Patents

Literature

77 results about "ADHESIVE REMOVER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick-release self-contained medical electrode

InactiveUS20130172724A1Decrease (or eliminate completely) painHigh bonding strengthContact member manufacturingElectrocardiographyFast releaseData acquisition

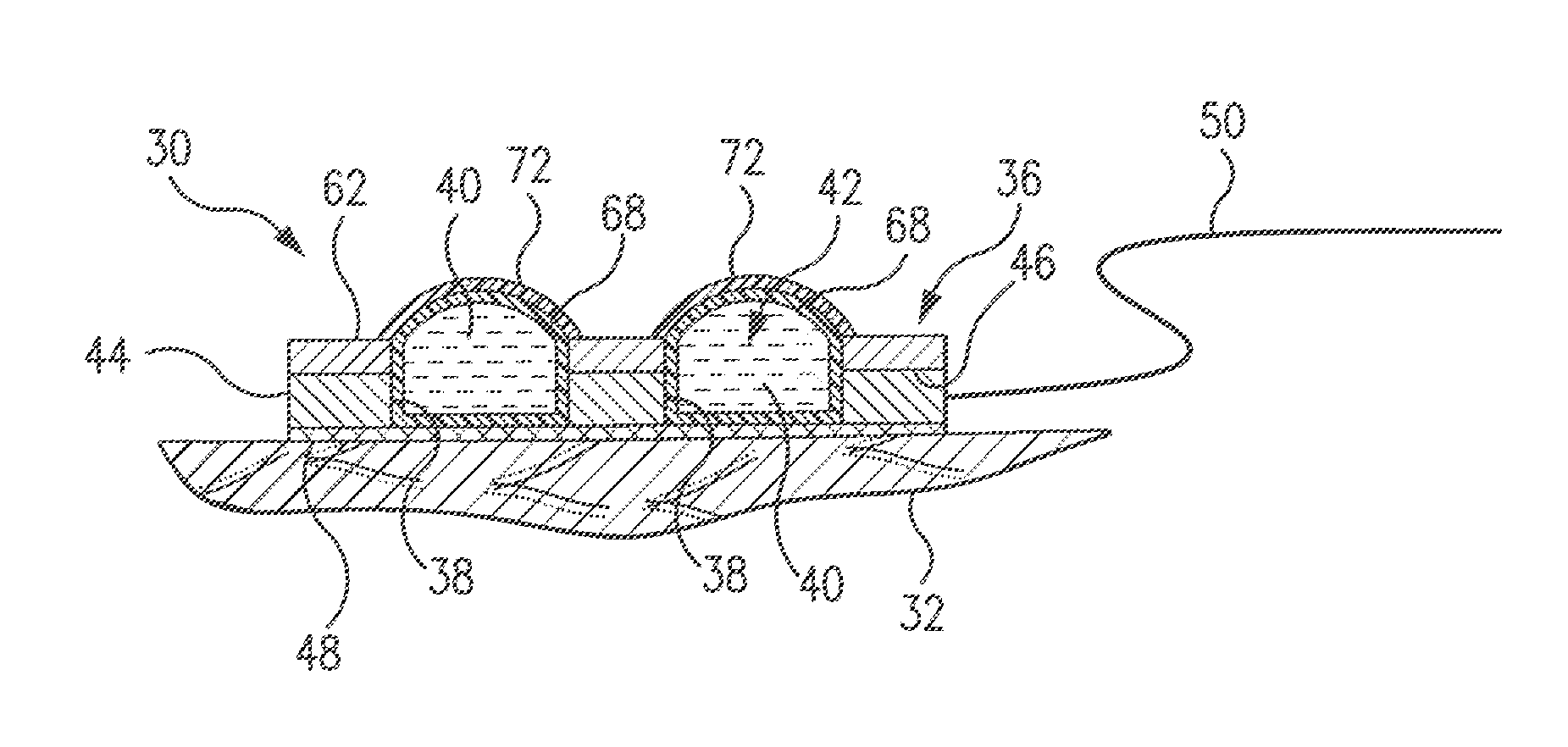

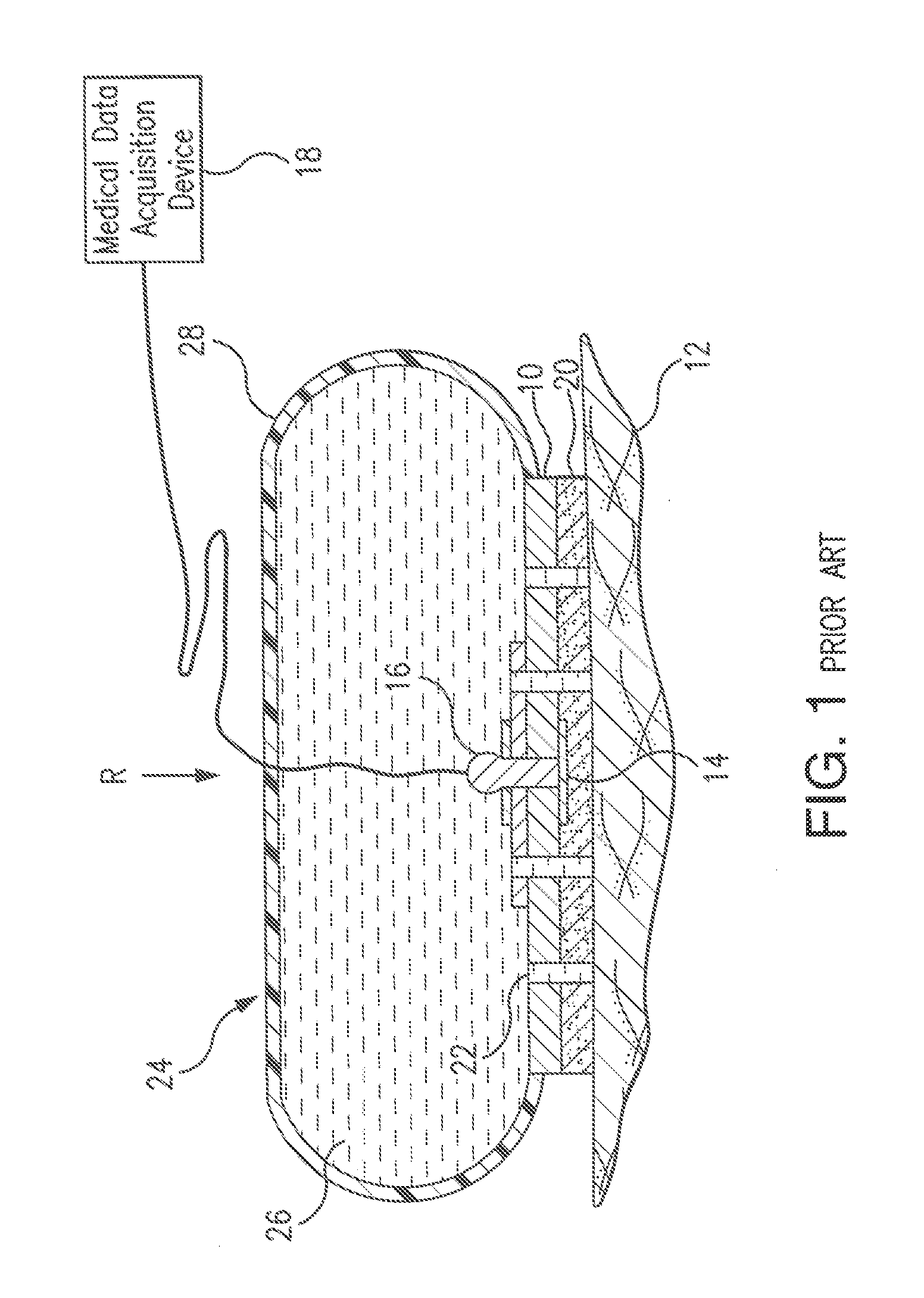

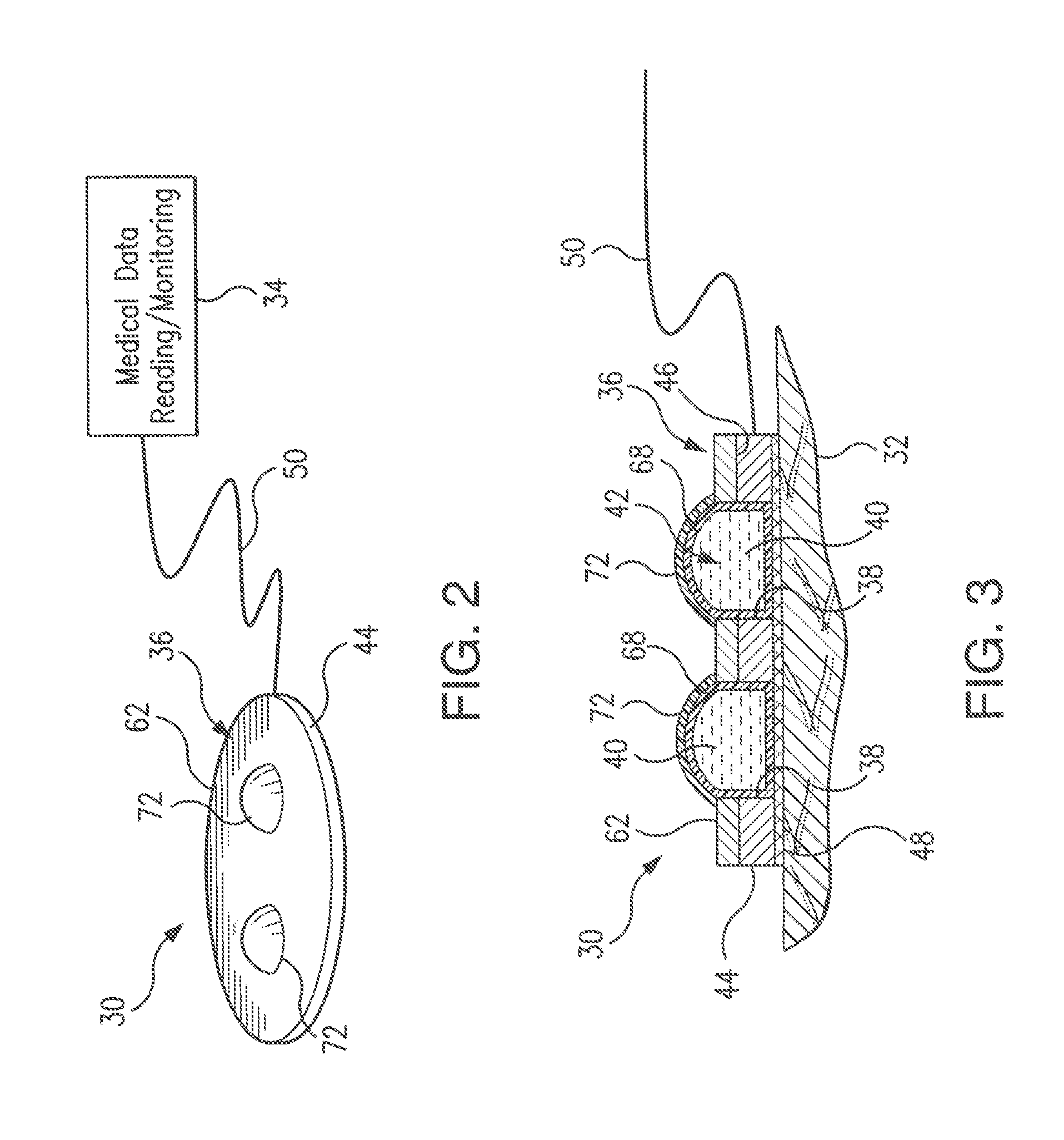

A medical electrode demonstrates a superior adhesiveness to a patient's skin during medical data acquisition or treatment procedure yet attaining painless electrode removal from the skin when needed. The subject medical electrode is designed with adhesive neutralizer (or remover) solvent fully enveloped in one or several compartments embedded in an adhesive layer of the medical electrode unit. The compartments have a contact with the patient's skin when the electrode is attached thereto. When compressed by a medical personnel, the compartment releases the adhesive remover solvent directly to the skin-adhesive interface, thereby neutralizing (or removing) the adhesive material, thereby easing the electrode removal. The adhesive layer is made from PEO, sodium chloride, and water. The adhesive remover solvent contains isopropyl alcohol. A method of manufacturing the medical electrode is presented.

Owner:MARYLAND UNIV OF

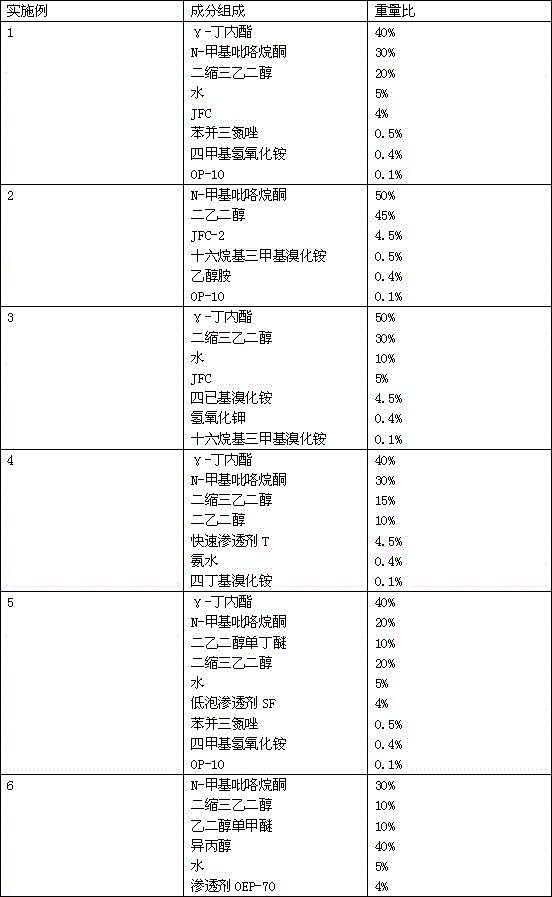

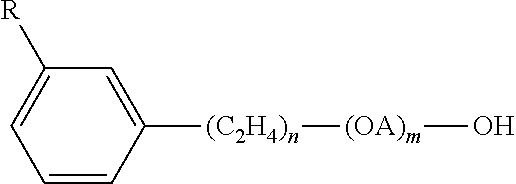

Adhesive remover and preparation method thereof

ActiveCN101899365ASmall smellEasy to removeOrganic detergent compounding agentsNon-ionic surface-active compoundsSilanesAlkylphenol

The invention relates to an adhesive remover and a preparation method thereof. The basic composition of the adhesive remover formula is as follows in percentage by weight: 12-25% of fatty alcohol-polyoxyethylene ether sodium sulfate and fatty alcohol-polyoxyethylene ether silane, 20-30% of alkylphenol polyoxyethylene ether, 4-5% of ethylene oxide / propane segmented copolymer, 5-7.9% of sodium chloride, 10-12% of triethyl phosphate and dimethyl adipate, 5-10% of tricarboxyl triethylamine, triethylamine, diethanol amine, EDTA, urea, triethanolamine and hexamethylene tetramine, 2-10% of ethylene glycol, butyl cellosolve, propylene glycol methyl ether, ethanol, isopropanol, benzyl alcohol and methyl isoamyl ketone and 0.1-42% of deionized water. Compared with the prior art, the invention has the advantages that the adhesive remover is aqueous and low irritating, is wide in application range, can rapidly remove various trade mark adhesives, eliminate adhesiveness, degrease, remove adhesive and deliquate adhering oil stain in the aspect of removing advertising posters on the surfaces of glass, ceramics, marbles, stainless steel, etc. The invention also provides an environment-friendly and safe method for preparing the adhesive remover.

