Filter-carrying micro plate

A filter and micro-plate technology, applied in the direction of fixed filter element filter, filtration separation, instrument, etc., can solve the problems of filter damage, assembly difficulty, sample backflow, etc., to achieve easy assembly, solve proficiency, prevent position effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

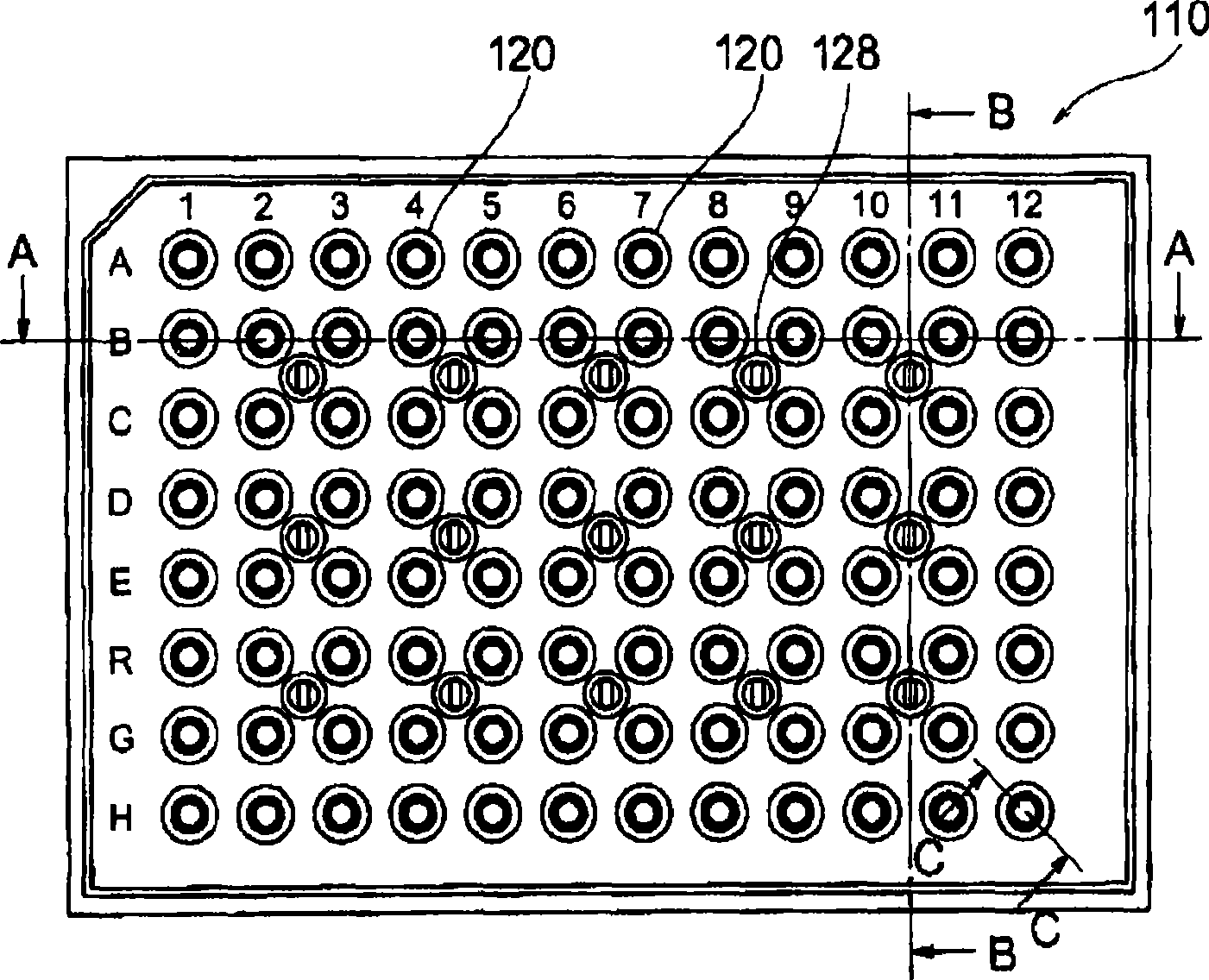

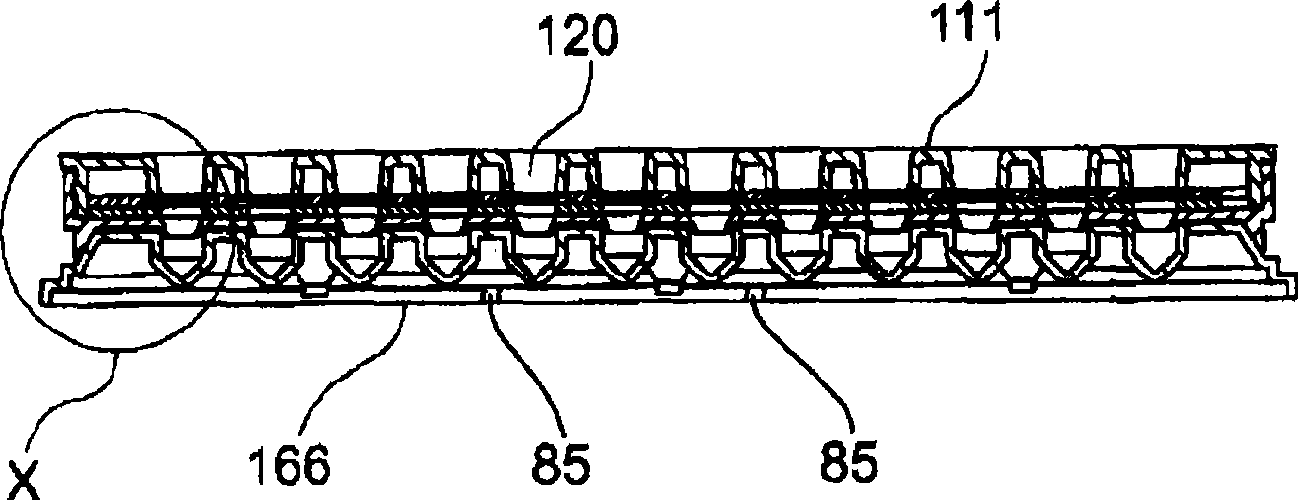

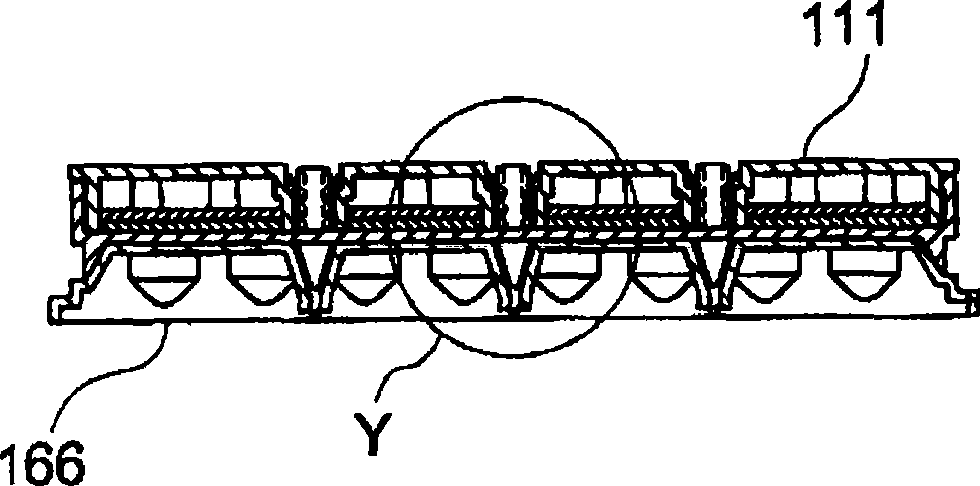

[0096] figure 1 It is an enlarged plan view showing a microplate 110 with a filter, which is an example of the device of the present invention. As shown in the drawing, the surface of the microplate has a rectangular shape, and the whole has, for example, a cuboid of about long side (120-150 mm)×short side (80-100 mm)×thickness (10-20 mm). However, it is obvious to those skilled in the art that the size and shape can be changed according to the application and other requirements. Therefore, the surface shape of the filter-attached microplate 110 of the present application may be, for example, a circle or an ellipse other than the illustrated rectangular shape and other rectangular shapes. However, in the following examples, the aforementioned rectangular microplates will be described. This microplate 110 is arranged with a plurality of (on figure 1 In the example, 12×8, a total of 96) openings 120, through which the culture solution (for example, a test substance such as co...

Embodiment 2

[0133] Figure 7 It is a plan view of the microplate 40 with a filter of the present invention. As shown in the drawing, the surface of the microplate 40 has a rectangular shape, and the whole has, for example, a cuboid of about long side (120-150 mm)×short side (80-100 