High-entropy alloy reinforced high-speed steel wear-resistant material and preparation method thereof

A high-entropy alloy and wear-resistant material technology, applied in additive processing, additive manufacturing, etc., can solve problems such as high cost and insufficient high-temperature wear resistance, and achieve fewer molding defects, improved molding finish, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

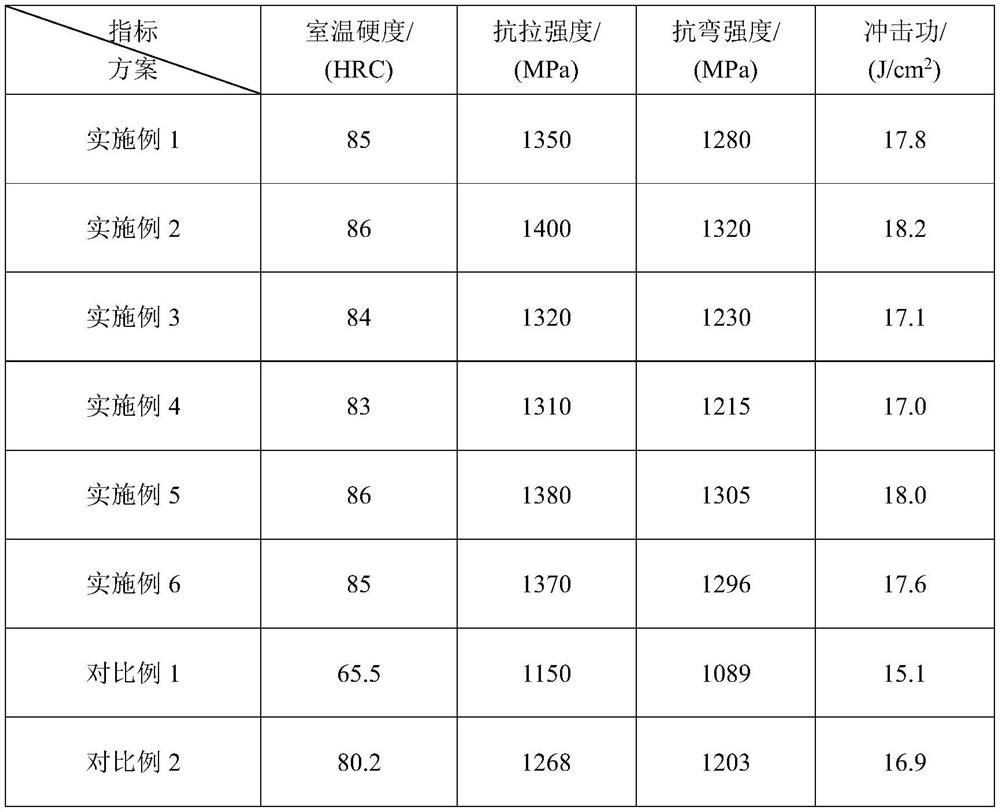

Examples

Embodiment 1

[0034] Take Fe, Cr, Co, Ni, Hf, B powders with a purity of 99% and a particle size of 5-20 microns. According to the atomic ratio: 1:1:1:1:0.2:0.8, weigh the mixed powder and add the mass fraction. 5% anhydrous ethanol is used as the dispersing medium, which is put into the stainless steel ball mill jar, and the stainless steel grinding ball is put into the ball-to-material ratio of 5:1, and then the ball mill jar is evacuated to 10 -3 Pa, mechanical alloying was achieved by ball milling in a vacuum ball mill, the ball milling speed was 300 r / min, and the ball milling time was 6 hours. Then, the alloy powder was dried in a vacuum drying box at 75 °C for 3 hours to obtain FeCrCoNiHf 0.2 B 0.8 The high-entropy alloy powder obtained is sieved to obtain a high-entropy alloy powder below 20 microns, which is used for later use.

[0035] The matrix of high-speed steel is high-speed steel containing Cr, Mo, V, W, Co, Al and B, and the specific components are calculated by mass perce...

Embodiment 2

[0038] The Fe, Cr, Co, Ni, Hf, B powders with a purity of 99% and a particle size of 5-20 microns are weighed according to the atomic ratio: 1:1:1:1:0.8:0.2, and the mass fraction is added. 5% anhydrous ethanol is used as the dispersing medium, which is put into the stainless steel ball mill jar, and the stainless steel grinding ball is put into the ball-to-material ratio of 5:1, and then the ball mill jar is evacuated to 10 -3 Pa, mechanical alloying was achieved by ball milling in a vacuum ball mill, the ball milling speed was 300 r / min, and the ball milling time was 6 hours. Then, the alloy powder was dried in a vacuum drying box at 75 °C for 3 hours to obtain FeCrCoNiHf 0.8 B 0.2 The high-entropy alloy powder obtained is sieved to obtain a high-entropy alloy powder below 20 microns, which is used for later use.

[0039] The matrix of high-speed steel is high-speed steel containing Cr, Mo, V, W, Co, Al and B, and the specific components are calculated by mass percentage: C...

Embodiment 3

[0042] Take Fe, Cr, Co, Ni, Hf, B powders with a purity of 99% and a particle size of 5-20 microns. According to the atomic ratio: 1:1:1:1:0.2:0.8, weigh the mixed powder and add the mass fraction. 5% anhydrous ethanol is used as the dispersing medium, which is put into the stainless steel ball mill jar, and the stainless steel grinding ball is put into the ball-to-material ratio of 5:1, and then the ball mill jar is evacuated to 10 -3 Pa, mechanical alloying was achieved by ball milling in a vacuum ball mill, the ball milling speed was 300 r / min, and the ball milling time was 6 hours. Then, the alloy powder was dried in a vacuum drying box at 75 °C for 3 hours to obtain FeCrCoNiHf 0.2 B 0.8 The high-entropy alloy powder is sieved to obtain a high-entropy alloy powder below 20 microns for use.

[0043] The matrix of high-speed steel is high-speed steel containing Cr, Mo, V, W, Co, Al and B, and the specific components are calculated by mass percentage: C0.75%, Si 0.30%, Mn 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com