Processing technology of easy-to-peel sheathed cable

A processing technology and easy stripping technology, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., can solve the problems of difficult stripping and high friction, so as to shorten the time of stripping, reduce friction, prevent sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The embodiment of the present application discloses a processing technology for an easy-peeling sheath cable, which includes the following steps:

[0027] Step S1: extruding to form an insulated wire core;

[0028] Step S2: Twisting the insulated wire cores in step S1 to make a cable core, wherein the cabled pitch is L, the cabled outer diameter is D, and L=24D. This step is mainly to control the cabled pitch , because the inside of the extruded sheath is in direct contact with the cable core, a threaded inner surface will be formed. In the actual production process, the size of the pitch has a great influence on the friction between the sheath and the cable core, and the larger the pitch, The smaller the friction force, in order to increase the pitch of the inner surface of the sheath, when the insulated core wire is cabled, the cabled pitch is controlled to be 24 times the outer diameter of the cabled cable, and the accuracy of the cabled pitch is improved at the same...

Embodiment 2

[0037] Compared with Example 1, the embodiment of the present application changes the ratio of the cable pitch to the cable outer diameter, so that L=24.5D.

Embodiment 3

[0039] Compared with Example 1, the embodiment of the present application changes the ratio of the cable pitch to the outer diameter of the cable so that L=25D.

