Welding clamp for cylindrical battery

A welding jig, cylindrical battery technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

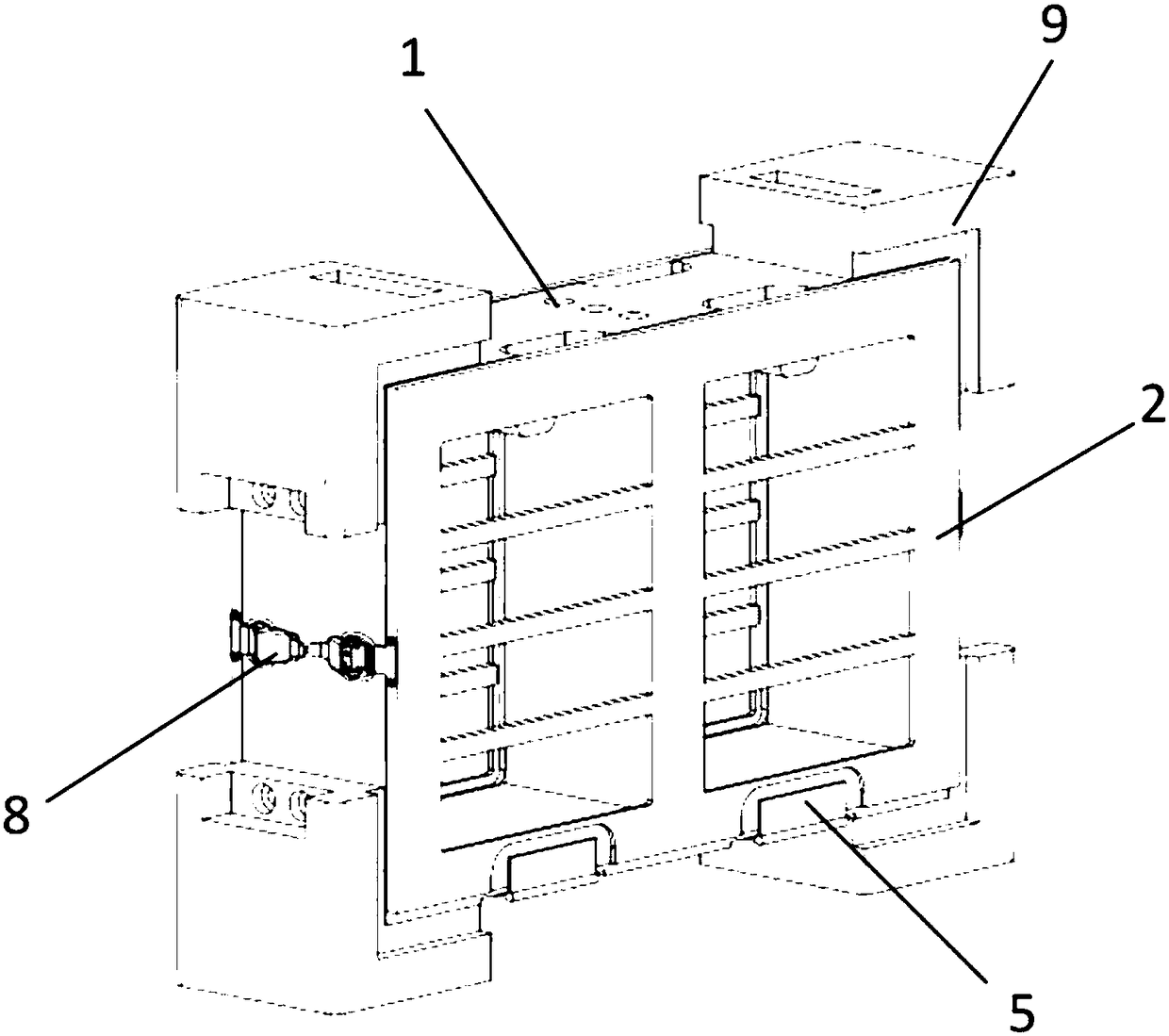

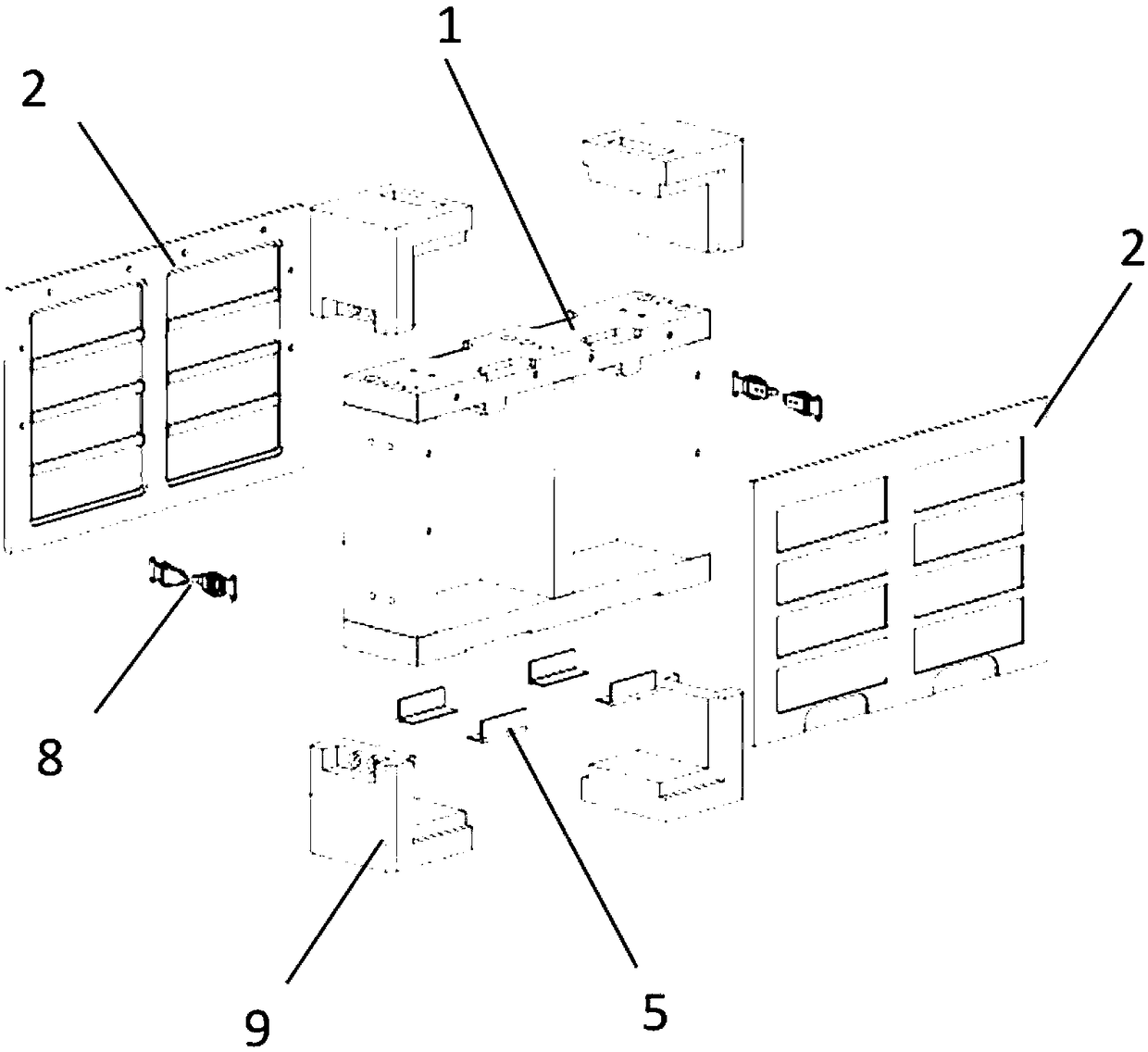

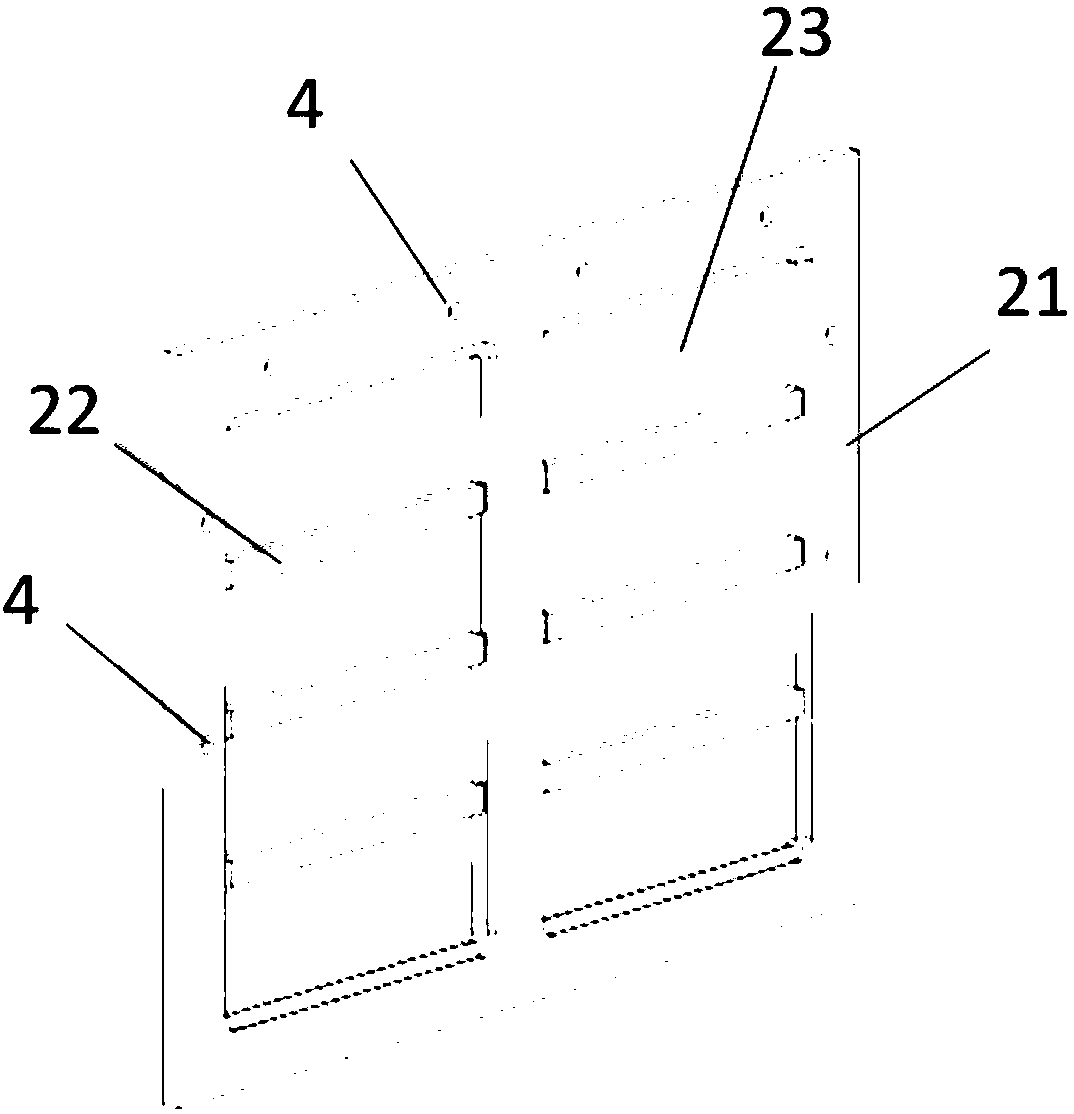

[0035] Figure 1 to Figure 5 A preferred embodiment of a cylindrical battery welding jig according to the present invention is shown. As shown in the figure, the cylindrical battery welding jig includes a frame body 1 for placing the battery module 10. The bus plate on the top is fixed and pressed on the battery module, wherein the bus plate includes a board body and a plurality of bus bars located on the board body, and the plurality of bus bars correspond to the positions of the battery electrodes of the battery module 10 one by one. . The pressing plate 2 is provided with a welding operation window 23 for one-to-one welding of a plurality of bus bars and a plurality of cell electrodes. When in use, the pressure plate 2 is opened, the battery module 10 is placed in the frame body 1, and the bus plate is covered on the battery module 10, and the multiple bus pieces on the bus plate are connected with the multiple batteries of the battery module 10. The positions of the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com