A fast mold change device for the upper mold of the bending machine

A bending machine, fast technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of restricting production efficiency and precision of parts, long mold changing time, low mold loading accuracy, etc., to achieve mold changing speed Fast, high mold loading accuracy, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

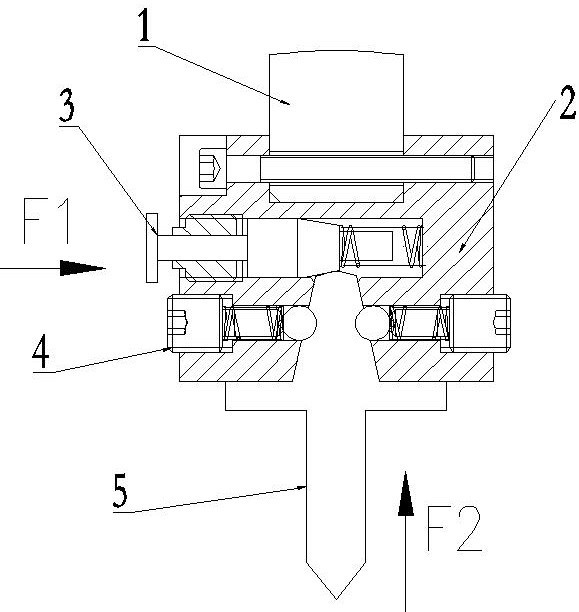

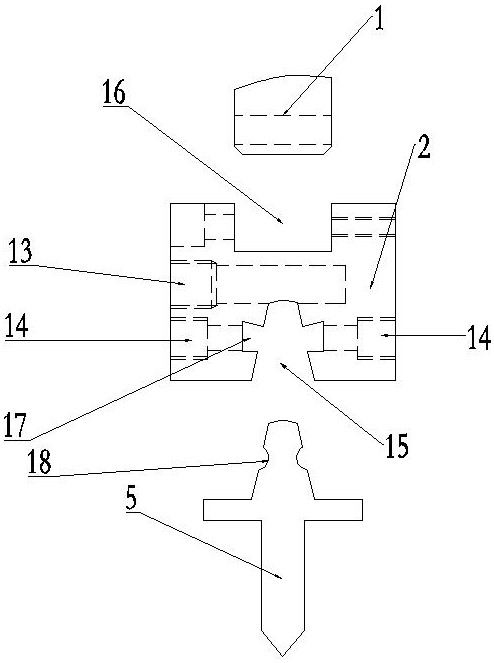

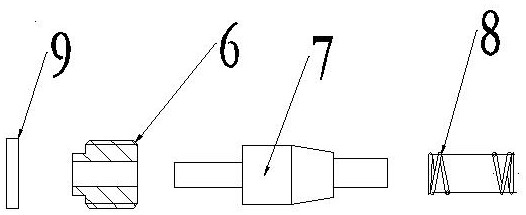

[0016] Such as Figure 1-4 As shown, a quick die change device for the upper die of a bending machine includes a slider 1, a die change base 2, a die change switch assembly 3, an upper die positioning assembly 4 and an upper die 5, and the lower part of the slider 1 is provided with an installation hole, the shape of the mold change base 2 is as figure 2 As shown, the top of the mold changing base 2 is processed with a U-shaped slider connecting screw hole 16. The slider 1 is connected to the mold changing base 2 through screws, including the upper mold 5. The installation part of the upper mold 5 is a cone, and the cone The upper end face is also conical, and the two sides of the cone are provided with grooves 18, including the mold changing base 2, and the bottom of the mold changing base 2 is provided with a taper mounting groove 15 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com