Owner:NINGBO PASCO UNITED IND

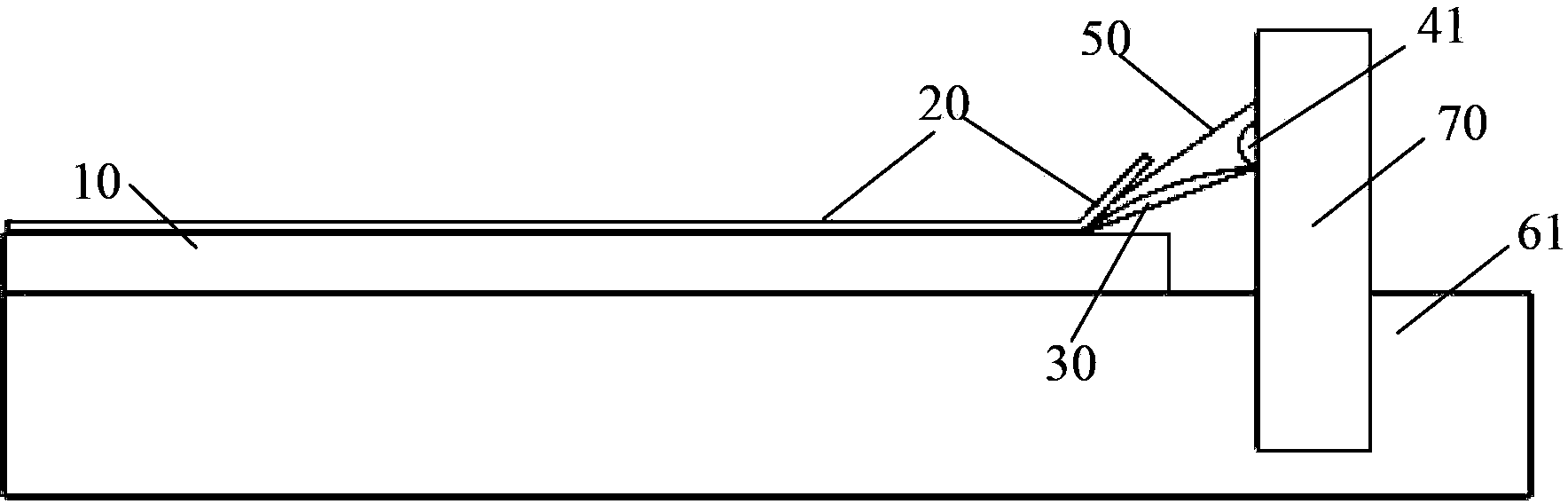

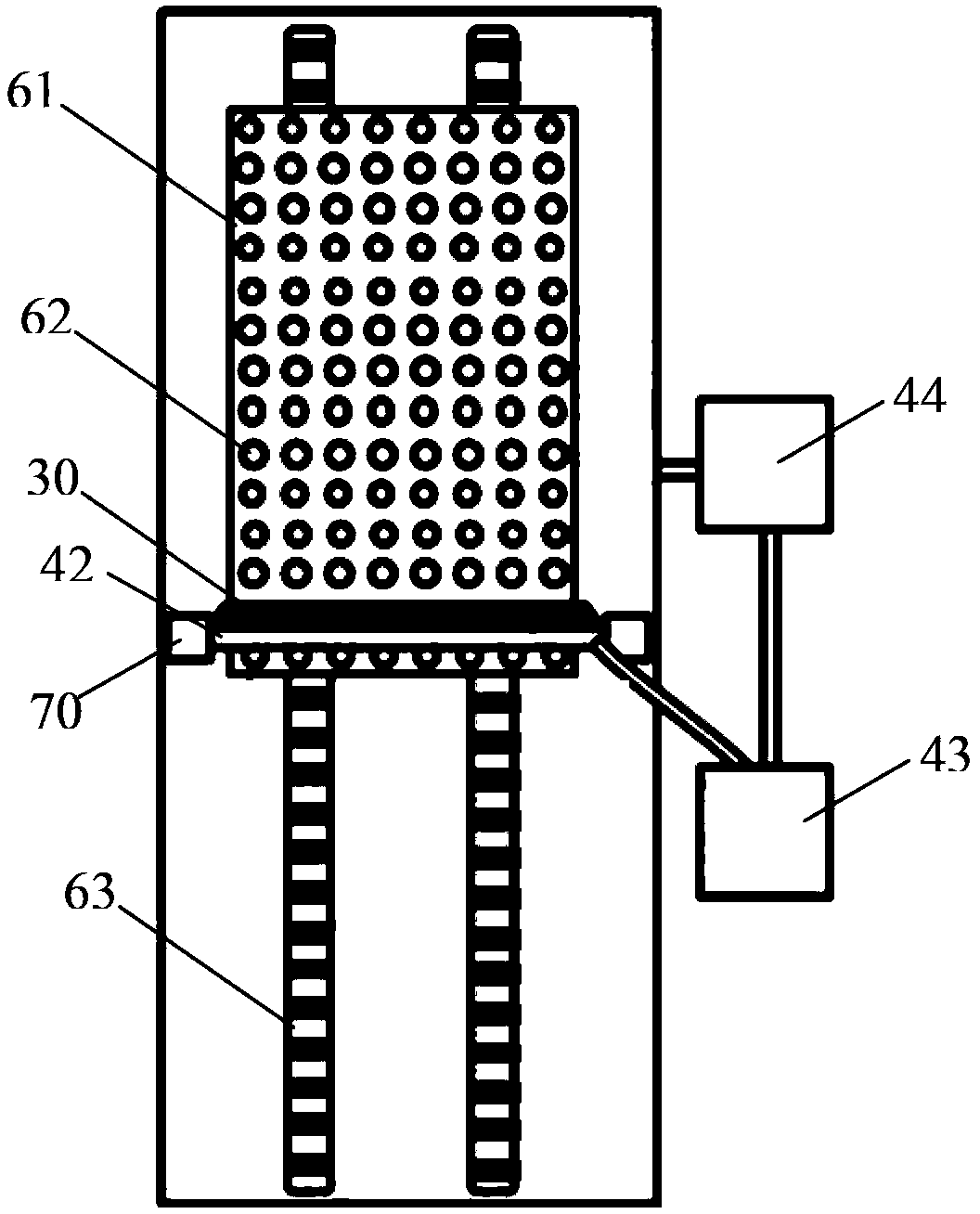

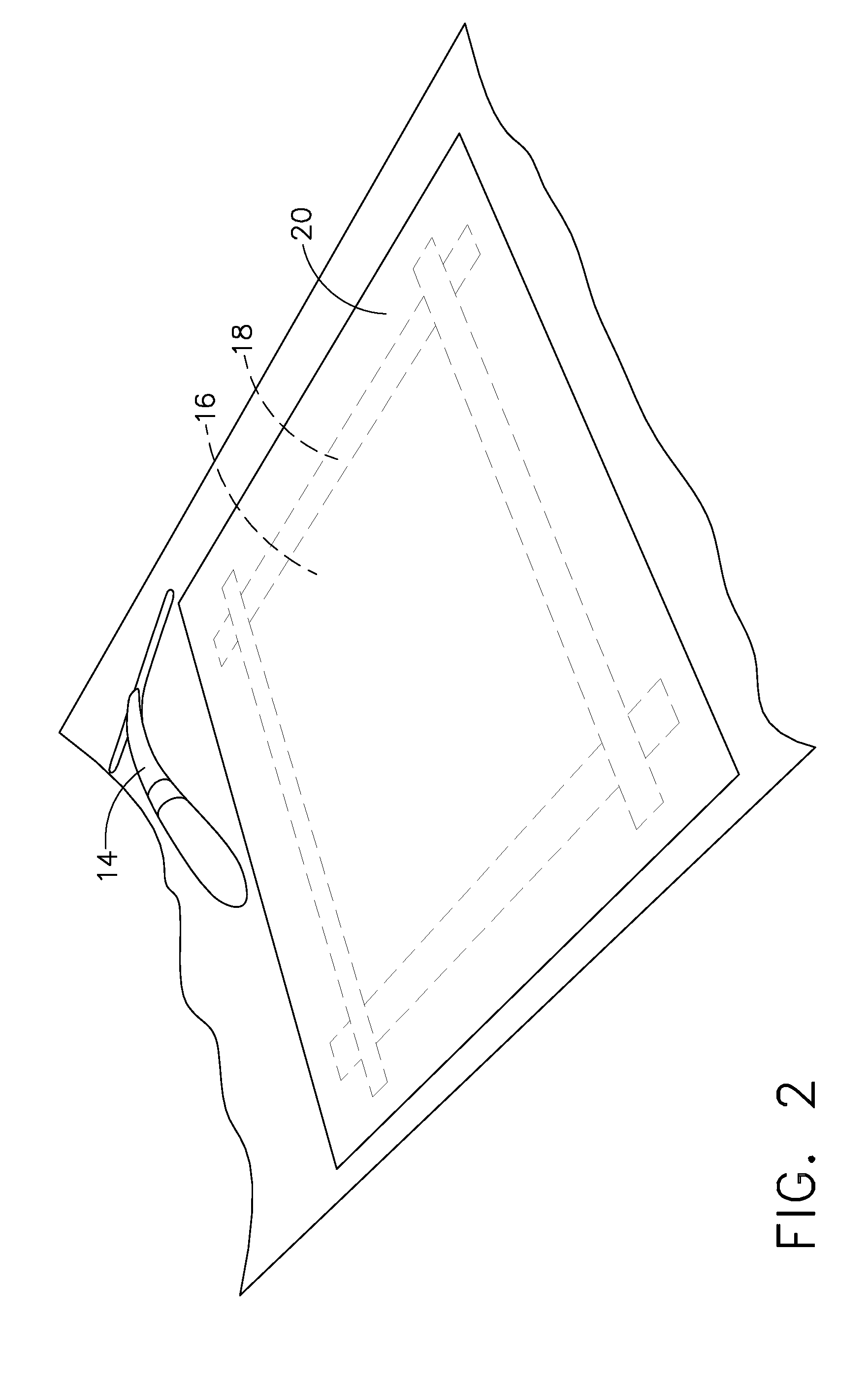

Polarizer peeling machine and peeling method

ActiveCN103407279AEasy to peelEnsure safetyLamination ancillary operationsLayered product treatmentThin-film-transistor liquid-crystal displayLiquid crystal

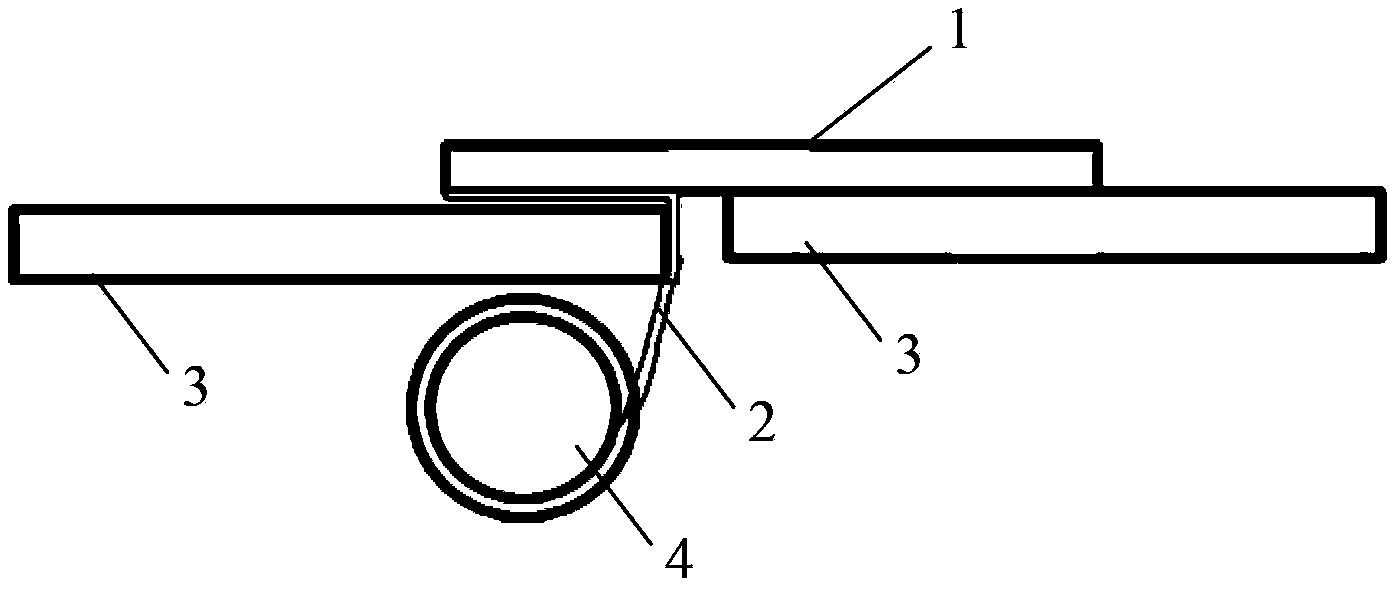

The invention relates to the technical field of thin-film transistor liquid crystal display, and discloses a polarizer peeling machine and a polarizer peeling method. The peeling machine comprises a peeling blade and an agent system. The peeling blade is used for peeling the polarizer. The agent system comprises an agent nozzle. When the peeling blade peels the polarizer, the agent nozzle sprays an adhesive remover between the polarizer and the liquid crystal surface plate. Two ends of the blade of the peeling blade are arc. The agent nozzle is positioned above the peeling blade. According to the invention, when the polarizer is peeled, the adhesive remover is sprayed, such that the adhesive between the polarizer and the liquid crystal surface plate can be removed, and the adhesion effect between the polarizer and the liquid crystal surface plate fails. Therefore, the polarizer can be easily peeled, and peeling effect can be improved. Also, with the adhesive remover, static electricity can be eliminated, such that safety of operators and circuit devices can be ensured.

Owner:BOE TECH GRP CO LTD +1

Adhesive remover and adhesive removing method of adhesive remover

InactiveCN106467872AReduce floodingReduce volatilityOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsSolventADHESIVE REMOVER

An adhesive remover is used for removing an adhesive on the surface of a base material. The adhesive remover comprises, by weight, 10-80 parts of a first solvent, 10-50 parts of a second solvent and 1-30 parts of a macromolecular compound. The first solvent is volatile and has faster volatilization speed than the second solvent. The second solvent has capability of removing an adhesive. The macromolecular compound is dissolved in the first solvent but is insoluble in the second solvent. The invention also provides an adhesive removing method using the above adhesive remover.

Owner:正一特殊材料材料股份有限公司

Gelled adhesive remover composition and method of use

ActiveUS20080146480A1Effective vapor pressureConvenient amountOrganic detergent compounding agentsChemical paints/ink removersJet aeroplaneAirplane

The present invention includes a process using environmentally friendly materials for the removal of adhesive residues from hard substrates, particularly vehicles, e.g., cars, trucks, buses, aerospace vehicles including airplanes, and the like. The process uses a novel adhesive remover composition comprising one or more non-halogenated organic solvents, a non-abrasive thickening agent, a surfactant, and a vapor-pressure modulating agent. The total Hansen Solubility Parameter (δt) at 25° C. for each of the non-halogenated organic solvents is from about 14 MPa1 / 2 to about 24 MPa1 / 2. The invention provides a cost effective, safe, environmentally friendly adhesive remover composition specifically formulated for removal of, e.g., pressure sensitive adhesive residues from large areas of aircraft composite and aluminum surfaces, as well as others.

Owner:THE BOEING CO

Glue removing agent for LED (light emitting diode) encapsulation residue glue

InactiveCN105695150AEfficient removalSimple configurationInorganic/elemental detergent compounding agentsCationic surface-active compoundsEpoxyMethylene Dichloride

The invention discloses a glue removing agent for LED (light emitting diode) encapsulation residue glue. The glue removing agent is basically prepared from the following ingredients in percentage by weight: 30 to 80 percent of solvents, 10 to 60 percent of diluting agents, 5 to 10 percent of penetrating agents, 0.1 to 5 percent of metal protecting agents, 0.1 to 5 percent of catalysts and 0.1 to 0.5 percent of surface active agents. The product can be used for removing silica gel and epoxide resin encapsulation glue remained by an LED encapsulation material on equipment; the effect is good; no corrosion is left on the equipment; toxicity on the human body is low; compared with conventional methylene dichloride, carbon tetrachloride, tetrachloroethylene, acetone, toluene, xylene and vinyl acetate, the effect is equivalent; the consumption is low; the environment-friendly effect is achieved; the use is convenient.

Owner:SHENZHEN SHENGYUAN SEMICON

Water-based adhesive remover

InactiveCN109722672AHigh glue removal efficiencyPromote degradationInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedChemical oxygen demand

The invention discloses a water-based adhesive remover. The water-based adhesive remover comprises strong alkali, a main solvent, a volatilization inhibitor, a cosolvent, a corrosion inhibitor, a penetrating agent, a thickening agent, a surfactant and water. The water-based adhesive remover is a water-based formula, and the water-based formula is not prone to volatilizing or burning; when the water-based adhesive remover is used for removing the adhesive on the surface of a magnesium material, it can be guaranteed that the magnesium material cannot be burnt, the safety is high, and a magnesiumalloy substrate cannot be corroded. The water-based adhesive remover can be used by heating, thus curing adhesives which are difficult to remove can be quickly removed, and the adhesive removing efficiency is high. The water-based adhesive remover further has good degradability and little harm to the environment. The water-based adhesive remover does not contain chlorine or benzene, has low toxicity and is environmentally friendly and healthy. The water-based adhesive remover does not contain specific fluorine-chlorine carbohydrates, ethane or other harmful substances which damage the ozone layer, and has a low chemical oxygen demand. The surface of the magnesium material treated by the water-based adhesive remover does not contain grease residues and can be directly washed with water.

Owner:KANGZHUN ELECTRONICS TECH KUNSHAN

Composition and method for removing adhesive residue

ActiveUS20080146479A1Cost effectiveReduce usageCosmetic preparationsToilet preparationsJet aeroplaneOrganic solvent

The present invention includes a process using environmentally benign materials for the removal of adhesive residues from hard substrates, particularly vehicles, e.g., cars, trucks, buses, aerospace vehicles including airplanes, and the like. The invention uses an absorbable indicator (tracer) dye to aid in detection of remaining residues that may be in need of additional cleaning. The process uses a novel adhesive remover composition comprising a non-halogenated organic solvent, a non-abrasive thickening agent, a surfactant, glycerine, and an absorbable indicator dye. The invention provides a cost effective, safe, environmentally friendly adhesive remover composition specifically formulated for removal of, e.g., pressure sensitive adhesive residues from large areas of aircraft composite and aluminum surfaces, as well as others.

Owner:THE BOEING CO

Adhesive remover compositions and methods of use

PendingUS20150052689A1Efficient removalSmall volumeNon-ionic surface-active compoundsDetergent mixture composition preparationGlycol ethersSURFACTANT BLEND

The invention is directed to adhesive remover compositions and methods of their use. The adhesive remover compositions generally comprise a glycol ether solvent system comprising an aliphatic glycol ether, an aromatic glycol ether, a hydrophobic glycol ether, and a hydrophilic glycol ether, and a surfactant system. In further embodiment of the invention, the surfactant system may comprise three surfactants. In another aspect of the invention, the composition effectively removes medical adhesives from healthcare textiles. In a particular embodiment of the invention, the surfactant system may comprise one or more nonionic surfactants

Owner:ECOLAB USA INC +1

Gelled adhesive remover composition and method of use

ActiveUS7977294B2Reduce usageControl damageOrganic detergent compounding agentsChemical paints/ink removersEnvironmental resistanceAirplane

The present invention includes a process using environmentally friendly materials for the removal of adhesive residues from hard substrates, particularly vehicles, e.g., cars, trucks, buses, aerospace vehicles including airplanes, and the like. The process uses a novel adhesive remover composition comprising one or more non-halogenated organic solvents, a non-abrasive thickening agent, a surfactant, and a vapor-pressure modulating agent. The total Hansen Solubility Parameter (δt) at 25° C. for each of the non-halogenated organic solvents is from about 14 MPa1 / 2 to about 24 MPa1 / 2. The invention provides a cost effective, safe, environmentally friendly adhesive remover composition specifically formulated for removal of, e.g., pressure sensitive adhesive residues from large areas of aircraft composite and aluminum surfaces, as well as others.

