Fiber reinforced flame-retardant plastic and preparation method thereof

A flame-retardant plastic and fiber-reinforced technology, which is applied in the field of fiber-reinforced flame-retardant plastic and its preparation, can solve problems such as excessive performance degradation, insufficient flame retardancy, and weak impact resistance, and achieve reduced shrinkage, light weight, and The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

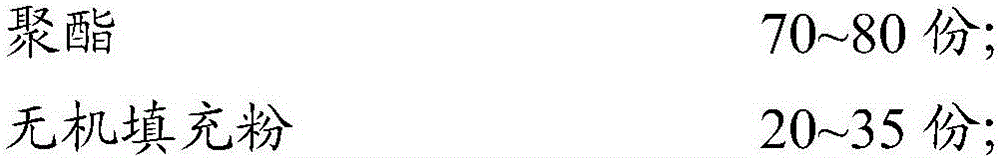

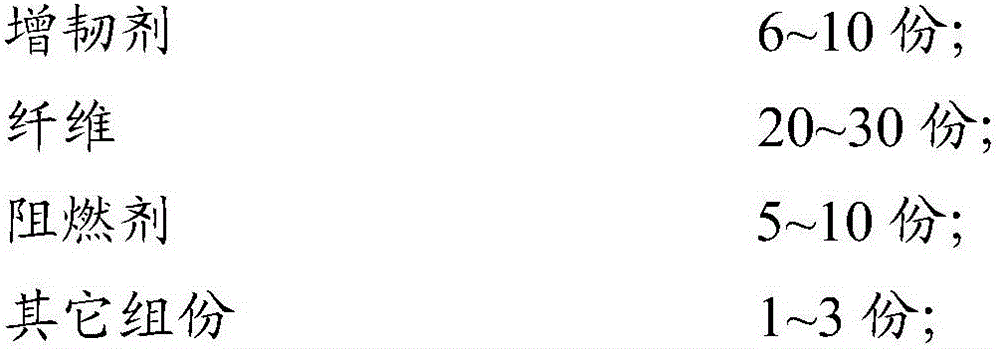

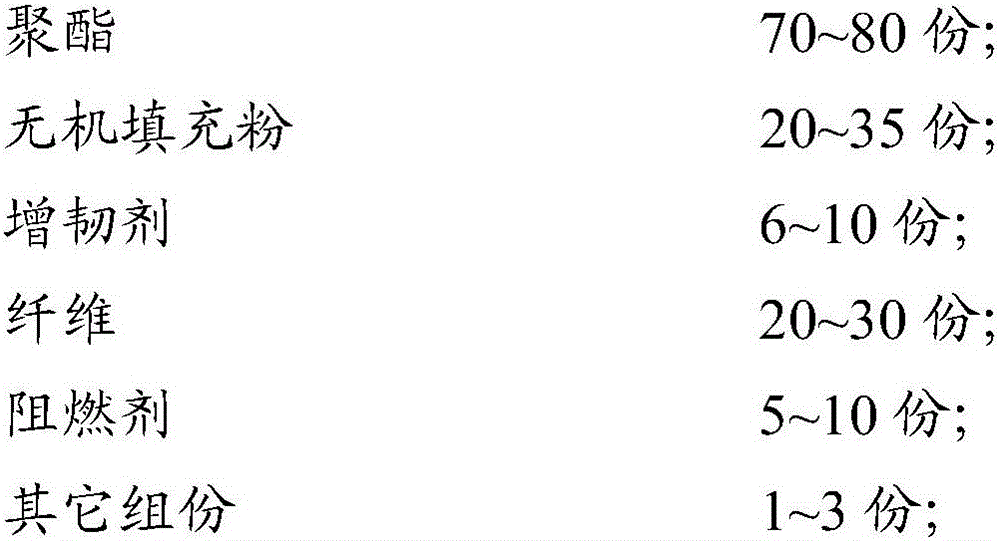

Method used

Image

Examples

Embodiment 1

[0023] The fiber-reinforced flame-retardant plastics provided by the embodiments of the present invention are mainly used as polyester, polyester, and the general term for polymers obtained by polycondensation of polyhydric alcohols and polybasic acids. It mainly refers to polyethylene terephthalate (PET), and customarily also includes linear thermoplastic resins such as polybutylene terephthalate (PBT) and polyarylate. It is a kind of engineering plastic with excellent performance and wide application. It can also be made into polyester fiber and polyester film. Polyester includes polyester resins and polyester elastomers. Polyester resins include polyethylene terephthalate (PET), polybutylene terephthalate (PBT) and polyarylate (PAR). Polyester elastomer (TPEE) is generally polymerized from dimethyl terephthalate, 1,4-butanediol and polybutanol. The chain segment includes hard segment and soft segment, and is a thermoplastic elastomer.

[0024] Polyester Polyethylene tere...

Embodiment 2

[0026] A fiber-reinforced flame-retardant plastic, comprising the following components in parts by weight: 70 parts of polyester, 25 parts of magnesium hydroxide, 5 parts of titanium dioxide, 7 parts of GMA grafts, 30 parts of glass fiber, and 10 parts of nano-melamine Cyanurate, 0.4 part of antioxidant, 0.5 part of lubricant, 0.6 part of coupling agent, 0.4 part of anti-UV agent.

[0027] Preparation:

[0028] Weigh 70 parts of polyester, 25 parts of magnesium hydroxide, 5 parts of titanium dioxide, 7 parts of GMA grafts, 10 parts of nano-melamine cyanurate, 0.4 parts of antioxidant, 0.5 parts of lubricant, 0.6 parts of even Joint agent, 0.4 parts of anti-UV agent.

[0029] The components are fully mixed through a mixer to obtain a uniform mixture;

[0030] Put the mixture into the twin-screw extrusion granulation unit for melting, the processing temperature is 170° to 260°, the screw speed is 350-380r / min, feed 30 parts of glass fiber into the glass fiber port, and extrude...

Embodiment 3

[0032] A fiber-reinforced flame-retardant plastic, comprising the following components in parts by weight: 75 parts of polyester, 28 parts of magnesium oxide, 7 parts of titanium dioxide, 8 parts of EMA grafts, 20 parts of glass fiber, 5 parts of diethyl Aluminum phosphinate, 0.4 part of antioxidant, 0.5 part of lubricant, 0.6 part of coupling agent, 0.4 part of anti-UV agent.

[0033] Preparation:

[0034] Weigh 75 parts of polyester, 28 parts of magnesium oxide, 7 parts of titanium dioxide, 8 parts of EMA grafts, 5 parts of aluminum diethylphosphinate, 0.4 parts of antioxidant, 0.5 parts of lubricant, 0.6 parts of even Joint agent, 0.4 parts of anti-UV agent.

[0035] The components are fully mixed through a mixer to obtain a uniform mixture;

[0036] Put the mixture into the twin-screw extrusion granulation unit for melting, the processing temperature is 170°-260°, the screw speed is 350-380r / min, feed 20 parts of glass fiber into the glass fiber port, and extrude through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com