Preparation process of polymer pre-filled syringe

A preparation process and syringe technology, which is applied in the field of pharmaceutical packaging materials, can solve the problems of drug migration of vulcanization aids, product failure to meet performance, complex production process, etc., and achieve improved product appearance, low residual stress, and reduced product deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The preparation technology of described macromolecule prefilling syringe, comprises the following steps:

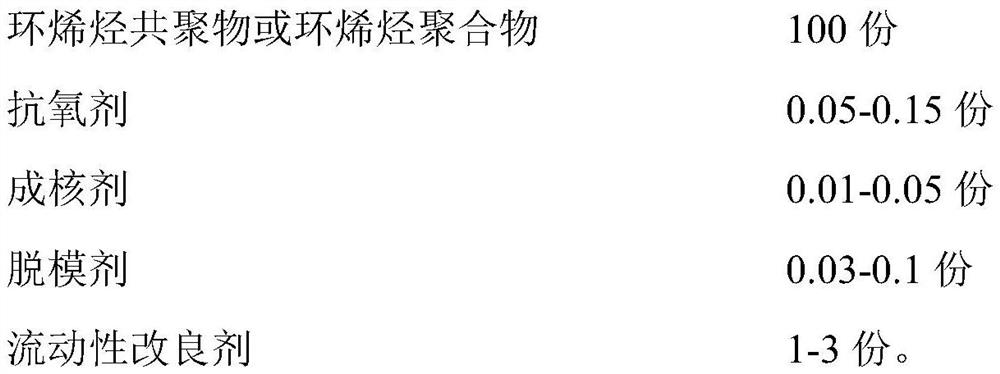

[0068] (1) Ingredients

[0069] Select the syringe needle tube material and the syringe sealing piston material;

[0070] (2) Mold flow design

[0071] Establish the mold flow analysis model of injection molding products, then simulate the injection molding process parameters of the mold flow analysis model through CAE software, test the PVT parameters of the material, optimize the mold design and formulate the best process parameters through mold flow analysis;

[0072] (3) Injection molding

[0073] According to the optimal process parameters formulated, the syringe needle tube material and the syringe sealing piston material are respectively injection molded to obtain the syringe needle tube and the syringe sealing piston;

[0074] (4) Finished product assembly

[0075] Assembling the obtained syringe needle tube and syringe sealing piston with the push rod ...

Embodiment 2

[0085] The preparation technology of described macromolecule prefilling syringe, comprises the following steps:

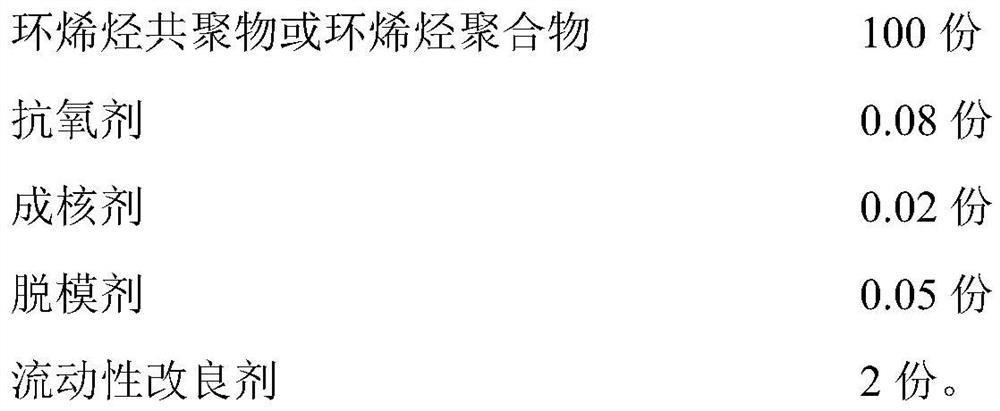

[0086] (1) Ingredients

[0087] Select the syringe needle tube material and the syringe sealing piston material;

[0088] (2) Mold flow design

[0089] Establish the mold flow analysis model of injection molding products, then simulate the injection molding process parameters of the mold flow analysis model through CAE software, test the PVT parameters of the material, optimize the mold design and formulate the best process parameters through mold flow analysis;

[0090] (3) Injection molding

[0091] According to the optimal process parameters formulated, the syringe needle tube material and the syringe sealing piston material are respectively injection molded to obtain the syringe needle tube and the syringe sealing piston;

[0092] (4) Finished product assembly

[0093] Assembling the obtained syringe needle tube and syringe sealing piston with the push rod ...

Embodiment 3

[0102] The preparation technology of described macromolecule prefilling syringe, comprises the following steps:

[0103] (1) Ingredients

[0104] Select the syringe needle tube material and the syringe sealing piston material;

[0105] (2) Mold flow design

[0106] Establish the mold flow analysis model of injection molding products, then simulate the injection molding process parameters of the mold flow analysis model through CAE software, test the PVT parameters of the material, optimize the mold design and formulate the best process parameters through mold flow analysis;

[0107] (3) Injection molding

[0108]According to the optimal process parameters formulated, the syringe needle tube material and the syringe sealing piston material are respectively injection molded to obtain the syringe needle tube and the syringe sealing piston;

[0109] (4) Finished product assembly

[0110] Assembling the obtained syringe needle tube and syringe sealing piston with the push rod a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com