Fiberglass enhanced polyphenyl thioether/polyphenylether composite material and preparation method thereof

A glass fiber and polyphenylene sulfide technology, which is applied in the field of glass fiber reinforced polyphenylene sulfide/polyphenylene oxide composite material and its preparation, can solve the problems of poor fatigue resistance, poor welding strength, poor stress cracking resistance and the like, Achieve the effect of improving molding precision, excellent comprehensive performance and good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

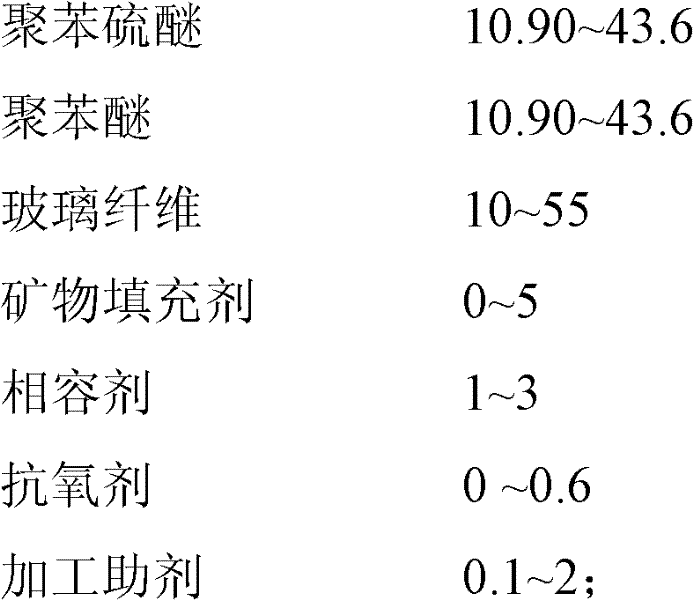

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A glass fiber reinforced polyphenylene sulfide / polyphenylene ether composite material, mainly made of the following parts by weight: 43.6 parts of PPS, 10.9 parts of PPO, 40 parts of alkali-free coarse-twist long glass fiber, four parts [3-(3,5-Di-tert-butyl-4-hydroxyphenyl)propionic acid] 0.2 part of pentaerythritol ester (Irganox1010), 0.2 part of tris(2,4-di-tert-butylphenyl phosphite) (Irganox168) , Compatibilizer 3 parts of ethylene-methyl acrylate copolymer, 5 parts of talc, 0.2 parts of calcium stearate.

[0036] Preparation method: including the following steps:

[0037] a: First, the polyphenylene sulfide resin and polyphenylene ether resin are blast-dried at 160°C and 140°C for 3 hours;

[0038] b: Weigh the dried polyphenylene sulfide resin, polyphenylene ether resin and mineral fillers, compatibilizers, antioxidants, and processing aids;

[0039] c: Put the raw materials of step b together and put them into a high-speed mixer for high-speed dry mixing fo...

Embodiment 2

[0042] Example 2: A glass fiber reinforced polyphenylene sulfide / polyphenylene ether composite material, mainly made of the following parts by weight: 32.7 parts of PPS, 21.8 parts of PPO, 40 parts of alkali-free coarse-twist long glass fiber, four [3-(3,5-Di-tert-butyl-4-hydroxyphenyl)propionic acid] 0.2 part of pentaerythritol ester (Irganox1010), 0.2 part of tris(2,4-di-tert-butylphenyl phosphite) (Irganox168) , Compatibility agent ethylene-methyl acrylate copolymer 2 parts, talc powder 5 parts, zinc stearate 0.2 parts.

[0043] Preparation method: including the following steps:

[0044] a: First, the polyphenylene sulfide resin and polyphenylene ether resin are blast-dried at 160°C and 140°C for 3 hours;

[0045] b: Weigh the dried polyphenylene sulfide resin, polyphenylene ether resin and mineral fillers, compatibilizers, antioxidants, and processing aids;

[0046] c: Put the raw materials of step b together and put them into a high-speed mixer for high-speed dry mixing for 4 mi...

Embodiment 3

[0049] Example 3: A glass fiber reinforced polyphenylene sulfide / polyphenylene ether composite material, mainly made of the following parts by weight: 21.8 parts of PPS, 32.7 parts of PPO, and 40 parts of alkali-free coarse-twist long glass fiber , Tetra[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester (Irganox1010) 0.2 parts, phosphite tris(2,4-di-tert-butylphenyl ester) (Irganox168) 0.2 parts, compatibilizer ethylene-methyl acrylate copolymer 2 parts, barium sulfate 5 parts, zinc stearate 0.2 parts.

[0050] Preparation method: including the following steps:

[0051] a: First, the polyphenylene sulfide resin and polyphenylene ether resin are blast-dried at 160°C and 140°C for 3 hours;

[0052] b: Weigh the dried polyphenylene sulfide resin, polyphenylene ether resin and mineral fillers, compatibilizers, antioxidants, and processing aids;

[0053] c: Put the raw materials of step b together and put them into a high-speed mixer for high-speed dry mixing for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com