Owner:THE BOEING CO

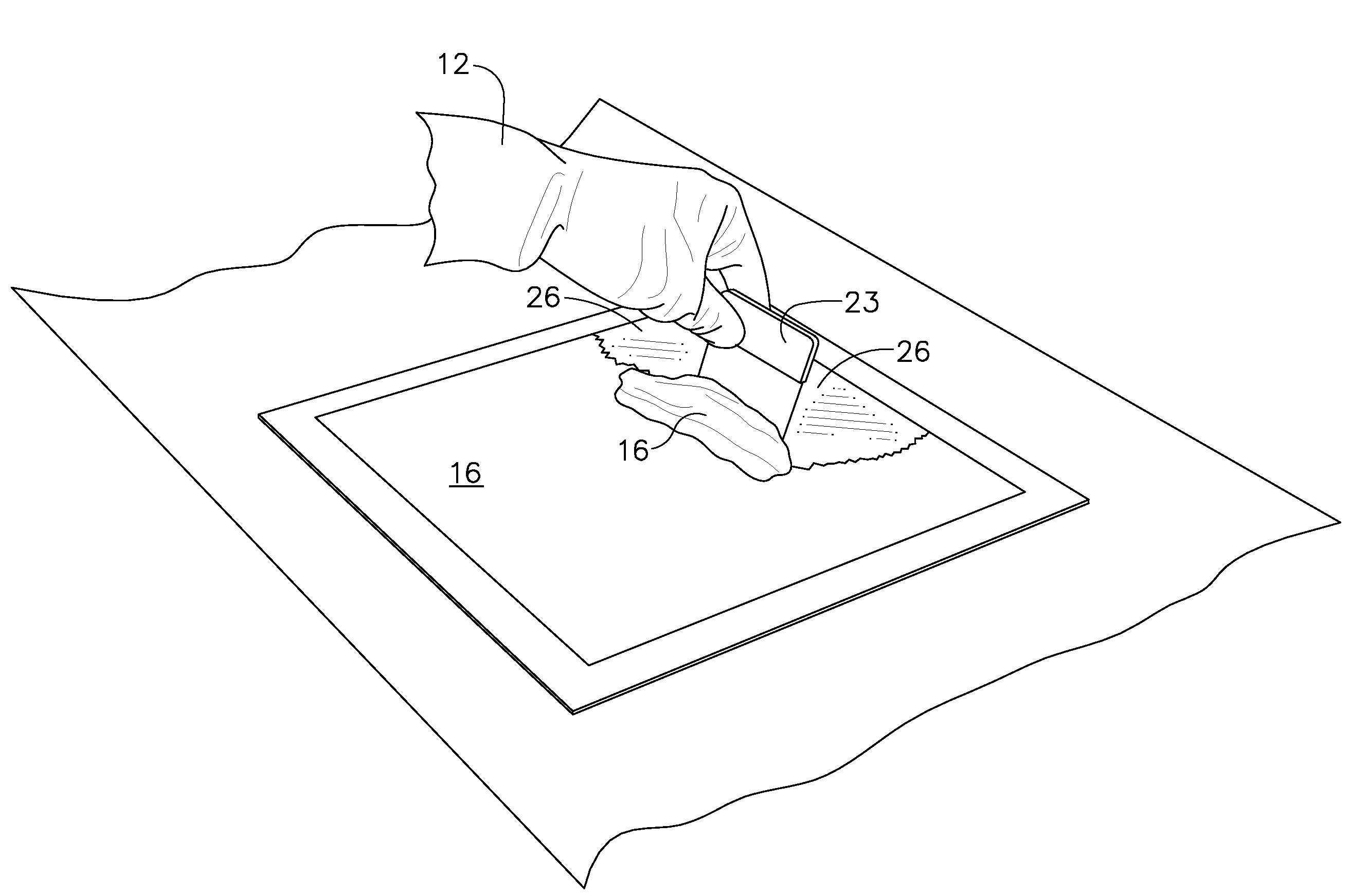

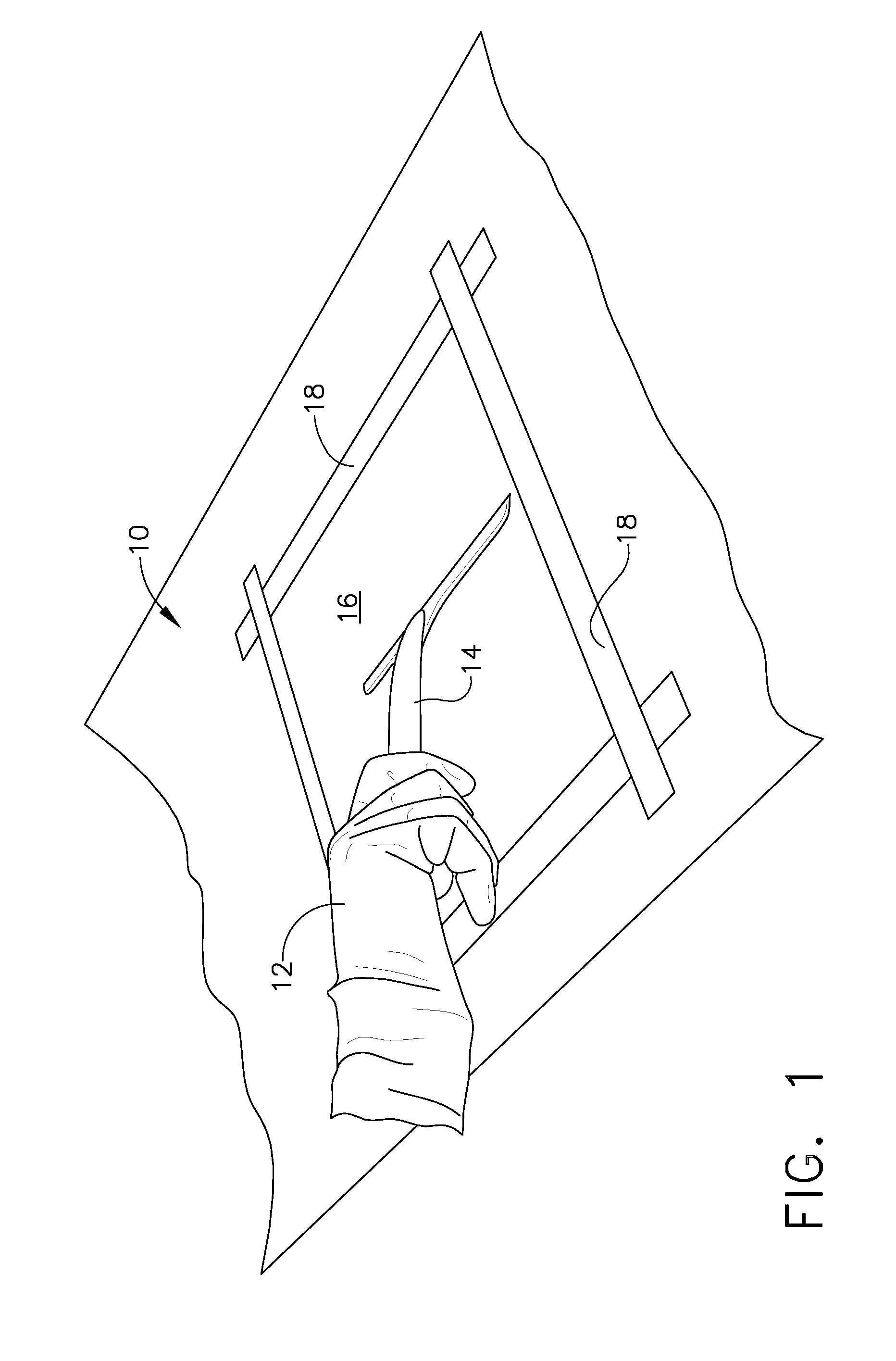

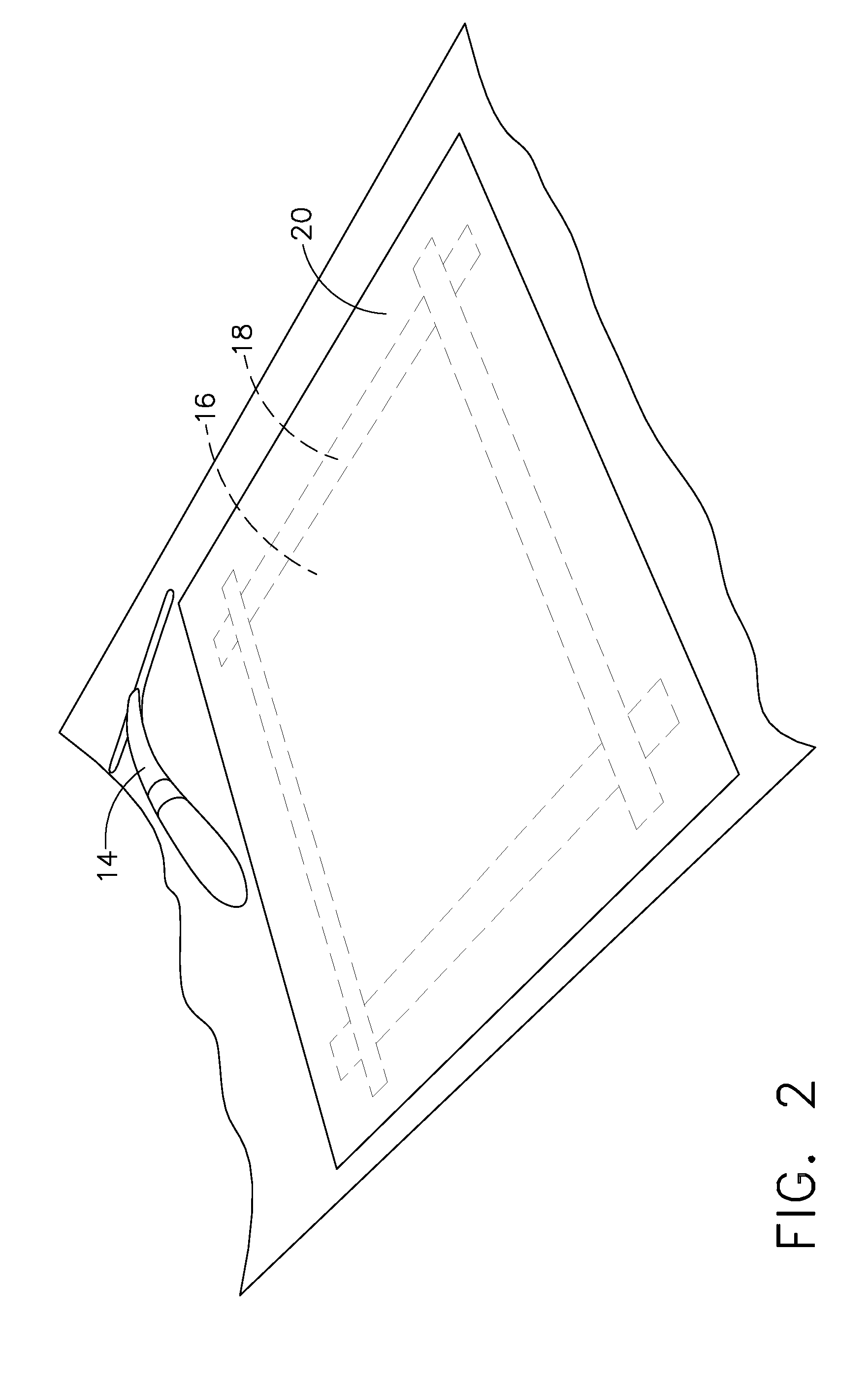

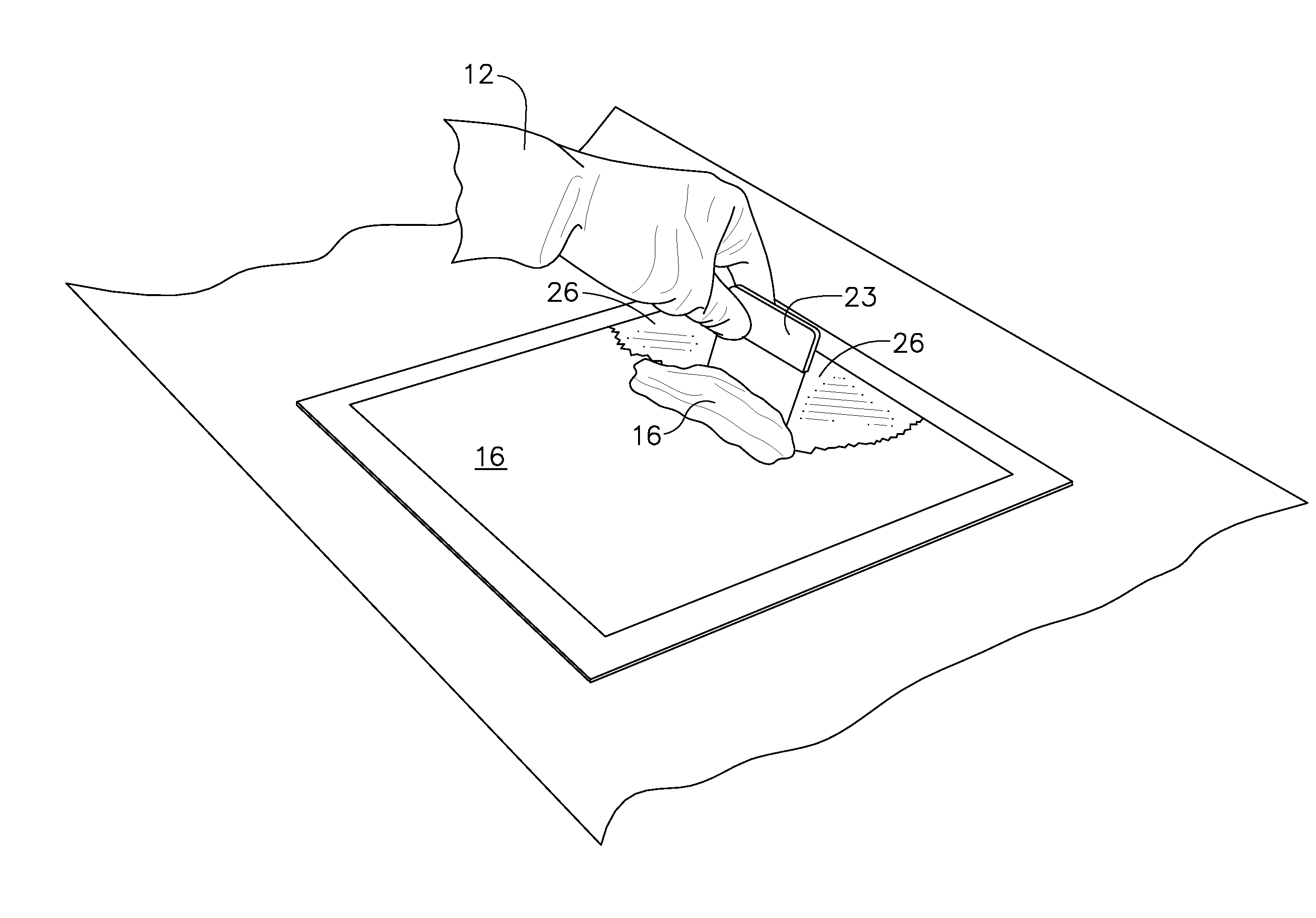

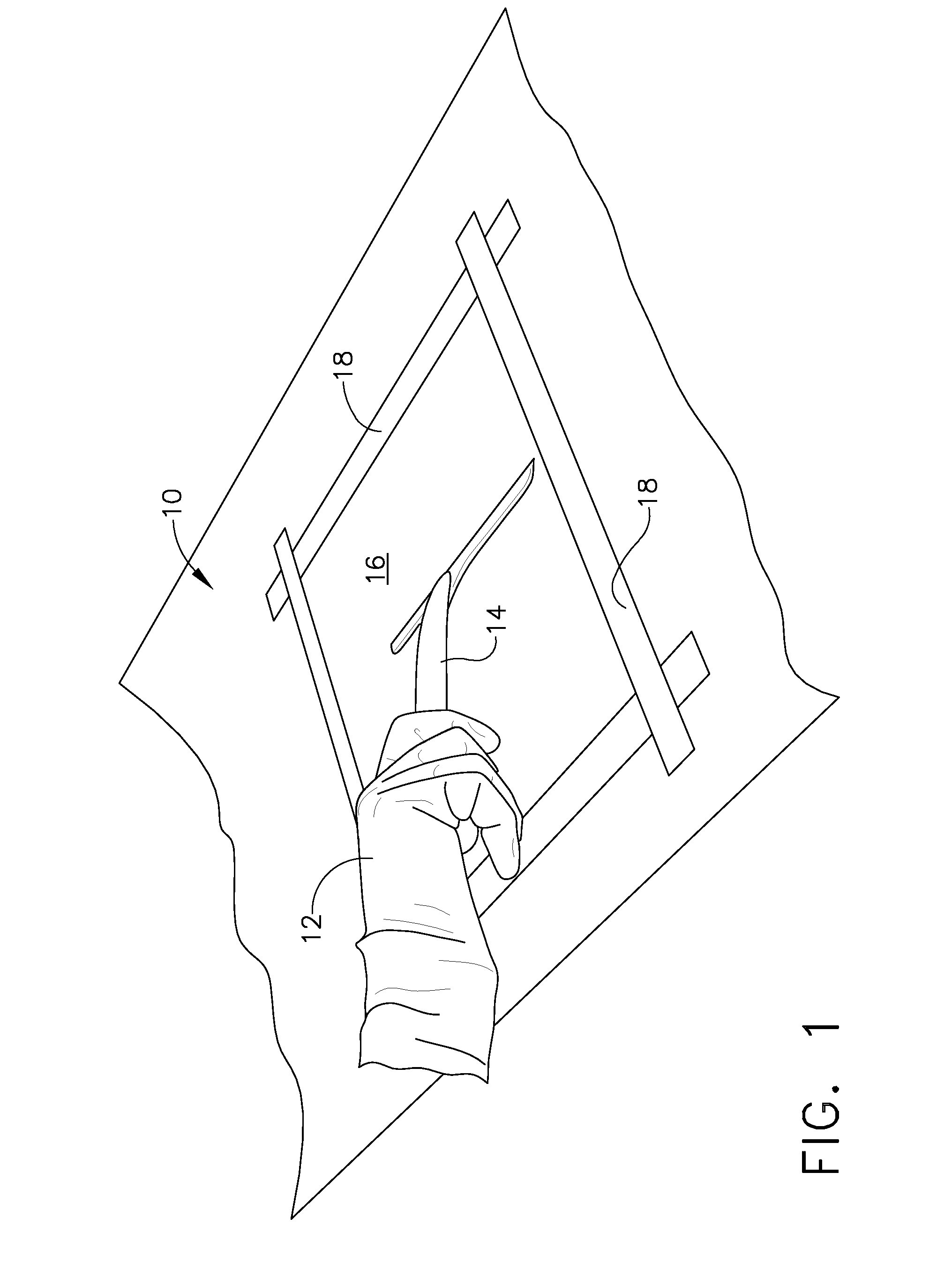

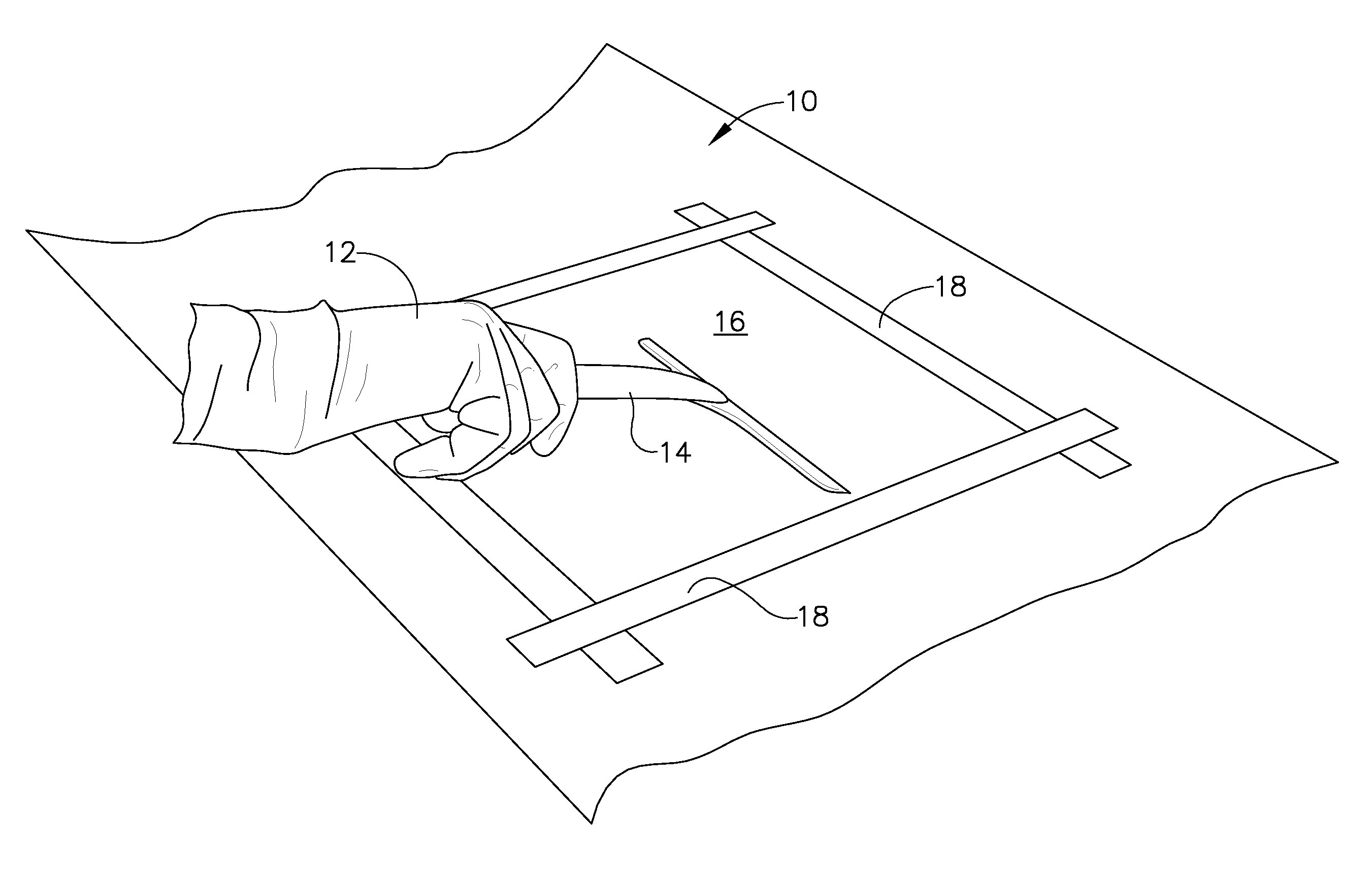

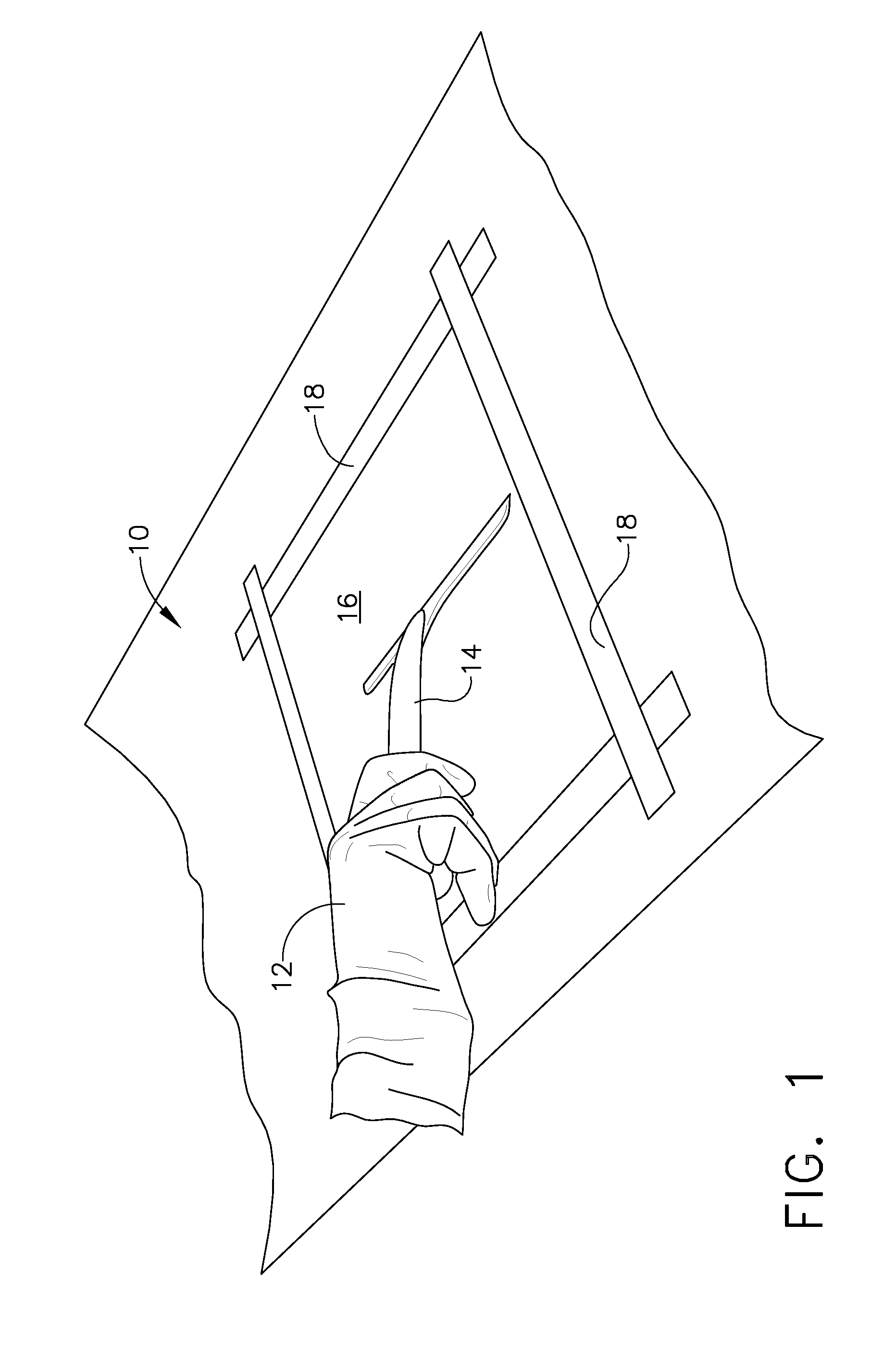

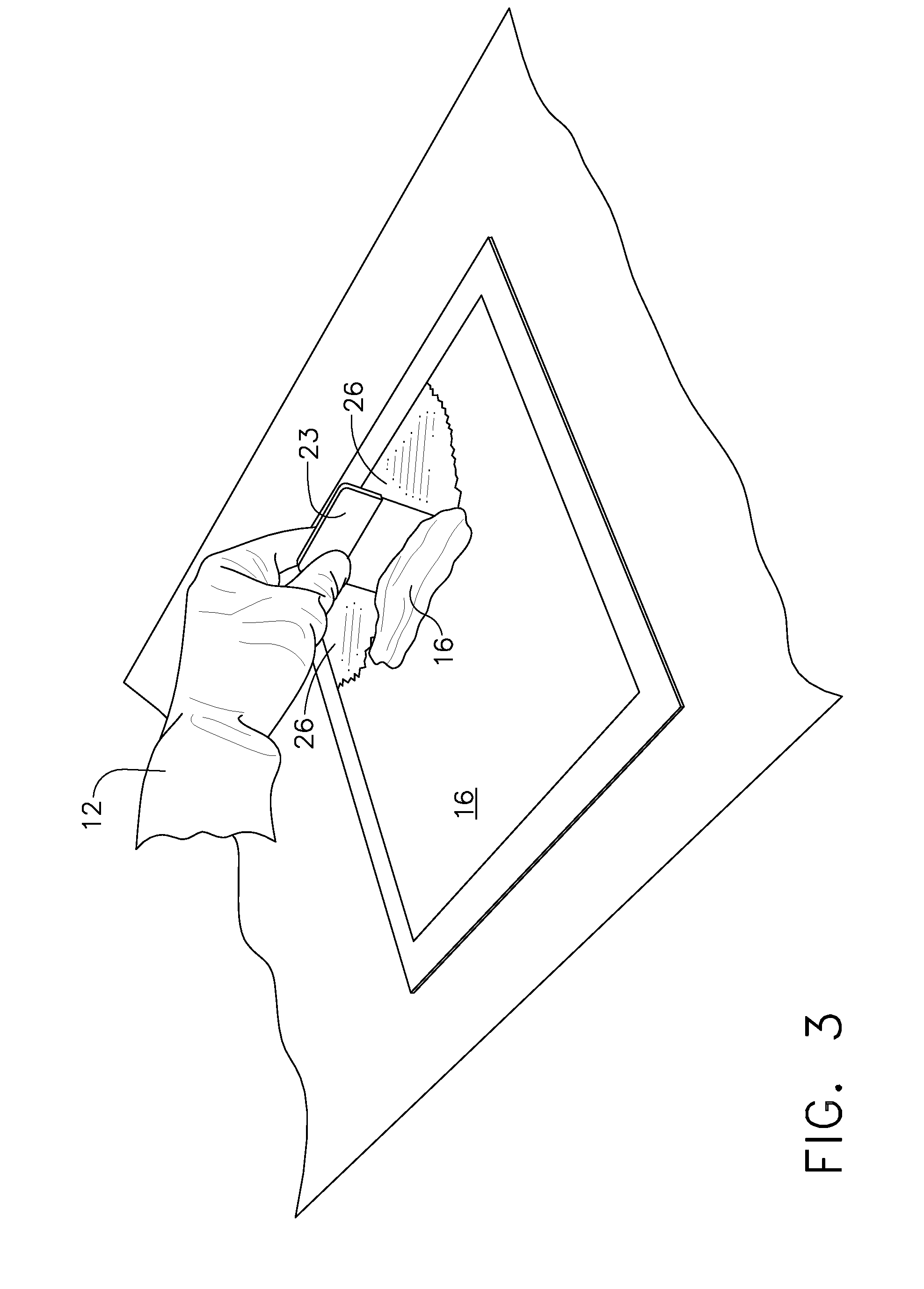

Wound Closure Adhesive Remover

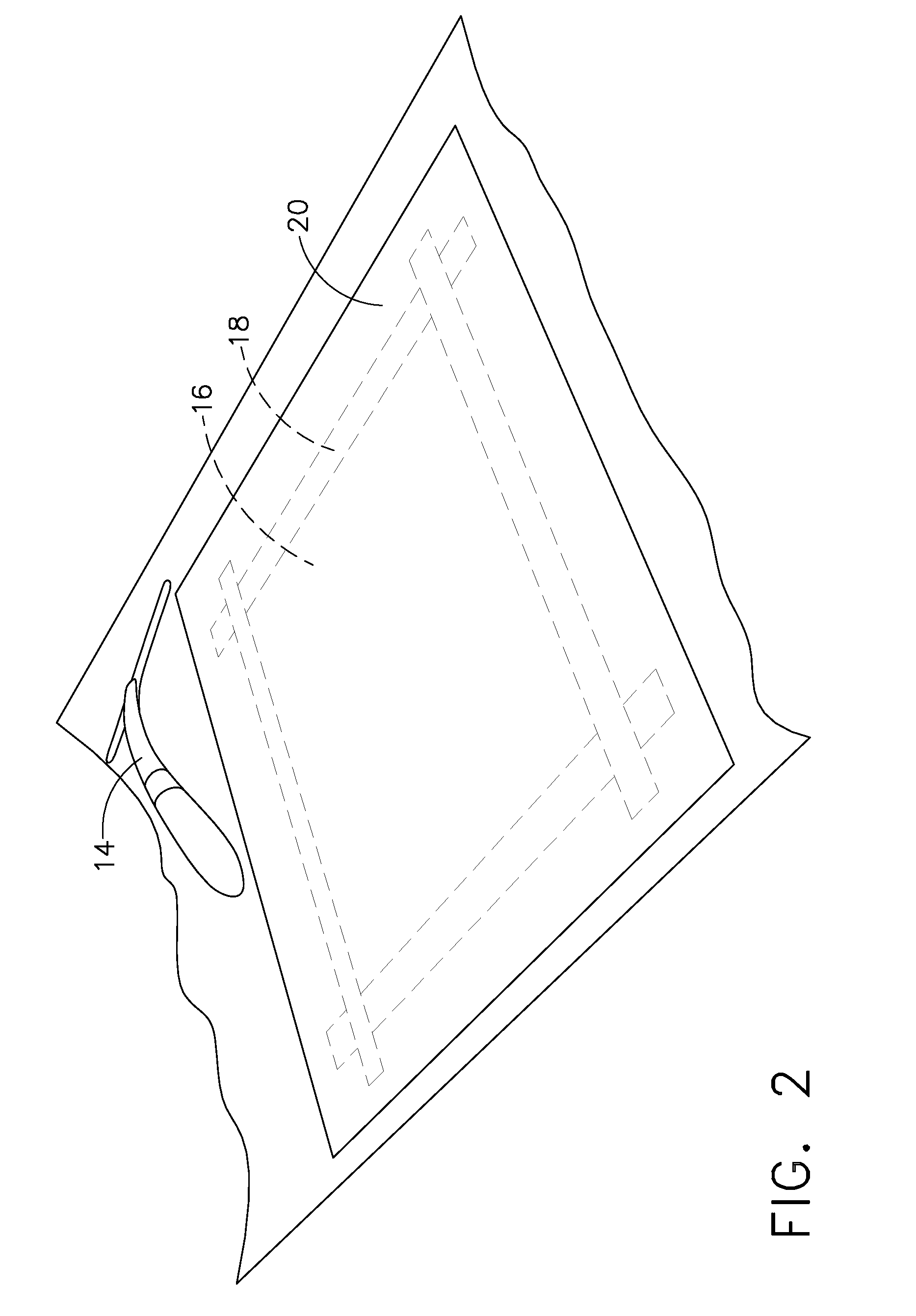

ActiveUS20090118658A1No effect on effectivenessConvenient and efficient applicationPower operated devicesDiagnosticsEngineeringSolvent

A kit for storing and applying an adhesive removing device comprising an enclosure which includes a base portion and a removable top layer releasably secured to the base portion; an adhesive removing device including at least one wiping mechanism which includes at least one absorbent portion; and a biocompatible composition including a solvent and a moisturizing agent embedded in the absorbent portion of the wiping mechanism. A method for storing and applying an adhesive removing device comprises a series of steps for using the adhesive removing device to remove an adhesive from a surface.

