Pressing machine, crank pressing machine, and vibration processing method in these machines

一种振动加工、压力机的技术,应用在压力机领域,能够解决操作员作业烦杂、振动加工加工时间变长、花费时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

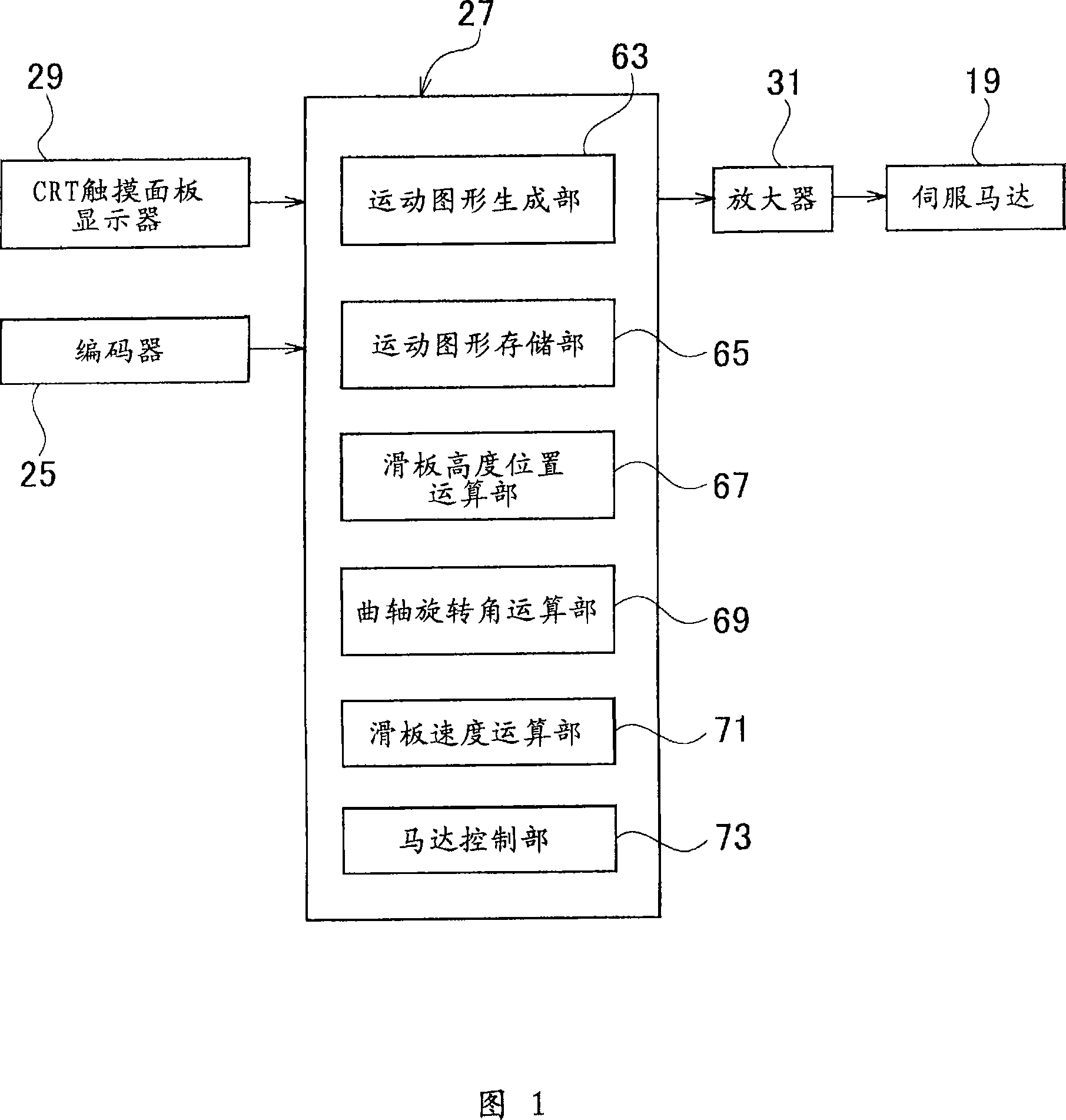

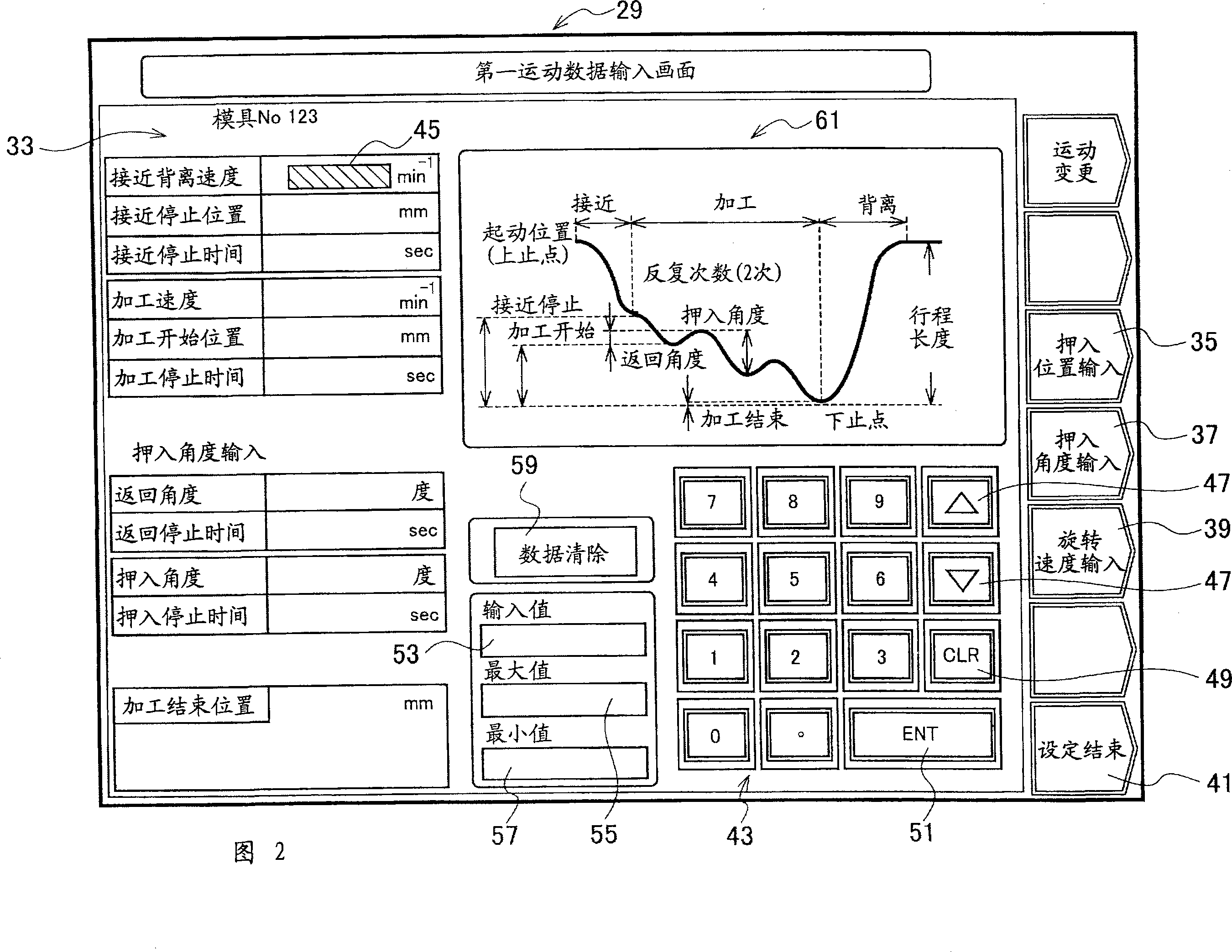

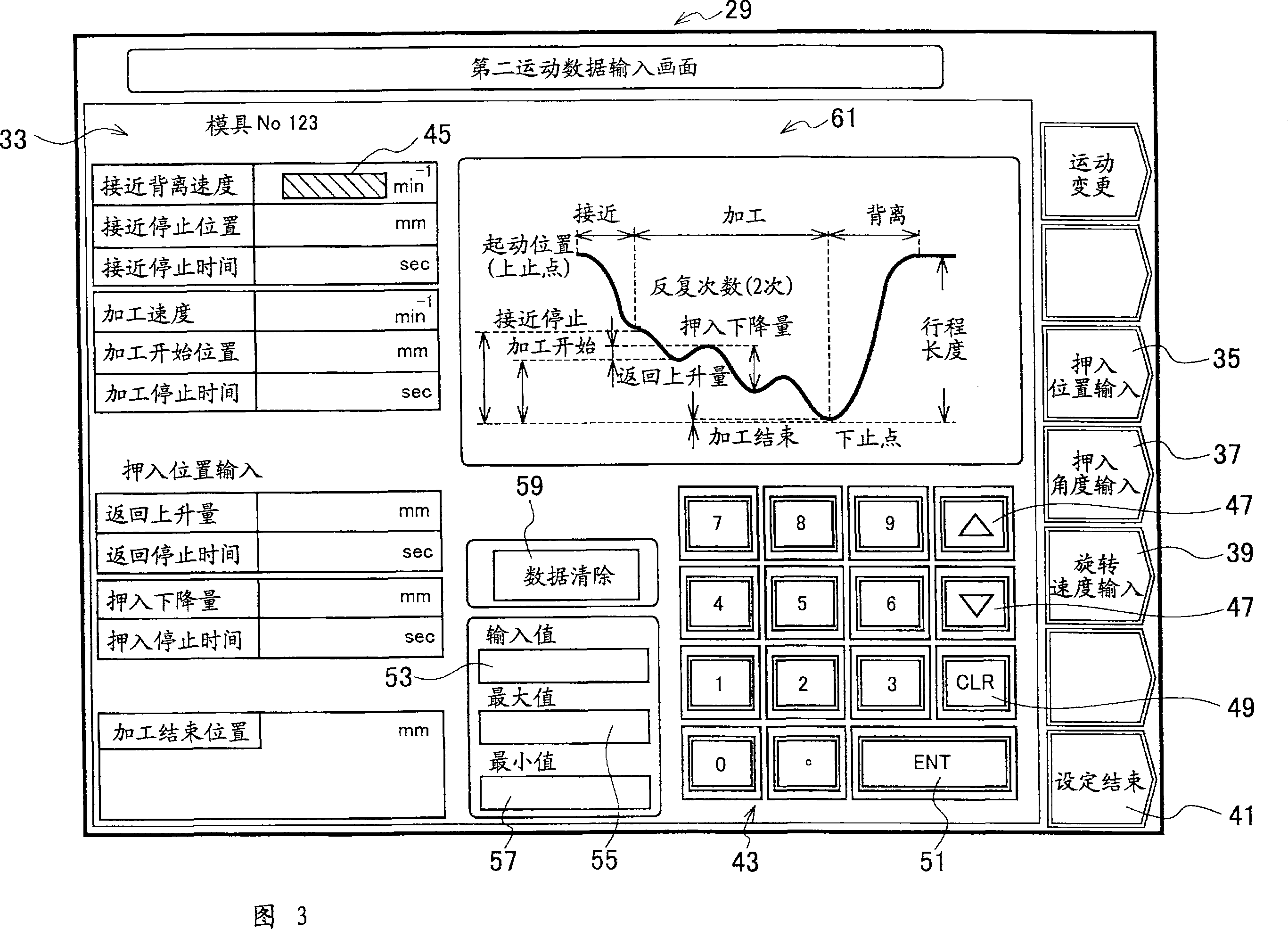

[0050] Hereinafter, embodiments of the present invention will be described with reference to FIGS. 1 to 6 .

[0051] Here, Fig. 1 is a control block diagram related to an embodiment of the present invention, Fig. 2 is a diagram showing the first motion data input screen displayed on the CRT touch panel display, and Fig. 3 is a diagram showing the first motion data input screen displayed on the CRT touch panel display The figure of the second motion data input screen, Fig. 4 is a figure showing the third motion data input screen displayed on the CRT touch panel display, and Fig. 5 shows the rotation speed of the crankshaft and the height of the slider in vibration processing of another method As for the positional relationship, FIG. 6 is a side sectional view of a crank press according to an embodiment of the present invention.

[0052] As shown in FIG. 6 , in the crank press 1 according to the embodiment of the present invention, the workpiece W is stamped (including vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com