Detape method for integrated circuit packaging post-treatment

An integrated circuit and glue removal technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid devices, etc., can solve the problem that the potion cannot remove tape glue and overflow in one step, the damage of the plastic package and the substrate, and the short life of the chemical potion, etc. problems, to achieve the effect of facilitating automatic operation, prolonging life, and shortening the glue removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

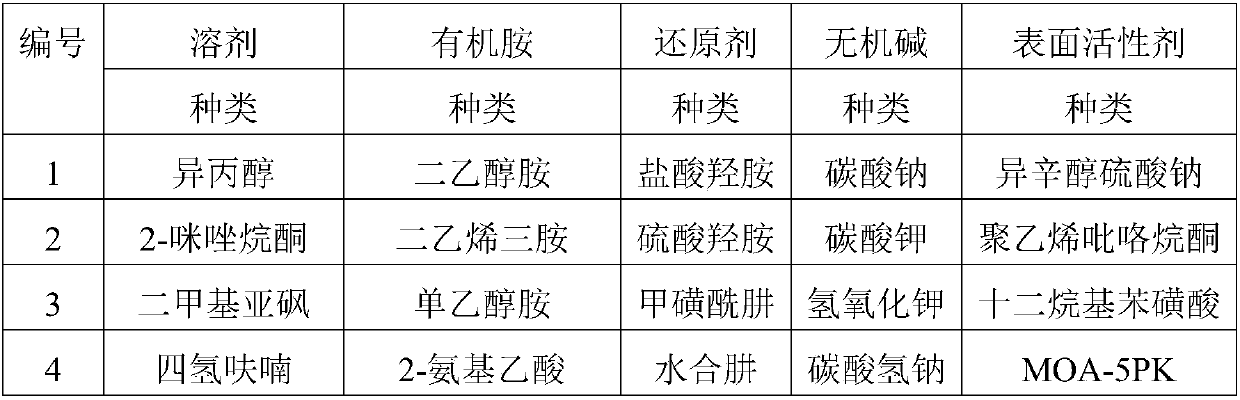

[0070] Table 1 The raw material components of glue remover

[0071]

[0072]

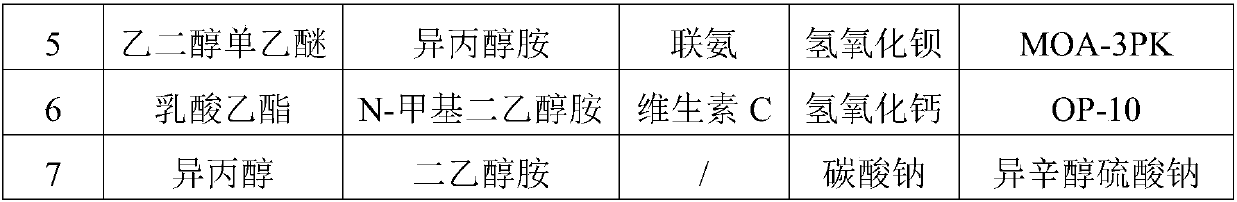

[0073] Table 2 The pH value of each raw material component mass fraction and glue remover

[0074]

[0075] According to the raw material components and their mass fractions recorded in the above Tables 1 and 2, each raw material component was weighed and mixed to obtain 7 different adhesive removers, and the adhesive removers in the following examples were also prepared by the same method .

Embodiment 13-14

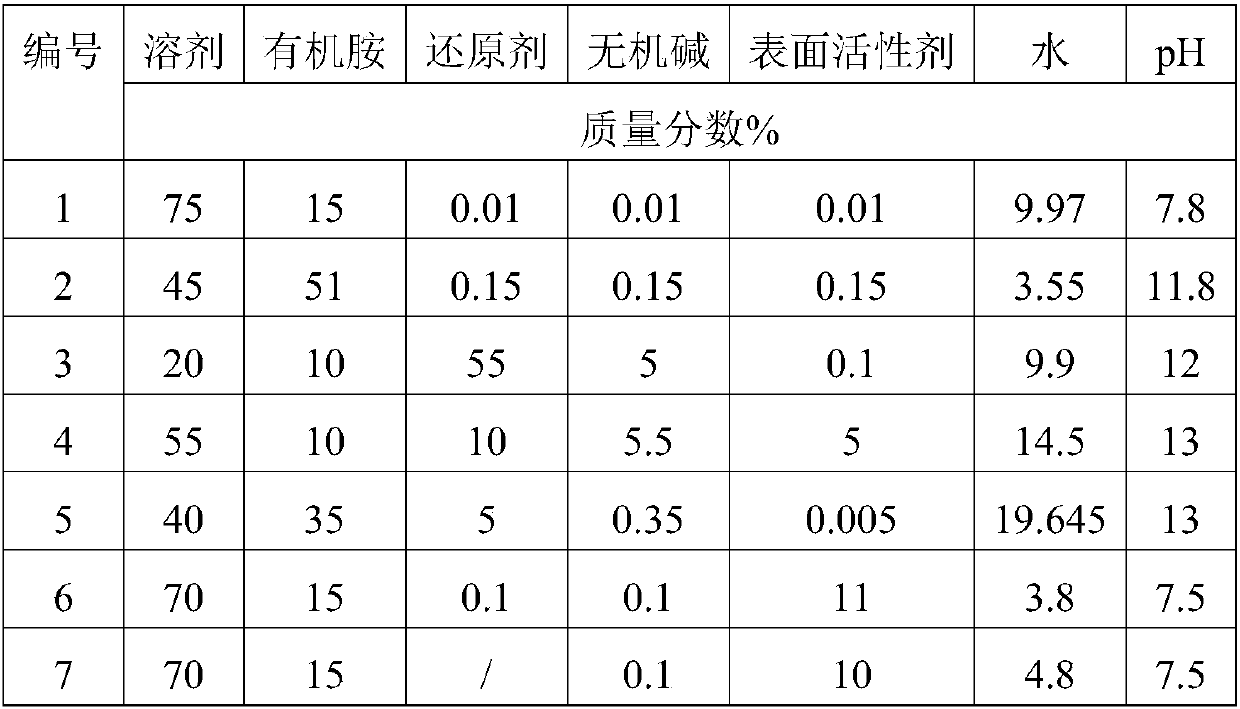

[0089] Each raw material component of table 4 adhesive remover

[0090]

[0091] The mass fraction of each raw material component of table 5 and the pH value of gel remover

[0092]

[0093] The preparation method of the adhesive remover in Examples 13-14 is the same as the preparation method of the adhesive remover in Examples 1-7. The operation process in the following application examples is the same as the above application examples 1-120.

Embodiment 1

[0104] Example 1'-Example 6'

[0105] Each raw material component of table 8 glue remover

[0106]

[0107] The mass fraction of each raw material component of table 9 and the pH value of gel remover

[0108]

[0109] The degumming agent of embodiment 1'-6' is operated according to the degumming temperature and time of table 10, can obtain better degumming effect (see table 10 specifically), and after adding bubbling, overflow and megasonic When one or more of the operations are performed, the effects of tape removal, flash removal and tin plating can still be obtained in the case of shortening the removal time (5 minutes). The effect of de-flashing and tin-plating; only when the single method of Megasonic is added, the effect of removing tape glue, de-flashing and tin-plating is not significantly improved. When observed by a metallographic microscope, no damage to the substrate of the lead frame before and after tin plating was observed. In addition, changing the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com