Owner:TYCO HEALTHCARE GRP LP

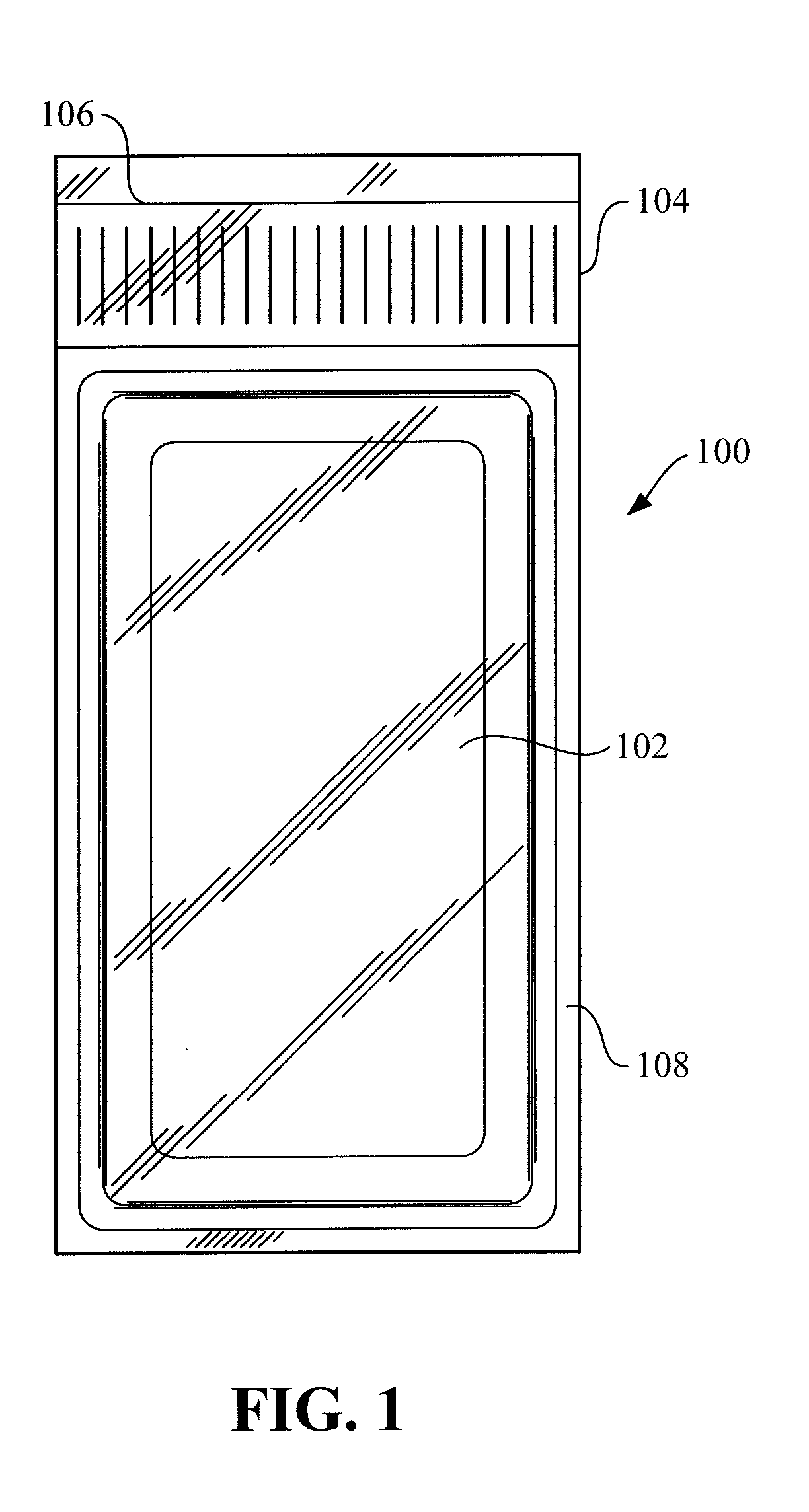

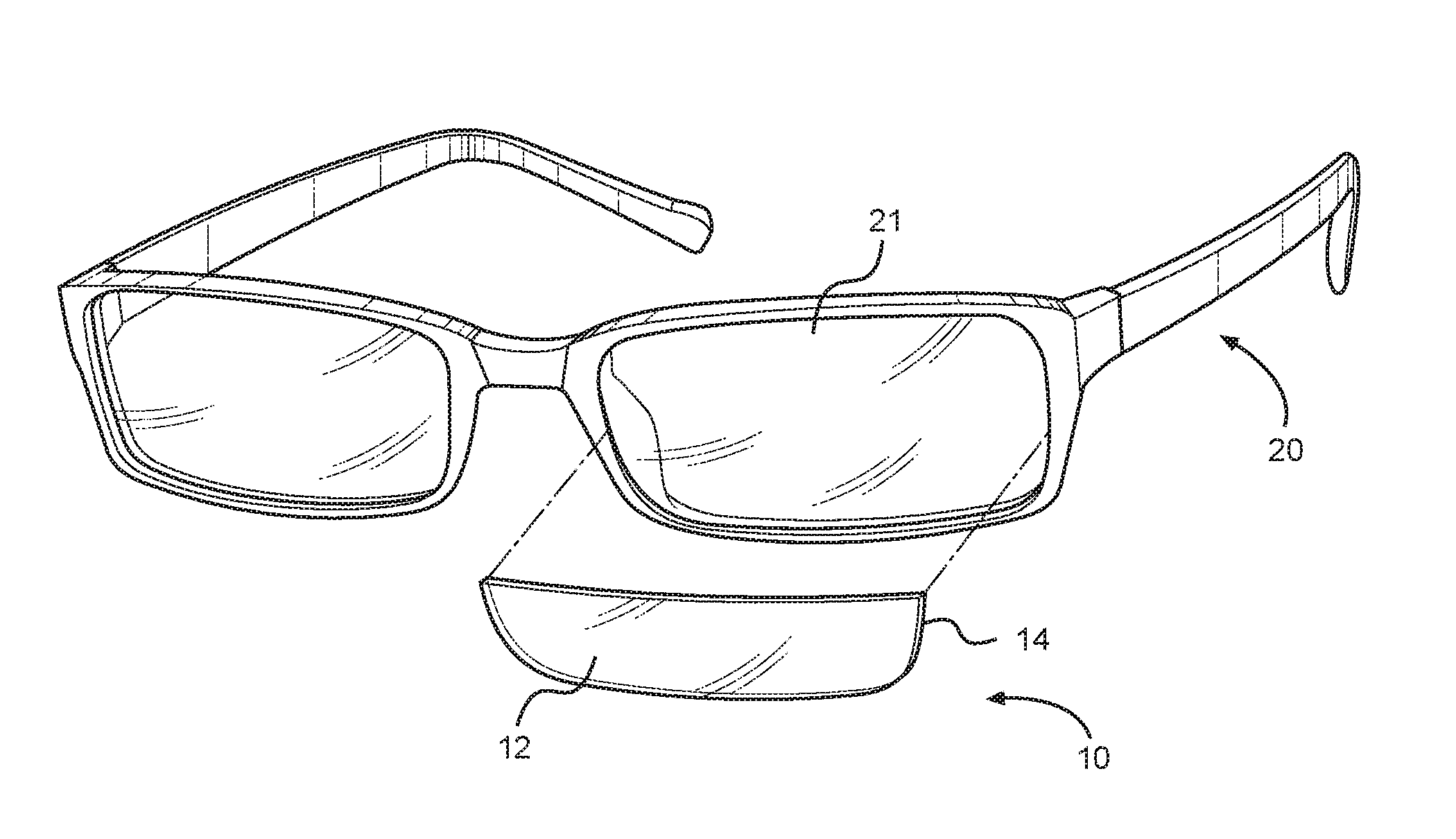

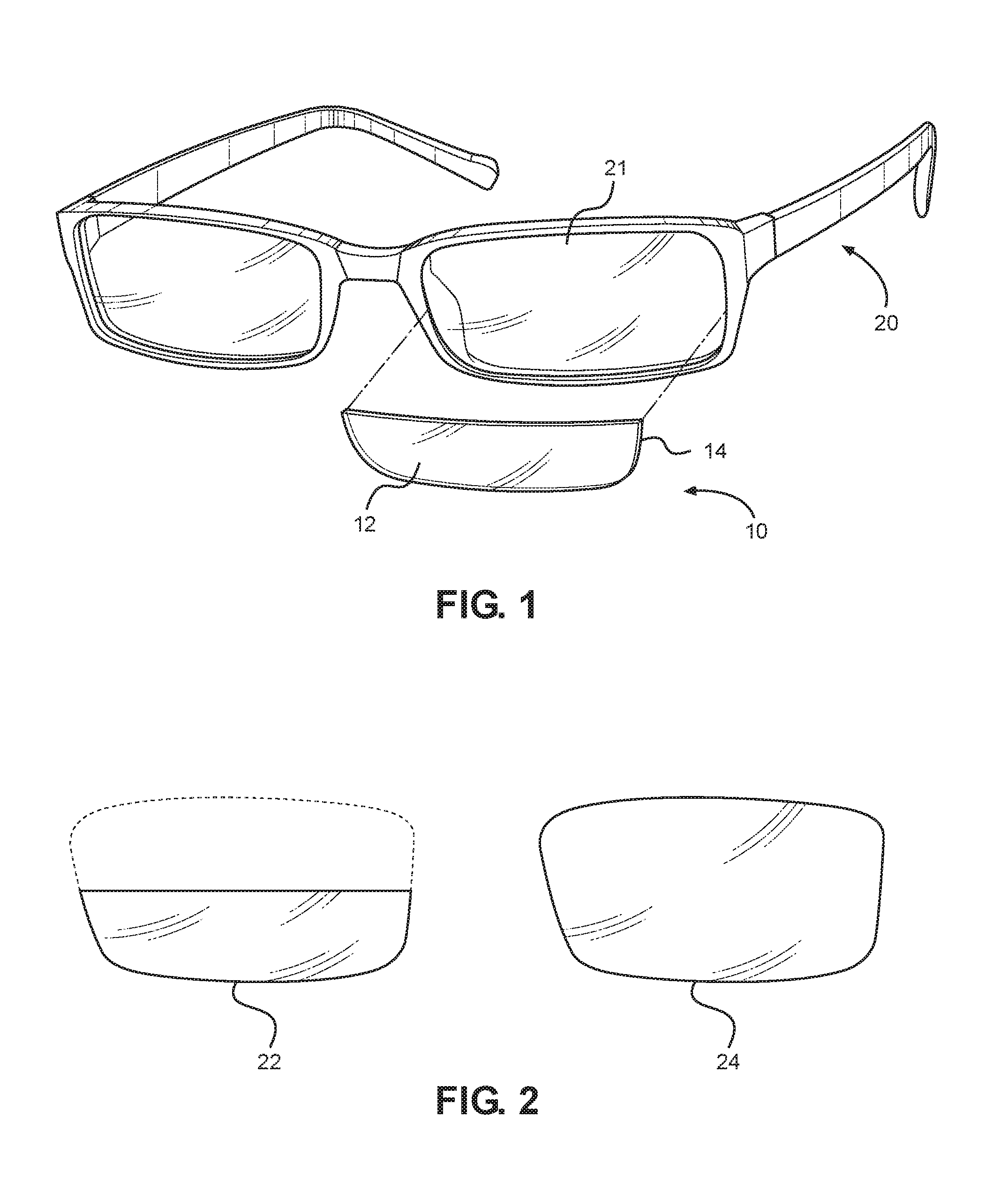

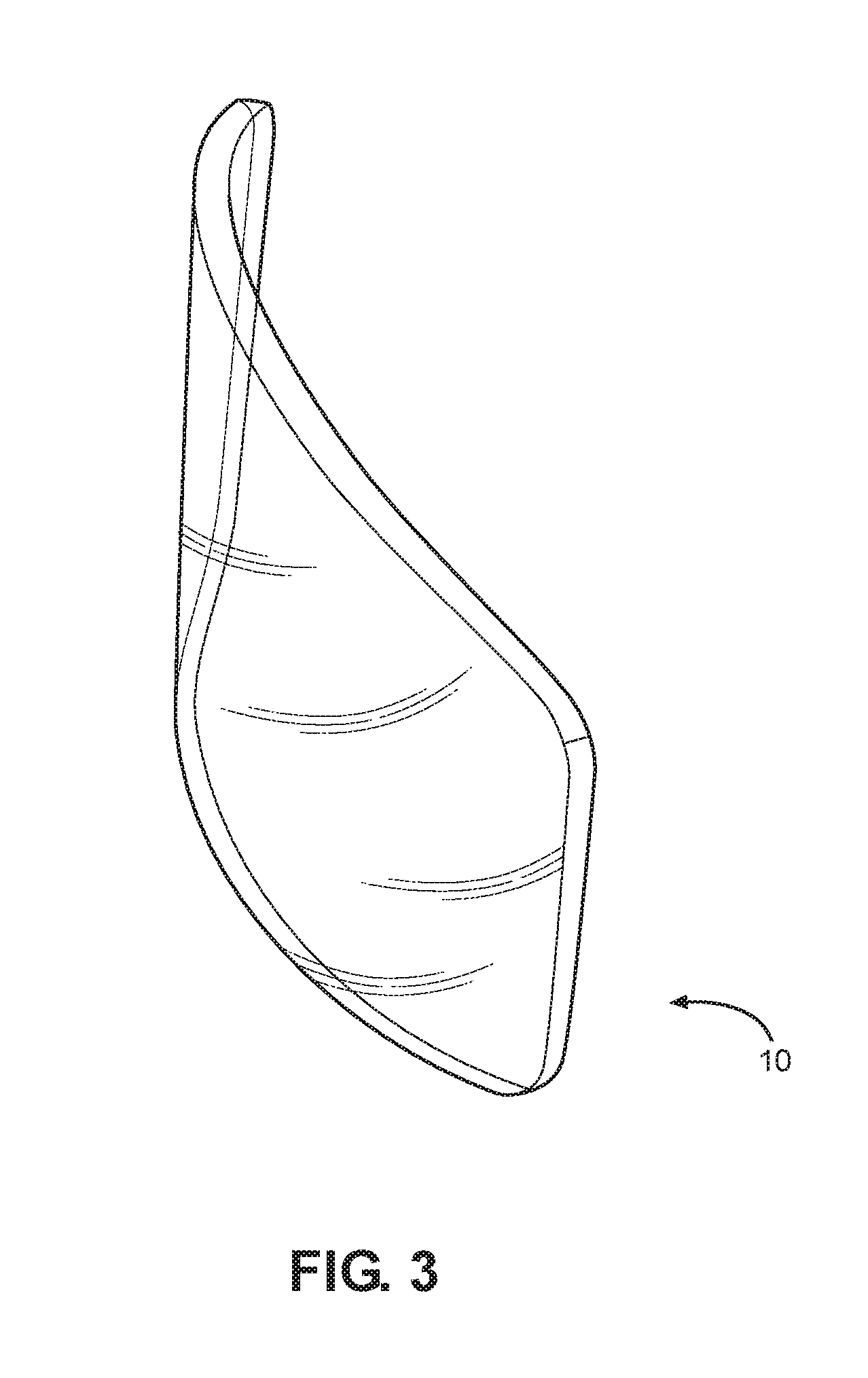

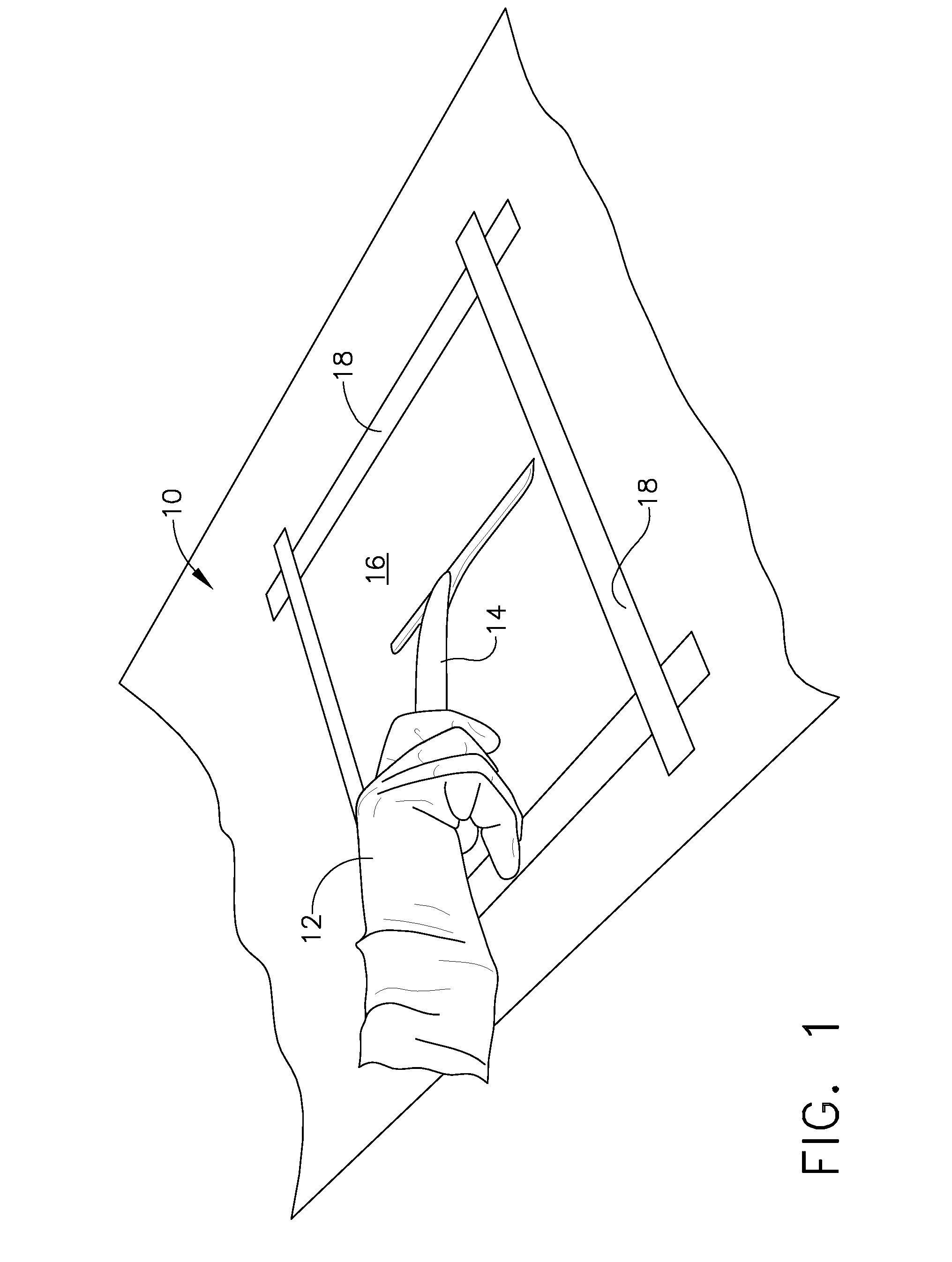

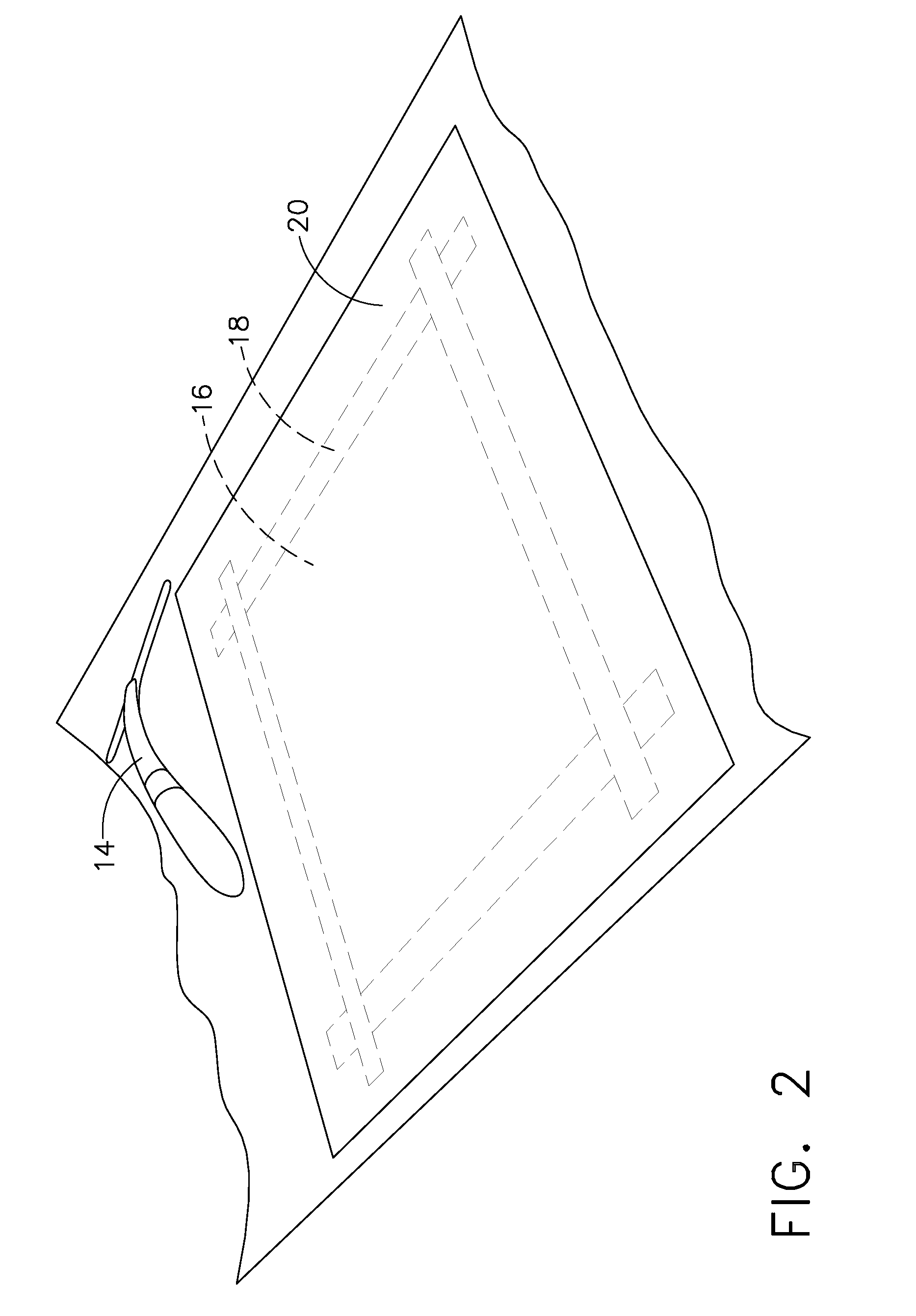

Removably Attachable Corrective Lens

A method and device for a removably attachable corrective lens. The removably attachable corrective lens is a corrective lens having an adhesive applied thereon. The removably attachable corrective lens is then secured to an eyeglass lens to provide a new optical prescription for a user. The adhesive is configured to removably attach the corrective lens to an exterior surface of an eyeglass lens. When a user wishes to remove or replace the corrective lens, they may do so by applying an adhesive remover configured to dissolve the adhesive. In some embodiments of the removably attachable corrective lens, the corrective lens is made from a flexible polymer material that is lightweight and scratch resistant.

