Two-way corrugated compensation pipe

A technology of corrugated compensation and bellows, which is applied in the field of compensation pipes, can solve the problems of easy to hide dirt, complex stable structure, and affect the appearance of compensation pipes, and achieve the effects of not easy to be deformed by heat, easy to use, and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

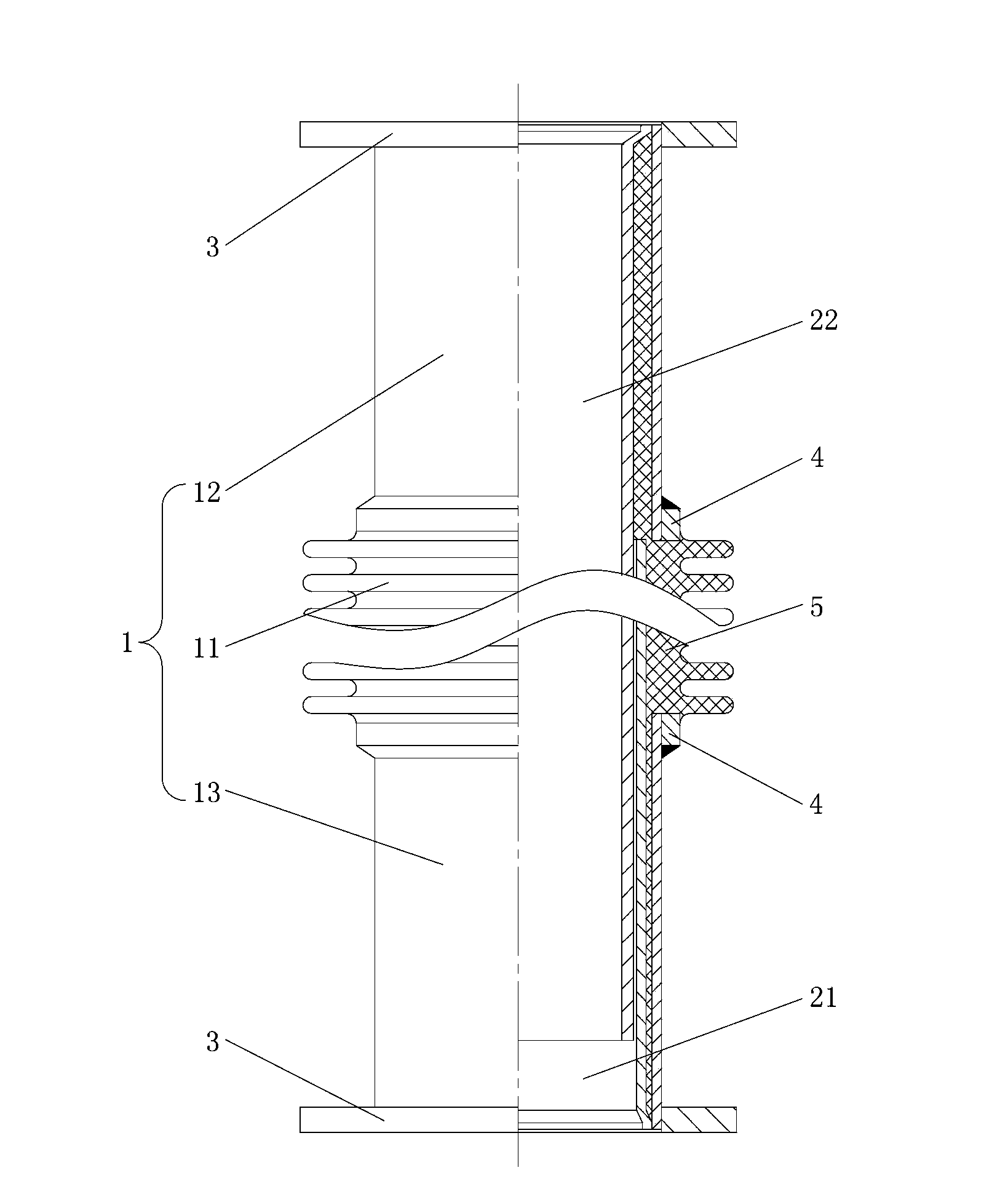

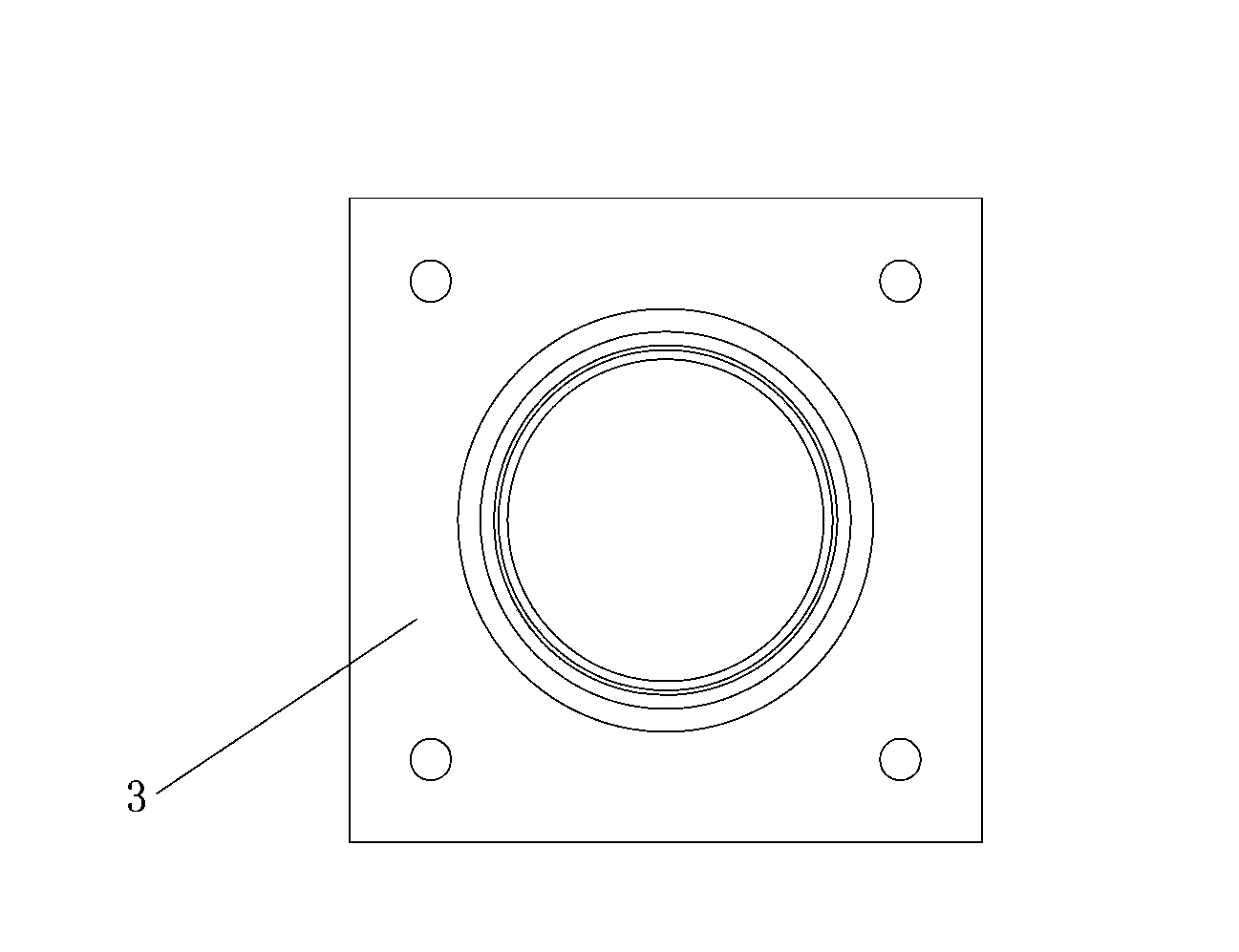

[0016] See figure 1 and figure 2 , the present invention has a telescopic tube 1; the telescopic tube 1 has a corrugated tube 11, an upper connecting tube 12 and a lower connecting tube 13, and the upper and lower ends of the corrugated tube 11 are respectively airtightly connected with the upper connecting tube 12 and the lower connecting tube 13; the bellows 11 A ring of bushings 4 is respectively provided at the connection with the upper connecting pipe 12 and the lower connecting pipe 13; the upper and lower ends of the telescopic pipe 1 are fixedly connected with a square flange 3; the inner sliding part of the telescopic pipe 1 is provided with a large Caliber guide tube 21 and a small-caliber guide tube 22; the large-diameter guide tube 21 is slidably sleeved outside the small-diameter guide tube 22; the large-caliber guide tube 21 has a fixed end and a non-fixed end , the port of the fixed end of the large-diameter guide tube 21 is fixedly connected with the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com