Patents

Literature

50results about How to "Avoid missing defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

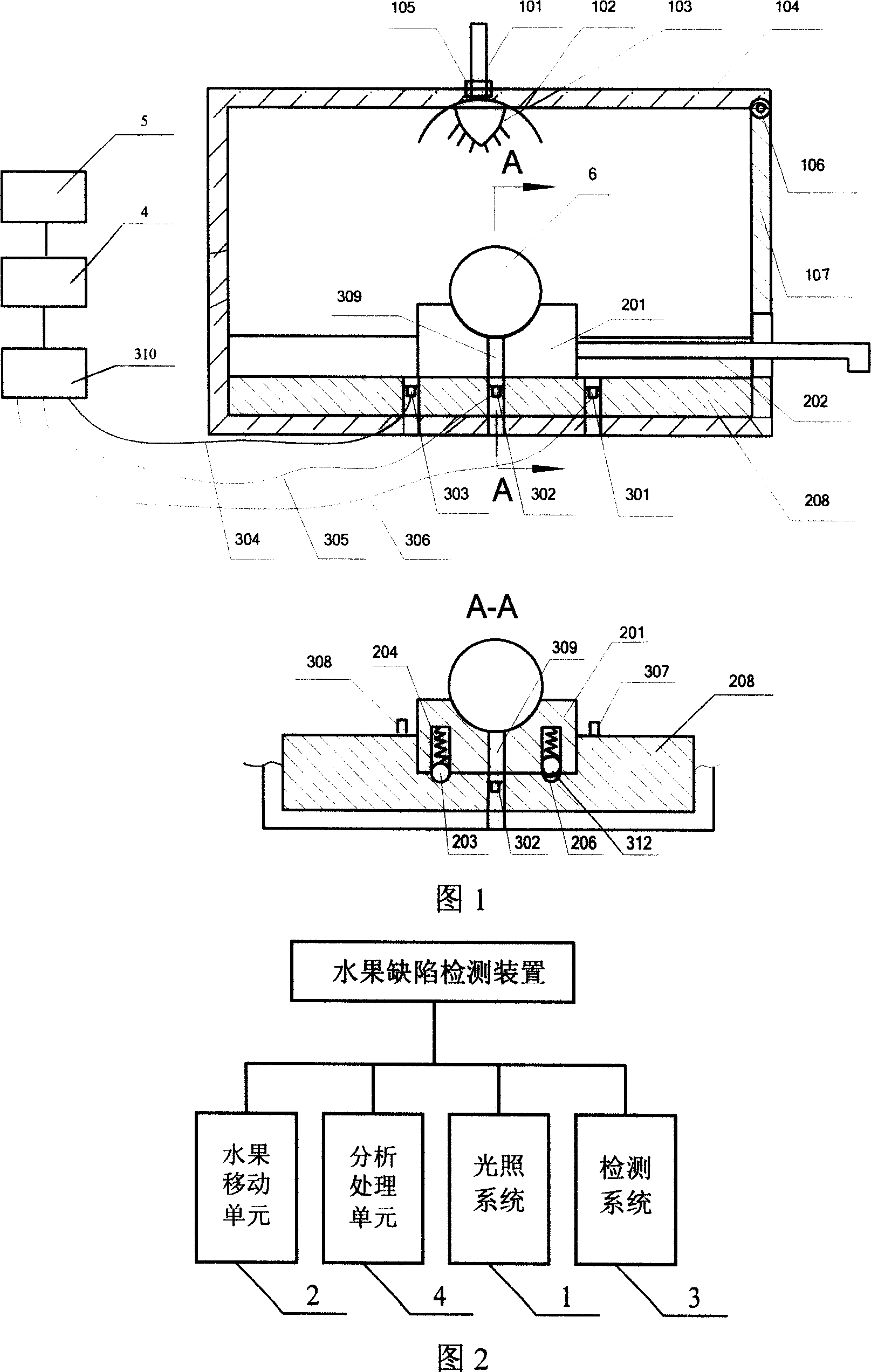

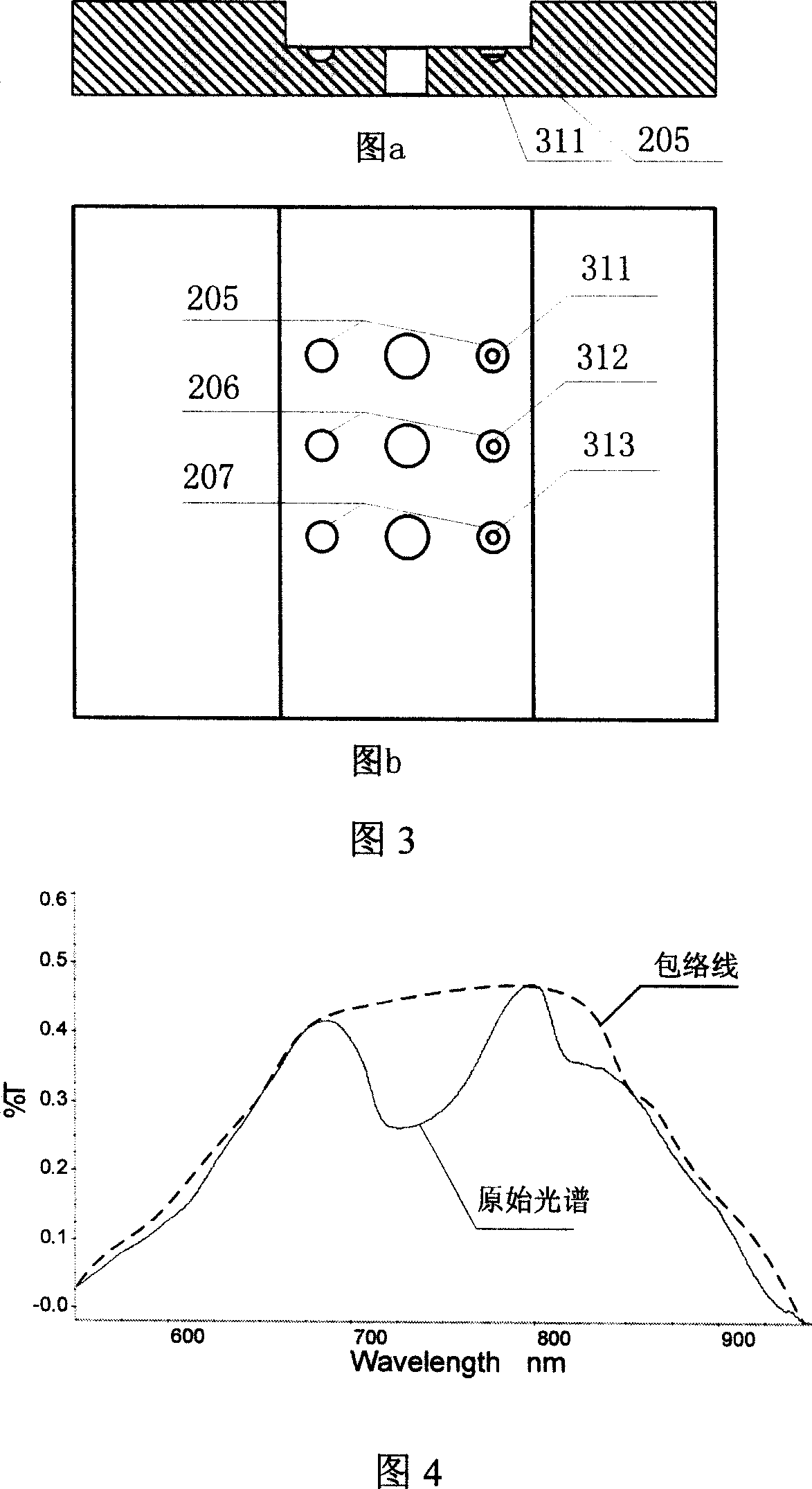

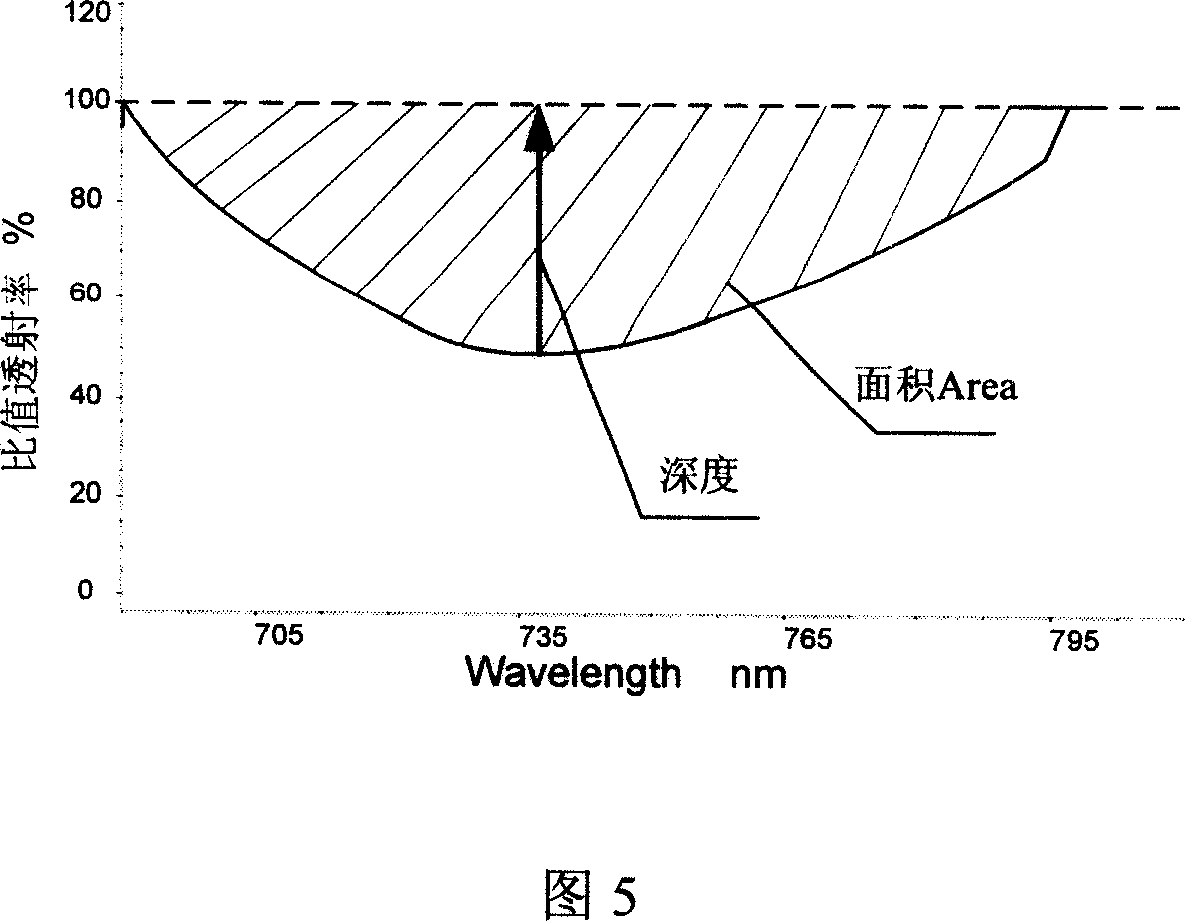

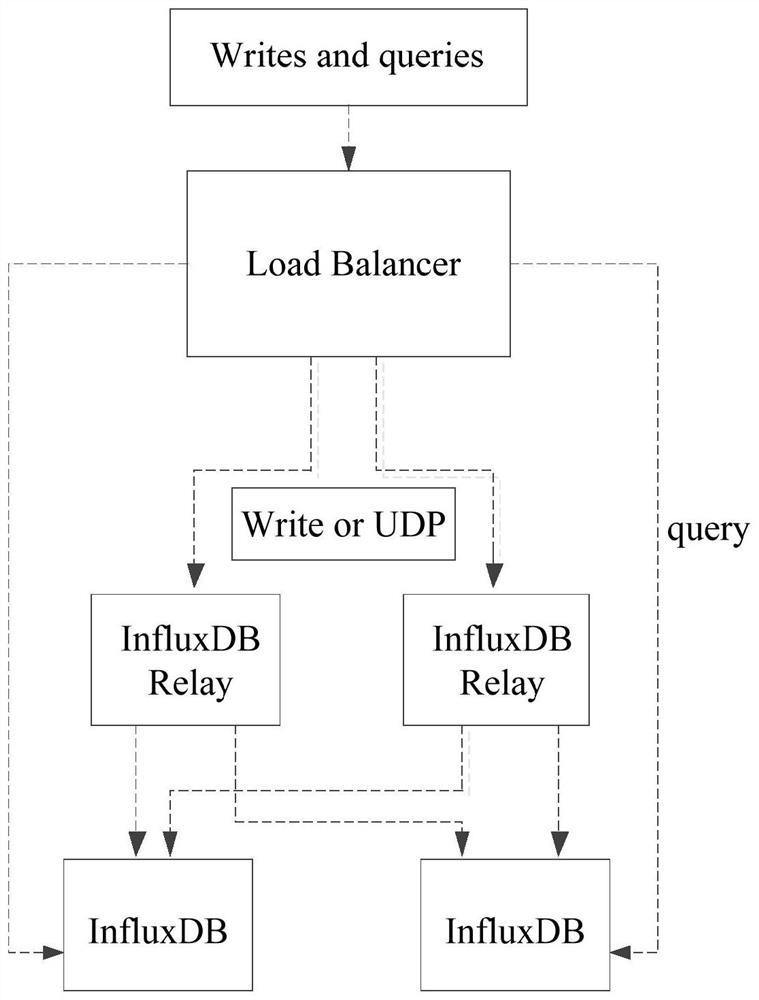

Method and device for detecting fruit defects based on multi-sensor information fusion

InactiveCN101008621AAvoid missing defectsImprove detection accuracy and stabilityOptically investigating flaws/contaminationColor/spectral properties measurementsLight sourceLight spectrum