Owner:PATEL JITENDRAKUMAR

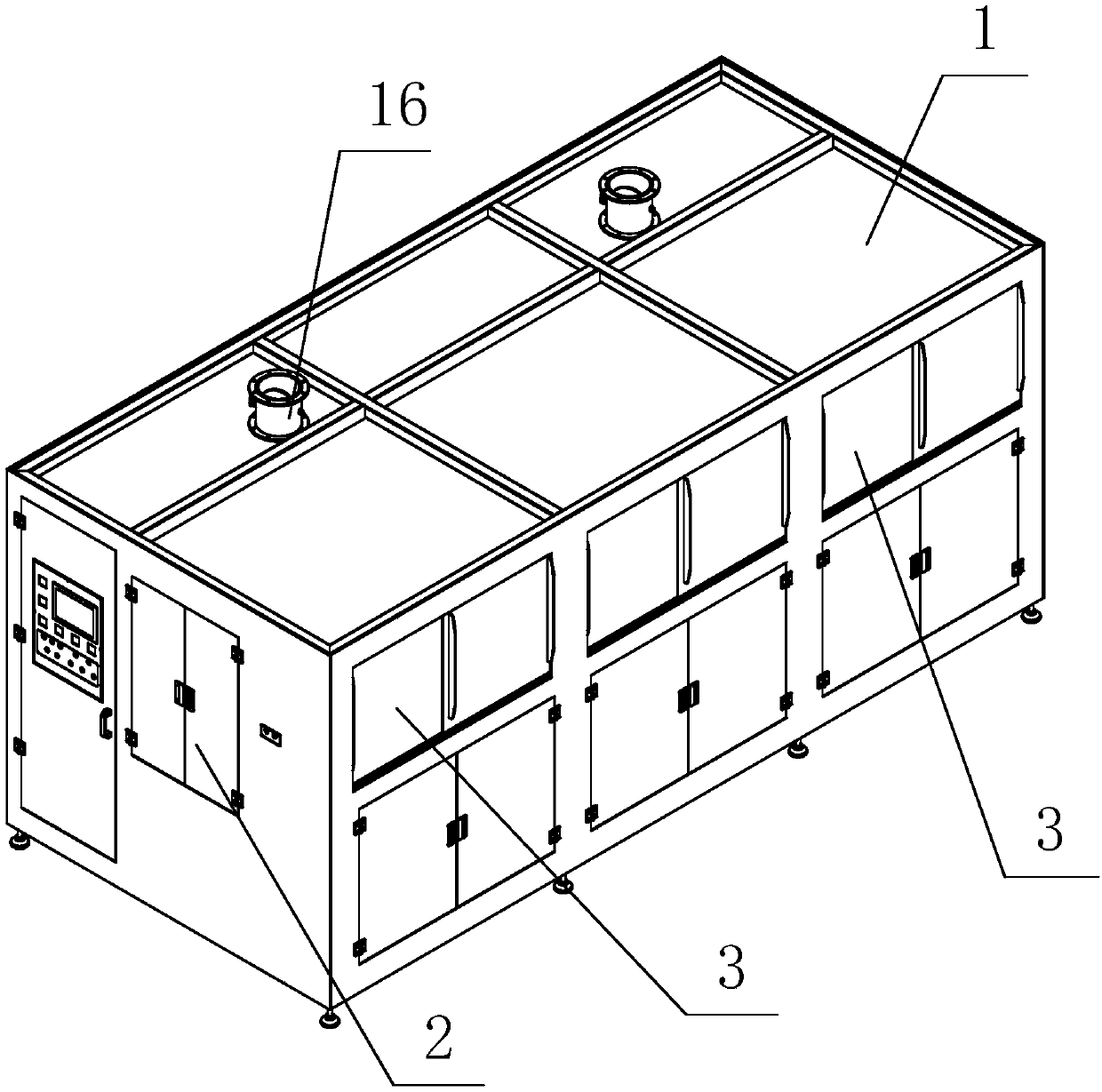

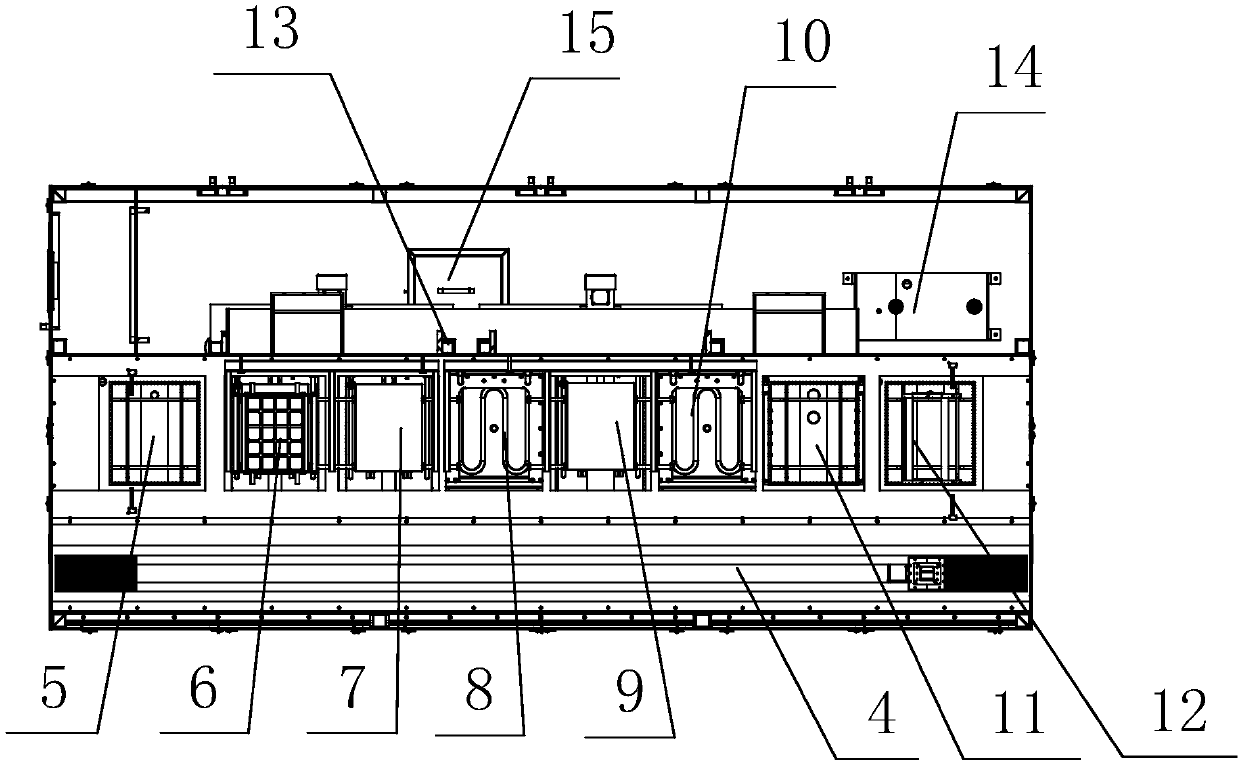

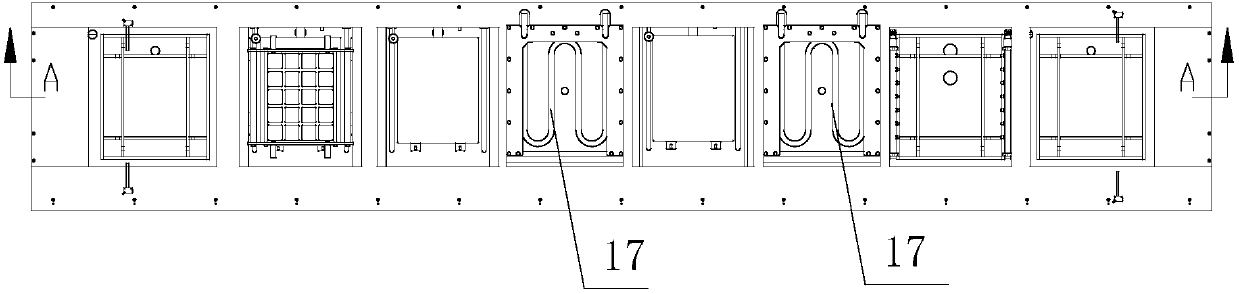

Wafer adhesive remover

PendingCN107818935AEasy to cleanFast cleaningSemiconductor/solid-state device manufacturingManipulatorChemical tank

The invention discloses a wafer adhesive remover. The wafer adhesive remover comprises a body; a workpiece basket material inlet and material outlet are formed in the side surface of the body; a perspective window is formed in the front surface of the body; cleaning tanks and a mechanical arm apparatus are arranged in the body; the mechanical arm apparatus automatically puts a workpiece basket into one cleaning tank for cleaning and then conveys to the next cleaning tank for cleaning; and the cleaning tanks comprise a first water tank, an ultrasonic medicinal tank, a first ultrasonic rinsing tank, a first acid tank, a second ultrasonic rinsing tank, a second acid tank, a quick discharging rinsing tank and a second water tank which are arranged in sequence. The wafer adhesive remover is good in cleaning effect, high in cleaning speed and cleanliness, free of human hand touching, safe and reliable, free of damage to workpiece surfaces, and capable of improving product performance, prolonging service life and improving reliability, satisfying requirement of a next manufacturing procedure of the product, improving production efficiency and appearance quality of the product, and lowering cleaning cost.

Owner:常州科沛达清洗技术股份有限公司

Thickened composition and method for removing adhesive residue

ActiveUS7759298B2Cost effectiveReduce usageCosmetic preparationsNon-ionic surface-active compoundsJet aeroplaneOrganic solvent

The present invention includes a process using environmentally benign materials for the removal of adhesive residues from hard substrates, particularly vehicles, e.g., cars, trucks, buses, aerospace vehicles including airplanes, and the like. The invention uses an absorbable indicator (tracer) dye to aid in detection of remaining residues that may be in need of additional cleaning. The process uses a novel adhesive remover composition comprising a non-halogenated organic solvent, a non-abrasive thickening agent, a surfactant, glycerine, and an absorbable indicator dye. The invention provides a cost effective, safe, environmentally friendly adhesive remover composition specifically formulated for removal of, e.g., pressure sensitive adhesive residues from large areas of aircraft composite and aluminum surfaces, as well as others.

Owner:THE BOEING CO

Stainless steel adhesive remover

A stainless steel adhesive remover composition of the present invention is prepared from a main solvent, a cosolvent, a penetrating agent, a surfactant, a corrosion inhibitor and a volatilization inhibitor. It is mainly used to remove all kinds of residual glue and its protective film on the surface of stainless steel, especially suitable for the removal of protective film and adhesive paper that have become brittle due to long-term light oxidation and aging. It has the following advantages: 1. The glue removal speed is fast and the effect is good. The hard-to-tear protective film can be softened, foamed and peeled off within 20 minutes. 2. No corrosion to stainless steel metal materials. 3. The residue is easy to wash with water. The preparation method of the stainless steel adhesive remover of the present invention is as follows: adding a certain amount of solvent in proportion to a container, and stirring evenly at a certain temperature.

Owner:钟发昌

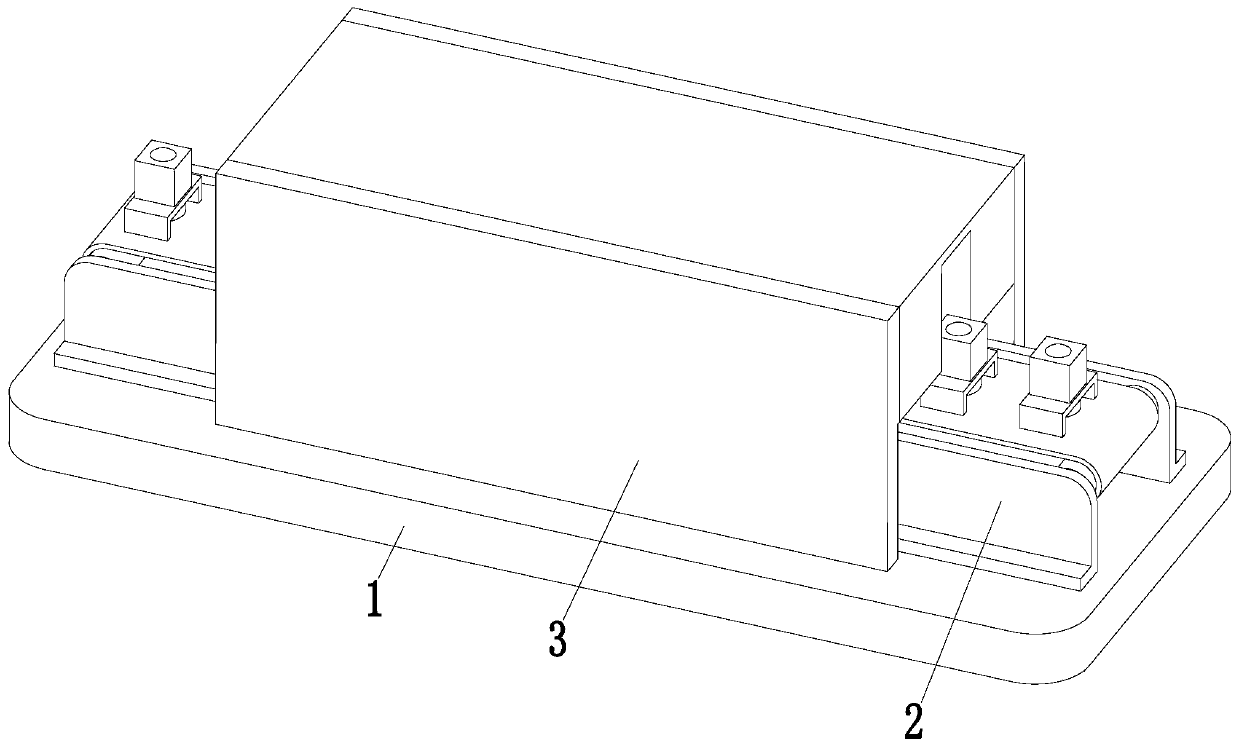

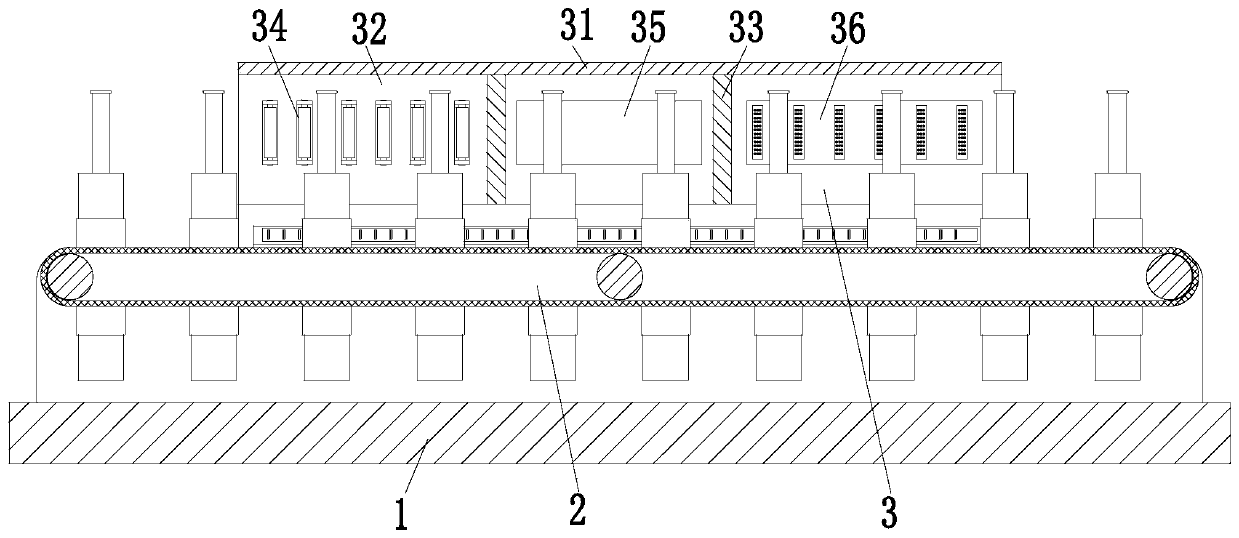

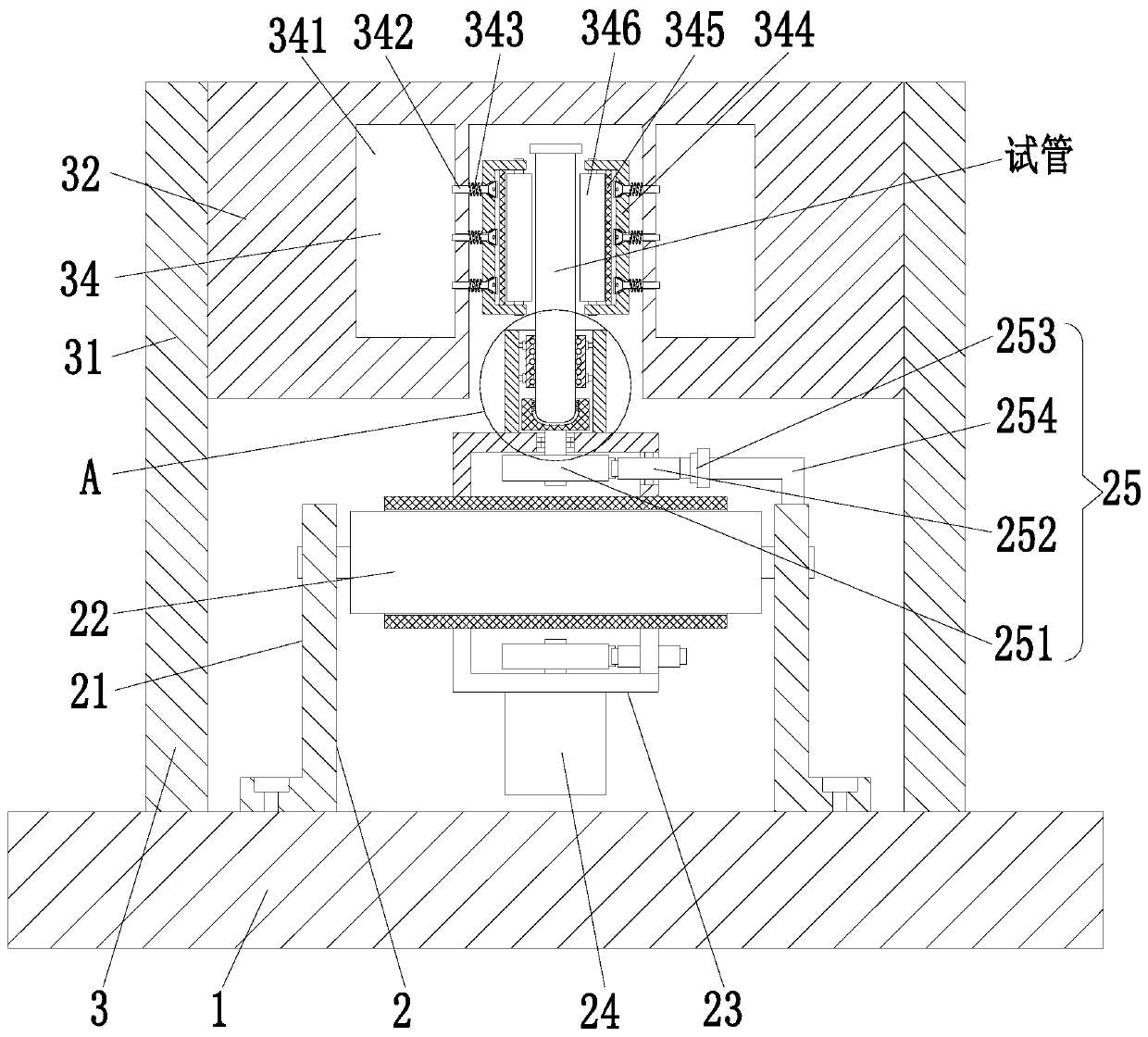

Quick removing device for temporarily-attached labels of glass test tubes

ActiveCN111318530AEffective clamping and positioningAvoid tiltingHollow article cleaningEngineeringStructural engineering

The invention relates to a quick removing device for temporarily-attached labels of glass test tubes. The quick removing device for the temporarily-attached labels of the glass test tubes comprises abottom plate, a conveying device and a removing device, the conveying device is installed in the middle of the upper end of the bottom plate, the removing device is arranged above the conveying device, and the lower end of the removing device is installed on the bottom plate. According to the quick removing device for the temporarily-attached labels of the glass test tubes, the problems that whenthe labels on the outer sides of the test tubes are removed through existing equipment, a direct scrubbing mode is generally adopted, but the label removing effect is poor, an adhesive layer is proneto being generated to be adhered to the outer walls of the test tubes, and the subsequent label adhering effect is influenced through the mode, when the existing equipment applies an adhesive removingagent to the outer sides of the test tubes, the applying effect is poor, applying is not uniform, the adhesive removing agent cannot fully dissolve the labels, and the removing effect of the labels on the outer sides of the test tubes is poor are solved.

Owner:FUYANG NORMAL UNIVERSITY

Combined degumming method for rubberized track shoe

InactiveCN111484907AShorten the timeNo pollution in the processDetergent mixture composition preparationOrganic non-surface-active detergent compositionsProcess engineeringPolymer chemistry

The invention provides a combined degumming method for a rubberized track shoe. According to the method, low-temperature treatment and solution soaking are combined to remove glue; when the rubber onthe old rubber-coated track shoe subjected to low-temperature freezing reaches the characteristics of brittle materials (similar to common glass and cement products), the rubber can be recycled; the rubber body is knocked by a manipulator or a manual hammer; the irregular fragments are separated from the metal matrix; wherein the removal rate can reach 98%-99% according to the bonding area, then the material is transferred into a solution in the second step to soak and remove the rubber, a rubber remover permeate and dissolve along the bonding interface of the rubber and the metal, and meanwhile, the residual rubber is subjected to volume expansion under the soaking of the rubber remover, so that the bonding agent is invalid, and the residual rubber is automatically separated from the metal. After low-temperature treatment, knocking and degumming, little rubber remains on the metal matrix, and the solution soaking and degumming time can be greatly shortened. The rubber remover adopts an environment-friendly formula, does not contain toxic components such as dichloromethane and methane chloride, and is pollution-free.

Owner:河北前进机械厂

Glue removing agent and application method thereof

InactiveCN110846155ANot easy to damageSmall appearanceOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsSolventMaterials science

The invention provides a glue removing agent. The glue removing agent comprises the following components in parts by weight: 280-500 parts of an alcohol solvent, 1.5-2 parts of an auxiliary agent, 220-280 parts of a humectant and the balance water. The invention also provides an application method of the glue removing agent. According to the glue removing agent and the application method thereof,glue removal can be effectively carried out on base materials, the glue removal efficiency is high, and damages on base materials are not easily caused.

Owner:FUTAIHUA PRECISION ELECTRONICS ZHENGZHOU

Antibacterial adhesive remover for marine organisms

InactiveCN103805375AThe degumming effect is thorough and efficientEfficient sterilizationBiocideDead plant preservationCelluloseBiotin

The invention relates to the technical field of organisms, and particularly relates to an antibacterial adhesive remover for marine organisms applicable to removal of organic adhesive residues such as a sticking adhesive, chewing gum, sealing glue, kinds of oil paints and the like left on the surfaces of kinds of objects in a family or a public place. The formula comprises the following components by weight percent (%): 5.0-6.0% of seaweed lymphokine, 1.0-1.5% of agaroidin gelatum sugar, 7.0-9.5% of dicaproate, 2.0-4.0% of acetone, 2.0-4.0% of mineral oil, 0.5-2.0% of hydroxy propyl cellulose, 2.0-4.0% of sea mud saponin and purified water added to 100%. Pure natural active ingredients of the marine organisms, and nontoxic and nonirritant green marine biotin products which are free of corrosion and fragrant in flavor are adopted, so that the antibacterial adhesive remover has the characteristics of being high in efficiency, low in concentration, good in stability, good in degumming sterilization effect, free of poison and harm, convenient to carry and the like, and has broad applicability.

Owner:QINGDAO ANBEIKANG BIOLOGICAL MEDICINE TECH CO LTD

Reduction in polystyrene foams with low vapor pressure dibasic esters

The present invention relates to a foam reduction agent comprising low vapor pressure dibasic esters and a method of using a liquid to contact with polystyrene foam wherein the higher boiling temperature of the low vapor pressure dibasic esters and contact with the liquid provides a volume reduction process and less evaporation loss as well as safer transportation of the chemicals and the polystyrene in its reduced state. The resulting reduced sludge is also recyclable to superior quality raw polystyrene foam beads and the reduction agents are recoverable for future use. The resulting sludge also has unexpected beneficial uses heretofore unknown as a waterproofing agent, a paint stripper, as a graffiti remover, as an extender of the life of concrete, as an adhesive remover, as a stain remover, as a scuff mark remover, and as a general degreaser.

