A weighing measurement and control synthesis method and loading device

A technology of loading device and synthesis method, which is applied in the direction of weighing equipment testing/calibration, etc., which can solve the problems of accurate weighing influence and low accuracy of actual weighing value

- Summary

- Abstract

- Description

- Claims

- Application Information

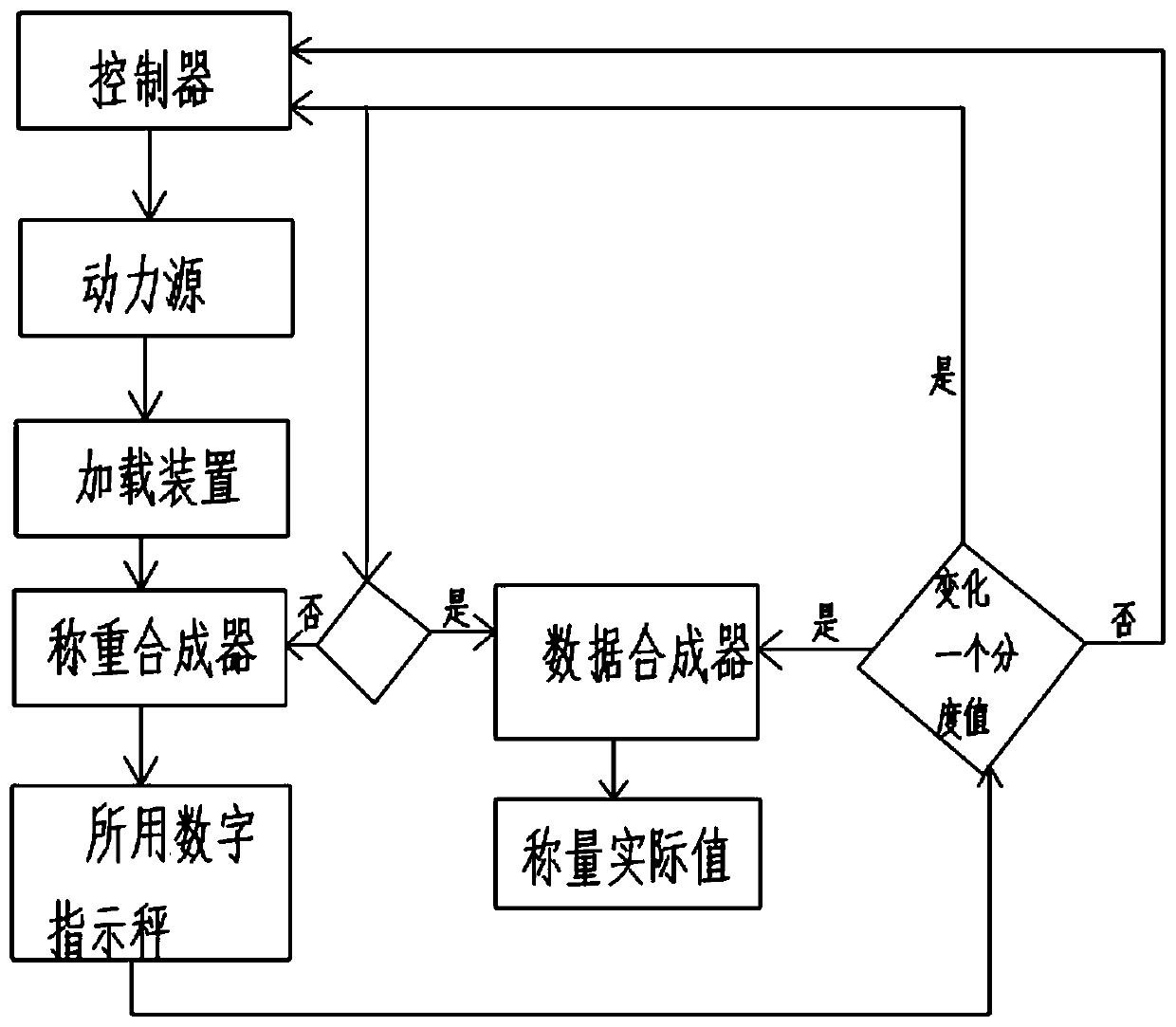

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

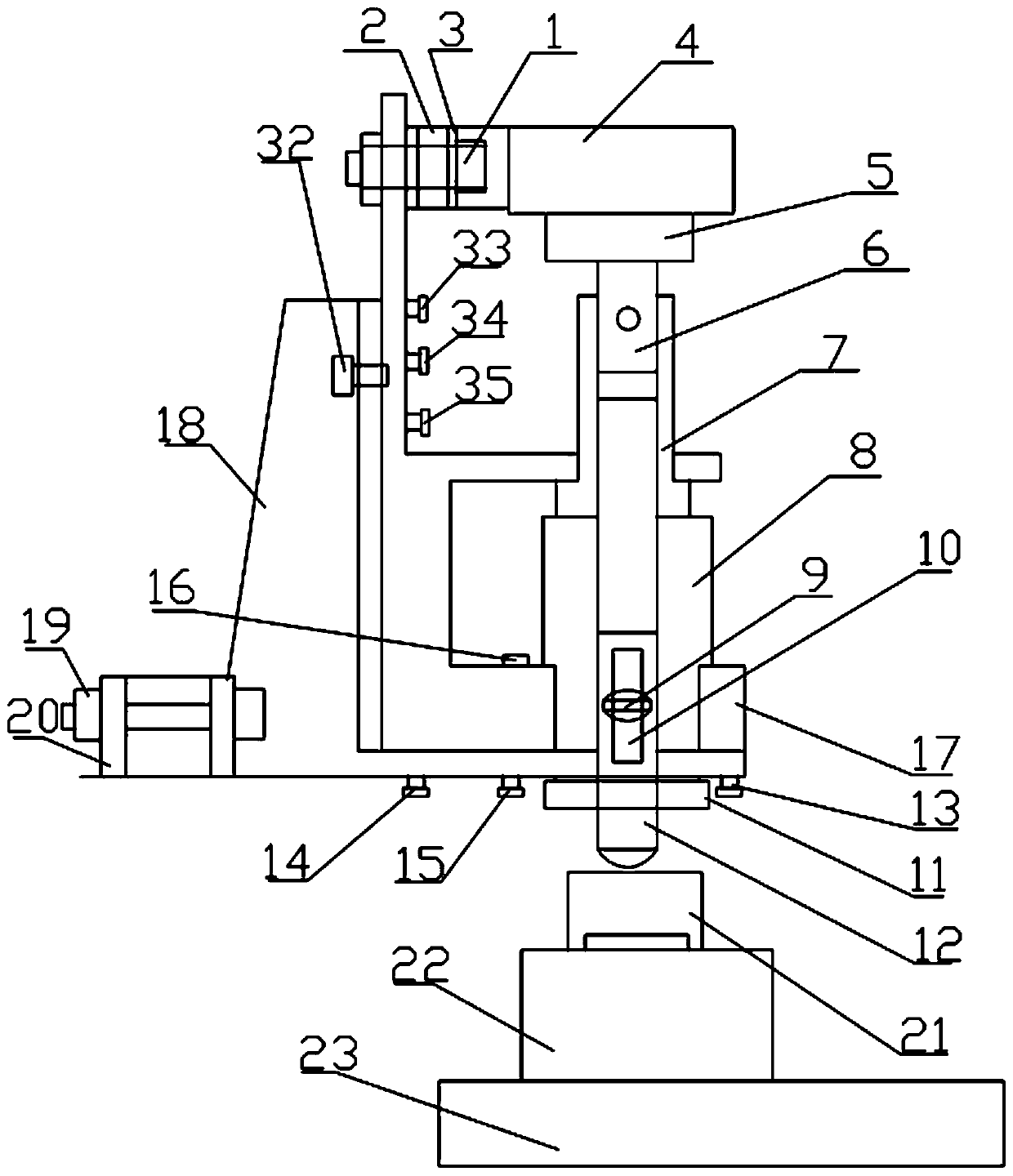

