Quick Die Change Device

A fast and fixed device technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of difficult mold cores to be fixed in a fixed position and not to be replaced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

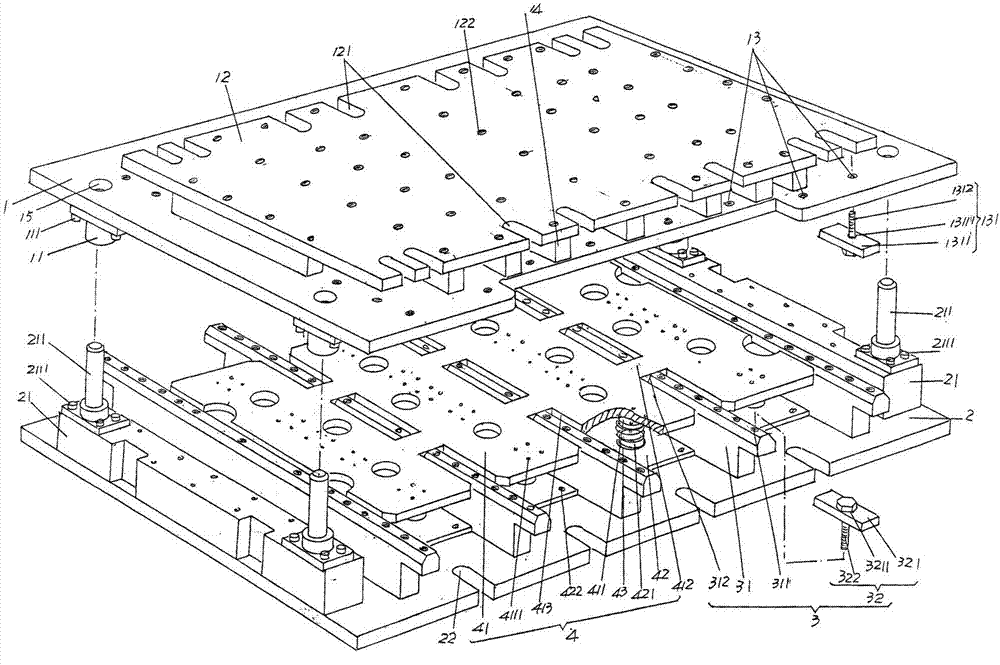

[0022] In the following descriptions, all concepts involving up, down, left, right, front and back direction positions are aimed at figure 1 As far as the position status shown is concerned, the purpose is to facilitate the understanding of the public, so it should not be construed as a limitation on the technical content of the present invention.

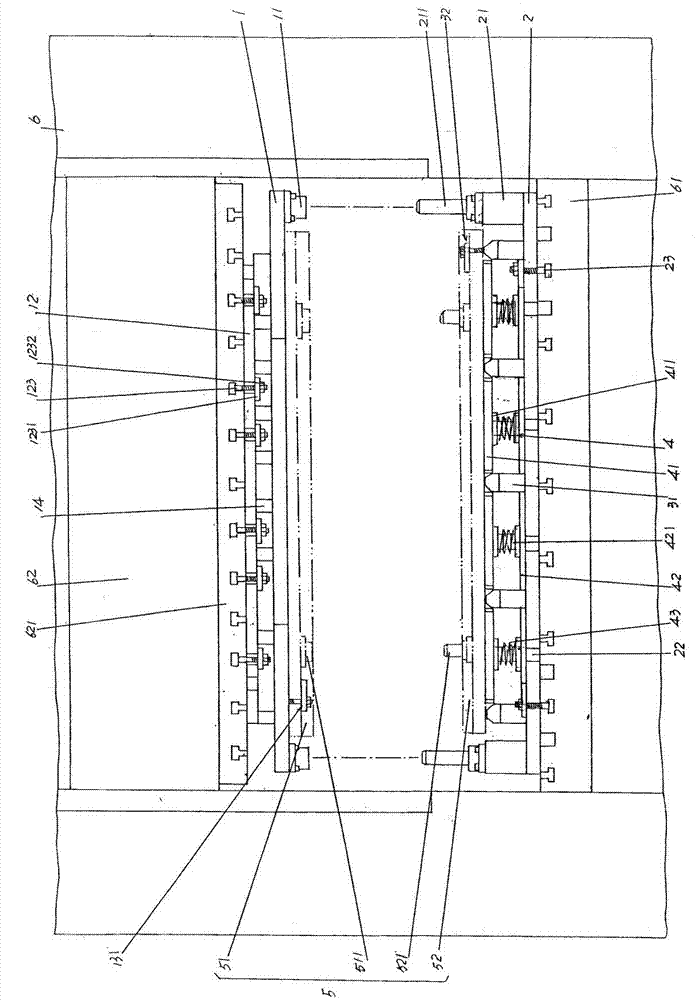

[0023] Please see figure 1 , provides an upper formwork plate 1 and a lower formwork plate 2 which are made of metal materials and are rectangular, that is, a cuboid. In the state of use, the upper formwork plate 1 is used for the figure 2 The schematic stamping device 6 such as the punch 62 of the hydraulic press is fixedly connected to the cylinder column (the connection device connected with the upper mold frame plate 1 is provided on the oil cylinder column, such as the punch upper table 621), and the lower mold frame plate 2 is in use. under and by figure 2 The punching operation platform 61 (also called the working table)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com