Construction technology for compensation for anti-crack special concrete

A construction technology and concrete technology, applied in the treatment of formwork, the treatment of building materials, and the preparation of building components on site, can solve the problem of reducing the crack resistance, impermeability and durability of concrete, and cannot guarantee the use of buildings. functions, the inability to obtain social benefits, etc., to achieve the effect of reducing the difficulty of disassembly, low cost, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a construction technique for compensating crack-resistant special concrete, wherein the main materials used include the following raw materials in parts by weight: 35-40 parts of cement, 30-45 parts of medium sand, 10-15 parts of fine sand, water 18-22 parts, 1-5 parts of anti-cracking agent, the auxiliary materials include 75wt%-80wt% of waste engine oil and 20wt%-25wt% of waste engine oil emulsifier by weight percentage;

[0033] And specifically in the present embodiment: wherein the main material used comprises the raw material of following parts by weight: 35 parts of cement, 30 parts of medium sand, 10 parts of fine sand, 18 parts of water, 2 parts of anti-cracking agent, described auxiliary material according to In terms of weight percentage, it includes 78wt% of waste engine oil and 22wt% of waste engine oil emulsifier;

[0034] The specific steps of the process are as follows:

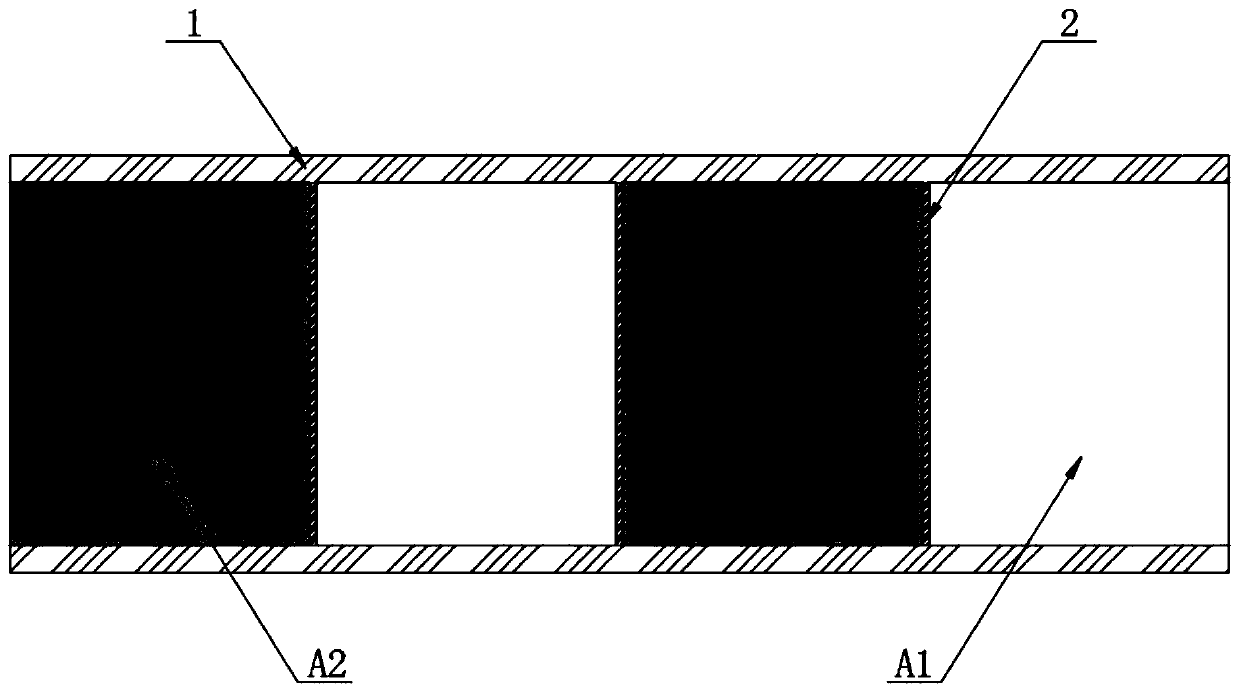

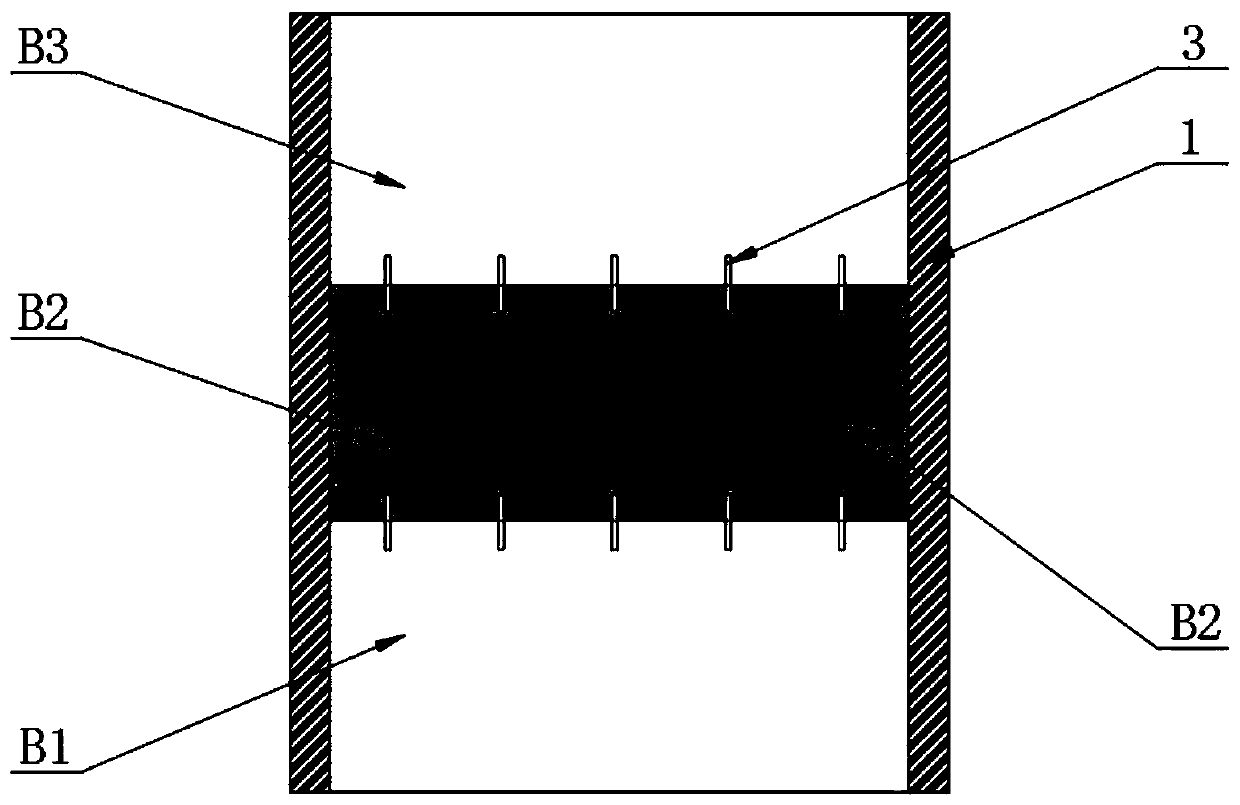

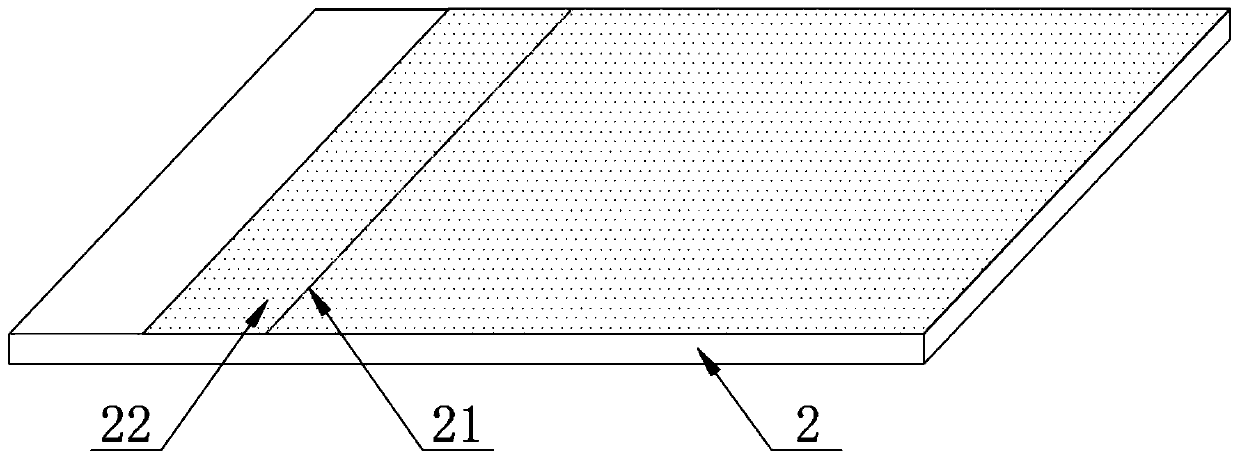

[0035] a) Formwork: Formwork is performed on the model of t...

Embodiment 2

[0047] The invention provides a construction technique for compensating crack-resistant special concrete, wherein the main materials used include the following raw materials in parts by weight: 35-40 parts of cement, 30-45 parts of medium sand, 10-15 parts of fine sand, water 18-22 parts, 1-5 parts of anti-cracking agent, the auxiliary materials include 75wt%-80wt% of waste engine oil and 20wt%-25wt% of waste engine oil emulsifier by weight percentage;

[0048] And specifically in the present embodiment: wherein the main material used comprises the raw material of following parts by weight: 35 parts of cement, 30 parts of medium sand, 10 parts of fine sand, 18 parts of water, 2 parts of anti-cracking agent, described auxiliary material according to In terms of weight percentage, it includes 78wt% of waste engine oil and 22wt% of waste engine oil emulsifier;

[0049] The specific steps of the process are as follows:

[0050] a) Formwork: Formwork is performed on the model of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com