Glass water degumming device and degumming method

A glass wafer and degumming device technology, applied in separation methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of reduced carbonization effect of concentrated sulfuric acid, large waste, waste of human and financial resources, etc., and achieves good removal effect and protection. The effect of environment and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

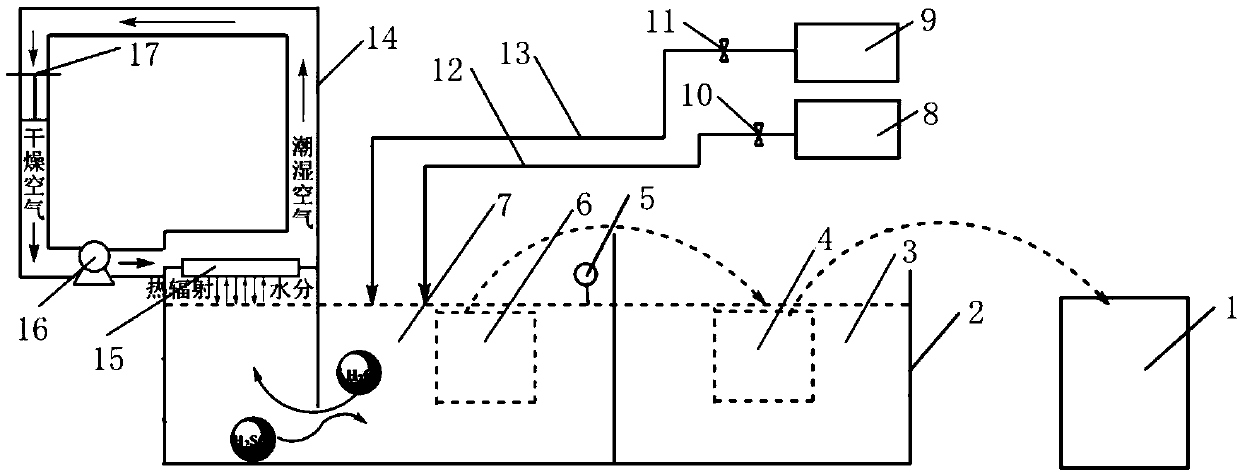

[0033] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

[0034] This embodiment provides a glass wafer degumming device, which uses concentrated sulfuric acid and hydrogen peroxide to remove the UV-cured glue from the glass wafer, and can overcome the reduction of sulfuric acid concentration and the impact of the water generated in the degumming process in the prior art. The problem of carbonization of sulfuric acid on cured glue.

[0035] Specifically, as figure 1As shown, the device includes a degumming tank 2, a dehydration assembly, concentrated sulfuric acid 8, a hydrogen peroxide tank 9, a dryer 1 and a microprocessor; wherein the microprocessor can directly select conventional devices such as 51 single-chip microcomputers to achieve the purpose of this application Whichever is the case.

[0036] The degumming t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com