Assembly type building supporting frame body and assembling method

A support frame and assembly technology, which is applied in the direction of construction, building structure, and on-site preparation of building components, can solve the problems of time-consuming and labor-consuming expansion of the outer formwork, assembly and disassembly, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

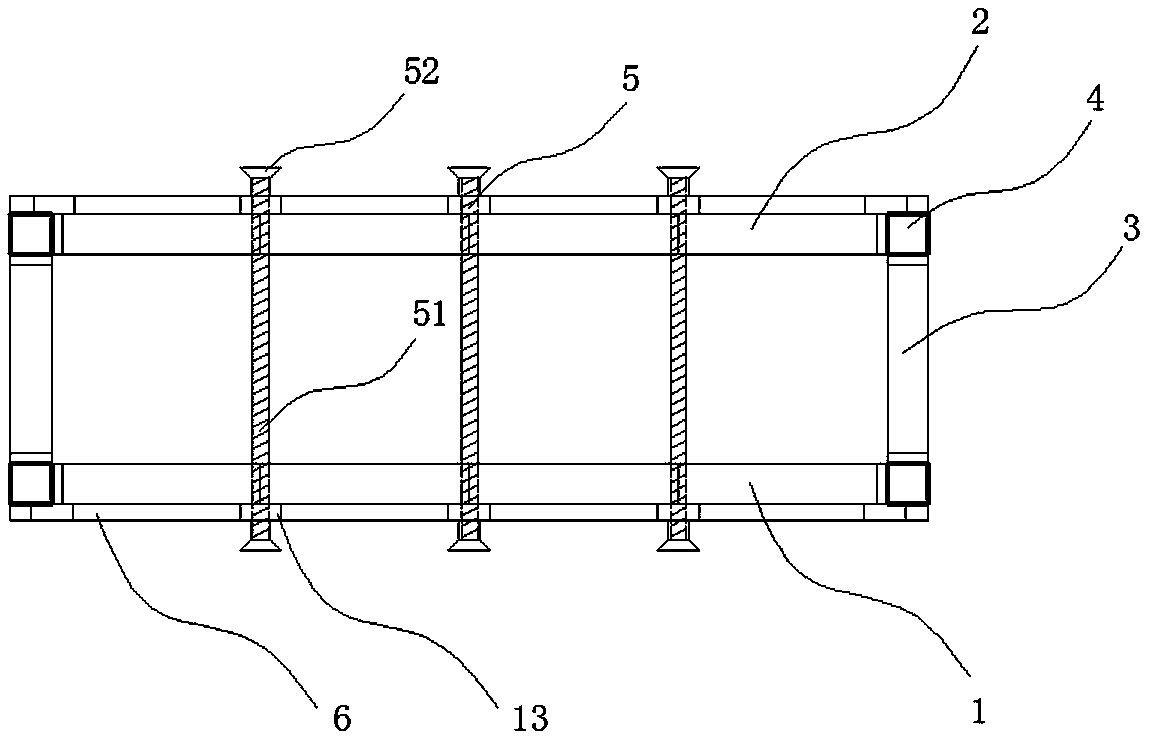

[0037] see figure 1 , a prefabricated building support frame body, comprising an outer formwork 1, an inner formwork 2 arranged parallel to the outer formwork 1, and end formwork 3 at both ends, the outer formwork 1, the inner formwork 2 and the end formwork 3 pass through a column 4 Connection, the outer formwork 1, the inner formwork 2 and the end formwork 3 at both ends are connected by columns 4 to form a square frame structure with a cavity.