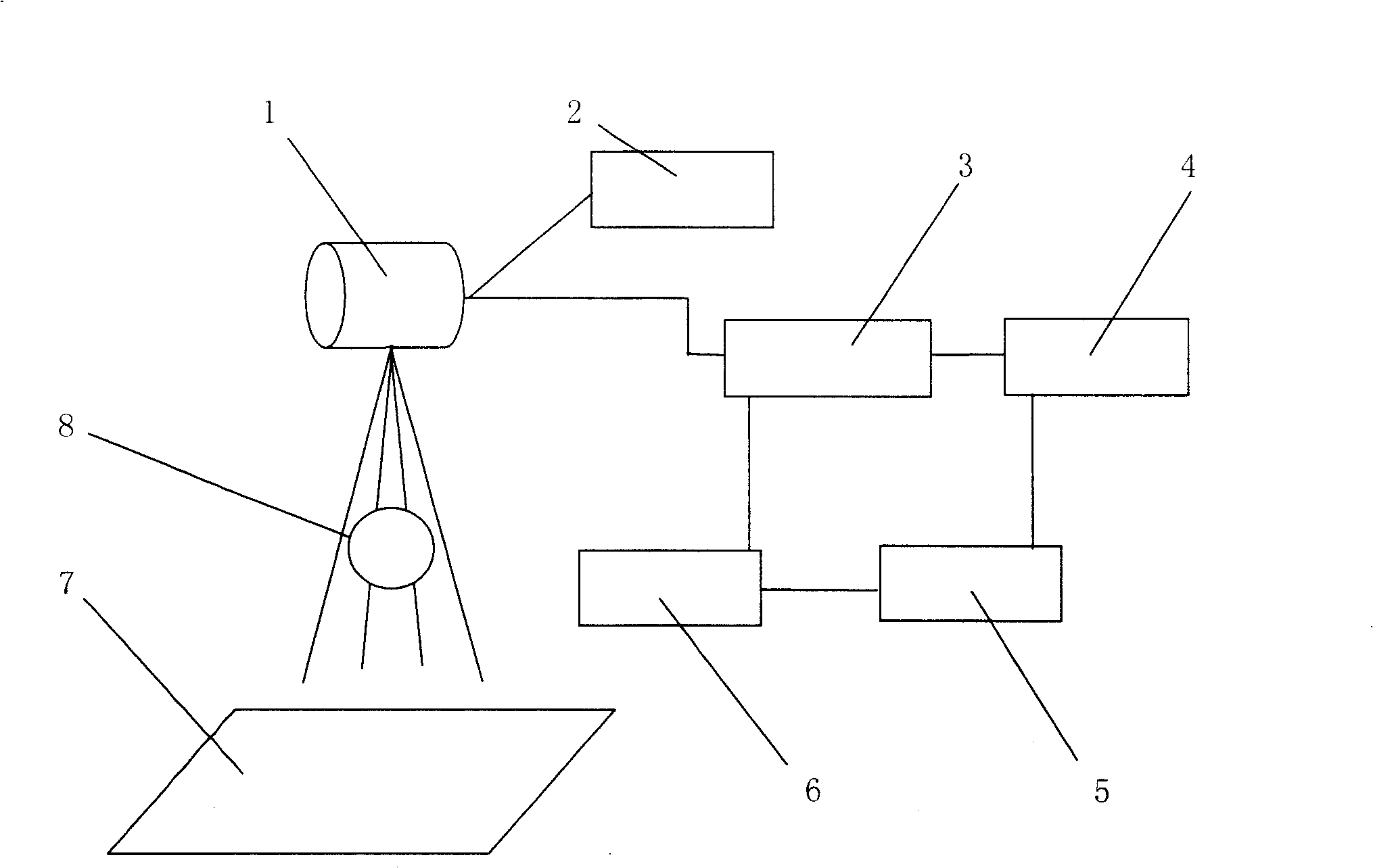

This invention discloses one method and device to test fruit deficiency based on multi-sensor information integration, which comprises the following steps: using multiple testers to get light source to light fruit different parts spectrum information; test mode adopts continuous remove method and K near method or their combination and referring to fruit environment temperature and humidity factors to identify deficiency. This invention method uses multiple testers to test fruit to avoid leakage.

Owner:ZHEJIANG UNIV

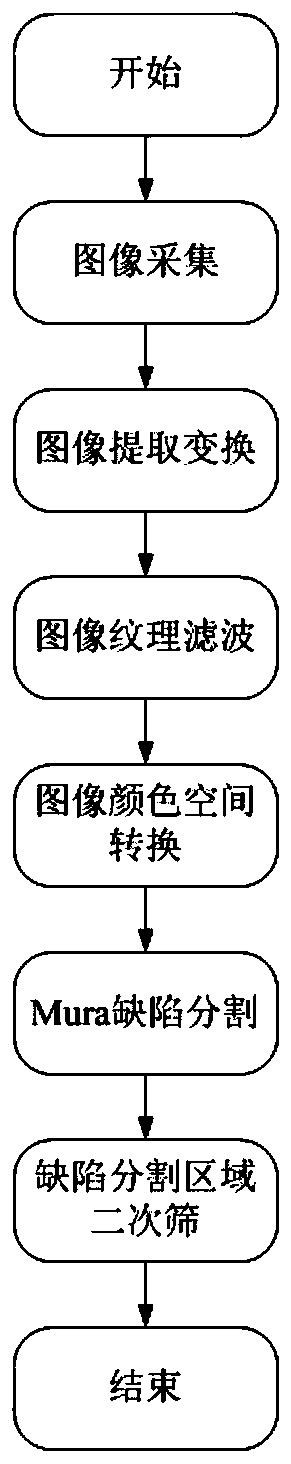

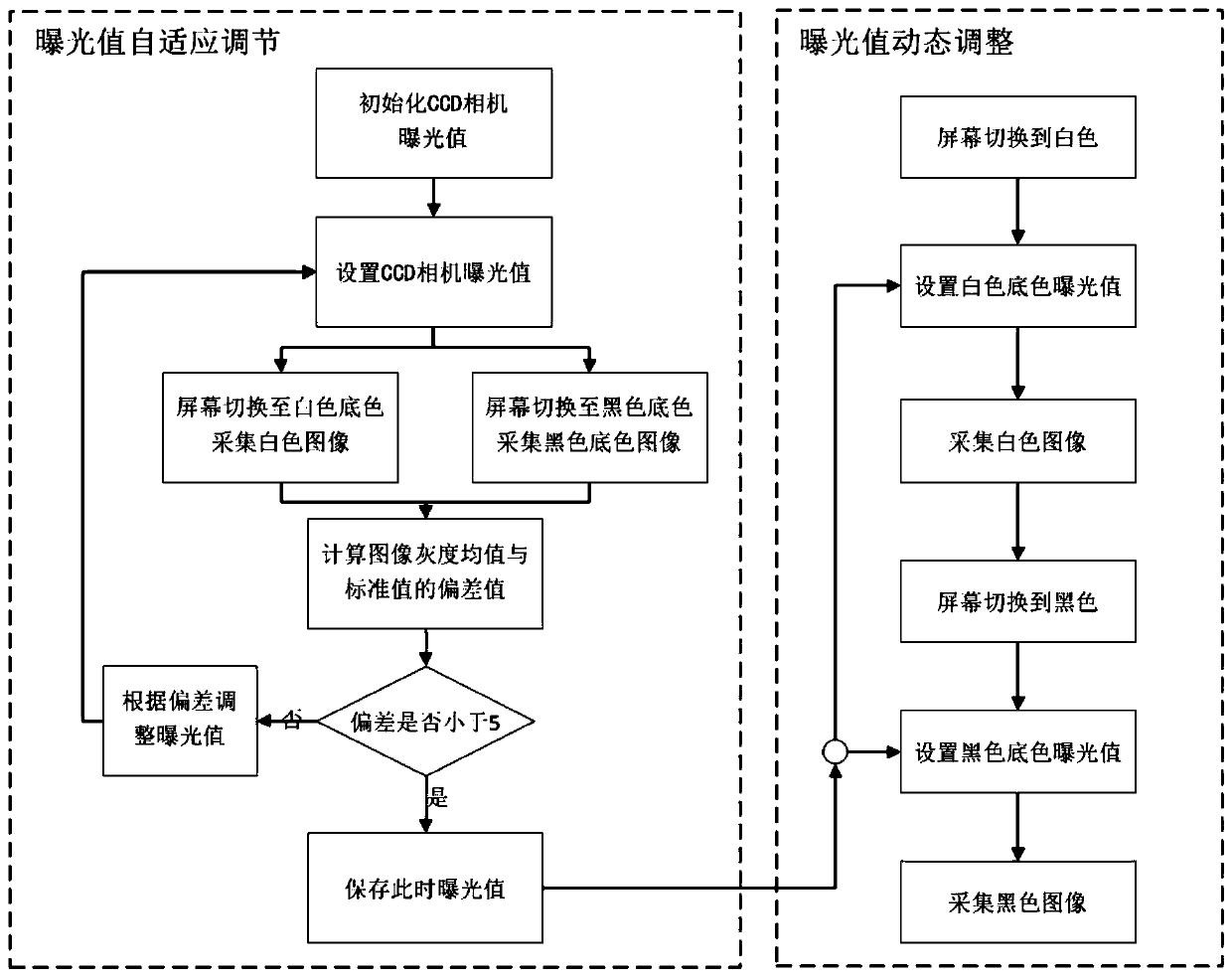

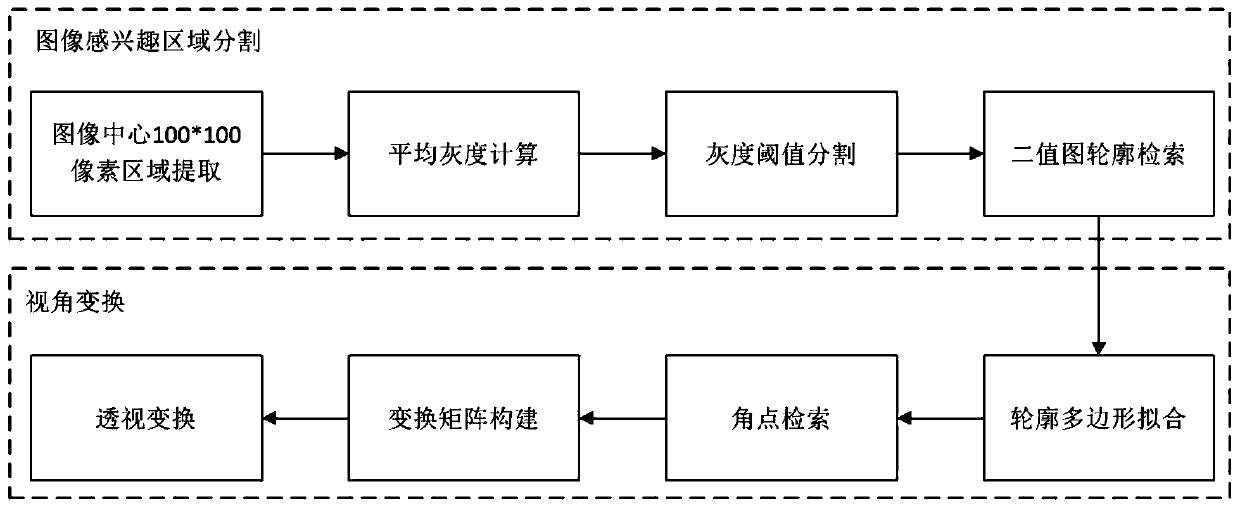

Liquid crystal screen Mura defect detection method based on computer vision

PendingCN111563889AEasy to handleAvoid Unobservable DefectsImage enhancementImage analysisSelf adaptiveRegion of interest

