Ramie peeling and washing integrated device

A technology of peeling and washing hemp, which is applied in the field of ramie textiles, can solve the problems of unsatisfactory peeling effect and high manual labor intensity, and achieve the effect of increasing the effect of peeling hemp, reducing the residue of impurities and improving the quality of hemp peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

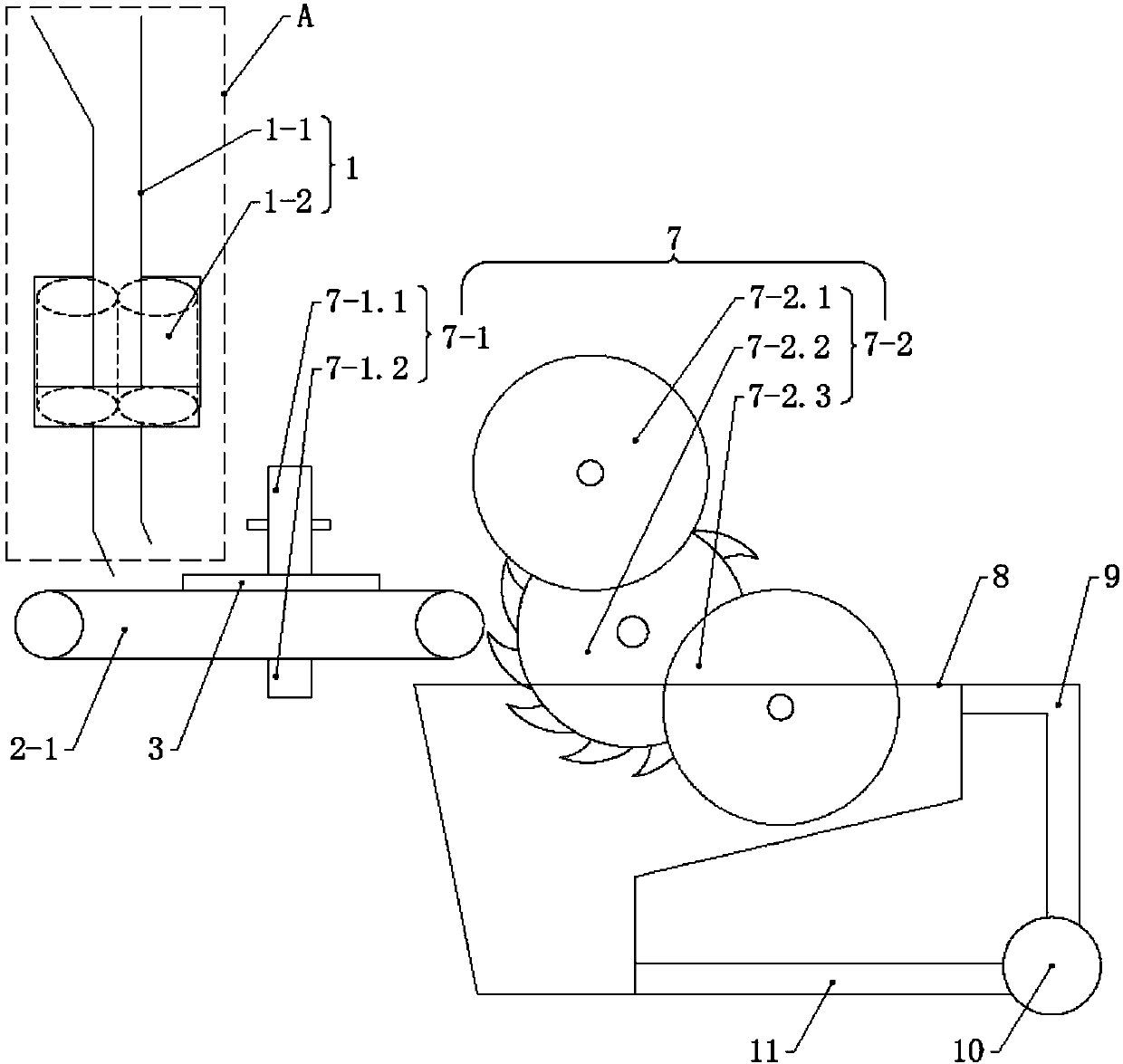

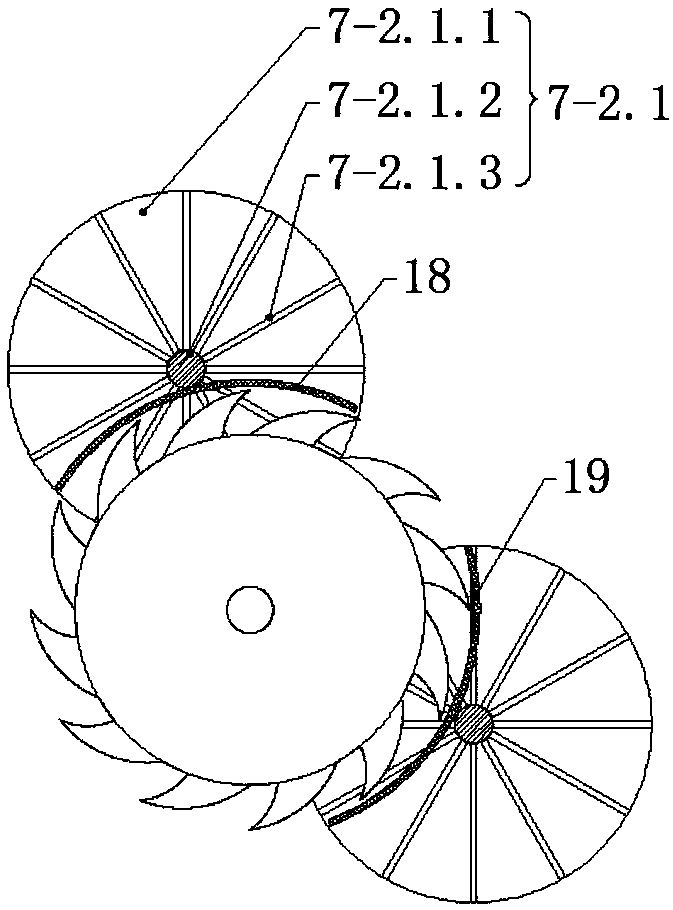

[0031]An integrated device for peeling and washing ramie, including a pretreatment mechanism 1, a conveying mechanism 2, a ramie stripping mechanism 7, and a ramie washing water tank 8 that are connected sequentially, and is characterized in that the pretreatment mechanism 1 includes a vertically arranged feeding box 1-1 and the inside of the feeding box 1-1 are provided with a pair of breaking rollers 1-2, and the conveying mechanism 2 is horizontally arranged under the feeding box 1-1, and the conveying mechanism 2 includes conveyor belts a2 arranged side by side on the same horizontal plane -1 and the conveyor belt b2-2, there is a gap 5 between the conveyor belt a2-1 and the conveyor belt b2-2, and the stripping mechanism 7 includes a pre-stripping mechanism 7-1 and a post-stripping mechanism arranged at the end of the conveying mechanism 2 7-2, the pre-stripping mechanism 7-1 includes the stripping roller 7-1.1 and the stripping groove 7-1.2 respectively arranged on the up...

Embodiment 2

[0035] This embodiment improves on the basis of Embodiment 1:

