Thermal insulation mortar with lower thermal conductivity coefficient and preparation method thereof

A technology of thermal conductivity and thermal insulation mortar, applied in the field of building materials, can solve the problems such as the thermal conductivity of thermal insulation mortar and large pores that cannot be further reduced, and achieve the effect of high use value and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

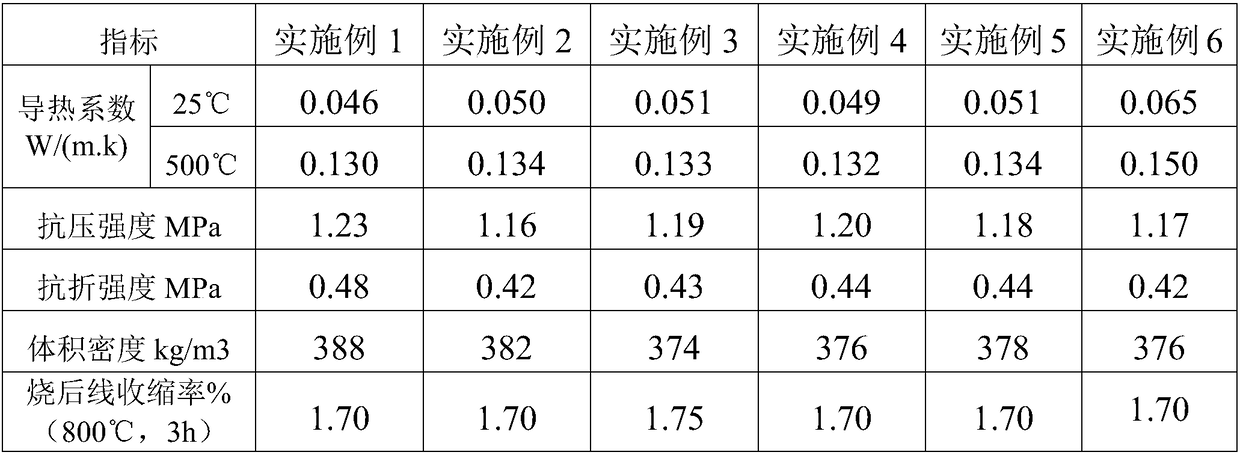

Examples

Embodiment 1

[0021] This embodiment provides a thermal insulation mortar with low thermal conductivity, which is made of the following raw materials: 300 parts of Portland cement, 210 parts of river sand, 200 parts of construction waste, 150 parts of talc, 15 parts of asphalt, heat insulation 50 parts of aggregate, 7 parts of mineral wool, 10 parts of lignocellulose, 5 parts of polyethylhydroxysiloxane emulsion, 4 parts of sulfonated melamine; the thermal insulation aggregate is composed of expanded perlite with a weight ratio of 1:0.2 and hollow glass microspheres.

[0022] The preparation method of the thermal insulation mortar with lower thermal conductivity in this embodiment comprises the following steps:

[0023] (1) Pitch and talc are put into 0.1% sodium chloride solution by mass ratio and immersed for 7 hours, taken out and dried, and crushed to 200 mesh;

[0024] (2) Calcinate river sand and construction waste residue at 700°C for 4 hours, take out and pulverize, add mineral woo...

Embodiment 2

[0027] This embodiment provides a thermal insulation mortar with a low thermal conductivity, which is made of the following raw materials: 250 parts of Portland cement, 240 parts of river sand, 160 parts of construction waste, 170 parts of talc, 10 parts of asphalt, heat insulation 80 parts of aggregate, 6 parts of mineral wool, 12 parts of lignocellulose, 3 parts of water-based silane, and 5 parts of polyethylene glycol; Beads composition.

[0028] The preparation method of the thermal insulation mortar with lower thermal conductivity in this embodiment comprises the following steps:

[0029] (1) Asphalt and talc are put into 0.1% sodium chloride solution by mass ratio and immersed for 8 hours, taken out and dried, and pulverized to 200 mesh;

[0030] (2) Calcinate river sand and construction waste residue at 600°C for 6 hours, take out and pulverize, add mineral wool, lignocellulose, and heat-insulating aggregate to stir and mix;

[0031] (3) Add the materials obtained in ...

Embodiment 3

[0033] This embodiment provides a thermal insulation mortar with a low thermal conductivity, which is made of the following raw materials: 350 parts of Portland cement, 180 parts of river sand, 240 parts of construction waste, 120 parts of talc, 20 parts of asphalt, heat insulation 30 parts of aggregate, 9 parts of mineral wool, 8 parts of lignocellulose, 8 parts of titanate, and 3 parts of polyethylene glycol; the heat-insulating aggregate is composed of expanded perlite and hollow glass with a weight ratio of 1:0.3 microbead composition.

[0034] The preparation method of the thermal insulation mortar with lower thermal conductivity in this embodiment comprises the following steps:

[0035] (1) Asphalt and talc are put into 0.1% sodium chloride solution by mass ratio and immersed for 8 hours, taken out and dried, and pulverized to 200 mesh;

[0036] (2) Calcinate river sand and construction waste residue at 600°C for 6 hours, take out and pulverize, add mineral wool, lignoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com