Return pull-type decorticating machine

A hemp stripping machine and a technology for stripping hemp, applied in mechanical treatment, fiber mechanical separation, textiles and papermaking, etc., can solve the problem of low connection strength between beating board and hemp peeling roller, which affects the efficiency and quality of hemp peeling, and board beating Unreasonable setting angles and other problems can achieve the effect of improving the quality of hemp stripping, improving the efficiency of hemp stripping, the quality of hemp stripping, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

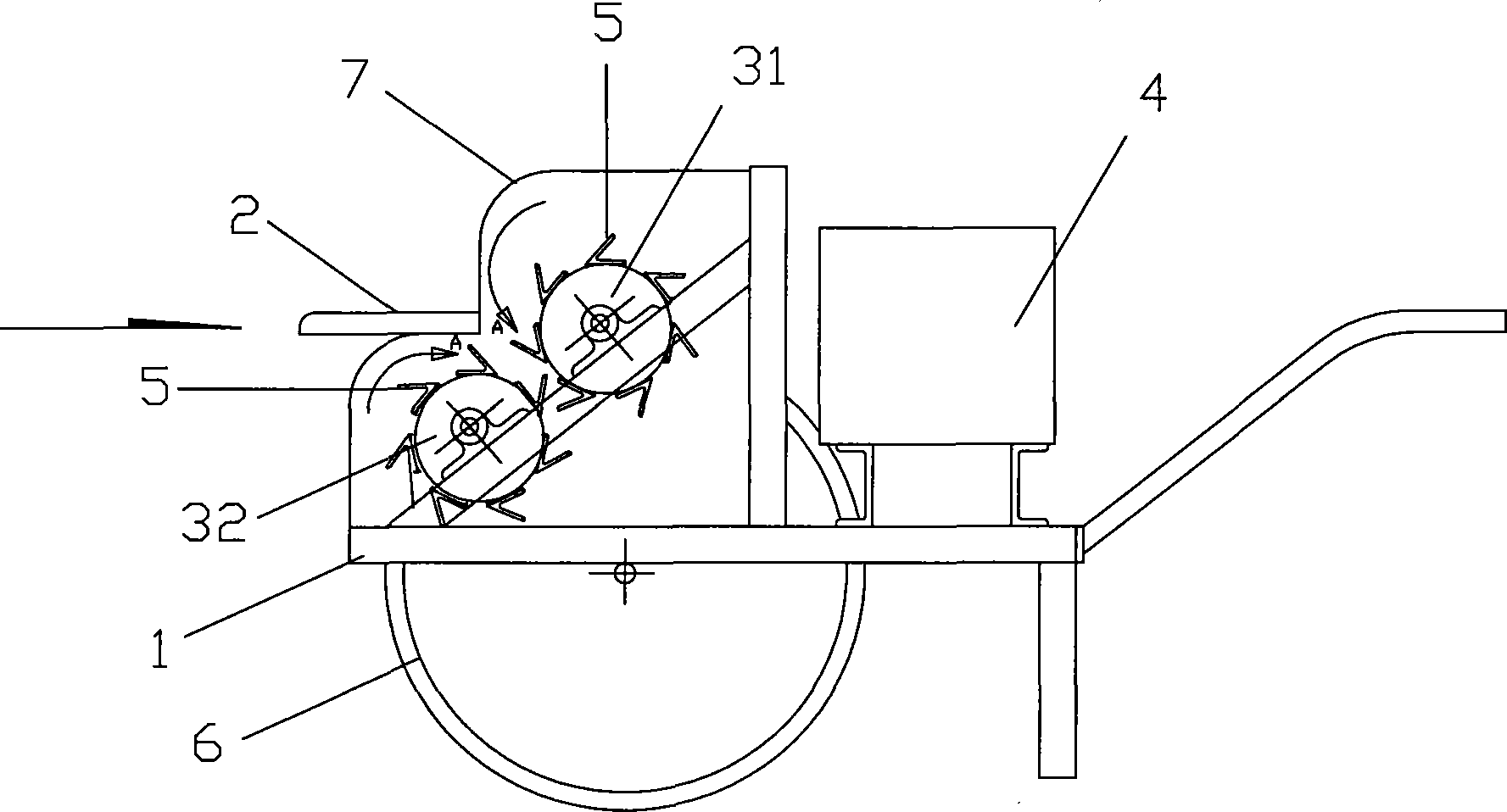

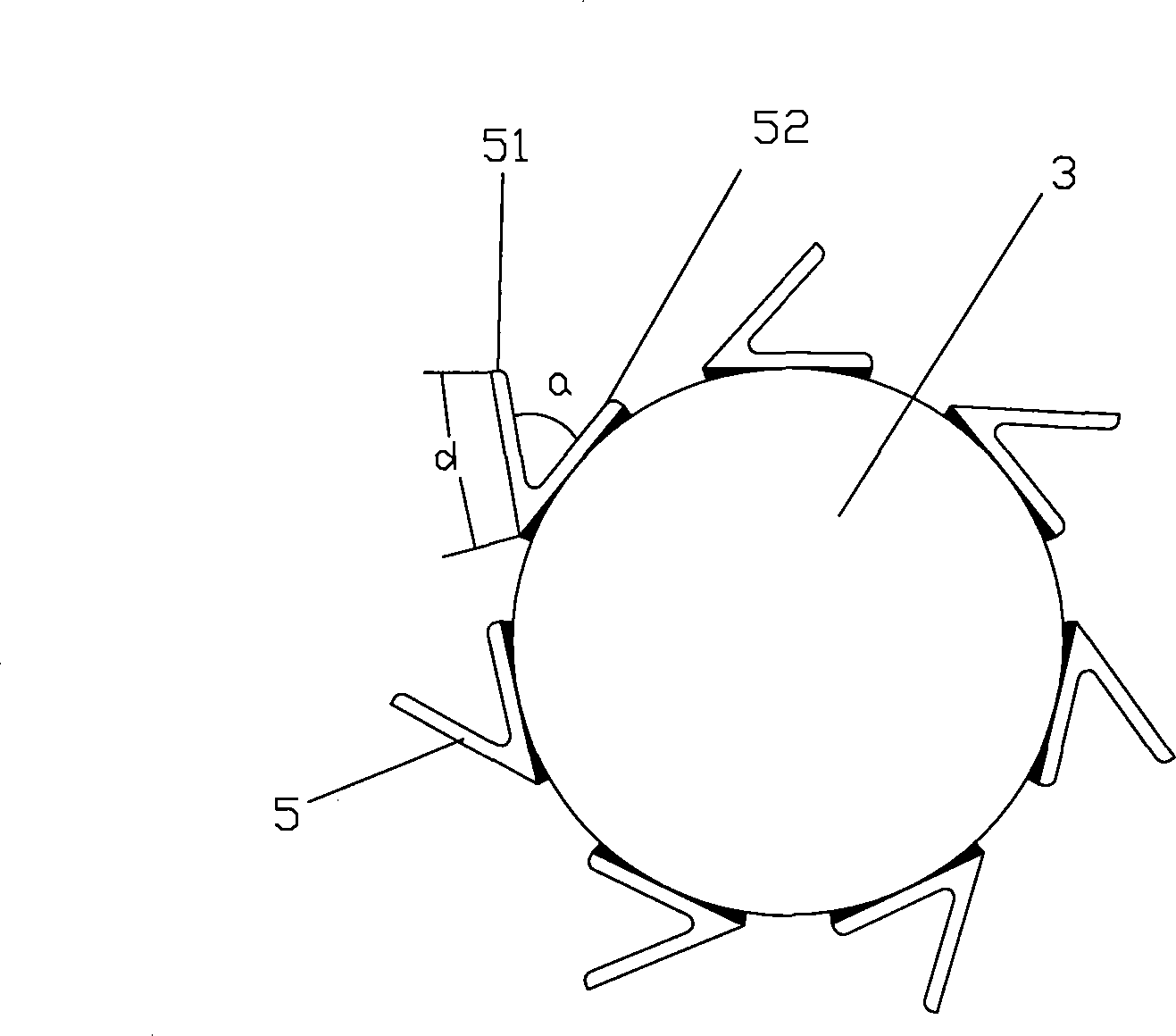

[0016] Such as figure 1 and figure 2 Shown, the pull-back type stripping hemp machine of present embodiment comprises frame 1, and the hemp feeding channel 2 that is installed on described frame 1 and stripping hemp roller 3, is used to drive described hemp stripping roller 3 Power unit 4, in the present embodiment, described power unit 4 is the air-cooled diesel engine of 3.2 kilowatts (kW), and described hemp removing roller 3 comprises active hemp removal roller 31 and passive hemp removal roller 32, so The circumferential surface of the active stripping cylinder 31 and the passive stripping cylinder 32 is evenly welded with a beating plate 5, and the beating plate 5 includes a working part 51 and a connecting part 52, and the working part 51 and the connecting part The included angle a of 52 is 45°, and the orientation of the included angle a is opposite to the rotation direction A of the delineating roller 3 .

[0017] When the hemp stripping machine is working, the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com