Tool for fixing 10kV insulated conductors

A technology of insulating wires and fixing tools, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of insufficient phase-to-phase, phase-to-ground distance, long operation time of wire insulation layer, damaged wires, etc. The expansion rate of the work operation, the effect of solving the deformation and energy storage and swinging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Best practice:

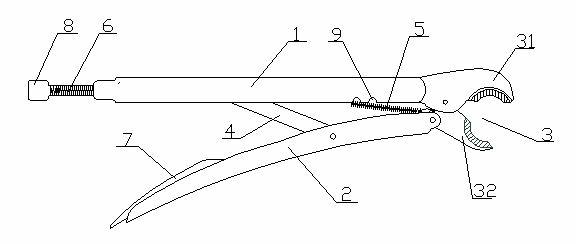

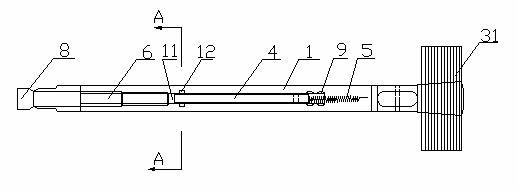

[0031] Refer to attached figure 1 , 10kV insulated wire fixing tool, including main tong arm 1, auxiliary tong arm 2, jaw 3, transmission rod 4 and return spring 5, the shape of jaw 3 is wing-shaped, and the extension of the main tong arm or auxiliary tong arm is Trunk, extending outward on both sides, with a total length of 10cm (see attached figure 2 And attached image 3 ), including a hinged fixed piece 31 and a movable piece 32, the front end of the main tongs arm 1 is connected to the fixed piece 31 of the jaw, and the front end of the auxiliary tongs arm 2 is connected to the movable piece 32 of the jaw.

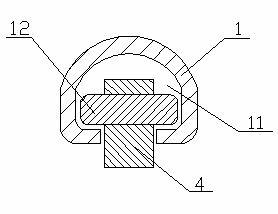

[0032] in the attached figure 1 Based on the reference to the attached figure 2 , the inner side of the main tong arm 1 has a long slot 11, the limit member 6 is installed in the long slot 11, the limit member 6 is an adjusting screw, the thread length is 50-60mm, and it is installed in the main tong A part of the tail end of the arm 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com