Owner:BLUE EARTH SOLUTIONS +3

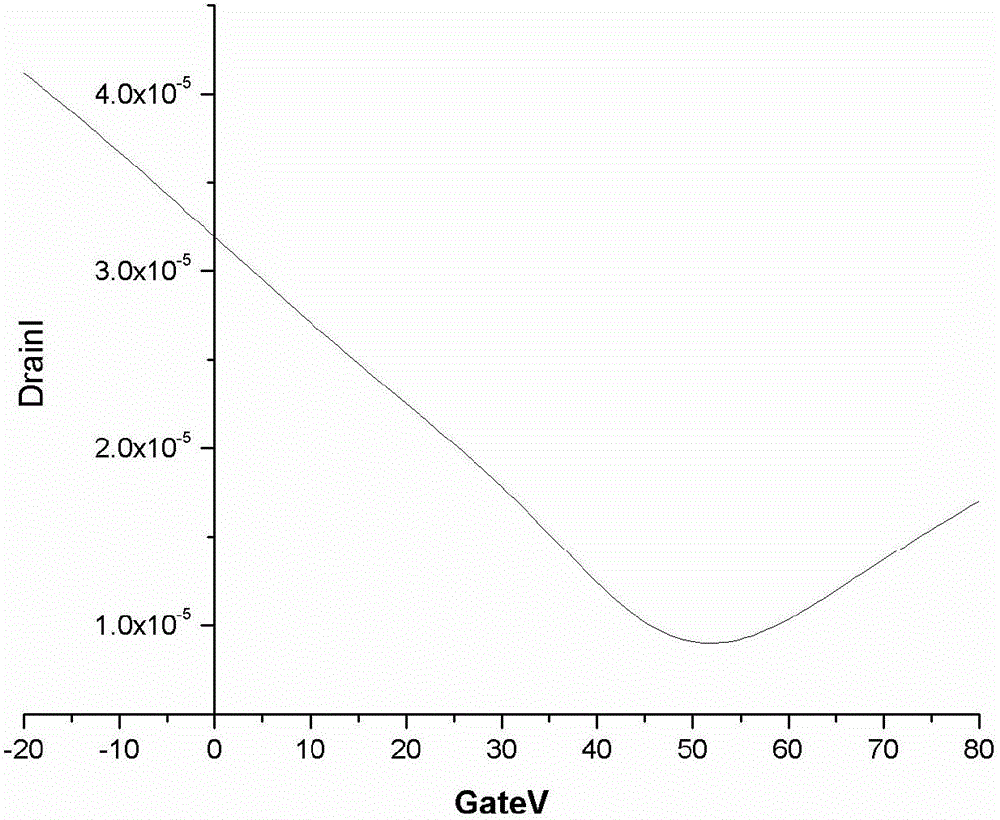

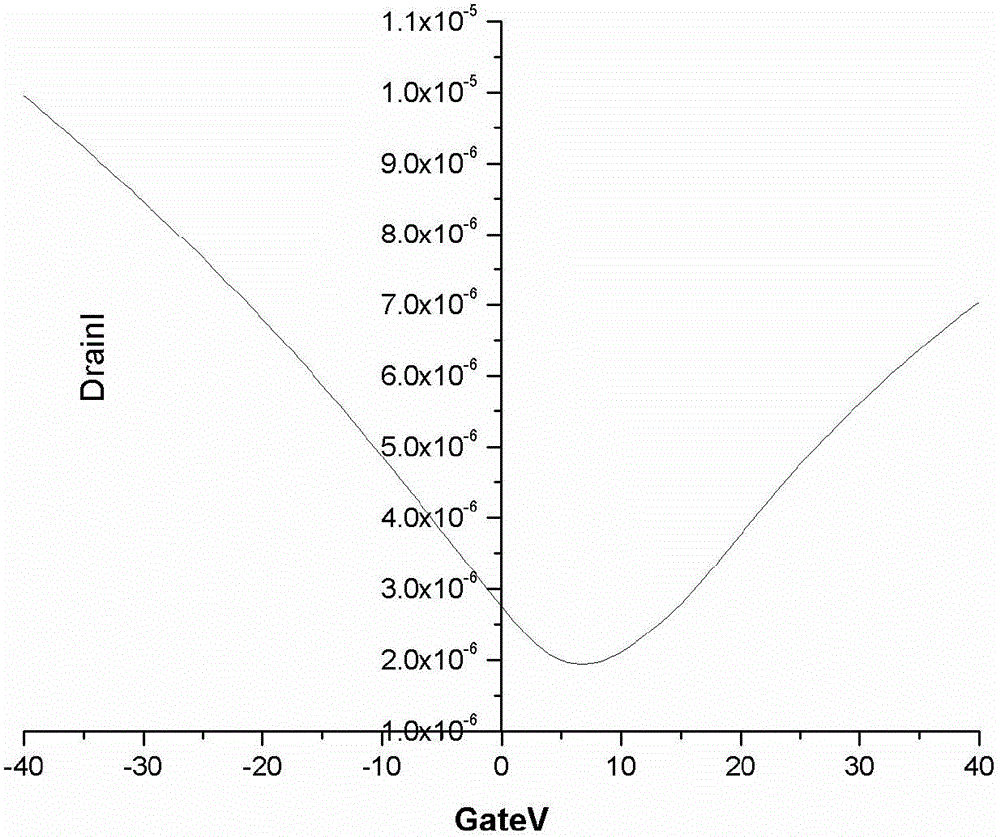

Method for preparing graphene devices

ActiveCN102751179ALow costProcess conditions are easy to controlNanoinformaticsPhotomechanical apparatusChemical treatmentElectrical resistance and conductance

The invention discloses a method for preparing graphene devices. After graphene materials are photoetched, the impacts of the photoetching process on the performances of graphene are eliminated through chemical treatment with chlorobenzene and an adhesive remover AR 300-70, and the Dirac point and channel resistance of graphene can be controlled. The method is simple, can be used for producing the graphene devices in batches and greatly improves the processing efficiency and does not damage the excellent performances of graphene.

Owner:PEKING UNIV

Adhesive remover special for nameplate

InactiveCN104046519ANot acidicNot alkalineSurface-active detergent compositionsDetergent compounding agentsAlkalinitySolvent

The invention relates to the technical field of chemical materials, and in particular to an adhesive remover special for nameplate. The adhesive remover comprises the following raw materials by weight: 11%-23% of a volatilization inhibitor, 10%-15% of a thickener, 5%-15% of an emulsifier, 9%-12% of an activating agent, 37-58% of a main solvent, 1.5%-7% of a penetrant and 21%-27% of water. The invention aims to provide the adhesive remover special for nameplate, wherein the adhesive remover has no acidity or alkalinity, and takes short time.

