Stepless width adjusting mold of heavy-duty vehicle U-shaped crossbeam

A heavy-duty vehicle, U-shaped technology, applied in the direction of molding tools, manufacturing tools, vehicle parts, etc., can solve the problems of inconvenient production and mold management, large production site area, long development cycle, etc., to save mold development costs, The effect of high technical content and fast mold change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

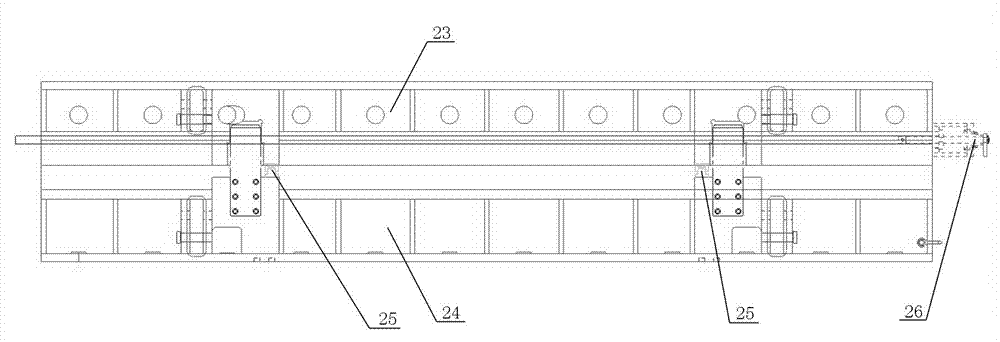

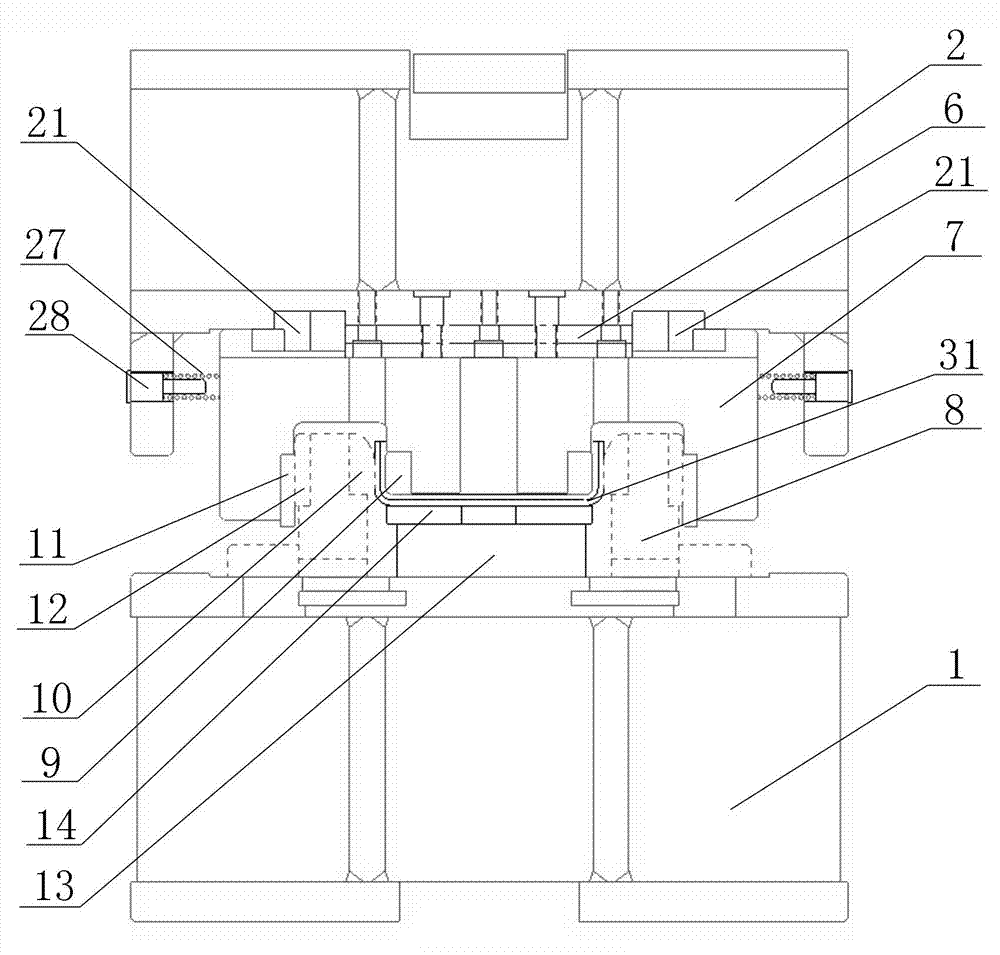

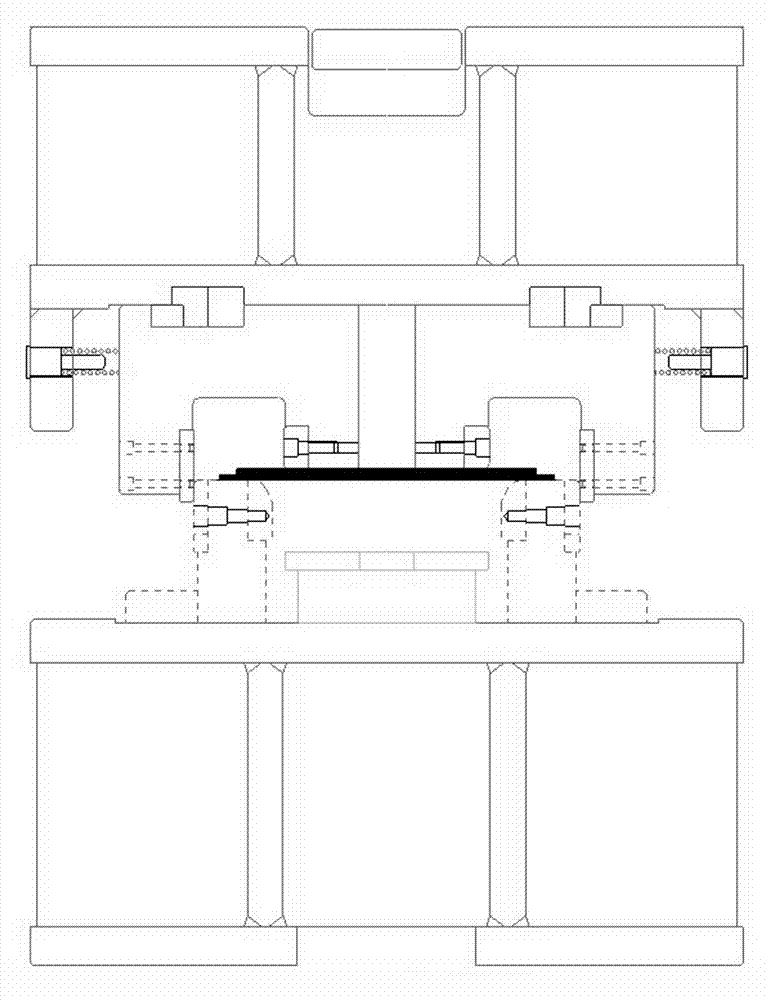

[0042] A heavy-duty vehicle U-shaped girder width steplessly adjustable mold, including an upper mold combination and a lower mold combination, the upper mold combination includes several upper mold assemblies 23, and the lower mold assembly includes the same number of upper mold assemblies The lower mold assembly 24; the upper mold assembly 23 and the lower mold assembly 24 correspond one-to-one, as figure 1 shown.

[0043] The lower mold assembly 24 includes a lower base 1, and the upper surface of the lower base 1 is fixedly installed with two die holders 8 with protrusions at a certain distance apart, and the distance between the die holders 8 is adjusted according to the width of the automobile frame. Sure.

[0044] The upper mold assembly 23 includes an upper base 2, and the lower surface of the upper base 2 is fixed with a convex mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com