The invention discloses a liquid crystal screen Mura defect detection method based on computer vision. The method comprises the following steps: acquiring an image at an inclined visual angle; extracting a region of interest based on a fixed threshold method and carrying out perspective transformation based on a perspective transformation method, image texture filtering based on a Gabor filter, image color space conversion, Mura defect segmentation based on a sliding window scanning mode of a dynamic change size and a self-adaptive double-threshold segmentation algorithm double mechanism, anddefect segmentation area secondary screening. According to the liquid crystal screen Mura defect detection method based on computer vision, the problems of missing detection and lack of consistency ofdetection results due to visual fatigue easily caused by long-time manual detection of Mura defects can be solved, the detection efficiency of the Mura defects is improved, and the consistency of thedetection results is ensured.

Owner:深圳市斑马视觉科技有限公司

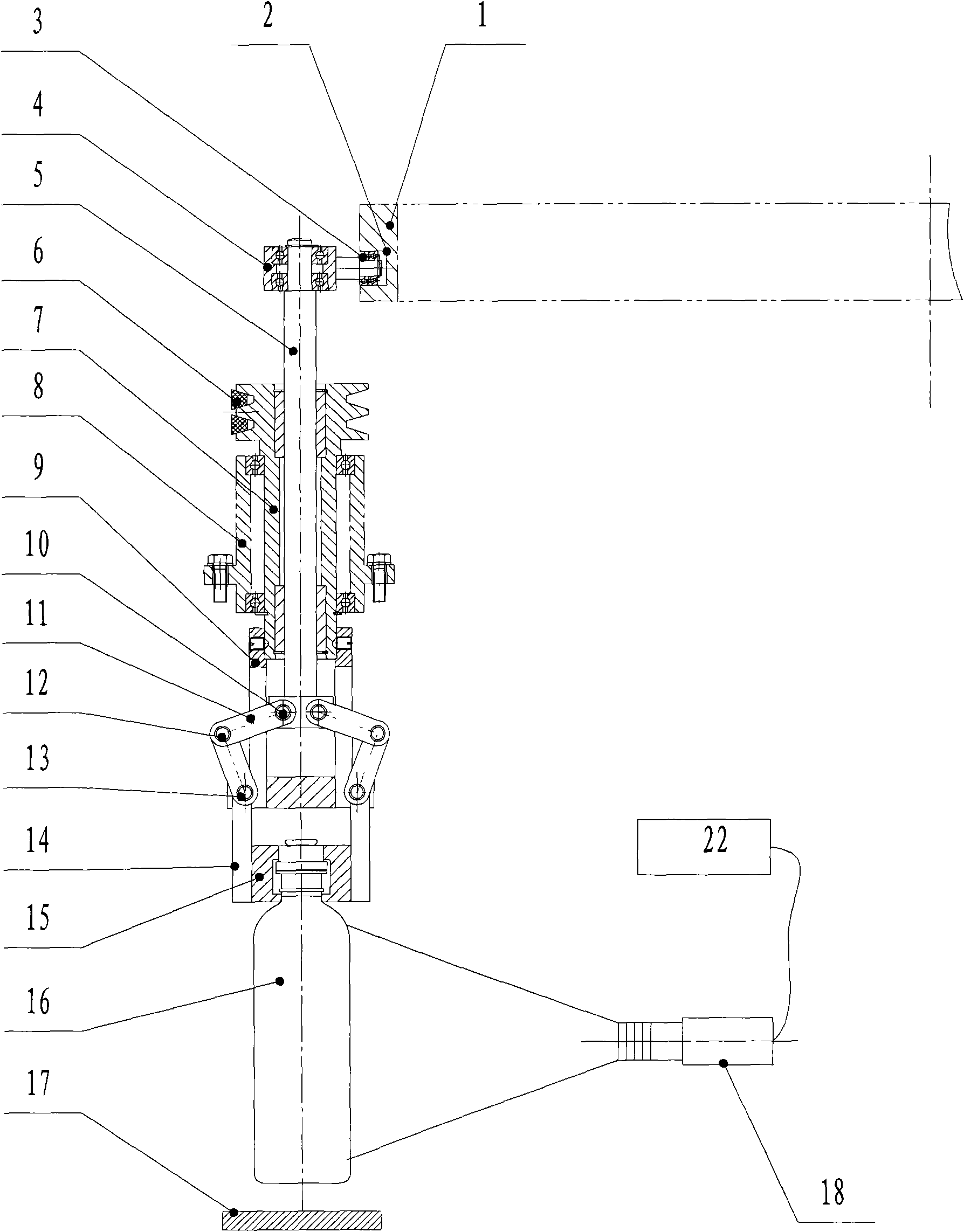

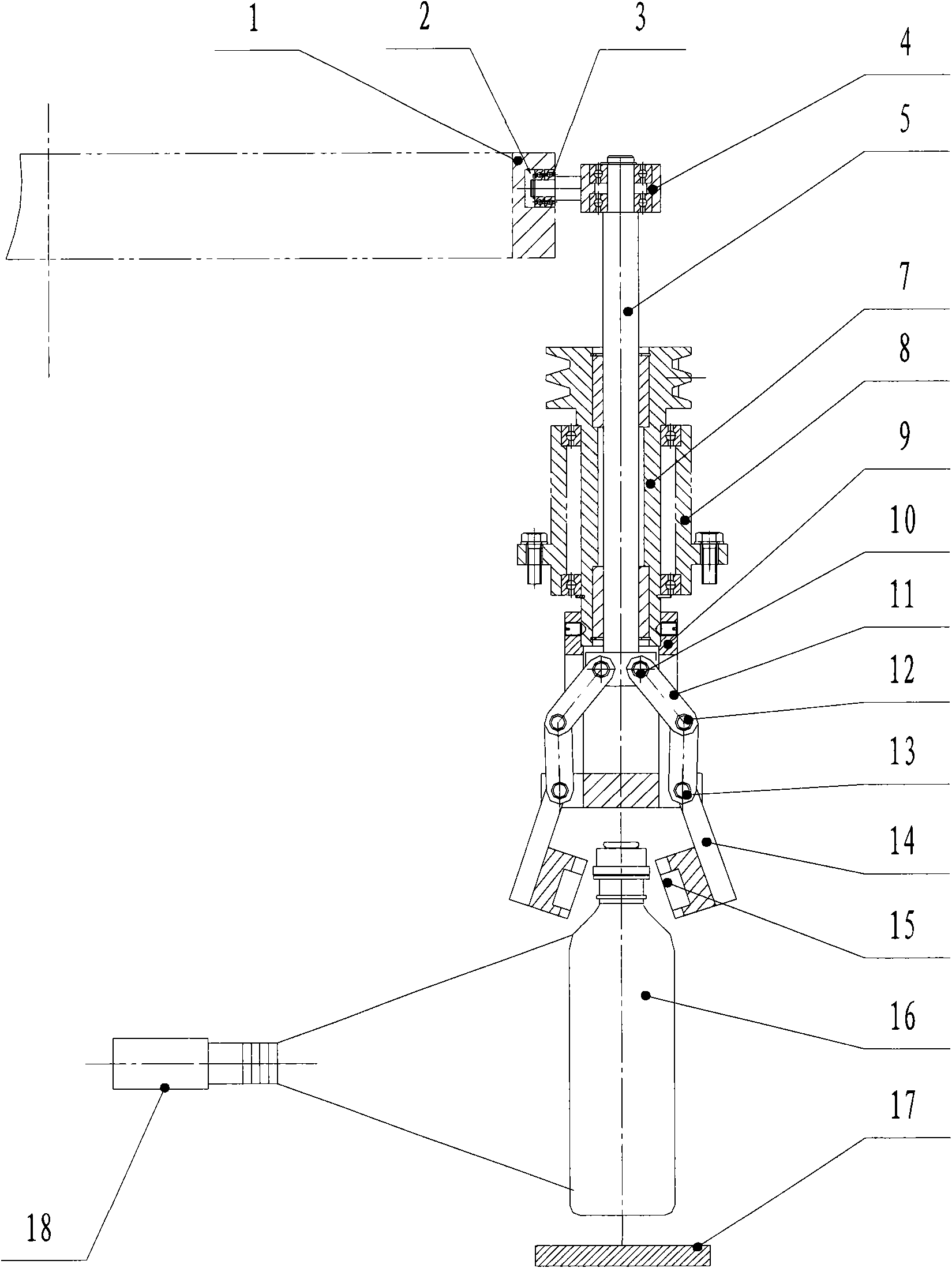

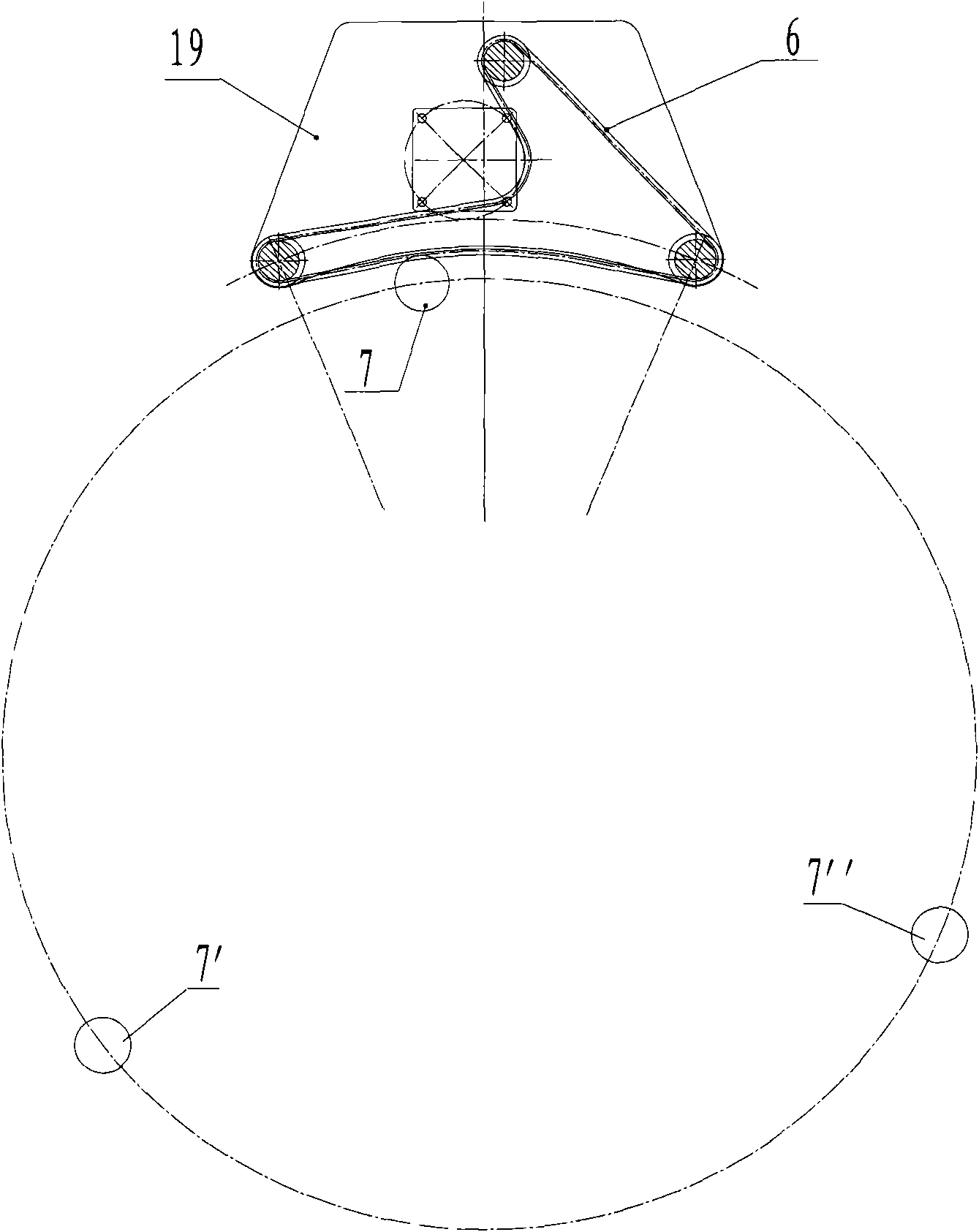

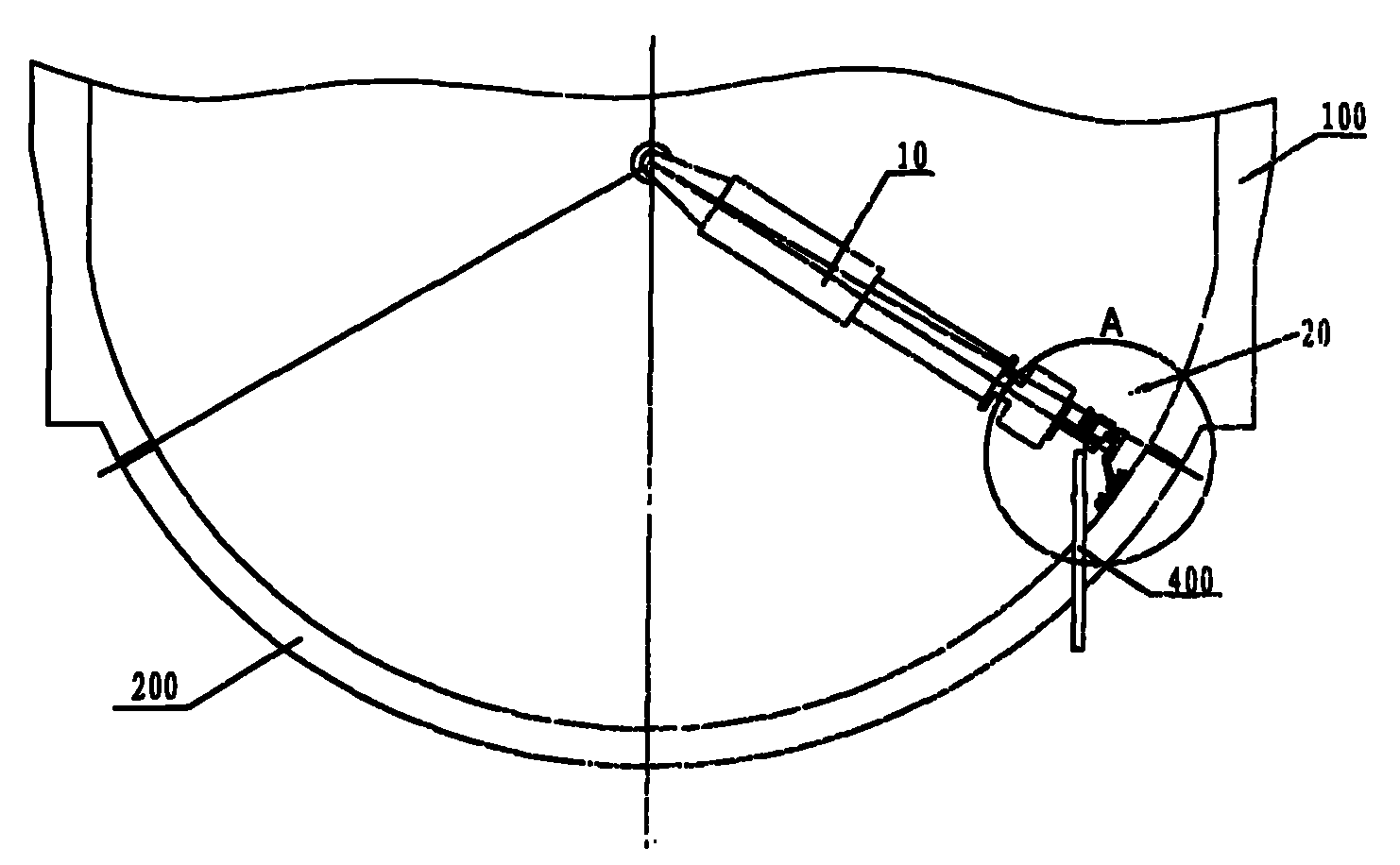

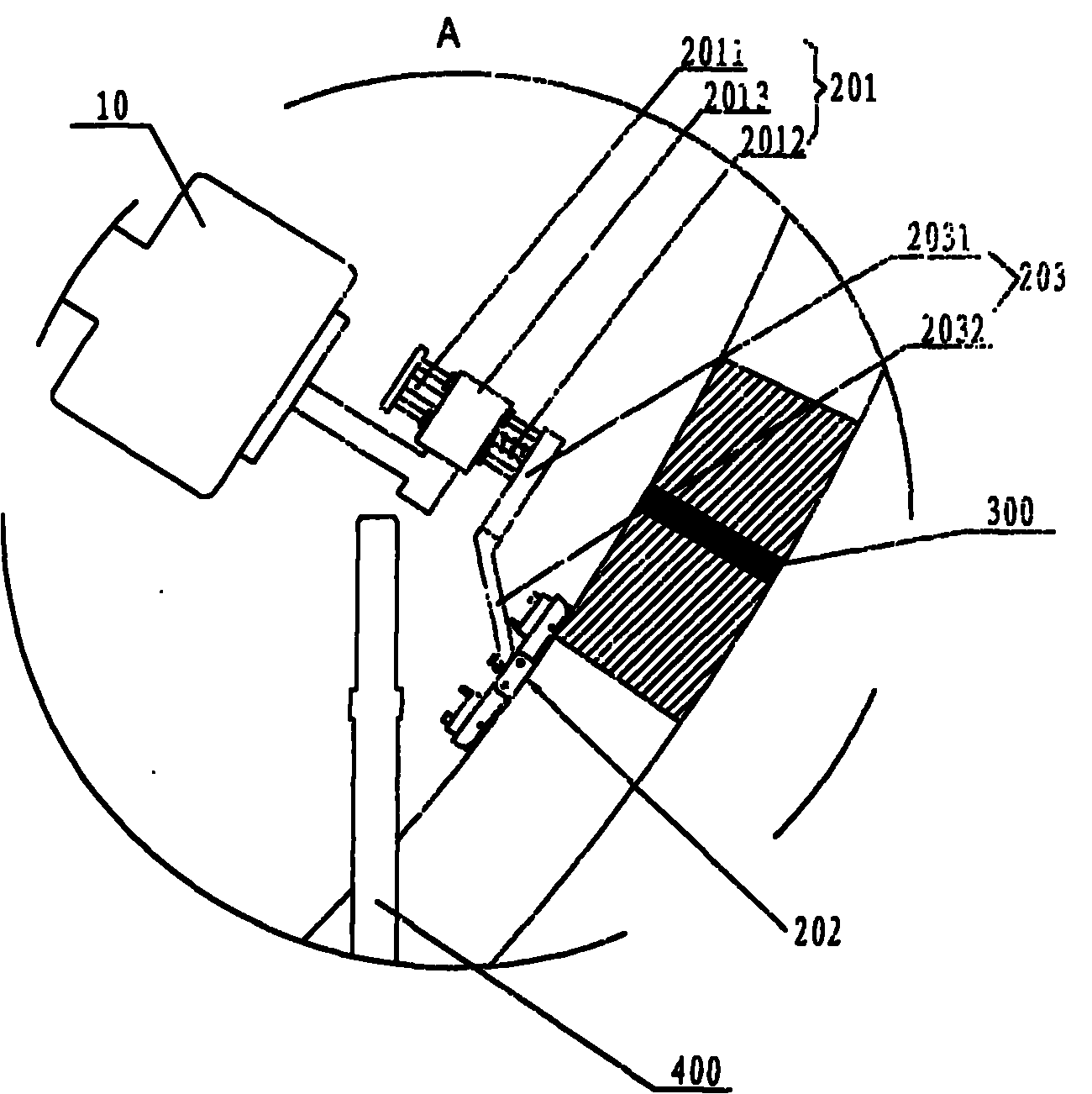

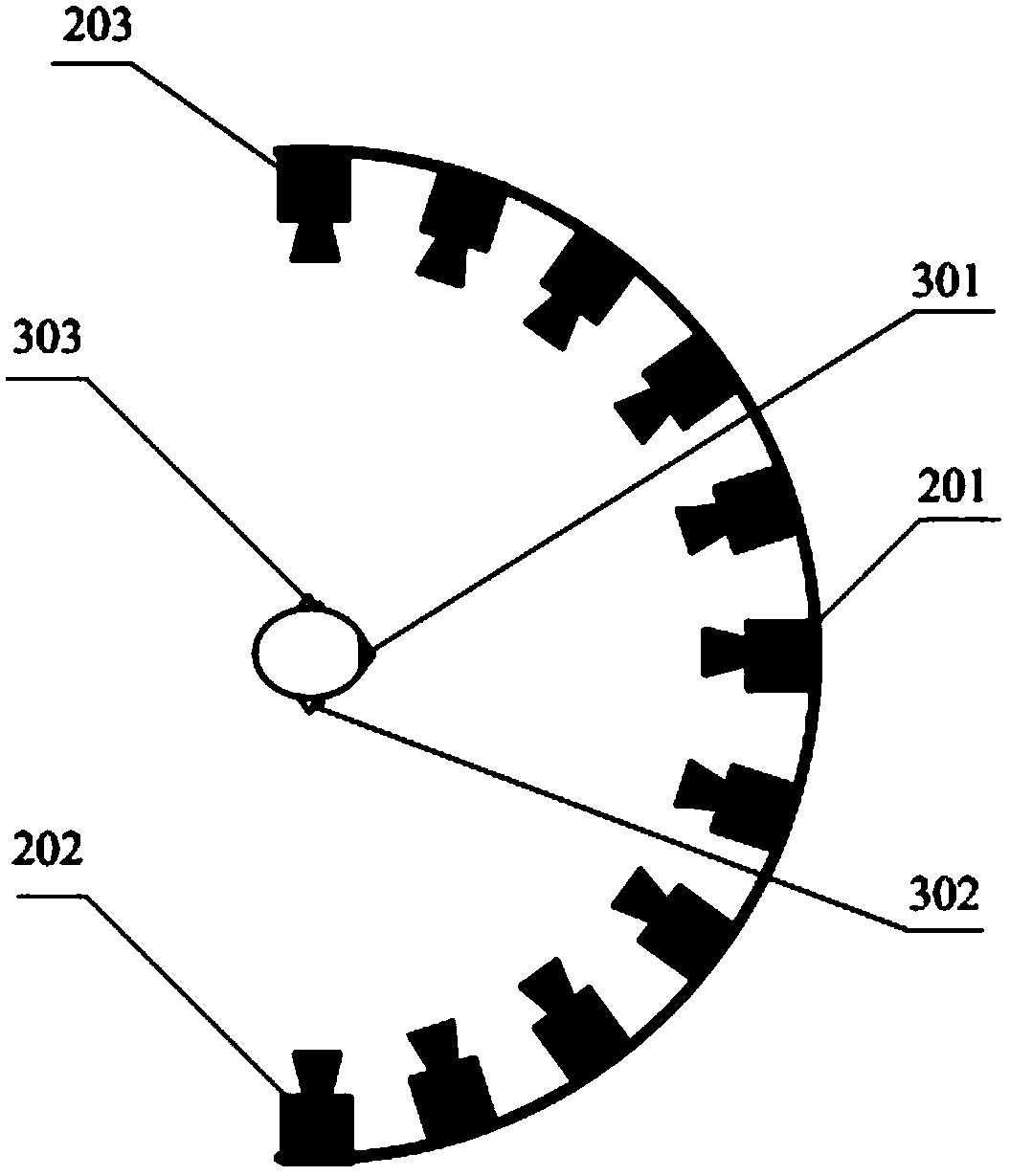

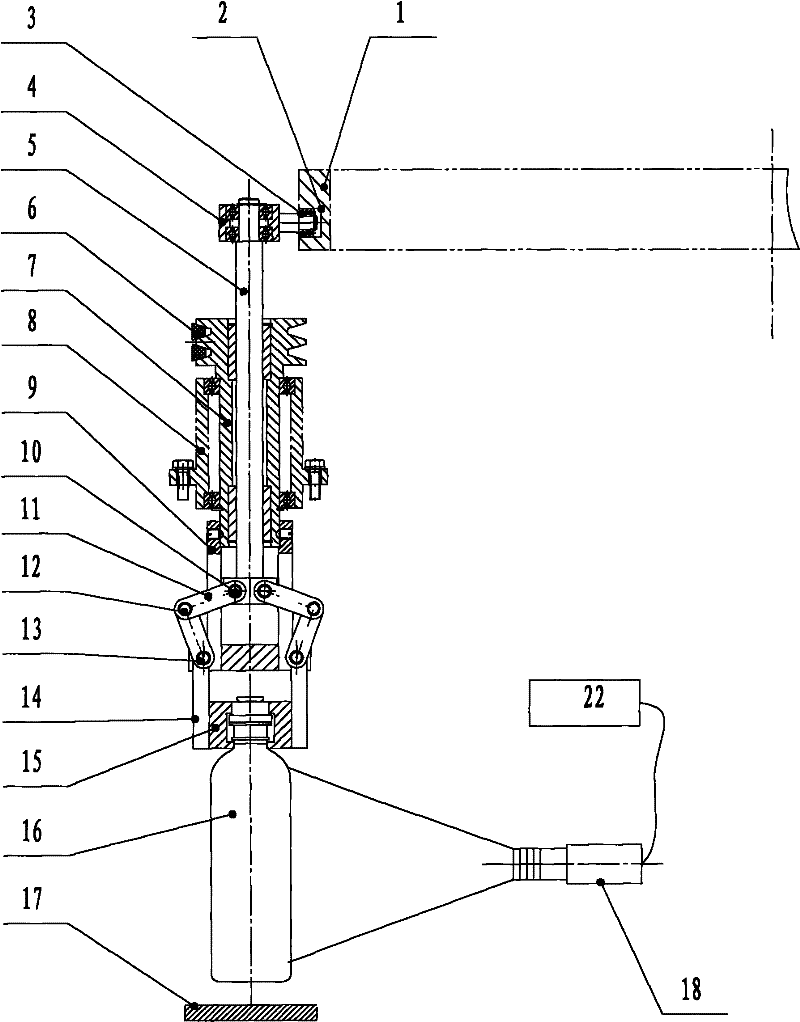

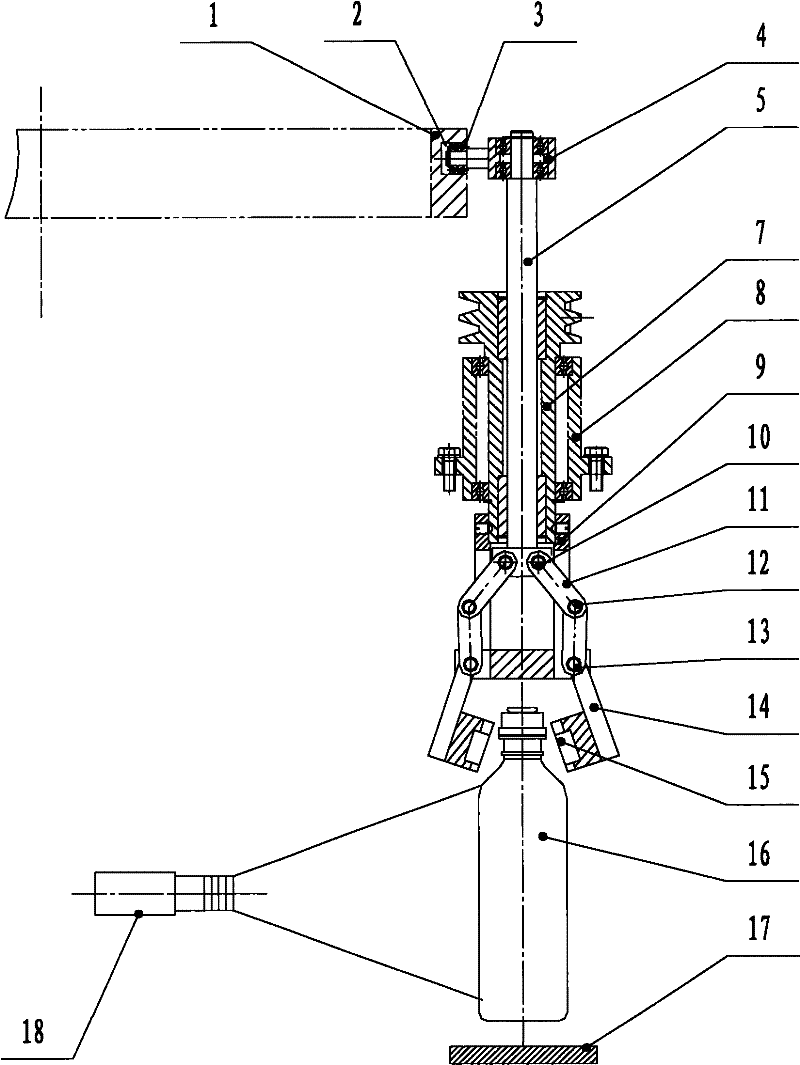

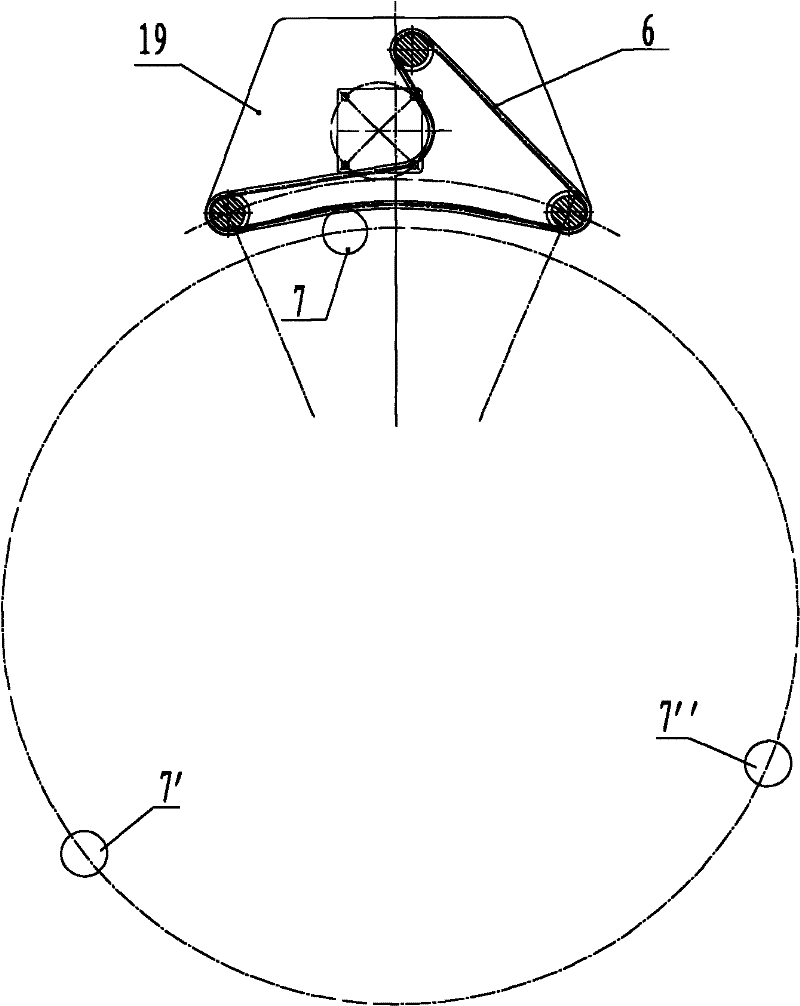

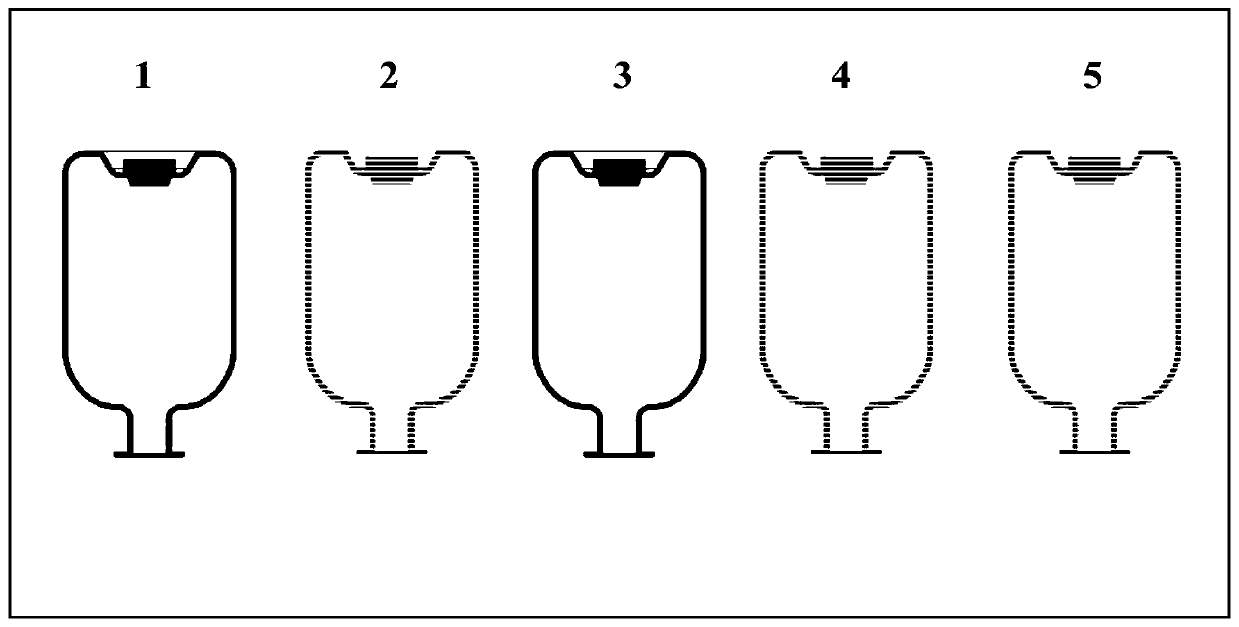

Equipment for detecting foreign matter in bottles and bottle-gripping and rotary device thereof

ActiveCN101644658AAvoid missing defectsWill not block collectionMaterial analysis by optical meansForeign matterImaging processing

The invention discloses equipment for detecting foreign matter in bottles, comprising a bottle-gripping and rotary device, an image collector which is arranged at