Wire stripper for sheath flexible cable

A technology of flexible cables and wire strippers, which is applied in the direction of cable installation, cable installation devices, equipment for dismantling/armoring cables, etc., and can solve the problems of incomplete cutting, misalignment of core wires or conductors, and unreliable wire stripping machines. Complete stripping and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation and examples of the present invention will be described below in conjunction with the accompanying drawings.

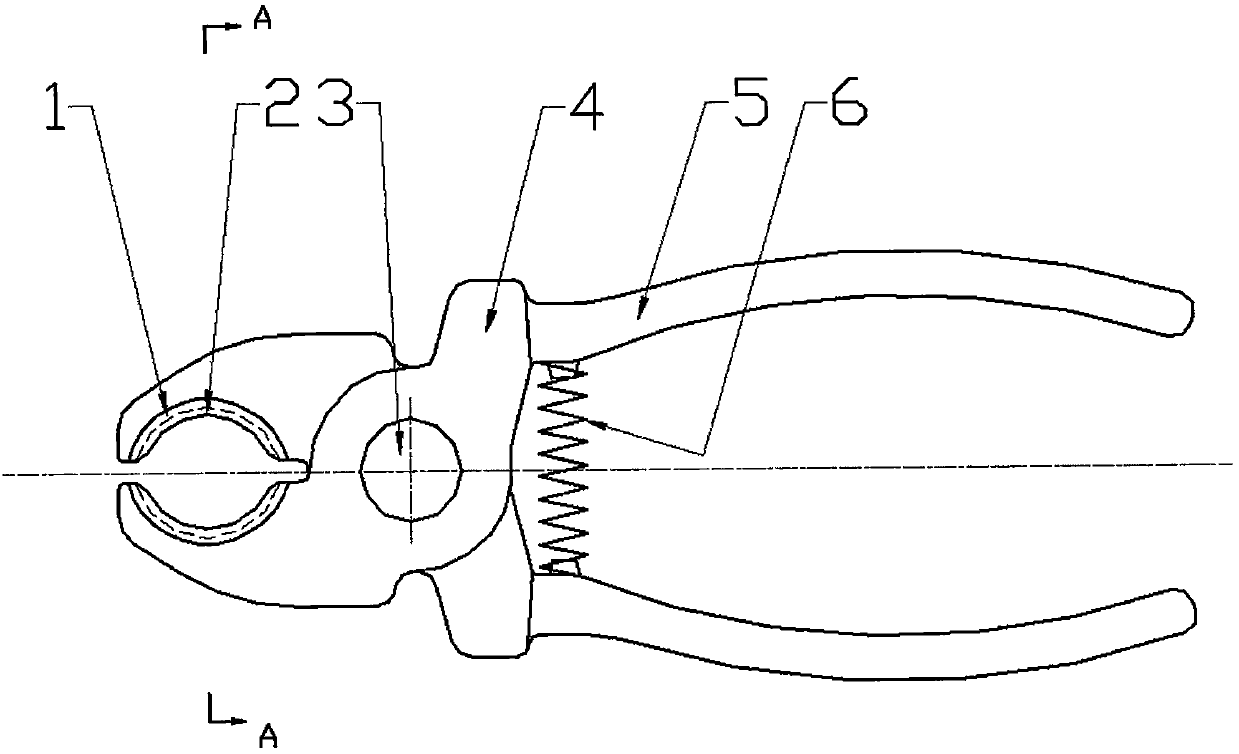

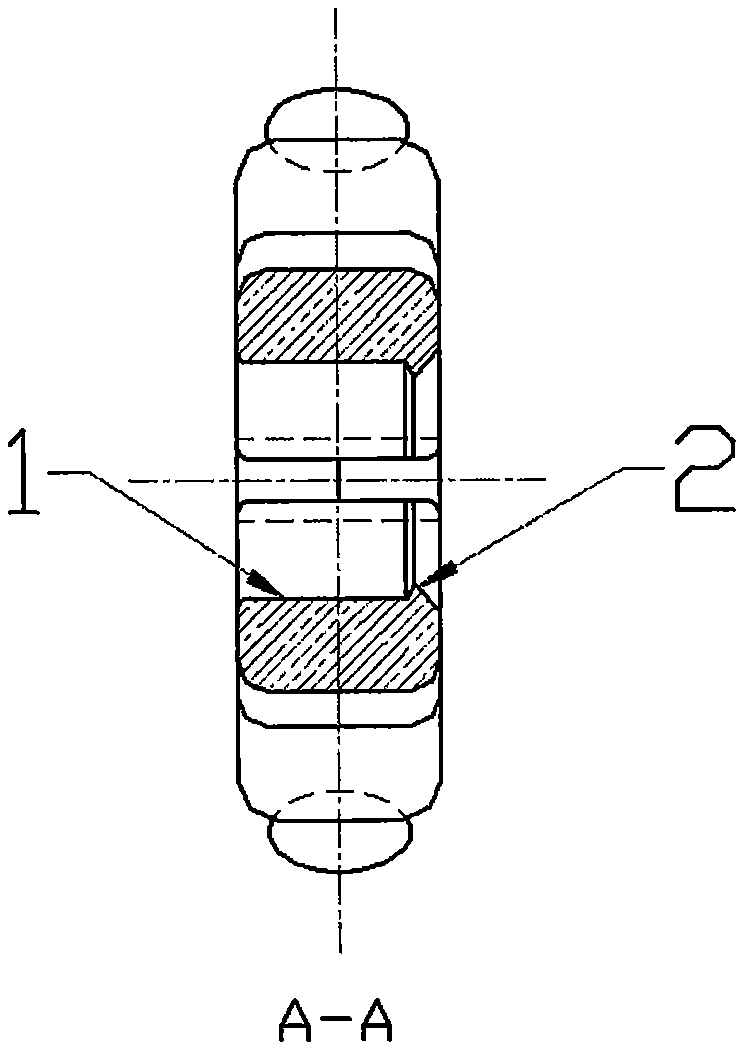

[0015] attached figure 1 And attached figure 2 The structural features and principles of specific embodiments of the tool of the present invention are shown. It can be seen that the jaw (1) is arc-shaped and is composed of two symmetrical arcs up and down, and one side of the jaw (1) has arc-shaped jaws (2) along the jaw (1). The pliers teeth (2) respectively protrude from the upper and lower symmetrical arc surfaces of the jaws (1), so they can hold the end section of the sheathed flexible cable or core wire to be stripped and make the pliers teeth (2) ) clamped at the ring-cut part, and can tear the sheathed flexible cable or core wire along the ring-cut part; The peeling direction required by the head section, so the sawtooth (2) can be caught in the ring-cut and torn part of the sheathed flexible cable or core wire to complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com