Wafer optical film graphical processing efficient photoresist removing process method

A technology of optical film and process method, applied in the direction of photosensitive material processing, photoengraving process coating equipment, etc., can solve the problems of long time, difficult to remove glue, low efficiency, etc., and achieve the effect of improving processing efficiency and shortening the time of removing glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

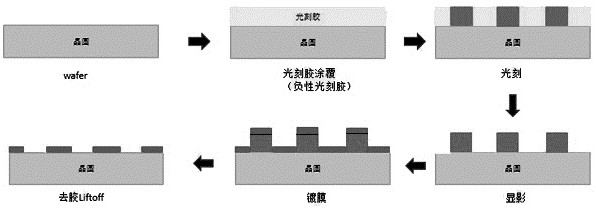

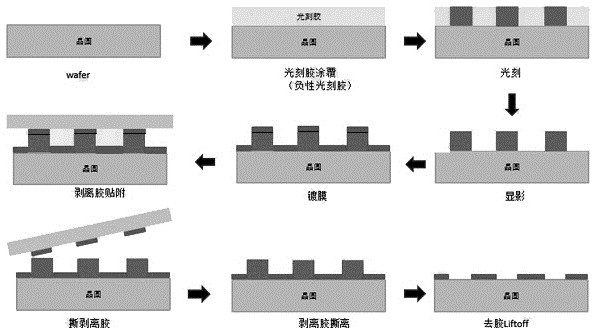

[0020] Example: as attached figure 2 As shown, a process method for patterning wafer optical film processing and efficient deglue, the steps of the process method are:

[0021] S1: select the wafer;

[0022] S2: Coating photoresist on the wafer by spin coating;

[0023] S3: Use the photolithography process to expose the photoresist, and the photoresist pattern depends on the Mask design; the photoresist in the pattern area illuminated by UV will form a substance that is not easily soluble in the developer solution, and will not be exposed to UV. The photoresist in the illuminated pattern area is easily soluble in the developer;

[0024] S4: Develop after photolithography, remove the photoresist in the pattern area that is easily soluble in the developer solution through the developer solution, and obtain a photoresist-patterned wafer;

[0025] S5: performing optical thin film deposition and coating on the photoresist patterned wafer to obtain a wafer after optical thin fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com