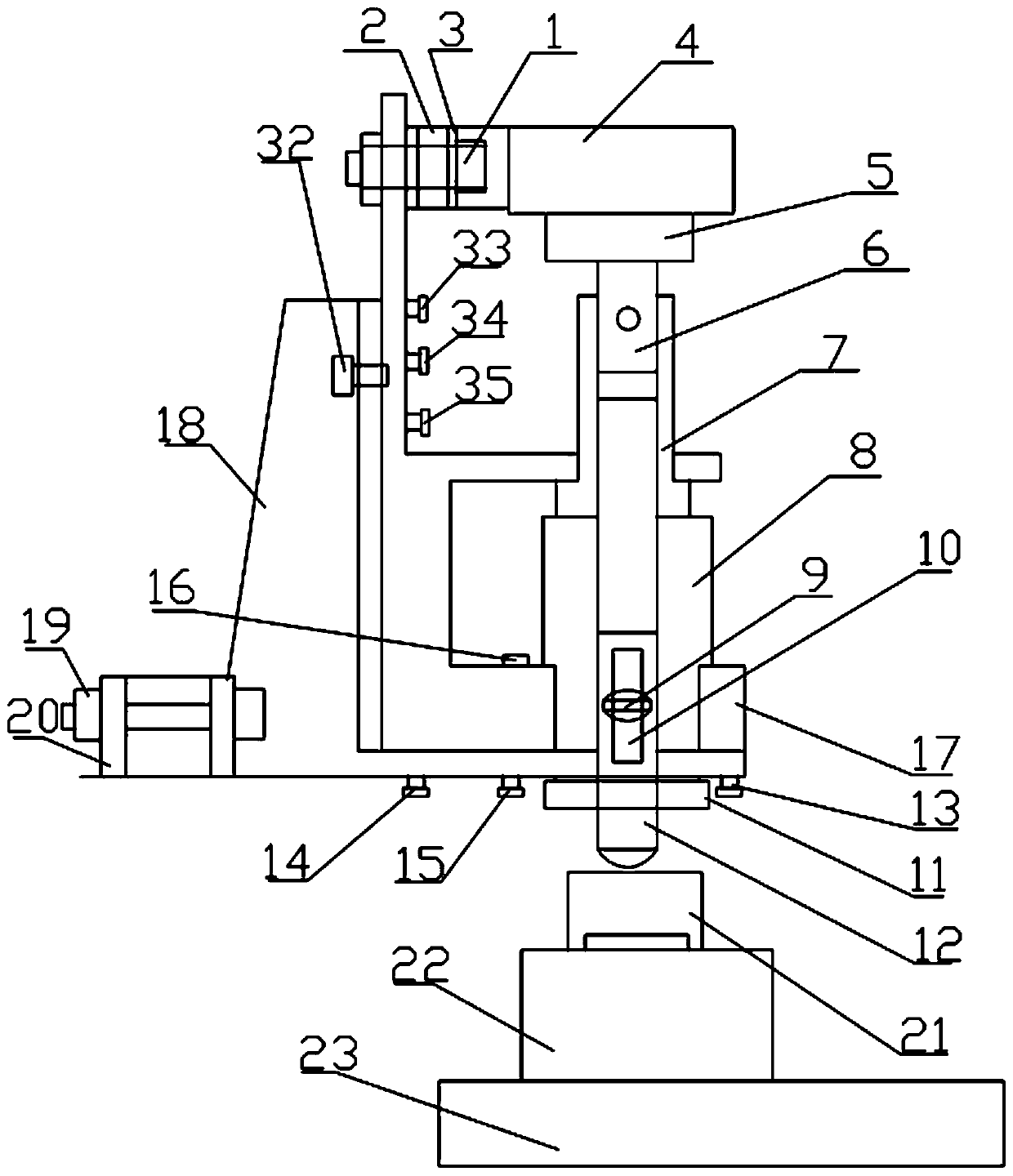

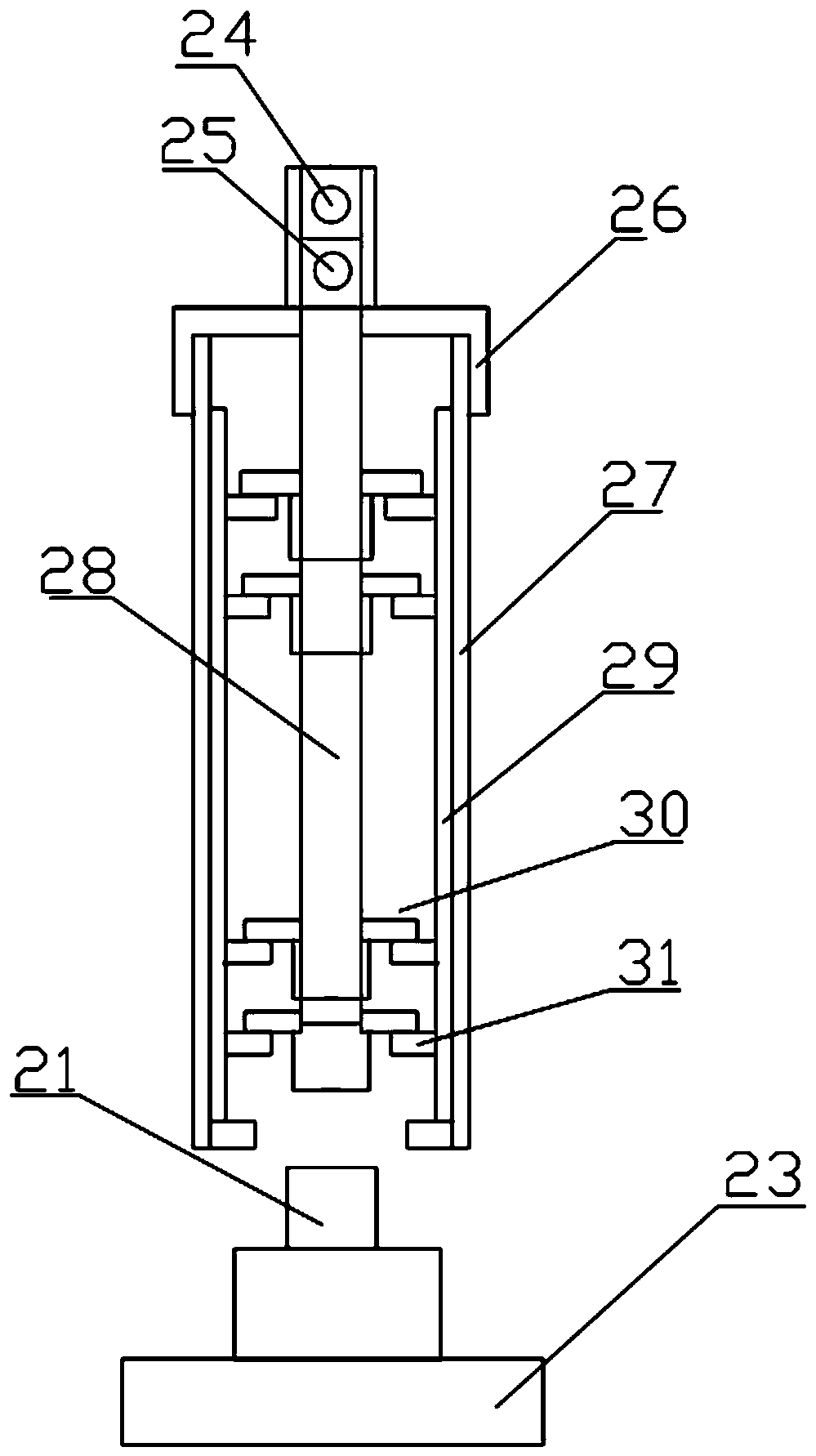

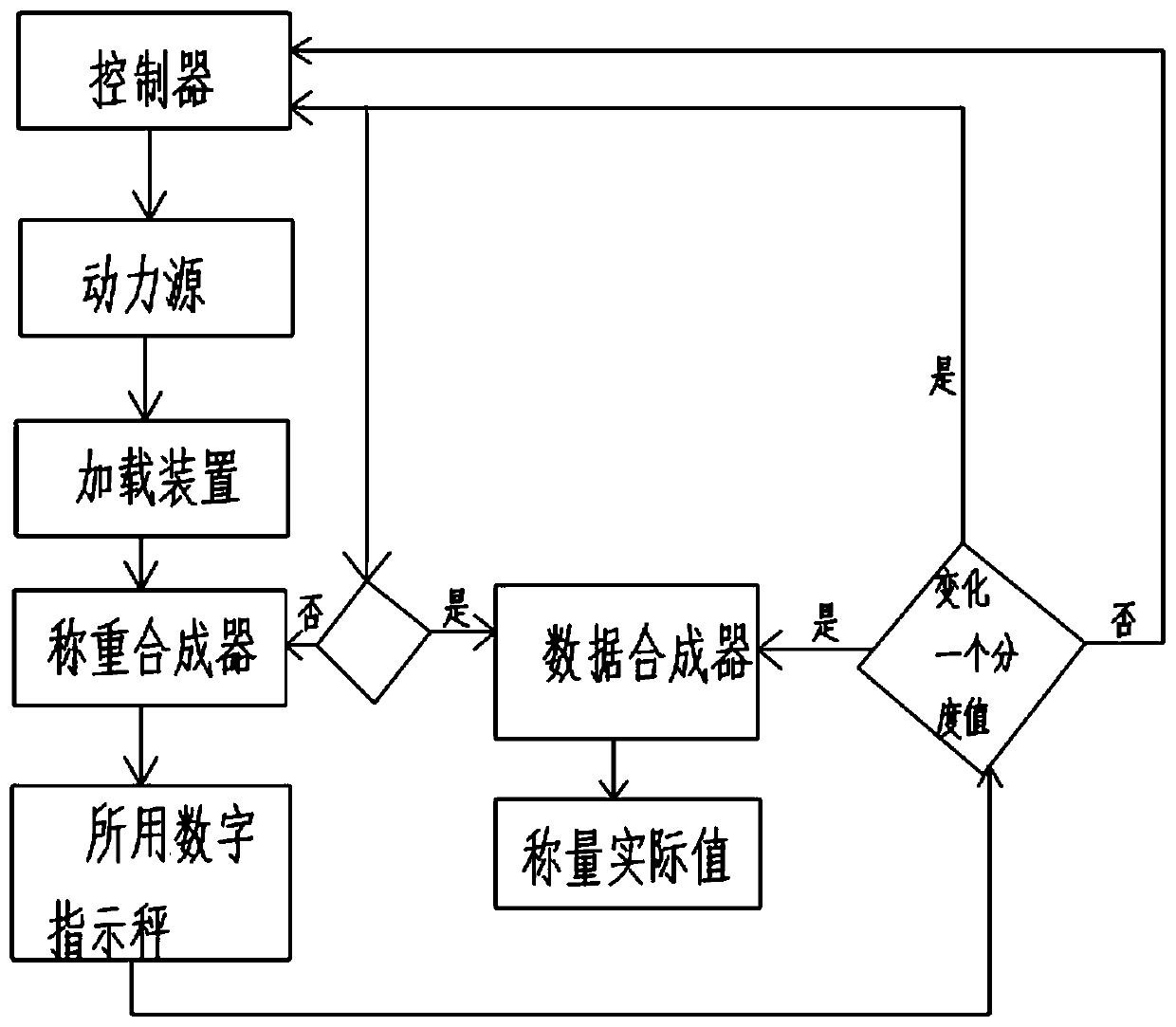

A weighing measurement and control synthesis method and loading device

PendingCN108871541ASolve the problem of the impact of accurate weighingRealize Mechatronics WeighingWeighing apparatus testing/calibrationEngineeringPost synthesis

The invention relates to the technical field of mass weighing and error determination / calibration of electronic scales and in particular provides a weighing measurement and control synthesis method and loading device. The loading device is connected to a digital indicator scale and is further connected to a mechanical loader and a matching block or a weighing synthesizer and a matching block so asto calculate the synthesis mass [delta] m; then, according to the formula M1=f+0.5e-[delta] m-f0-fc or M2=f+0.5e-[delta] m-f0, the post-synthesis actual weighing value is calculated and the actual weighing value is shown through digital display of a display. By correcting zero error, the accuracy can be increased by about 30%; when the indicating value error and zero error can be corrected, the accuracy can be increased by more than 60%; the accuracy is basically the same as the accuracy of common scale measurement, so that many conventional scales can realize electromechanical integration measurement automatically with greater accuracy, can complete weighing at a time conveniently, and can obtain more accurate weighing values; the related methods, techniques, processes and standards canbetter meet requirements; the weighing accuracy in trade is improved.