Owner:范振捷

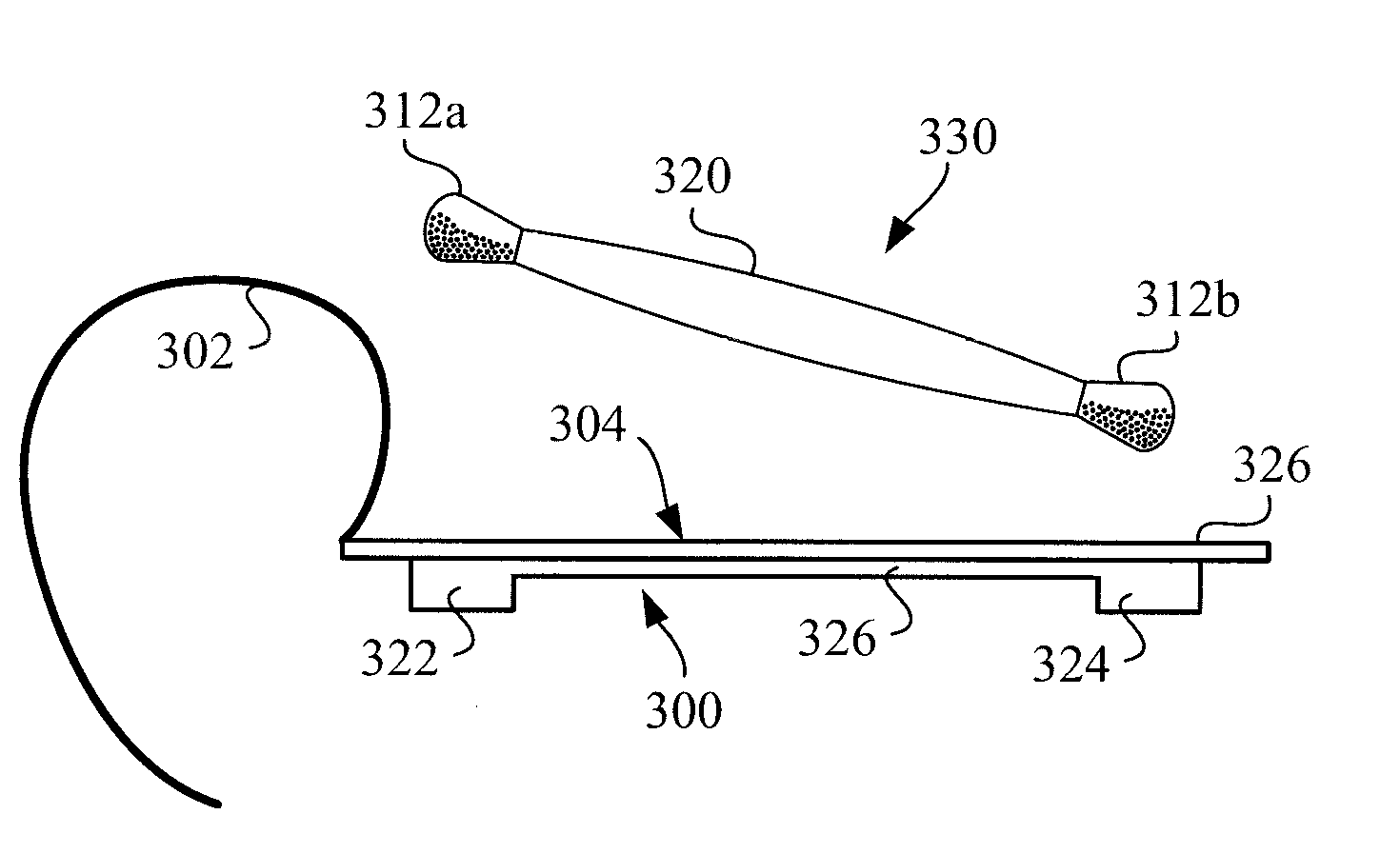

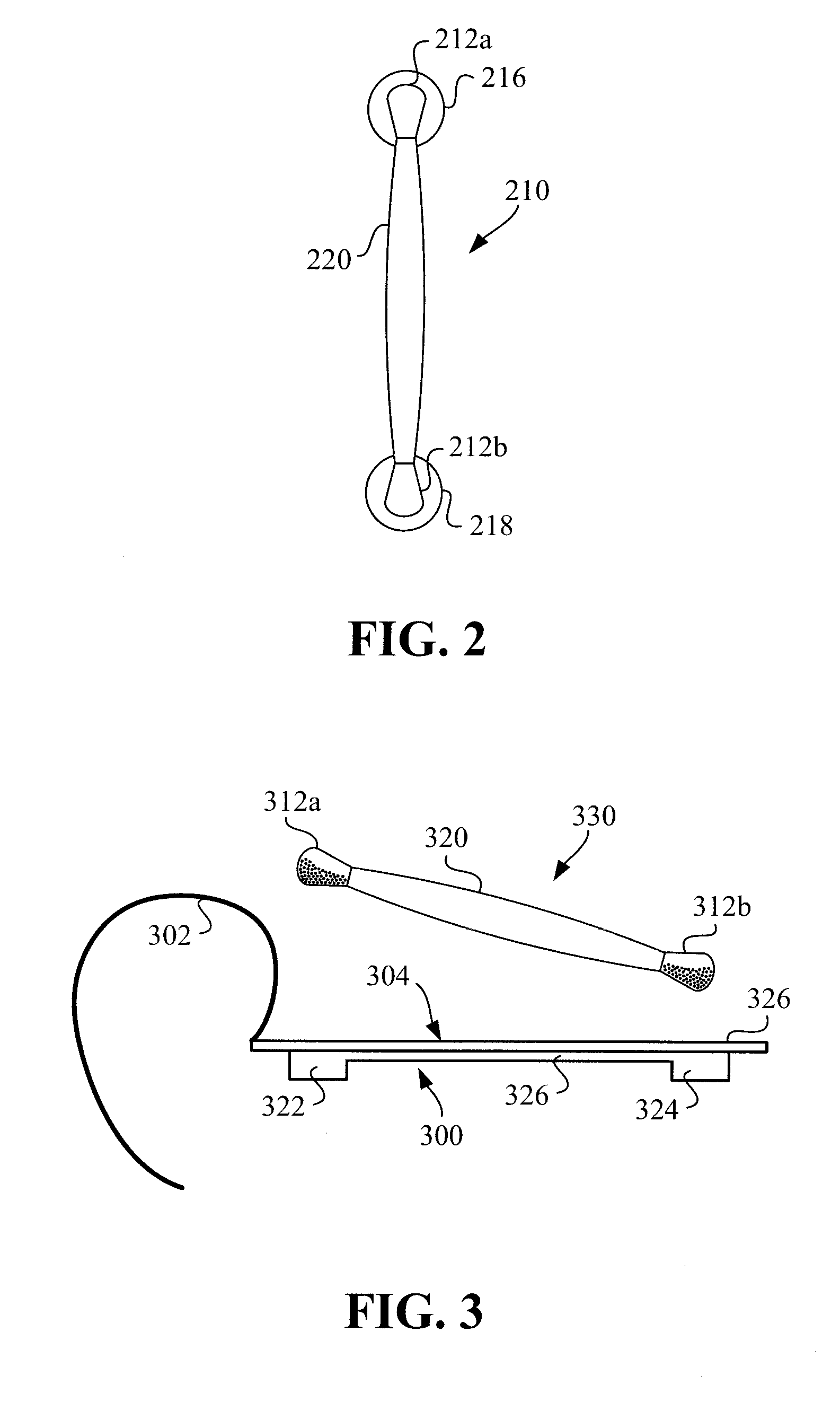

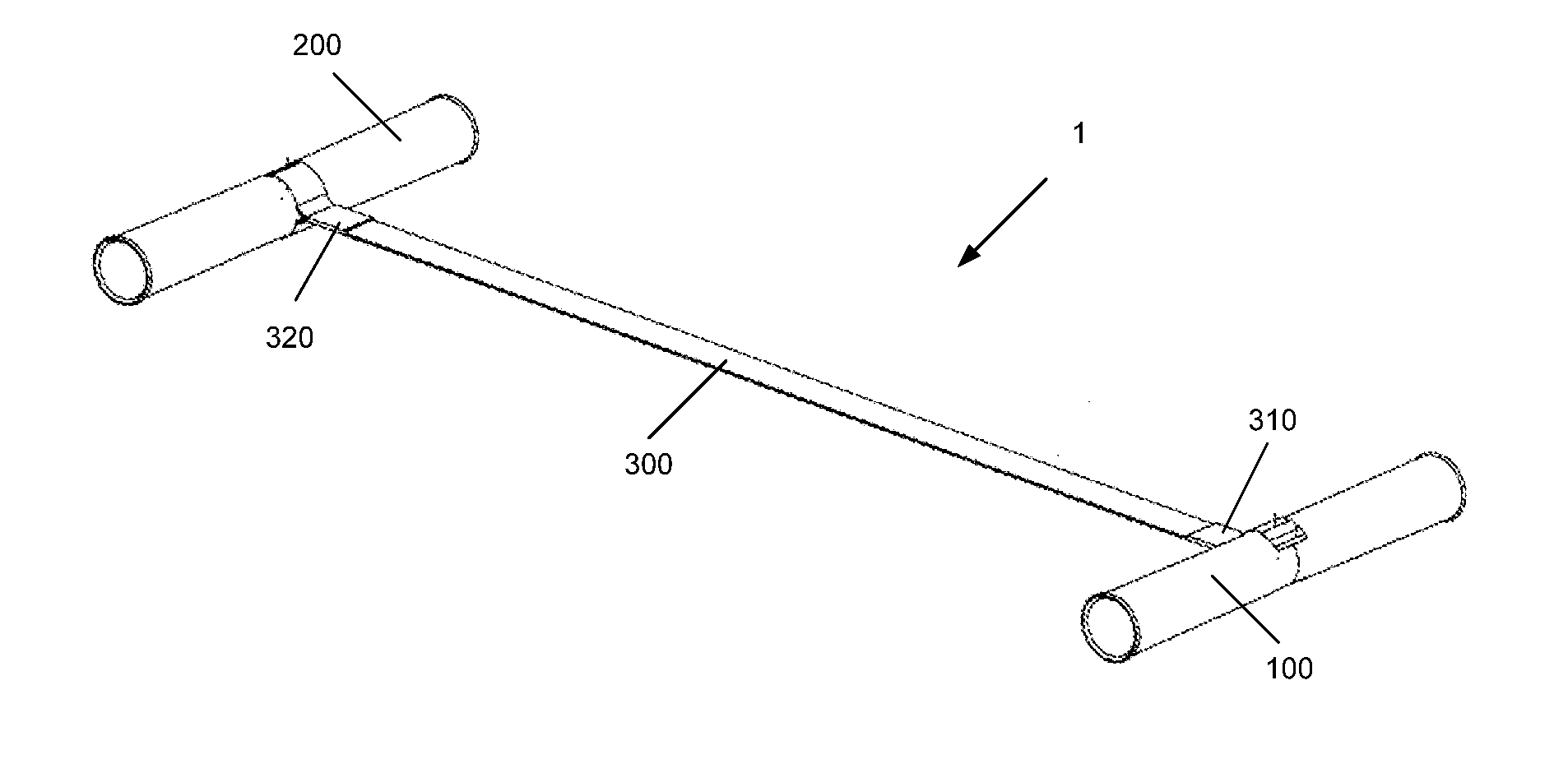

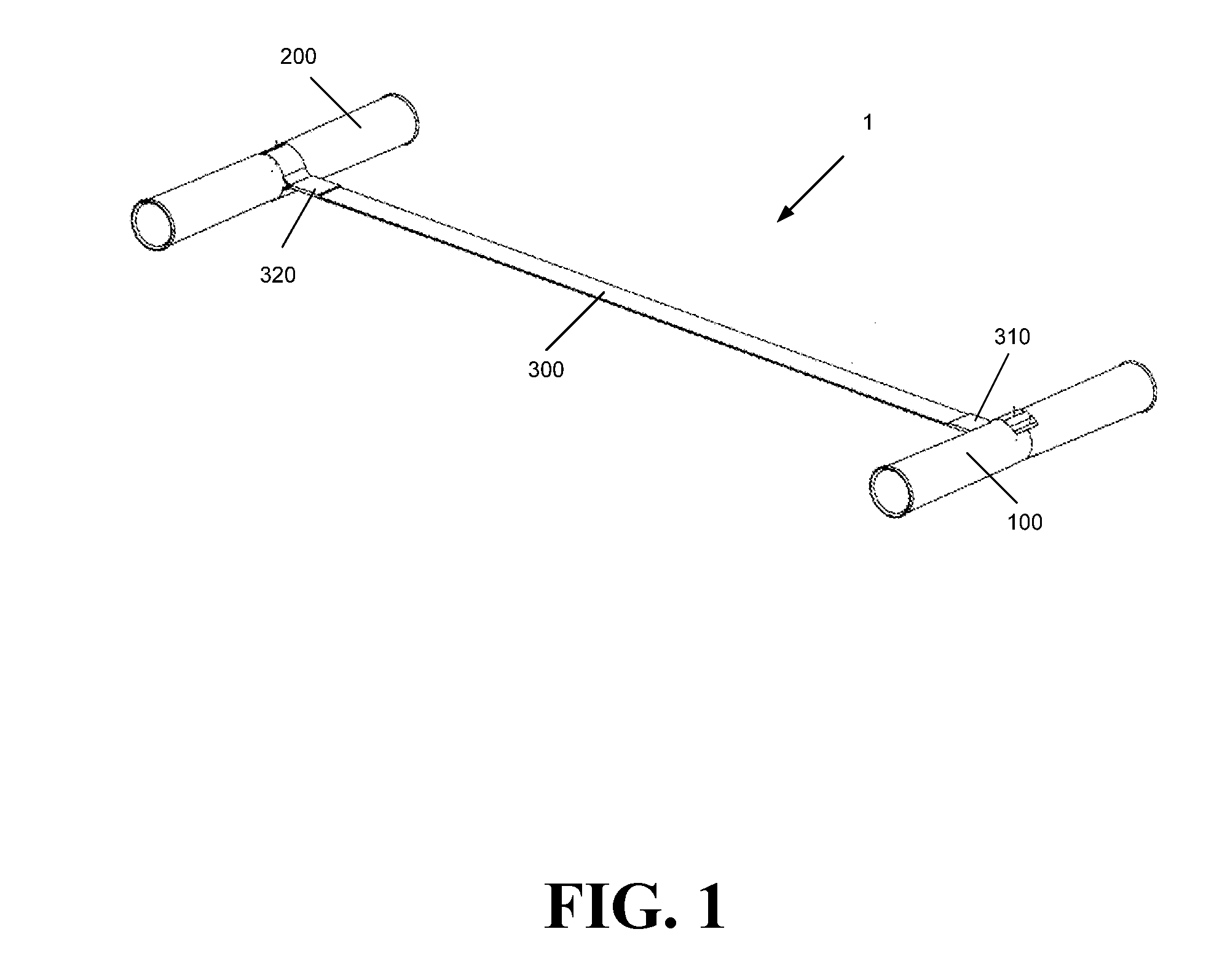

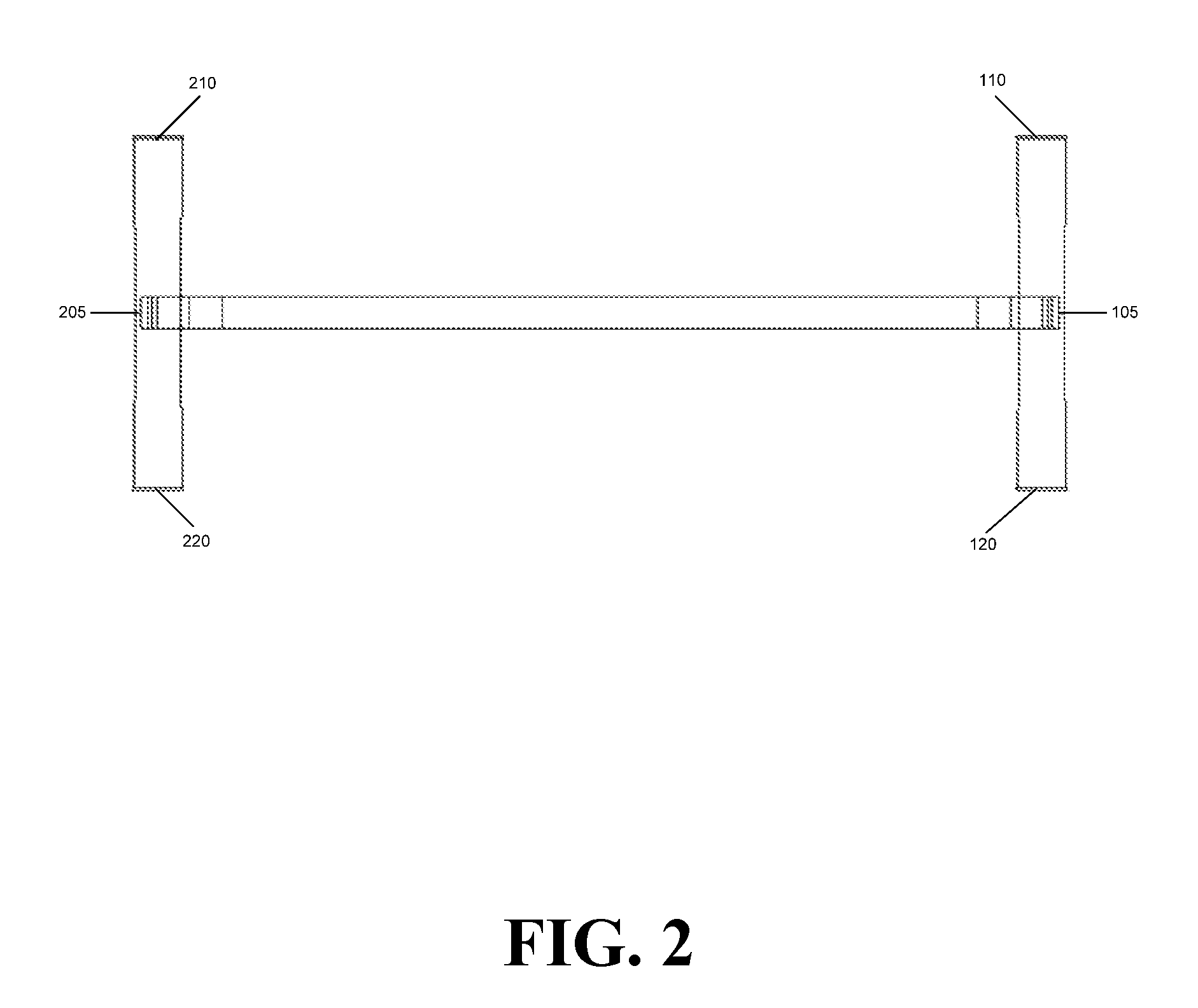

Portable exercise device

InactiveUS20070225134A1Facilitates two-person sit-upStiltsMuscle exercising devicesHand heldBiomedical engineering

A portable exerciser device for conducting two-person sit-ups is disclosed. The portable exerciser device has a hand-pulling assembly comprised of two hand holds joined by a connector. When combined into a kit, the additional elements may include a storage bag, shoe sole adhesive, shoe sole adhesive remover, one or more exerciser pads, and device information.

Owner:SLATTERY STEPHEN

Polyimide adhesive remover composition for wafer and preparation method of polyimide adhesive remover composition

PendingCN113736584AImprove permeabilityAvoid corrosionDetergent mixture composition preparationOrganic non-surface-active detergent compositionsImidePolymer science

The invention discloses a polyimide adhesive remover composition for wafers and a preparation method of the polyimide adhesive remover composition, and relates to the technical field of polyimide adhesive layer adhesive removers. According to the polyimide adhesive remover composition for the wafer, provided by the invention, the alkali, the organic solvent, the alcohol amine penetrant, the carbon-nitrogen heterocyclic corrosion inhibitor and the volatilization inhibitor are compounded to jointly achieve a synergistic adhesive removal effect. The alkali preferably adopts strong alkali with pKa greater than 12 to improve the protonation ability of the adhesive remover, the alcohol amine penetrant can enhance the permeability of the adhesive remover, and the carbon-nitrogen heterocyclic corrosion inhibitor can generate a coupling effect with metal to inhibit the corrosion of the alkali to the metal; besides, a layer of isolating membrane is formed on the surface layer of the adhesive remover by using the volatilization inhibitor, so that the volatilization loss of effective components in the adhesive remover is reduced. The composition has the advantages of high reaction activity and mild treatment conditions, and can be used for removing polyimide adhesive layers in the technical fields of semiconductors, photovoltaics, display panels and the like.

Owner:珠海市板明科技有限公司

Adhesive remover and preparation method thereof

ActiveCN101899365BSmall smellEasy to removeOrganic detergent compounding agentsNon-ionic surface-active compoundsSilanesAlkylphenol

The invention relates to an adhesive remover and a preparation method thereof. The basic composition of the adhesive remover formula is as follows in percentage by weight: 12-25% of fatty alcohol-polyoxyethylene ether sodium sulfate and fatty alcohol-polyoxyethylene ether silane, 20-30% of alkylphenol polyoxyethylene ether, 4-5% of ethylene oxide / propane segmented copolymer, 5-7.9% of sodium chloride, 10-12% of triethyl phosphate and dimethyl adipate, 5-10% of tricarboxyl triethylamine, triethylamine, diethanol amine, EDTA, urea, triethanolamine and hexamethylene tetramine, 2-10% of ethylene glycol, butyl cellosolve, propylene glycol methyl ether, ethanol, isopropanol, benzyl alcohol and methyl isoamyl ketone and 0.1-42% of deionized water. Compared with the prior art, the invention has the advantages that the adhesive remover is aqueous and low irritating, is wide in application range, can rapidly remove various trade mark adhesives, eliminate adhesiveness, degrease, remove adhesive and deliquate adhering oil stain in the aspect of removing advertising posters on the surfaces of glass, ceramics, marbles, stainless steel, etc. The invention also provides an environment-friendly and safe method for preparing the adhesive remover.

Owner:NINGBO PASCO UNITED IND

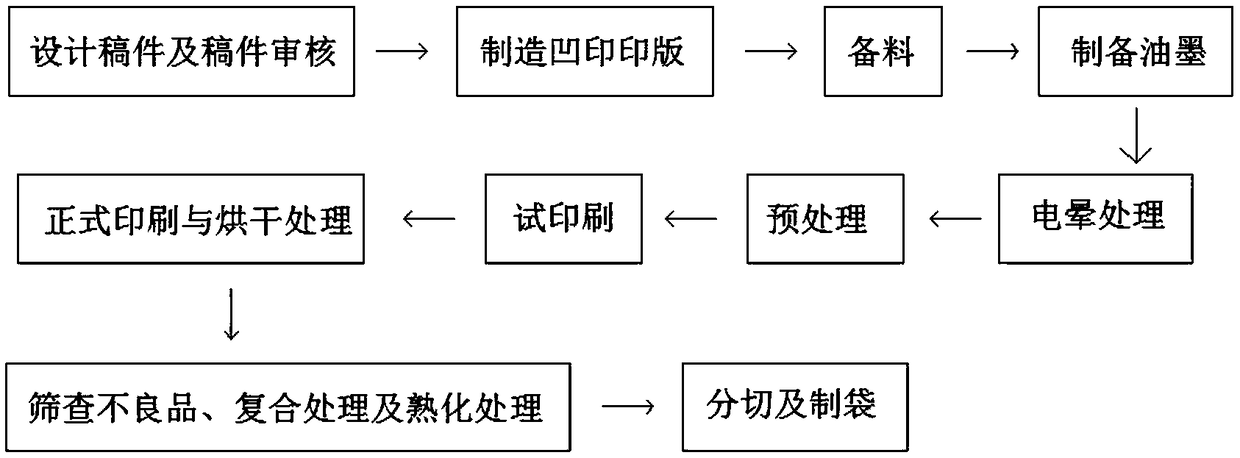

Gravure printing process for flexible packaging

InactiveCN109203742AModerate viscosityReduce stickinessInksOther printing apparatusMaterials preparationEngineering

The invention provides a gravure printing process for flexible packaging. The gravure printing process includes the following steps of manuscript design and manuscript reviewing, gravure printing plate making, material preparation, ink preparing, corona treatment, pretreatment, try printing, formal printing, drying treatment, defective product screening, compound treatment, curing treatment, cutting and bag making. According to the gravure printing process for flexible packaging, the particle size of ink particles made by ultrasonic dispersion treatment is uniform, the ink viscosity is moderate, thus the probability of a cutter line appearing in printed flexible packaging finished products is reduced, and the qualified rate and printing efficiency of the flexible packaging finished products are improved; an adhesive remover in ink compositions can reduce ink adhesion while not affecting the mobility of ink, thus the coloring rate of printing is improved, and the printed flexible packaging finished products have high quality; and through a drying inhibitor in the ink compositions, the phenomenon that the ink in the printing process dries too fast and consequently the ink on a printed material is peeled and skinned can be prevented.

Owner:广东新天丽控股有限公司

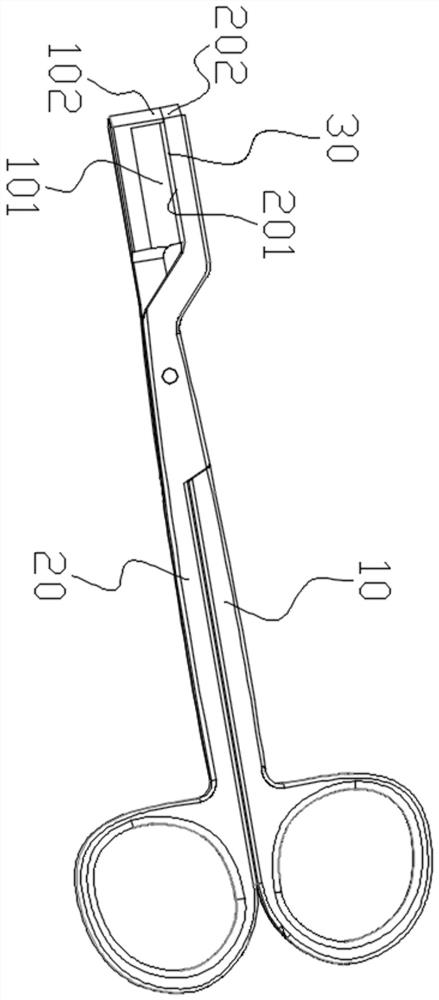

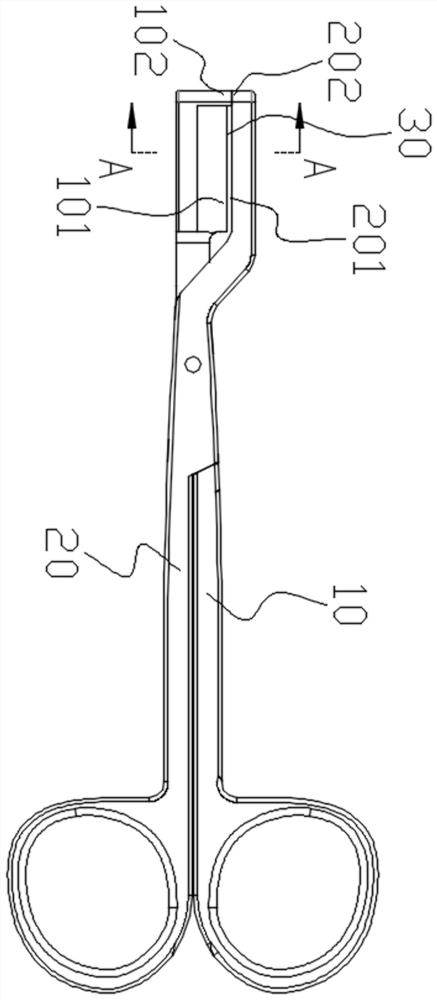

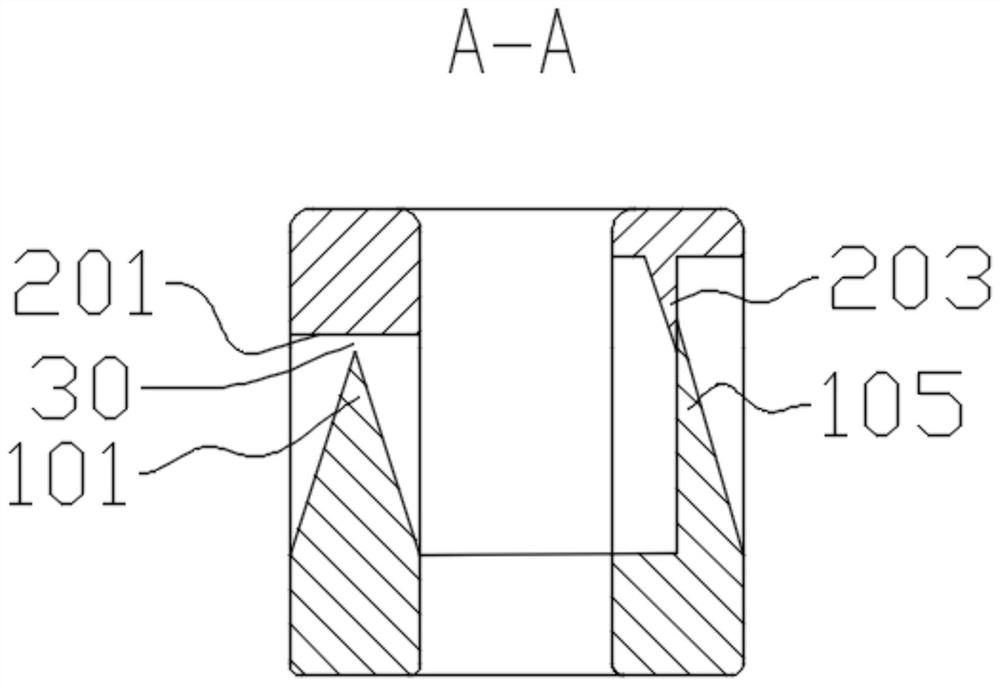

Scissors for generating double-sided adhesive remover

ActiveCN111844143AEasy to operateImprove cutting effectMetal working apparatusStructural engineeringMechanical engineering

The invention provides scissors for generating a double-sided adhesive remover. The scissors comprise a first scissor arm body and a second scissor arm body. The head end of the first scissor arm bodyis provided with a first blade edge part and a second blade edge part which are arranged side by side. The head end of the second scissor arm body is provided with a first planar part and a third blade edge part. After shearing, a gap substantially equal to the thickness of release paper is formed between a first blade edge part and the first planar part, and a second blade edge part is in contact with or intersects with the third blade edge part. During one-time shearing, the first blade edge part is matched with the first planar part to cut off a double-sided adhesive body, the release paper is retained without being cut, and the double-sided adhesive can be cut off through the cooperation of the second blade edge part and the third blade edge part, so that the semi-shearing of the release paper and the full shearing of the cut release paper are synchronously retained, the remover facilitating release paper removal is quickly formed at the shearing end, and the working efficiency isimproved.

Owner:FARO AUTOMATION (SUZHOU) CO LTD

Adhesive remover for aluminum alloy decorative panel of elevator

The invention relates to an adhesive remover for an aluminum alloy decorative panel of an elevator. The adhesive remover is characterized by comprising the following components of 10-15g / L of sulfuric acid (98%), 0.1-0.5g / L of Na2CO3, 1-5g / L of lauryl sodium sulfate, 0.1-1.0g / L of nonionic surfactant, 0.5-2g / L of aqueous-organic solvent, 1-10g / L of CMC-Na (sodium carboxymethylcellulose), 1-5g / L of microcrystalline cellulose, and the balance of water, and the aqueous-organic solvent is methanol, ethanol, isopropanol and acetonitrile. The adhesive remover can easily remove a retained trace of a binder, and does not damage a paint film.

Owner:SUZHOU FEN LAKE ELEVATOR

Preparing method for environmental compound adhesive remover

InactiveCN106350280AWill not polluteHarmful to healthInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsActivated sludgeSodium stearate

Owner:雷春生

Preparation method of environment-friendly biological adhesive remover

The invention relates to a preparation method of a green and environment-friendly biological glue remover, belonging to the technical field of glue removers. The present invention first obtains the value-added culture solution by culturing the dried stems and leaves of the water hyacinth, then selects several larger strains from the value-added culture solution to ferment, compares the activity of the fermentation liquid to obtain the degummed strain of the water hyacinth, and then extracts the degummed strain Cultivate and ferment to obtain enzyme liquid, ultrasonically extract lemon peel to obtain lemon extract, then add enzyme liquid, sodium dodecylbenzene sulfonate, sodium stearate, etc. in turn and stir to obtain a green and environmentally friendly biological degumming agent agent. The present invention does not contain dichloromethane, benzene and ethers, and the present invention will not cause corrosion to metal substrates, and is completely a biological adhesive remover, non-toxic, with good cleaning effect and no pollution; the present invention is simple to operate , suitable for industrial production.

Owner:郭迎庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com