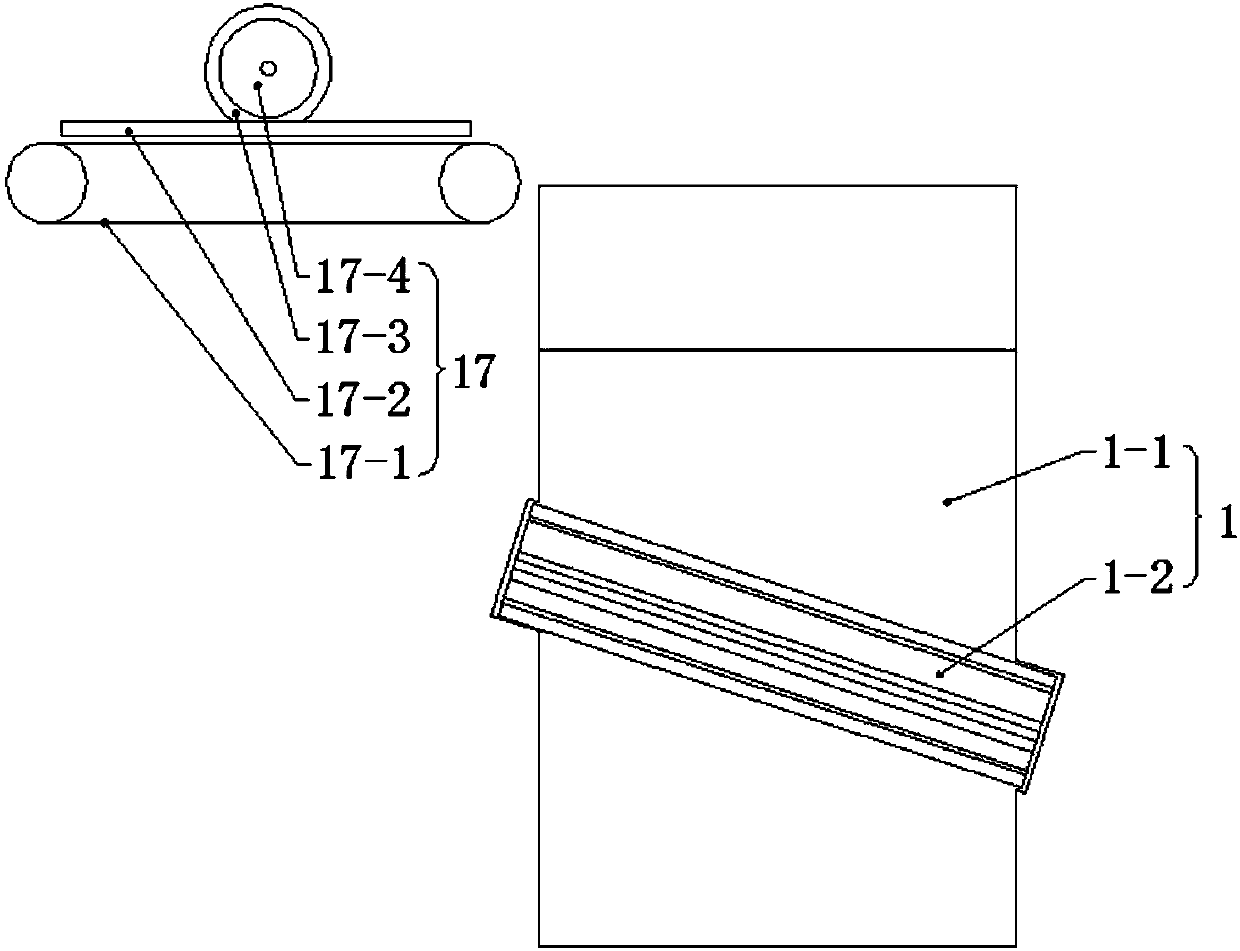

[0036] A cutting device 17 is arranged on one side of the feeding box 1-1, and the cutting device 17 includes a conveyor belt c17-1 arranged horizontally, and several guide strips 17-2 are evenly arranged side by side along the moving direction of the conveyor belt above the conveyor belt c17-1. A cutting wheel 17-3 is correspondingly arranged above the adjacent guide strips 17-2, and an annular blade 17-4 is sheathed on the circumference of the cutting wheel 17-3.

[0037] Working principle: the ramie stalks are transported through the conveyor belt 17-1 in the forward direction, and after being guided and shunted by the guide strips 17-2, there is only one ramie stalk between adjacent guide strips 17-2, which is passed through the cutting wheel 17-2 After the circular blade 17-3 cutting on the 4, cut the axial otch on the green skin and the bast of the ramie stalk.

[0038] Above improvement advantage is: utili...

Embodiment 3

[0040] This embodiment is improved on the basis of the above embodiments:

[0041] Conveyor belt a2-1 and conveyor belt b2-2 are respectively provided with grooves a15 and groove b16 which are perpendicular to the moving direction of the conveyor belt and correspondingly matched with each other. Above groove a15 and groove b16, baffles a3 and Bezel b4.

[0042] The advantages of the above improvements are: groove a and groove b enable the pretreated ramie stems to be evenly separated into a single stable delivery through the grooves, and at the same time, the pre-stripping can be carried out one by one separately, increasing the pre-stripping The ramie stripping effect, the baffle plate can flatten and stabilize the ramie stem when the ramie is pre-stripped in the middle, so as to prevent the two ends of the ramie from upturning or moving during the pre-stripping process in the middle, which will affect the pre-stripping work .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com