A kind of continuous preparation and purification device and method of graphene oxide

A purification device, graphene technology, applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problems such as the inability to achieve continuous stripping and purification, the oxidation stripping reaction is not easy to control, and the oxidation stripping reaction time is prolonged. , to achieve the effect of promoting oxidation reaction and stripping again, improving the efficiency of continuous preparation and purification, and shortening the time of stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

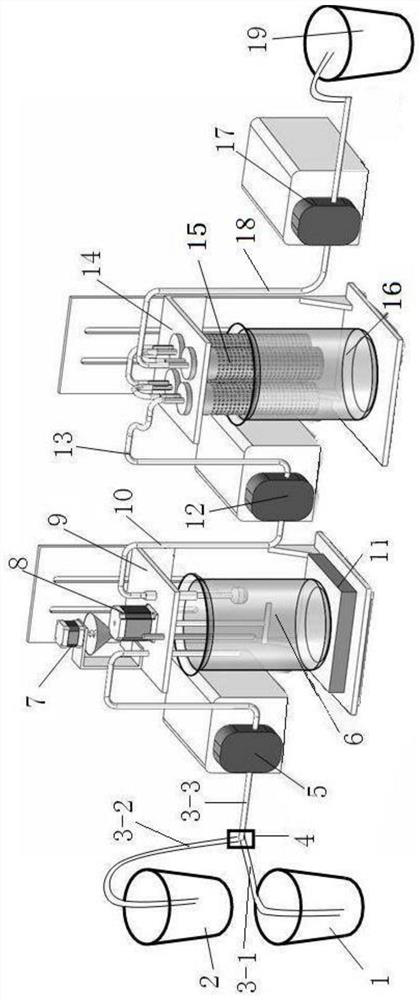

[0040] Such as figure 1 As shown, the continuous preparation and purification device of graphene oxide in this embodiment includes a reactor 6 and a concentrated sulfuric acid solution storage bottle 1 and a water / hydrogen peroxide storage bottle 2 connected to the reactor 6 through a delivery pipe respectively. There is a three-way valve 4, the concentrated sulfuric acid solution storage bottle 1 is connected to the three-way valve 4 through the first delivery branch pipe 3-1, and the water / hydrogen peroxide storage bottle 2 is connected to the three-way valve 4 through the second delivery branch pipe 3-2 , the reactor 6 is connected to the three-way valve 4 through the first delivery pipe 3-3, the first peristaltic pump 5 is arranged on the first delivery pipe 3-3, and the ultrasonic plate 11, the first lifting platform 9 is arranged directly above the reactor 6, and the first lifting platform 9 is respectively provided with holes for the feeder 7 and the reactor 6 to commun...

Embodiment 2

[0044] The preparation method of the graphene oxide of the present embodiment comprises the following steps:

[0045] Step 1, 250mL mass concentration is that the concentrated sulfuric acid solution of 98% is packed in the concentrated sulfuric acid solution storage bottle 1, water is packed in the water / hydrogen peroxide storage bottle 2, 5g flake graphite is packed in the reactor 6, open and adjust The three-way valve 4 communicates with the concentrated sulfuric acid solution storage bottle 1 and the reactor 6 and starts the first peristaltic pump 5, so that the 250mL concentrated sulfuric acid solution all enters the reactor 6, and then adds 15g of oxidizing agent in the reactor 6 through the feeder 7. Potassium manganate carries out oxidation reaction 1h, then opens stirring paddle 8 and ultrasonic plate 11 and continues to start the first peristaltic pump 5, feeds air in reactor 6, promotes the carrying out of oxidation reaction;

[0046] Step 2. After the oxidation reac...

Embodiment 3

[0053] The preparation method of the graphene oxide of the present embodiment comprises the following steps:

[0054] Step 1, put 250mL mass concentration of 98% concentrated sulfuric acid solution into the concentrated sulfuric acid solution storage bottle 1, put hydrogen peroxide into the water / hydrogen peroxide storage bottle 2, put 20g flake graphite into the reactor 6, open and adjust The three-way valve 4 communicates with the concentrated sulfuric acid solution storage bottle 1 and the reactor 6 and starts the first peristaltic pump 5, so that the 250mL concentrated sulfuric acid solution all enters the reactor 6, and then adds 20g of oxidizing agent in the reactor 6 through the feeder 7. Potassium manganate carries out oxidation reaction 5h, then opens stirring paddle 8 and ultrasonic plate 11 and continues to start the first peristaltic pump 5, feeds air in reactor 6, promotes the carrying out of oxidation reaction;

[0055] Step 2. After the oxidation reaction descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com