Integrated, heat-insulated and non-deformed sintering pallet device

A technology for sintering trolleys and trolleys, which is applied in the direction of lighting and heating equipment, furnace types, furnaces, etc. It can solve problems such as easy deformation due to heat, no open documents found, and overall deformation of sintering trolleys, so as to improve labor efficiency and reduce Influence and reduce the effect of spare parts cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

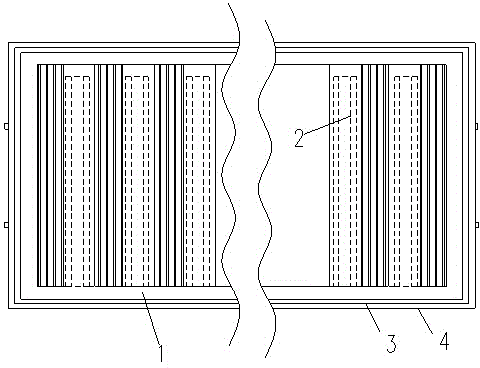

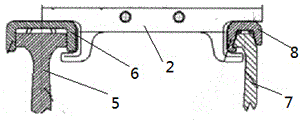

[0024] according to Figure 1-9 , an integrated, heat-insulated, non-deformable sintering trolley device, comprising a trolley body, a grate device, a baffle, a side sealing device, a side heat preservation device, and a heat insulation pad, and the grate device is installed on the trolley In the middle frame of the car body, the baffles are arranged at both ends of the trolley body, and side sealing devices are installed on the baffles, and the side heat preservation device is installed between the car body and the car body. The heat insulation pad It is set between the grating bar device and the trolley girder.

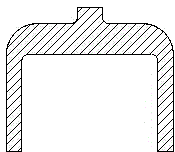

[0025] The upper shape of the heat insulating pad is consistent with the shape of the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com