Owner:冯淑青

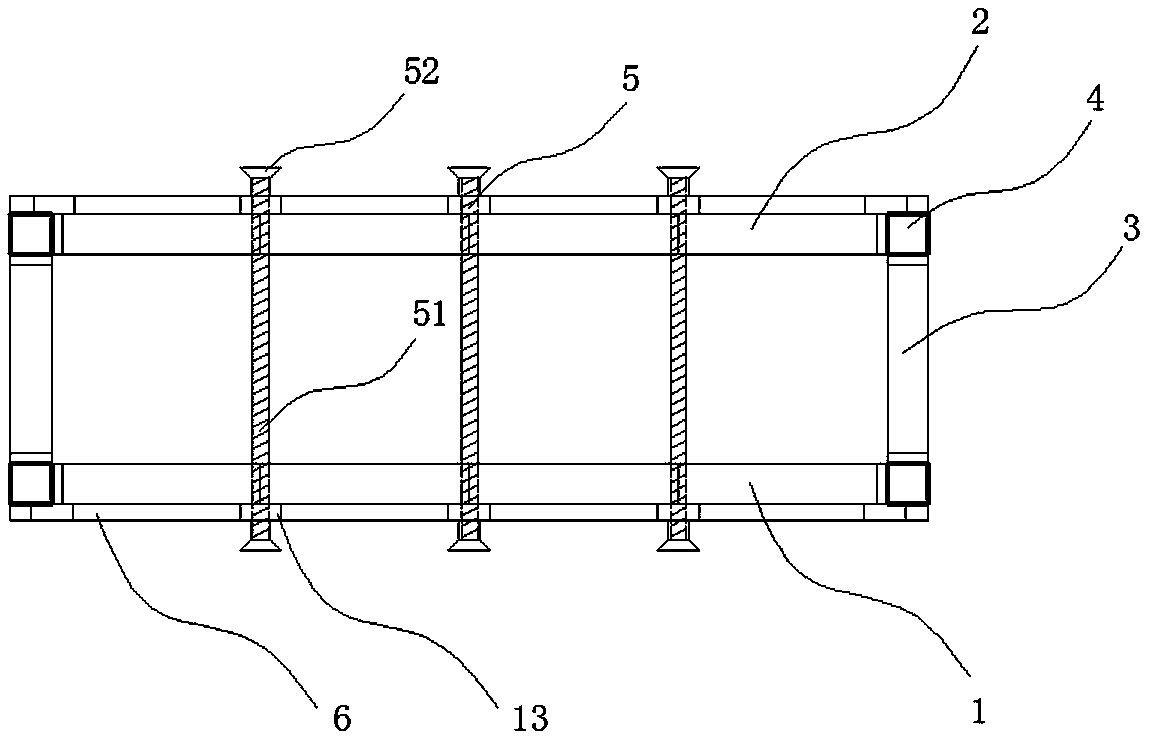

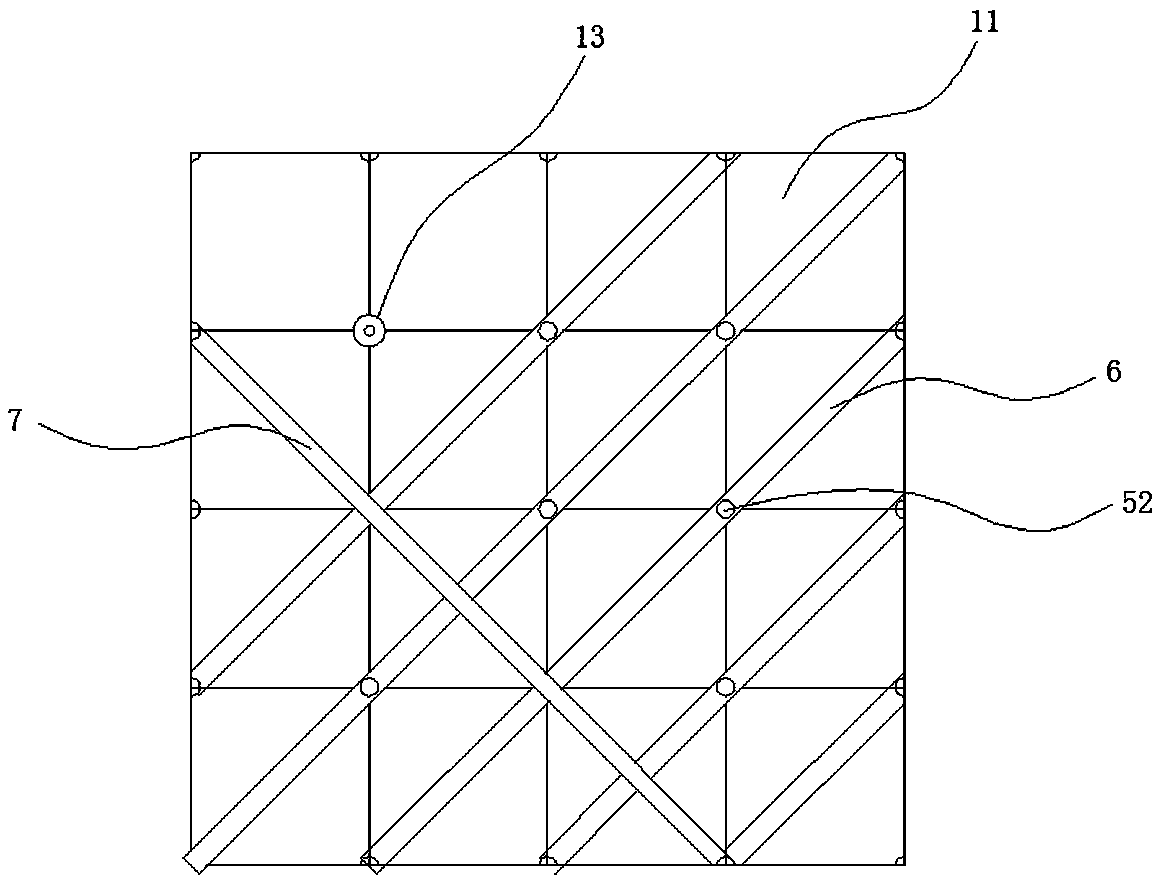

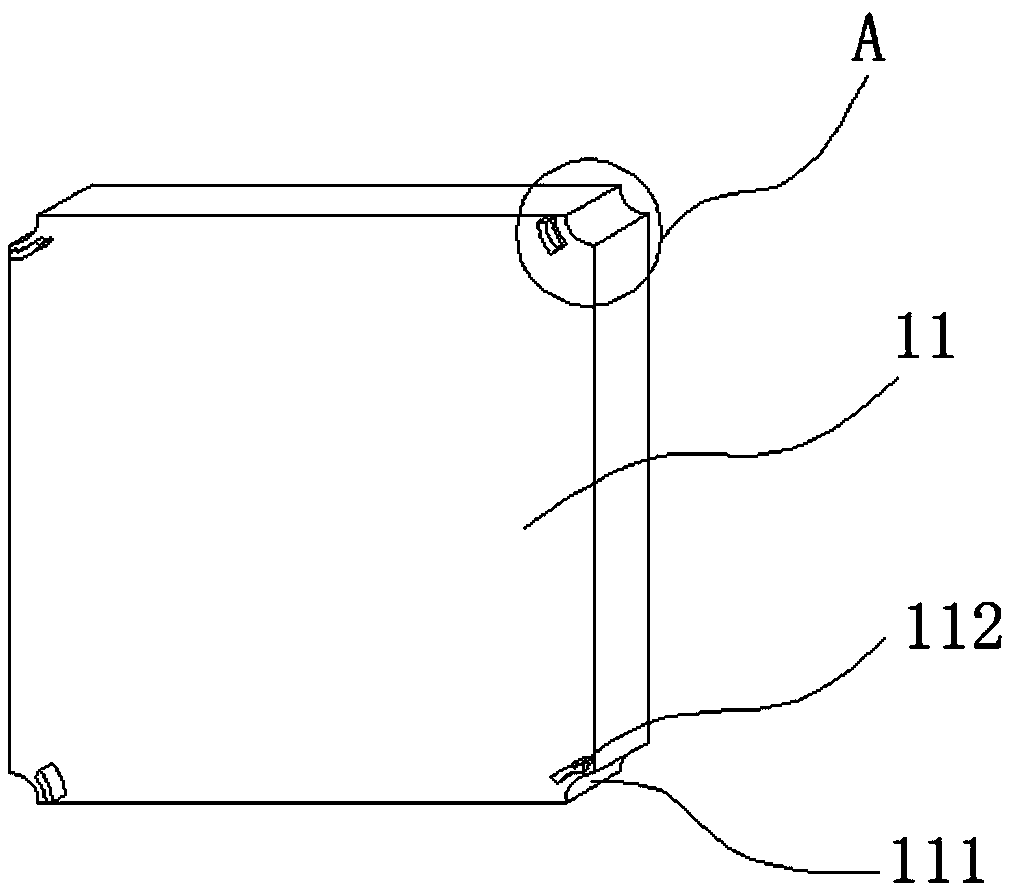

Assembly type building supporting frame body and assembling method

ActiveCN110173107AOmit fixed connectionTime-saving and labor-saving assemblyForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringSquare Shape