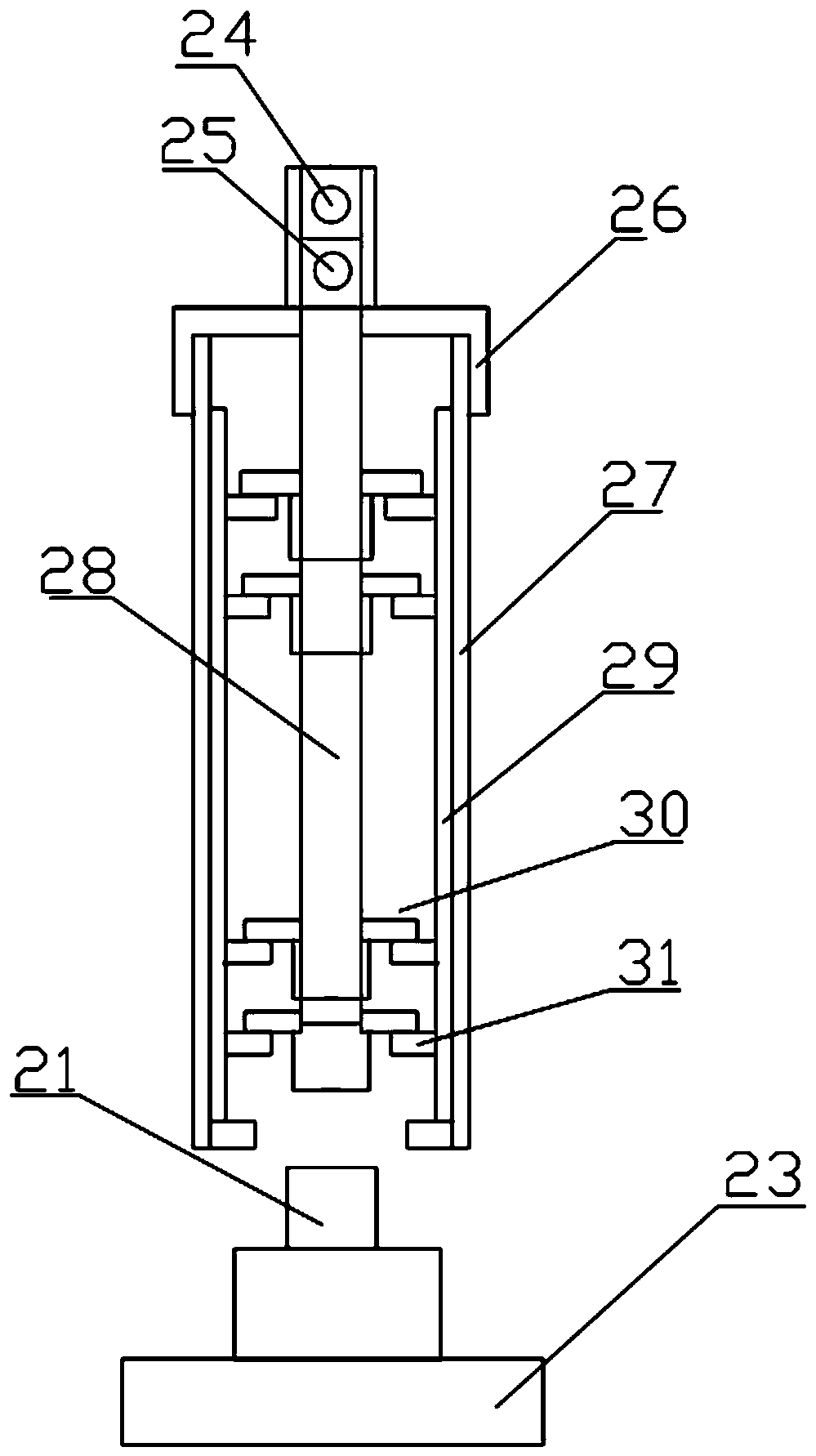

[0074] Such as figure 1 As shown, a weighing, measurement and control synthesis loading device includes a device seat 18, the bottom of one side of the device seat 18 is connected with a device fixing connection sleeve 20, and the bottom of the device seat 18 is connected with a horizontally arranged base plate; The bottom plate of the device seat 18 is installed with a shaped loading seat 17, the top of the loading seat 17 is connected with the motor 4, and the loading seat 17 includes two horizontally arranged upper and lower horizontal plates and a vertical plate fixedly connected to the same side of the upper and lower two horizontal plates, the loading seat 17 The vertical plate is connected to one side of the device seat 18 of the non-connecting device fixed connection sleeve 20 through the fastening bolt 32 of the loading seat, and the upper and lower horizontal plates of the loading seat 17 are provided with through holes;

[0075] The output end of the motor 4) faces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com