Lyocell multi-filament for tire cord, tire cord and tire

A tire cord and cord technology, applied in special tires, tire parts, tires, etc., can solve problems such as poor toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

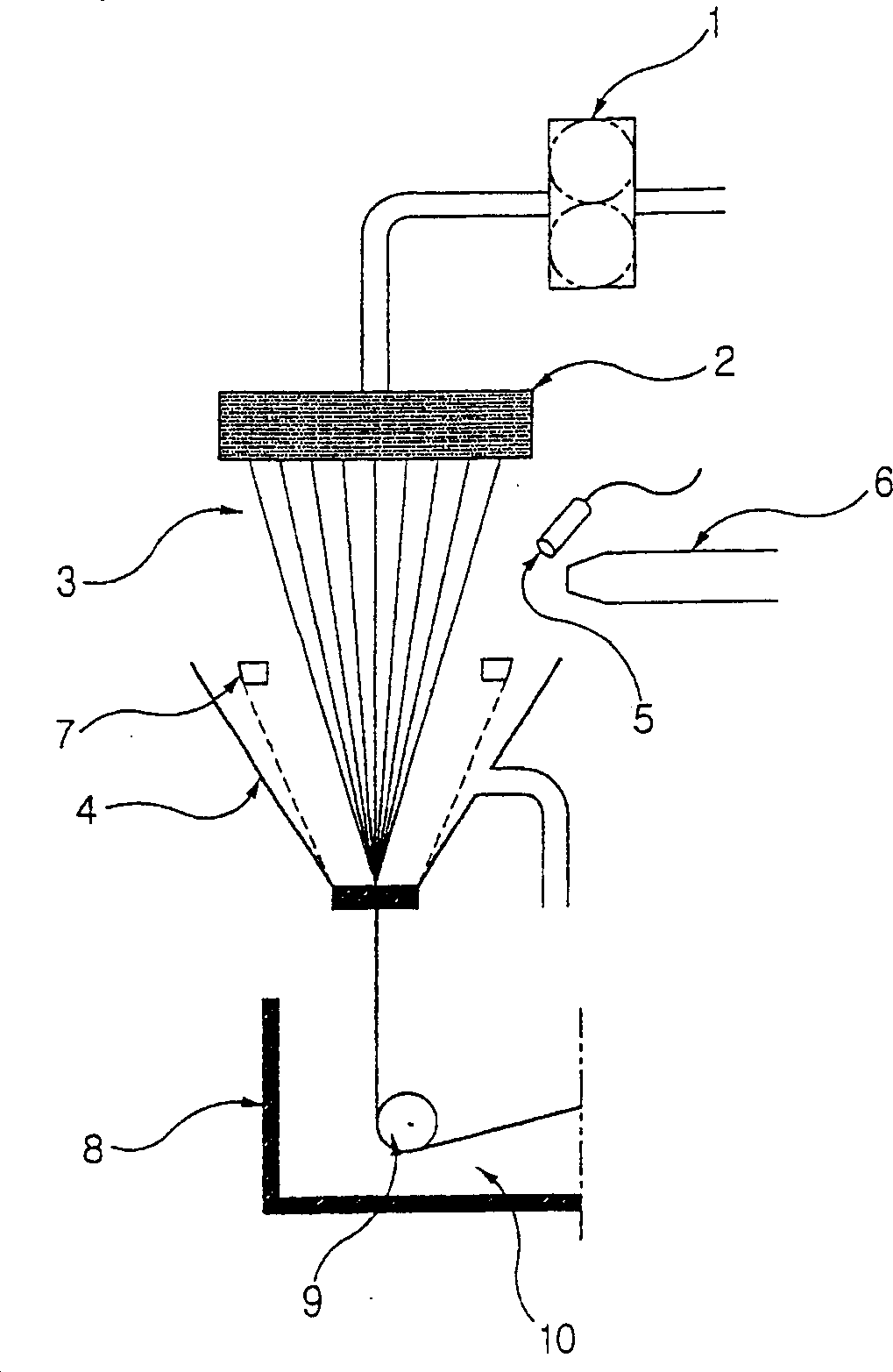

Image

Examples

Embodiment 1

[0070] The mixed powder, NMMO·1H 2 O and 0.01% by weight of propyl gallate (propyl gallate) are mixed to produce 11.5% cellulose solution, wherein in the mixed powder contains 97% α-cellulose content and has 1200 degree of polymerization (DP w ) pulp is mixed with PVA in a weight ratio of 20:1. Spinnerets comprising 800, 1000 and 1200 holes and having a diameter of 120 mm were used to extrude the cellulose solution. At this time, the diameter of each hole was 150 μm, and the length-to-diameter ratio (L / D) of each hole was 4 for all spinnerets. When the cellulose solution (top temperature: 100° C.) passing through the spinning head flows through the air gap at a point 50 mm away from the spinning head, the cooling air with a temperature of 20° C. and a relative humidity of 40% flows at 4 m / s The speed is blown to the solution, and the extrusion amount of the solution and the spinning speed are controlled in such a manner that the obtained multifilament has a fineness of 1500 ...

Embodiment 2

[0076] The first mixed powder, the second mixed powder, NMMO·1H 2 O and 0.01 weight percent propyl gallate were mixed to produce two different cellulose solution samples, wherein in the first mixed powder, 97% α-cellulose was contained and 800 degree of polymerization (DP w ) pulp is mixed with PVA at a weight ratio of 20:1, in the second mixed powder, containing 97% α-cellulose and having 1200 degree of polymerization (DP w ) pulp is mixed with PVA in a weight ratio of 20:1. In this regard, the concentration of the cellulose solution containing pulp having a polymerization degree of 800 was 13.5%, and the concentration of the cellulose solution containing pulp having a polymerization degree of 1200 was 11.5%. A spinneret comprising 1000 holes with three diameters of 120, 150, 200 microns and a diameter of 120 mm was used to extrude the cellulose solution. At this time, the length-to-diameter ratio (L / D) of each hole was 5 for all spinnerets. According to the same method as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

| Shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com