A mold transport track for foaming equipment

A technology of transportation track and foaming equipment, which is applied in the field of mold transportation track, can solve the problems of consumption, increased production cost, large manpower and working time, etc., and achieve the effects of accurate control, improved production efficiency and precise position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

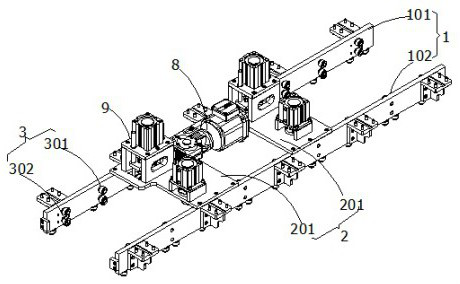

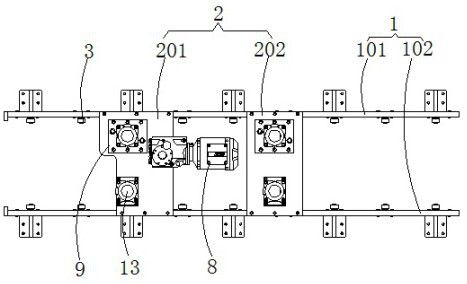

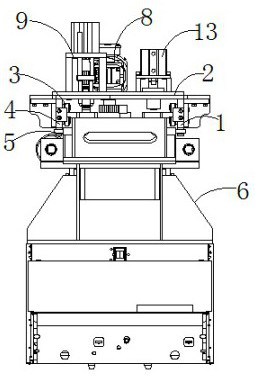

[0026] like Figure 1-4 As shown, a mold transport rail for foaming equipment includes a side plate 1 and a supporting top plate 2. The side plate 1 includes a left side plate 101 and a right side plate 102. There are two supporting top plates 2, respectively A support top board 201 and a second support top board 202, and the first support top board 201 and the second support top board 202 are horizontally fixedly installed on the upper ends of the left side board 101 and the right side board 102, the left side board 101 and the right side board 102 The inner side is closed with a guide wheel group 3, and the guide wheel group 3 on the same side includes several upper guide wheels 301 and several lower guide wheels 302, and the central axis connection line of several upper guide wheels 301 is connected with several lower guide wheels. The connecting lines of the central axis of the wheel 302 are parallel, and the lower ends of the left side plate 101 and the right side plate 1...

Embodiment 2

[0030] like Figure 1-6 As shown, a mold transport rail for foaming equipment includes a side plate 1 and a supporting top plate 2. The side plate 1 includes a left side plate 101 and a right side plate 102. There are two supporting top plates 2, respectively A support top board 201 and a second support top board 202, and the first support top board 201 and the second support top board 202 are horizontally fixedly installed on the upper ends of the left side board 101 and the right side board 102, the left side board 101 and the right side board 102 The inner side is closed with a guide wheel group 3, and the guide wheel group 3 on the same side includes several upper guide wheels 301 and several lower guide wheels 302, and the central axis connection line of several upper guide wheels 301 is connected with several lower guide wheels. The connecting lines of the central axis of the wheel 302 are parallel, and the lower ends of the left side plate 101 and the right side plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com