Low-frequency cable assembly crimping system wire cable laser stripping device

A cable assembly and cable technology, which is applied in the field of cable laser stripping devices in low-frequency cable assembly crimping systems, can solve problems affecting laser stripping operations, easy cable position changes, and laser lens pollution, etc., to achieve laser stripping operations Complete, improved stripping quality, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

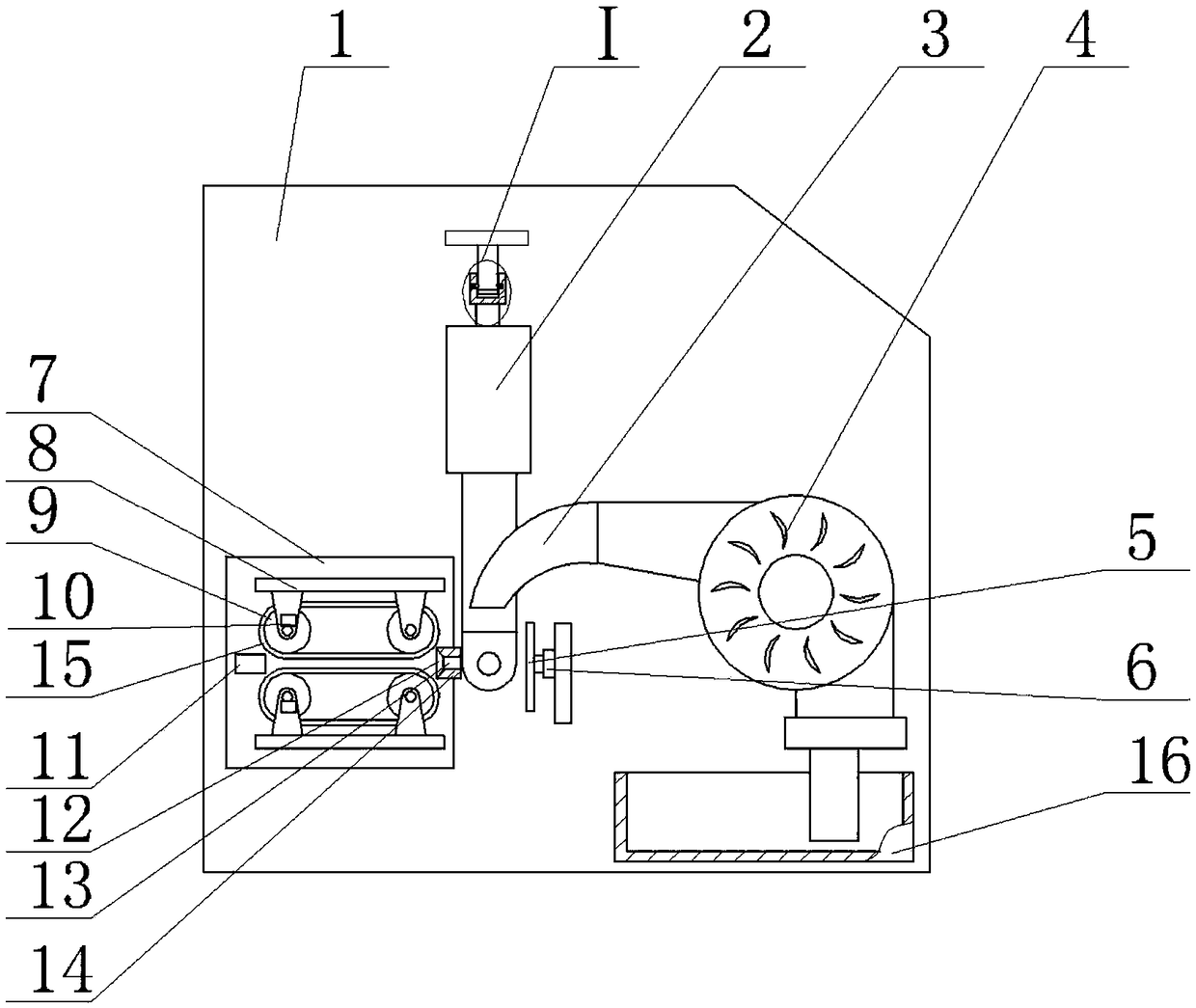

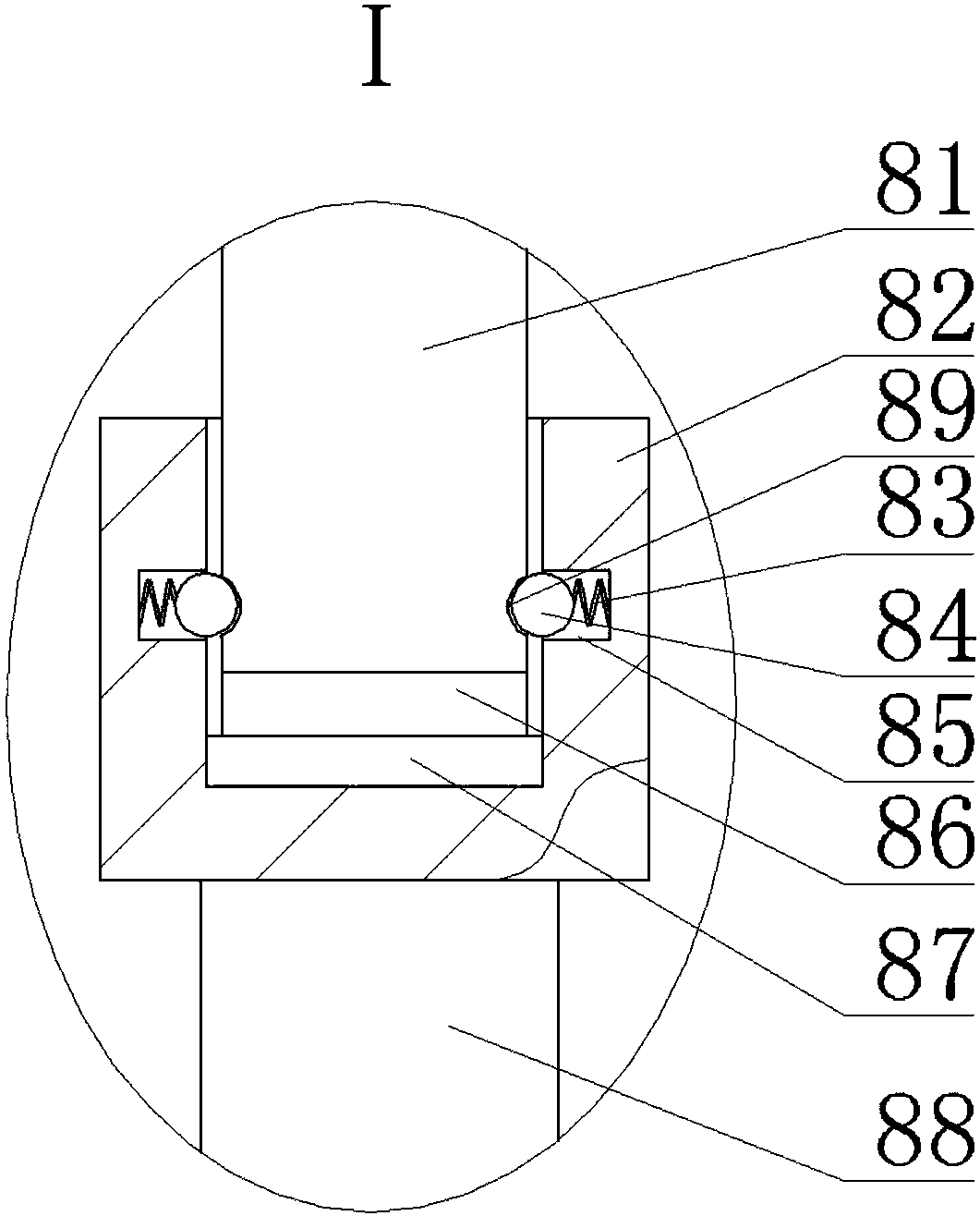