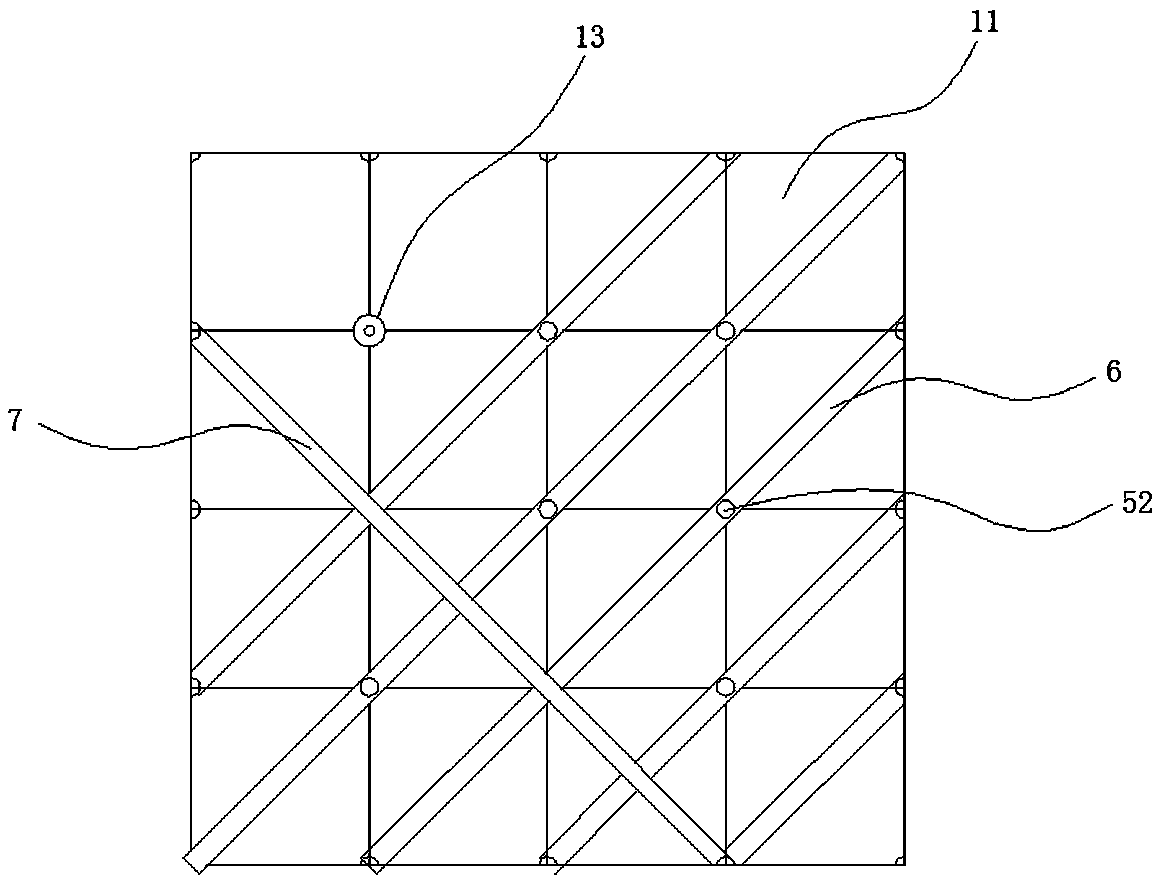

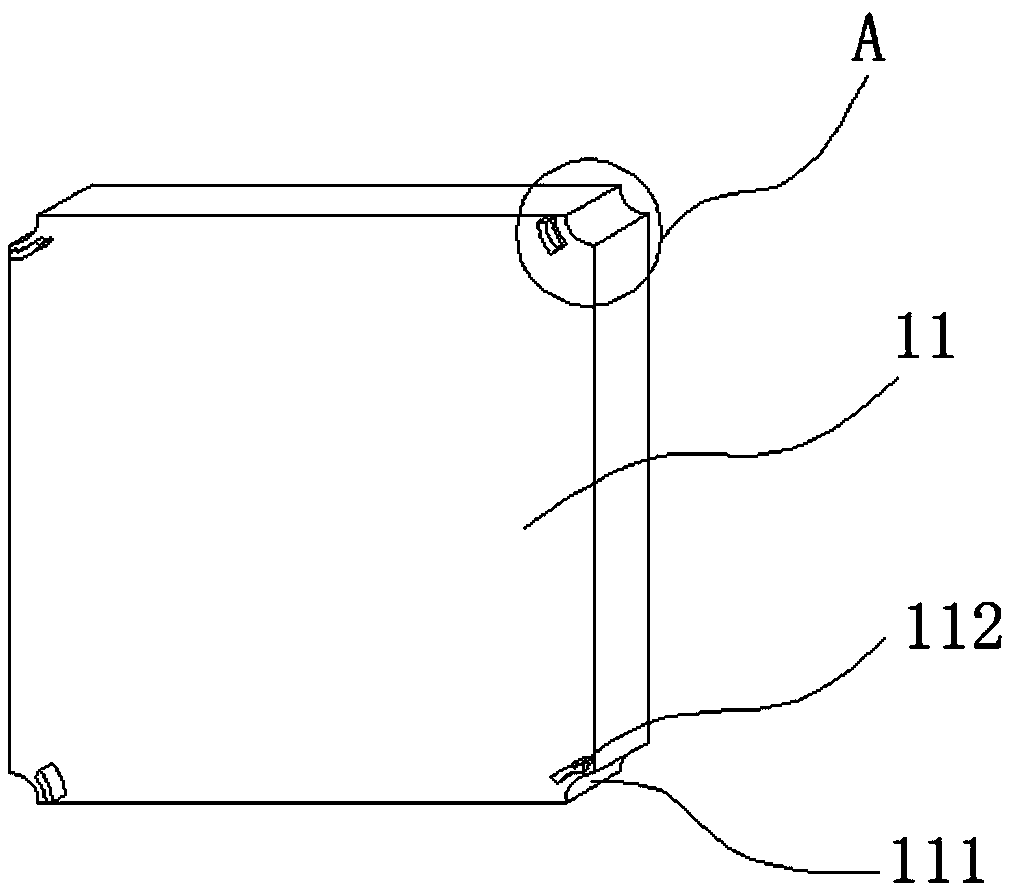

[0038] see Figure 2 to Figure 5 , the outer formwork 1, the inner formwork 2 and the end formwork 3 are assembled and connected by several formwork monomers 11. The template monomer 11 is a square, and the four peripheral corners of the template monomer 11 are provided with quarter-circular corner grooves 111, and the template monomer 11 outside the arc of the corner groove 111 is provided with Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com