Dry and wet gas mixing and humidifying device for inhibiting zinc ash in hot galvanizing and use method thereof

A humidification device and hot-dip galvanizing technology, which are applied in the hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems affecting the surface quality of strip steel, and achieve the suppression of zinc dust formation, precise control, and suppression effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

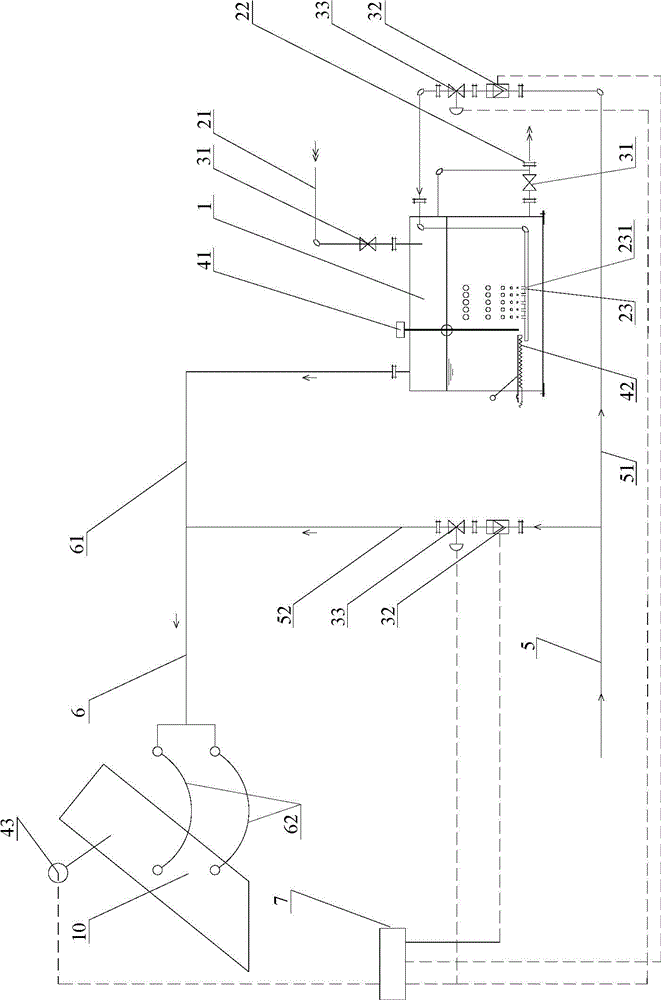

[0027] A dry and wet gas mixing humidification device for hot-dip galvanizing to suppress zinc dust, comprising a furnace nose 10, a water tank 1, a water inlet pipe 21, a drain pipe 22, an air inlet pipe 23, a valve 31, a regulating valve 32, a flow meter 33, Water level gauge 41, heater 42, dew point meter 43, dry gas main pipe 5, first dry gas branch pipe 51, second dry gas branch pipe 52, dry-wet mixing pipe 6, wet gas pipe 61, dry-wet mixing branch pipe 62 and control device 7 ,like figure 1 As shown, the specific structure is:

[0028] The water inlet of the water tank 1 is connected to the water source through the water inlet pipe 21 connected in series with the valve 31, and the water outlet of the water tank 1 is connected with the drain pipe 22 connected in series with the valve 31. The water tank 1 is filled with water and is provided with a water level gauge 41. An air intake pipe 23 and a heater 42 are provided, and an exhaust hole 231 is provided on the pipe wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com