Glue removing agent and application method thereof

A technology of adhesives and adhesives, applied in chemical instruments and methods, detergent compositions, non-surface-active cleaning solvents, etc., can solve problems such as glass damage, difficulty, and scratches on substrates, and achieve small appearance and performance , High degumming efficiency, high yield and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

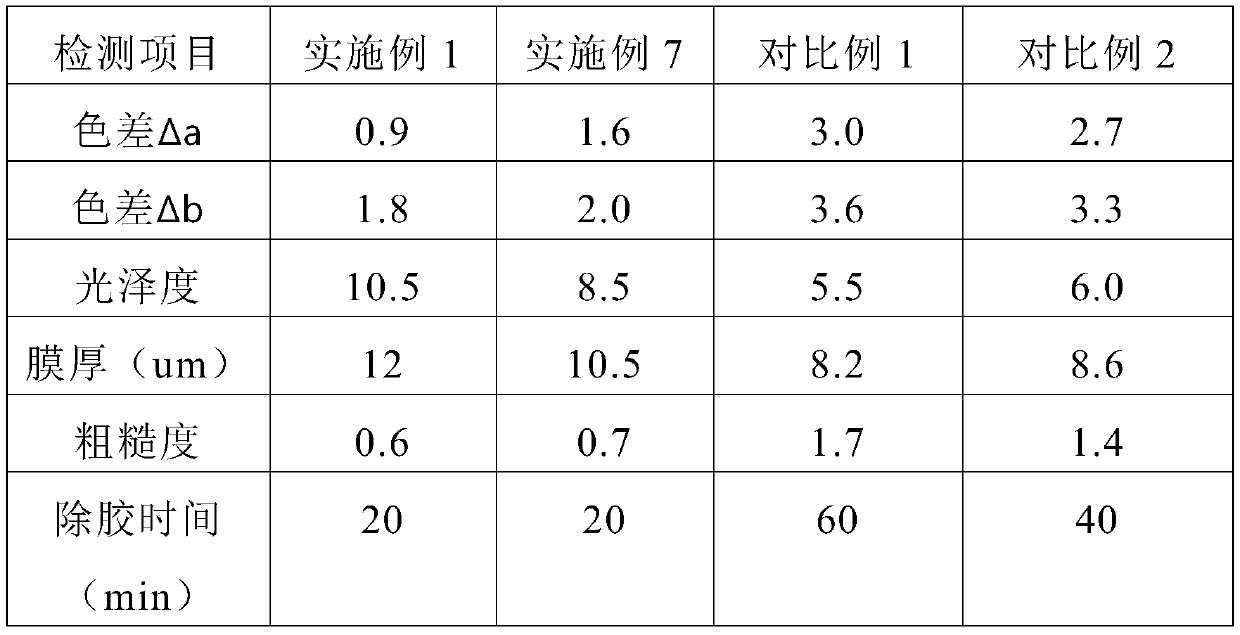

Examples

Embodiment 1

[0021] In the present embodiment, the glue remover includes 447g / L of diethylene glycol, 1.8g / L of ethylene glycol butyl ether, 252.3g / L of glycerin, 2.25g / L of triethanolamine, and 5g / L of BTA , and the balance is water. This embodiment is the best embodiment.

Embodiment 2

[0023] In the present embodiment, the glue remover includes 400g / L of diethylene glycol, 1.5g / L of ethylene glycol butyl ether, 217.5g / L of glycerin, 2.5g / L of triethanolamine, 4g / L of BTA , and the balance is water.

Embodiment 3

[0025] In the present embodiment, the glue remover includes the diethylene glycol of 500g / L, the ethylene glycol butyl ether of 2g / L, the glycerol of 278g / L, the triethanolamine of 2g / L, the BTA of 6g / L, the balance for water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com