The invention relates to an assembly type building supporting frame body and an assembling method. Each of an outer side template, an inner die template and end face templates of the supporting framebody is formed by splicing and connecting multiple template single bodies. The template single bodies are in a square shape. A corner groove in the shape of a quarter of a circle is formed in each ofthe peripheral corners of each template single body. Arc-shaped template clamping protrusions are arranged at the positions, on the outer sides of the arcs of the corner grooves, of the template single bodies. When every four adjacent template single bodies are spliced and attached to one another, the four corner grooves adjacent at the middle portion form a circular fixing hole. Every four template single bodies are fixedly connected in the manner that fixing parts are clamped to the corresponding adjacent four template clamping protrusions. The template single bodies of the outer side template or the inner side template are connected in a strengthened manner through connecting back ridges which are obliquely arranged. The outer side template and the inner side template are connected andfixed through screw rod assemblies, and the two ends of opposite-pulling screw rods of the screw rod assemblies horizontally penetrate fixing holes, the fixing parts and the connecting back ridges ofthe outer side template and the inner side template to be in threaded connection with fixing tenons.

Owner:福建省协兴建设有限公司

A self-compacting concrete aluminum alloy edge-sealing formwork for ballastless track

ActiveCN106948229BUnbroken strengthImprove bearing capacityBallastwayRailway track constructionMaterials scienceAluminium alloy

The invention relates to a self-compacting concrete aluminum alloy edge-sealing formwork for a ballastless track. The self-compacting concrete aluminum alloy edge-sealing formwork for the ballastless track comprises two end molds, four standard side molds, two adjusting side blocks, four corner formworks, and four inserting boards, which are symmetrically assembled into the quadrilateral self-compacting edge-sealing formwork, wherein the end mold comprises a panel and upper and lower frame plates, a reinforcing rib is arranged in the middle part of the panel to form a groove shape, and the end mold is integrally molded by extrusion once through an aluminum profile extrusion device; the standard side molds and the adjusting side molds are made of square tube aluminum profiles, and are molded by extrusion once through the extrusion equipment, the corner formworks and the inserting boards are made of arc-shaped aluminum profiles, and are molded by extrusion once through extrusion equipment. The self-compacting concrete aluminum alloy edge-sealing formwork for the ballastless track provided by the invention solves the problems of slow turnover of the formwork, fewer use times, easy deformation, easy rusting, formwork swelling and mortar leakage of self-compacting concrete, poor exhaust effect, uneasy installation, great waste of human resources and the like under construction.

Owner:湖南天象建筑科技有限公司

Wood plastic composite material cladding plywood formwork and manufacturing method thereof

ActiveCN103758340BReduced flatness errorGood dimensional stabilityFibre treatmentSynthetic resin layered productsPlastic filmUltimate tensile strength

Owner:NORTHEAST FORESTRY UNIVERSITY

Construction technology for compensation for anti-crack special concrete

InactiveCN110761561AGuaranteed crack resistanceGuaranteed impermeabilityBuilding material handlingForm treatmentSocial benefitsArchitectural engineering

The invention discloses a construction technology for compensation for anti-crack special concrete, and particularly relates to the field of engineering construction. Adopted main materials comprise,by weight, 35-40 parts of cement, 30-45 parts of medium sand, 10-15 parts of fine sand, 18-22 parts of water and 1-5 parts of an anti-crack agent. Auxiliary materials comprise, by weight, 75%-80% of used oil and 20%-25% of a used oil emulgator. The technology comprises the following specific steps of modeling, level measurement, oil film brushing, pouring of the first time, plate dismounting, pouring of the second time, form removal and maintaining. According to the construction technology, through the manner of adopting different reinforcers for carrying out pouring on different concrete buildings, the technology can adapt to pouring of concrete buildings of different specifications, cracks are prevented from being generated to formed concrete, the regional and layered pouring manner is adopted, the possibility of mold expansion or vibration or cracks brought by large-volume concrete pouring can be effectively avoided, and therefore social benefits are improved.

Owner:KUNMING RAILWAY CONSTR COMPANY OF CHINA RAILWAY NO 8 ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com