Asphalt pavement device for road engineering

A technology for road engineering and asphalt, applied in the field of asphalt paving devices for road engineering, can solve problems such as potholes, poor paving effect, troublesome operation, etc., achieve smooth construction, avoid asphalt sticking, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

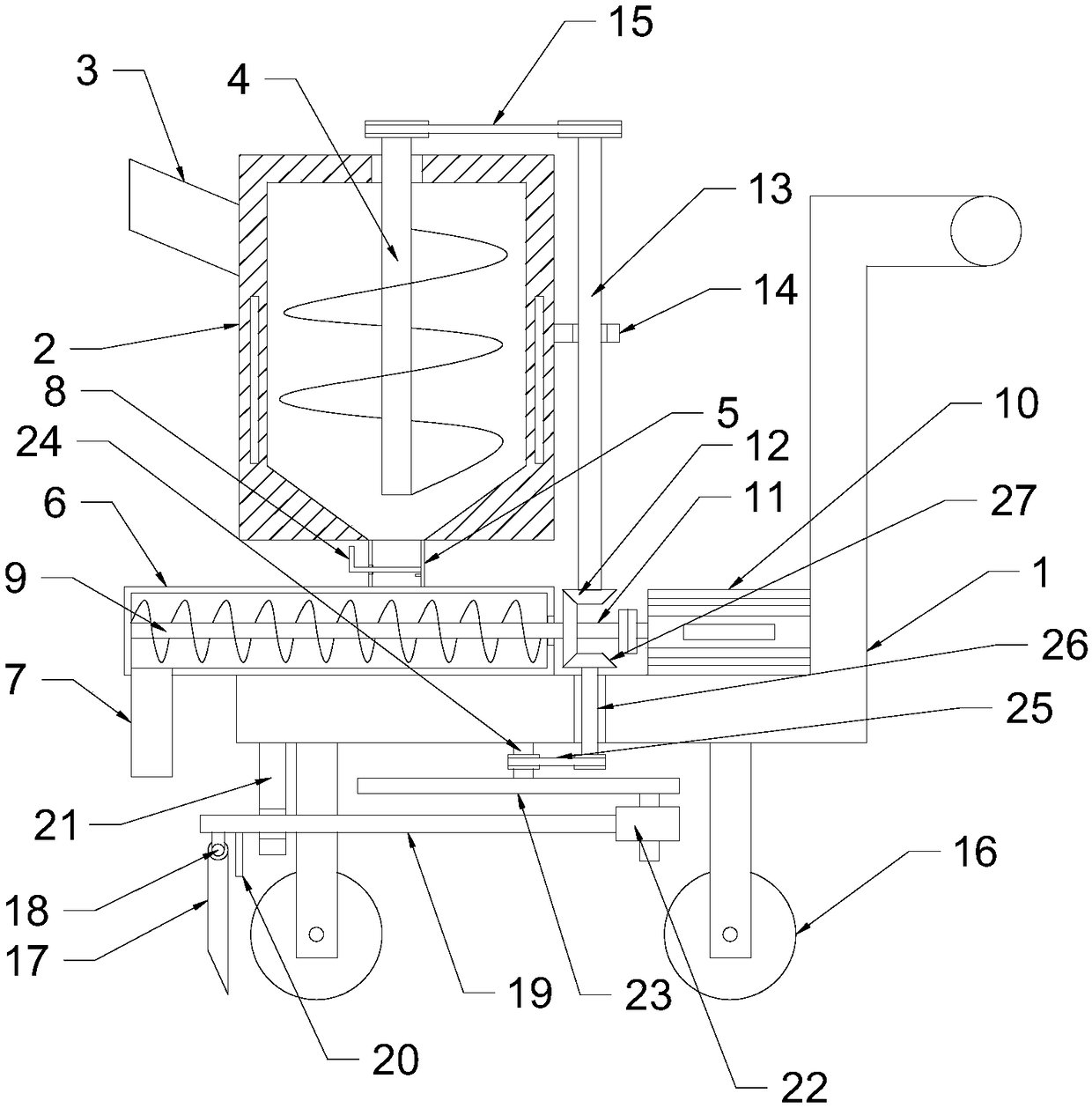

[0022] see Figure 1~3 , in an embodiment of the present invention, an asphalt paving device for road engineering, comprising a car body 1 and a mixing tank 2; 4. Stir the asphalt to avoid the stickiness of the asphalt, which is convenient for construction; the mixing barrel 2 is connected with the feeding tube 6 through the feeding pipe 5, and the feeding pipe 5 is nested with a pumping plate 8, which controls the feeding pipe 5 The conduction of the material feeding cylinder 6 is provided with a spiral feeding roller 9, and the feeding roller 9 is connected to a connecting shaft 11, and the connecting shaft 11 is connected to the output shaft of the driving motor 10 through a coupling, and the driving motor 10 is connected to the output shaft of the driving motor 10 through a bolt The fixed way is fixedly connected with the car body 1, and the driving motor 10 is electrically connected with the external power supply; the connecting shaft 11 is connected with a vertical shaft...