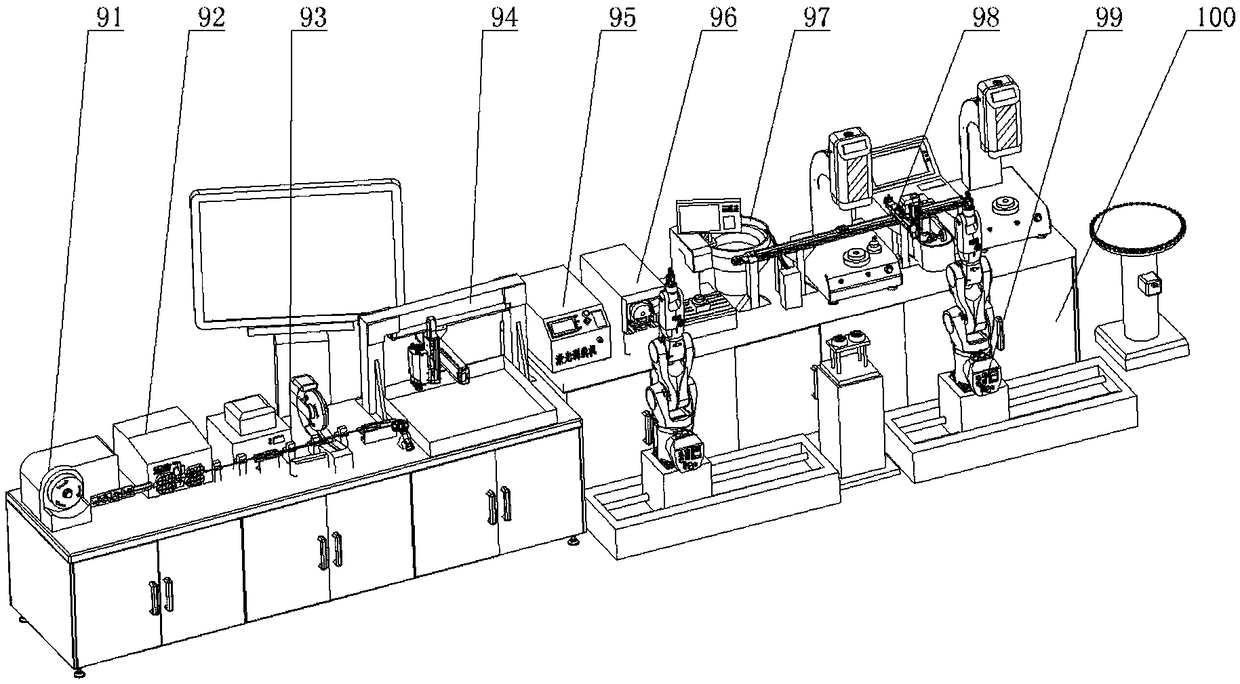

[0011] like figure 1 , figure 2 and image 3 As shown, a low-frequency cable assembly crimping system cable laser peeling device is disclosed, including a chassis 1, a carbon dioxide laser emitting device 2, a fan 4, a water tank 16, and a crawler-type guide device installed on the side of the cabinet 1, and the crawler-type guide device Including a base plate 7, two sets of crawler conveyors, guide tubes 11 and guide blocks 14 are installed on the base plate 7, the crawler conveyor includes a roller frame 8, a stepper motor 10 and two rollers are installed on the roller frame 8 9. The stepper motor 10 can drive the rollers 9 to rotate. A belt 15 is installed between the two rollers 9. The belts 15 of the two sets of crawler conveyors are set opposite to each other. The guide pipe 11 and the guide block 14 are respectively located on both sides of the crawler conveyor. , guide groove 12 and guide hole 13 are offered on guide block 14, and guide groove 12 is positioned at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com