mm)×thickness (10-30 mm). However, it is obvious to those skilled in the art that the size and shape can be changed according to the application and other requirements. Therefore, the surface shape of the microplate 40 with filter of the present application invention is except Figure 7 In addition to the illustrated rectangular shape and other rectangular shapes, for example, a circular or elliptical shape may also be used. However, in the following description, the above-mentioned rectangular microplate will be described. In this microplate 40, a plurality of (on Figure 7 In this example, 12×8, 96 in total) openings 50 , through which the culture solution (for example, the sample to be tested such as col...

Embodiment 3

[0174] The following will refer to Figure 41 Embodiment 3 of the invention of the present application will be described. Figure 41 The shown embodiment 3 is similar to the previously described embodiment 2, so only the parts different from the previously described embodiments will be mainly described below. exist Figure 41 In , elements or parts similar to those of the previous embodiments are denoted by appending A to the reference numerals of the previous embodiments. Additionally, from Figure 41 As can be seen in the illustrated embodiment, constituting Figure 41 elements of the previous drawings, especially Figure 9 The shown elements have slightly different shapes, but the basic structure of each element is basically the same as that of the previous embodiment, but it is a change that can be easily understood by those skilled in the art, so the description of each constitution of Embodiment 3 is omitted. A detailed illustration of the element.

[0175] exist F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com