Birdcage type rocket engine shell winding and forming die and manufacturing method thereof

A rocket engine and winding forming technology, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of not meeting the product accuracy requirements, insufficient mold strength and rigidity, and affecting the use of molds, etc., to achieve light weight and low cost. Low, easy assembly and disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The design and preparation technology of the present invention will be further described in detail through examples by taking a birdcage rocket motor shell winding mold as an example.

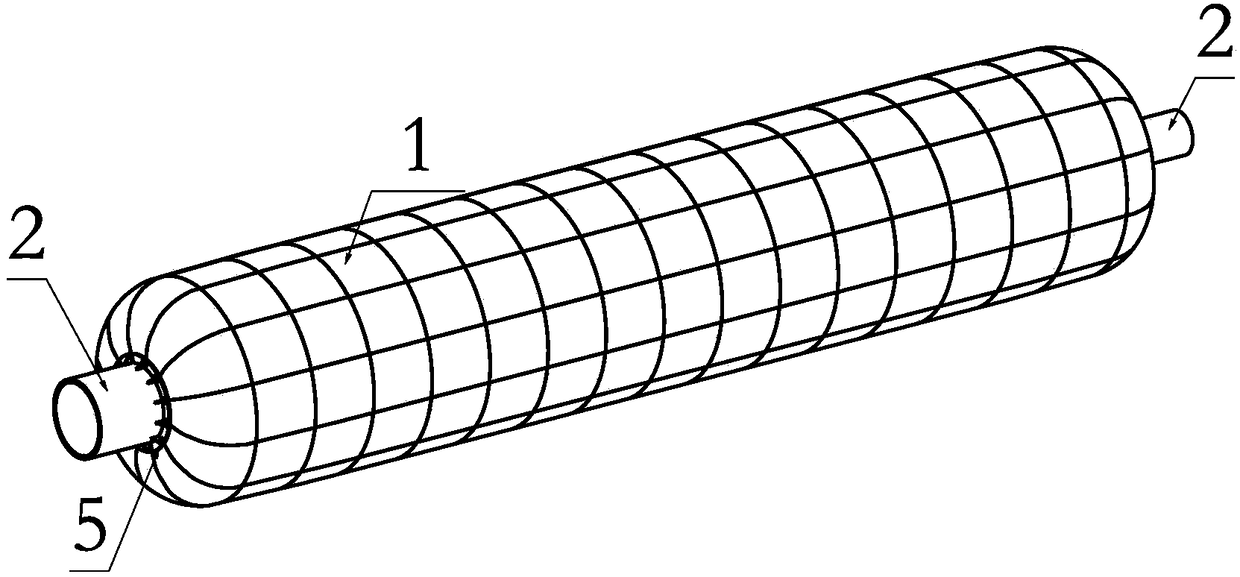

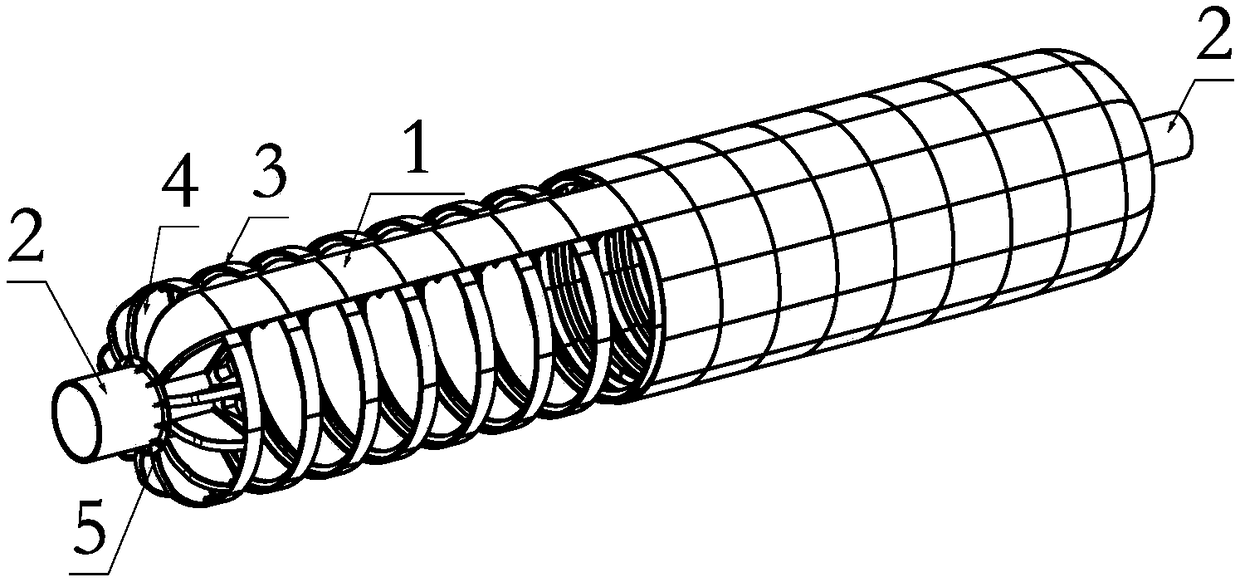

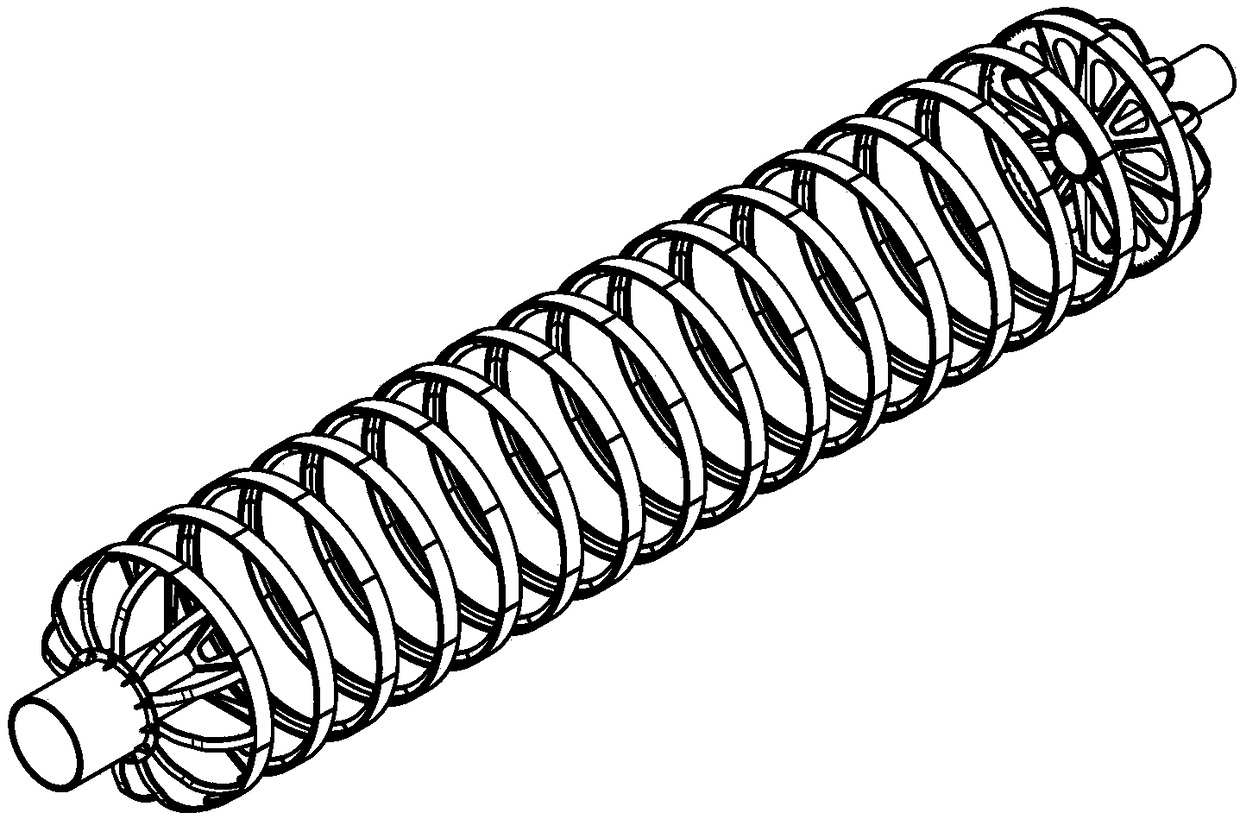

[0026] In this embodiment, a kind of birdcage type rocket motor shell winding molding die is combined with figure 1 and figure 2 As shown, it is composed of a shell 1, a mandrel 2, a frame 3, a support mechanism 4 and a head positioning device 5. The support mechanism 4, the shell 1 is a split composite material laminate structure, and the middle part is connected with the frame 3 by screws. The edge strip is fixed, and the two ends are fixed with the head positioning device 5 by screws.

[0027] The preparation process and method of above-mentioned mold are as follows:

[0028] (1) Calculate the size of each part according to the product length, diameter and allowable deformation.

[0029] (2) The frame 3, the support mechanism 4 and the head positioning device 5 are machined;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com