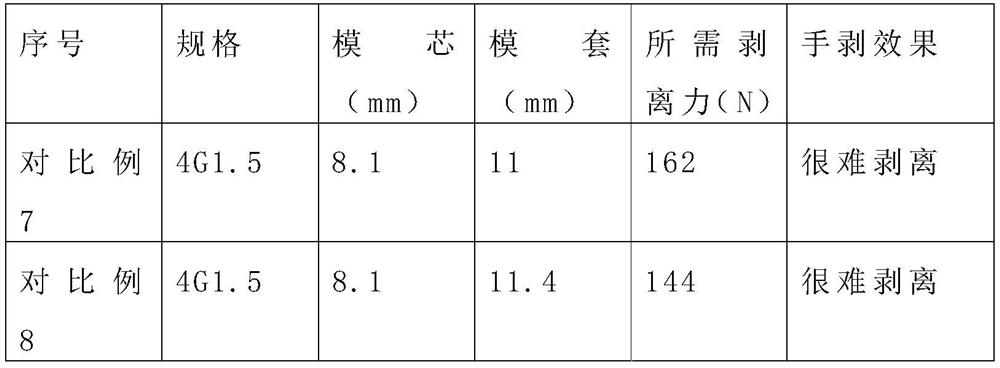

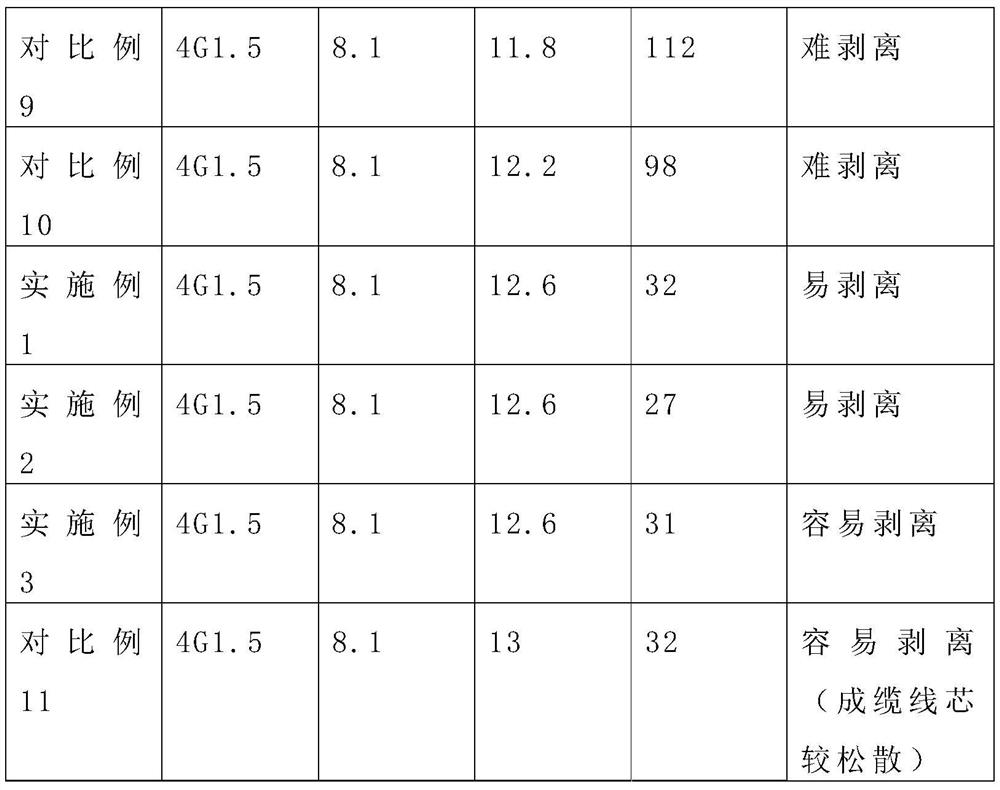

[0040] The influence of cable pitch times, mold core, mold sleeve value and talc powder on the required peeling force will be explained separately below.

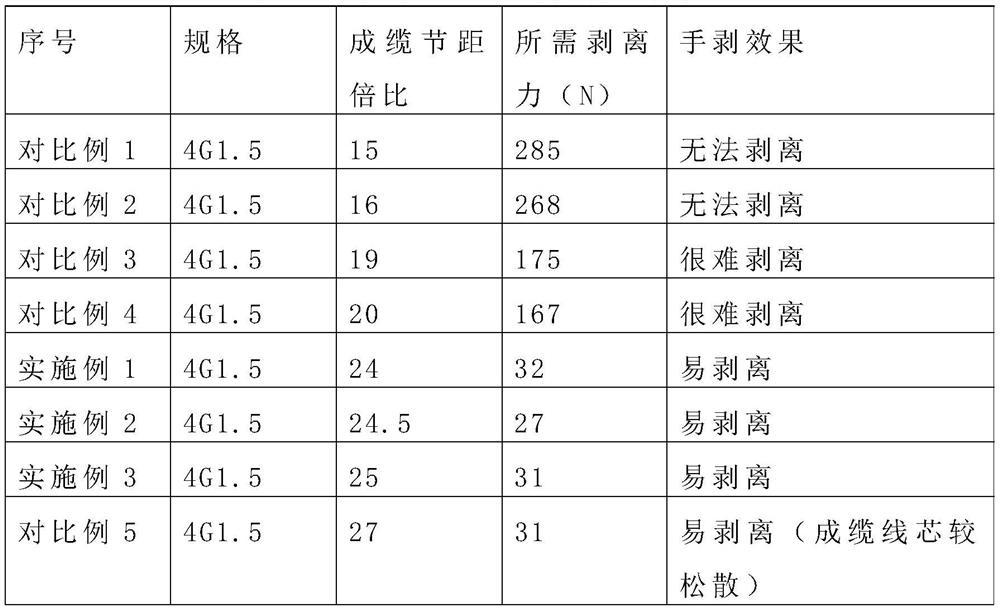

[0041] Table 1. Effect of Cable Pitch Ratio on Required Peel Force

[0042]

[0043] Comparative examples 1-5 in Table 1 in the embodiment of the present application are that the inner diameter of the die sleeve=cable outer diameter+2*mold sleeve wall thickness+3*sheath thickness, between the cable core and the sheath are smeared with Comparison in the case of 1200 mesh talcum powder;

[0044] From table 1, it can be drawn that along with the value of the cable-forming pitch ratio gradually increasing, the required peeling force will gradually decrease, and when the value of the cable-forming pitch ratio reaches 24, the required peeling force reaches the minim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com