Embodiment 2

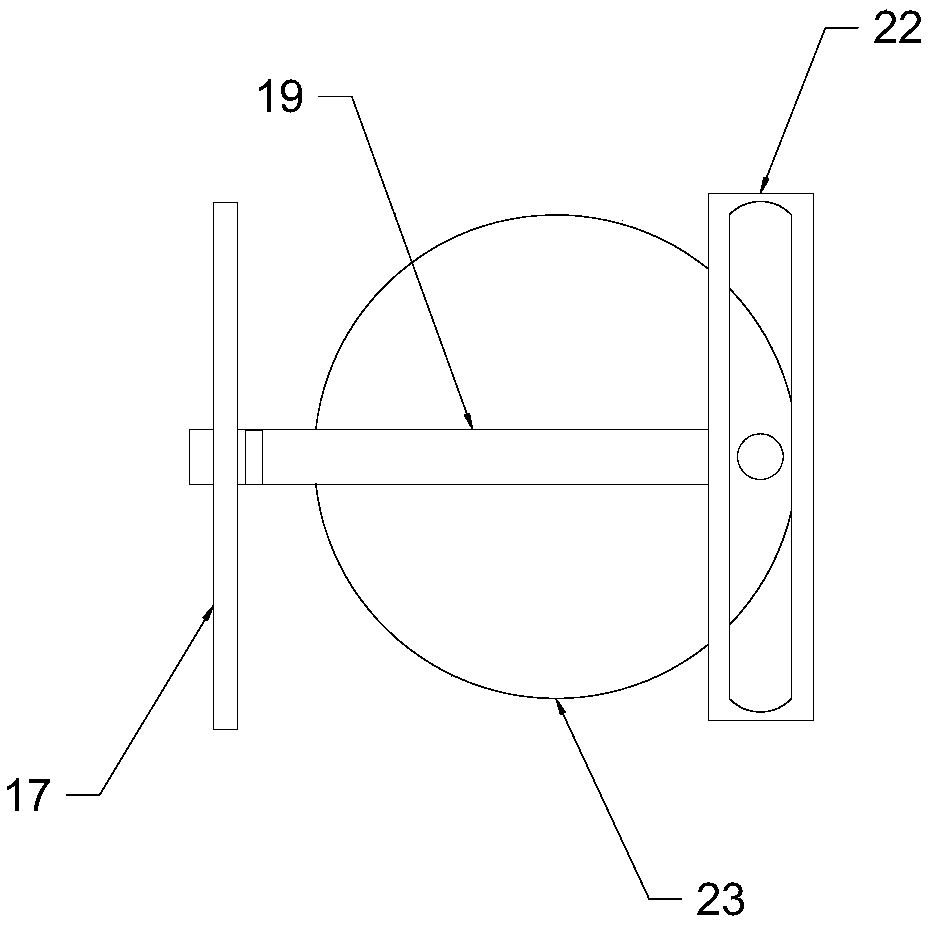

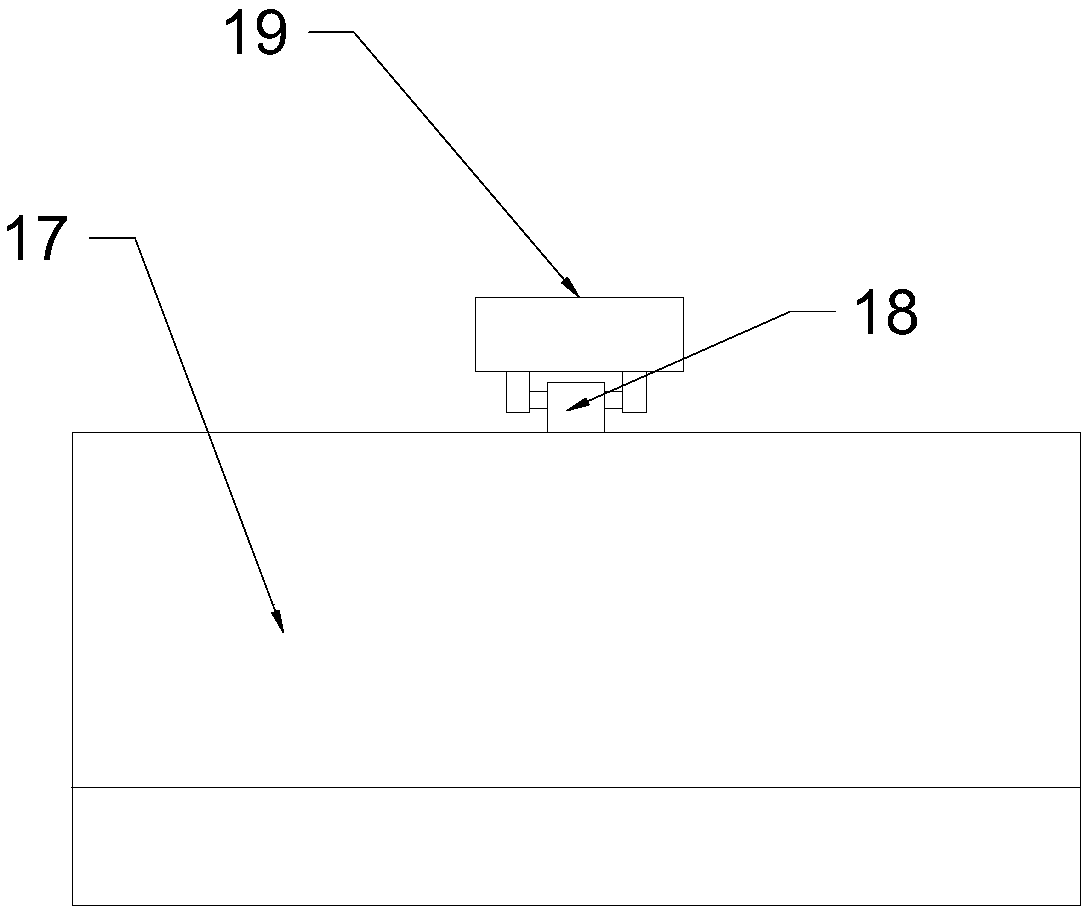

[0025] see Figure 4 , the difference of Embodiment 1 of this embodiment is: the paving mechanism is a compacting roller 28, and the compacting roller 28 is rotatably connected with a wheel frame 29. The wheel frame 29 is fixedly connected with the connecting rod 19, and the eccentric disc 23 drives the moving frame When 22 and connecting rod 19 reciprocate laterally, it drives the compacting roller 28 to reciprocate laterally to squeeze and spread the asphalt, improving the operation effect and efficiency; the mixing drum 2 is nested with a heating device 30, which is The resistance wire and the heating device 30 are electrically connected to an external power source to heat the asphalt to ensure the paving effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com