Polyimide adhesive remover composition for wafer and preparation method of polyimide adhesive remover composition

A polyimide and composition technology, which is applied to the polyimide adhesive remover composition for wafers and the field of preparation thereof, can solve the problem of the strong corrosion of metal under the film, the inability to effectively remove the adhesive layer, and the weakening of the adhesive remover. Peel force and other problems, to achieve the effect of reducing volatilization loss, removing glue without residual glue, and strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

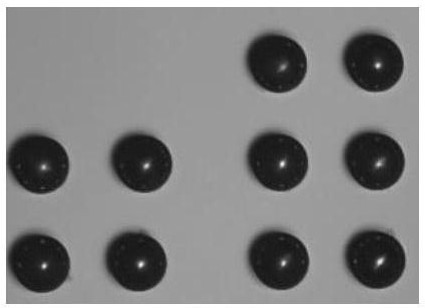

Image

Examples

Embodiment 1

[0051] Embodiments of the present invention provide a polyimide adhesive remover composition for wafers and a preparation method thereof, which contain the following components in parts by mass:

[0052] 60 parts of N-methylpyrrolidone, 35 parts of diglycolamine, 4 parts of tetramethylammonium hydroxide (95% purity), 0.1 part of benzimidazole and 0.9 part of liquid paraffin.

[0053] Put the above components in a stirring tank, use a glass rod to stir and mix well, and then prepare the adhesive remover.

[0054] This embodiment also provides a method for removing glue from a polyimide wafer. The wafer to be glued is placed in a glue remover, and the glue removal reaction is carried out; the reaction temperature is 80-95°C, and the reaction time is 0.5- 2h. After the reaction, the wafer was taken out, cleaned with isopropanol and pure water, and then dried.

[0055] Specifically, put the degumming agent in an oil bath at 90° C. and heat it up. After the temperature rises to t...

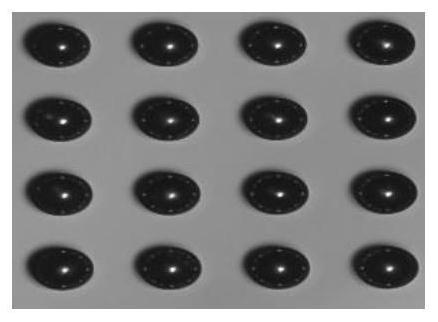

Embodiment 2

[0057] The embodiments of the present invention provide a polyimide adhesive remover composition for wafers and a preparation method thereof, which differ from Example 1 in that:

[0058] The components of the polyimide adhesive remover composition for wafers are 80 parts of N-methylpyrrolidone, 15 parts of diglycolamine, 4 parts of tetramethylammonium hydroxide (95% purity), 0.1 parts of benzimidazole parts and 0.9 parts of liquid paraffin.

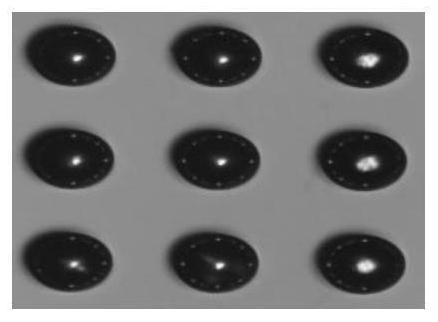

Embodiment 3

[0060] The embodiments of the present invention provide a polyimide adhesive remover composition for wafers and a preparation method thereof, which differ from Example 1 in that:

[0061] The components of the polyimide adhesive remover composition for wafers are 40 parts of N-methylpyrrolidone, 55 parts of diglycolamine, 4 parts of tetramethylammonium hydroxide (95% purity), 0.1 parts of benzimidazole parts and 0.9 parts of liquid paraffin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com