one side of a bottle and is used forcollecting images of rotary liquid in the bottle, and an image processing device for judging whether foreign matter exists in the liquid in the bottle, wherein, the bottle-gripping and rotary device comprises a bottle rotating sleeve which is supported at a supporting seat and driven to rotate by a drive mechanism, a clamping jaw seat which is connected with the bottle rotating sleeve and can rotate with the bottle rotating sleeve, a clamping jaw in pin-jointed connection with the clamping jaw seat with the bottom end thereof being provided with a clamping block for clamping bottleneck and thetop end thereof being in pin-jointed connection with one end of a connecting rod, a pull rod positioned in the bottle rotating sleeve with the bottom thereof being connected with the other end of theconnecting rod, and a lifting mechanism arranged at the upper end of the pull rod for driving the pull rod to move in the bottle rotating sleeve. The invention has the advantages of avoiding the defect of missed detection due to foreign matter depositing at the bottom of the bottle when the foreign matter in the bottle rotates with the bottle and using the clamping jaw to only clamp the bottleneck which is in favor of collecting images of the foreign matter.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

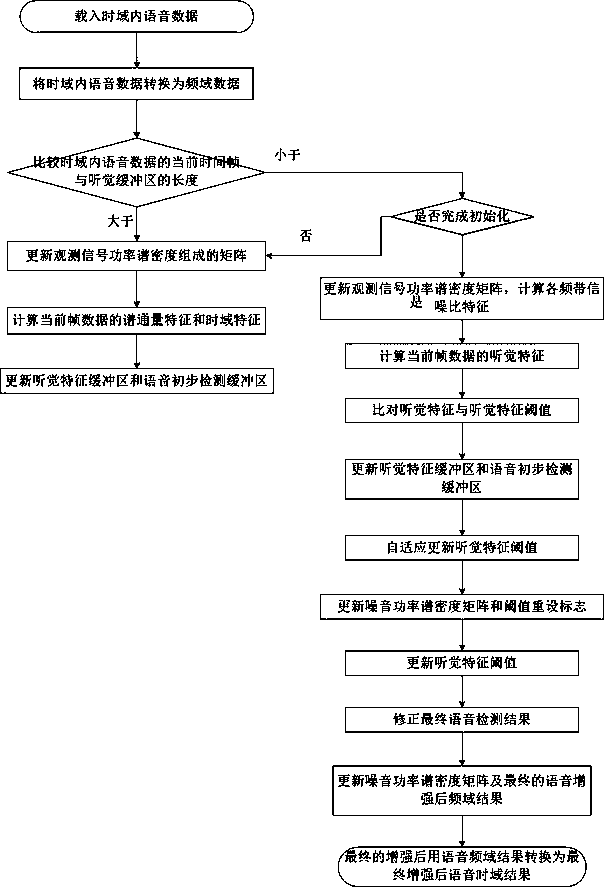

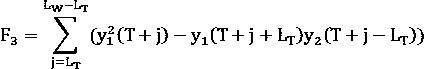

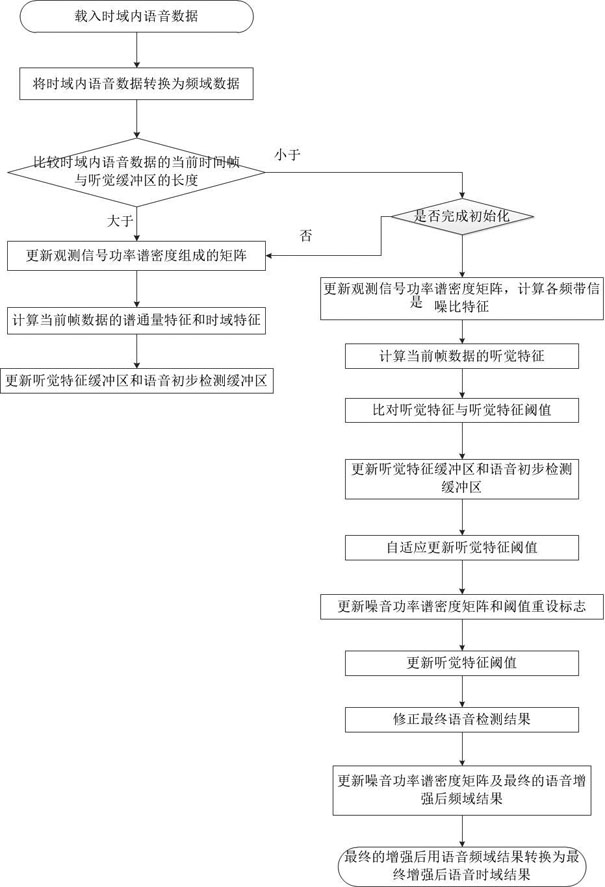

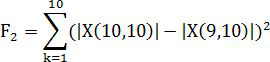

Novel dual-microphone speech detection and enhancement method

ActiveCN107863099AAvoid missing defectsSuppress noiseSpeech recognitionInformation processingVoice activity

The invention relates to the field of speech information processing technology and microphone array signal processing and especially relates to the fields of voice activity detection, voice detectionand speech recognition and interaction and the like. The method can effectively detect time frame of a voice activity and can also carry out dynamic regulation on threshold according to noise transform through two dynamic threshold update policies, by taking variability of noise environment into full consideration and based on three groups of auditory features capable of reflecting the ratio of noise energy in the total energy. The detection result can be corrected again through a detection result buffer mode, thereby preventing the defect of detection miss between continuous active voice frames; a noise power spectral density matrix is subjected to adaptive update according to the speech detection result; and furthermore, speech enhancement can be carried out through a Weiner filter, so that the noise can be suppressed under the minimum mean square error criterion.

Owner:成都启英泰伦科技有限公司

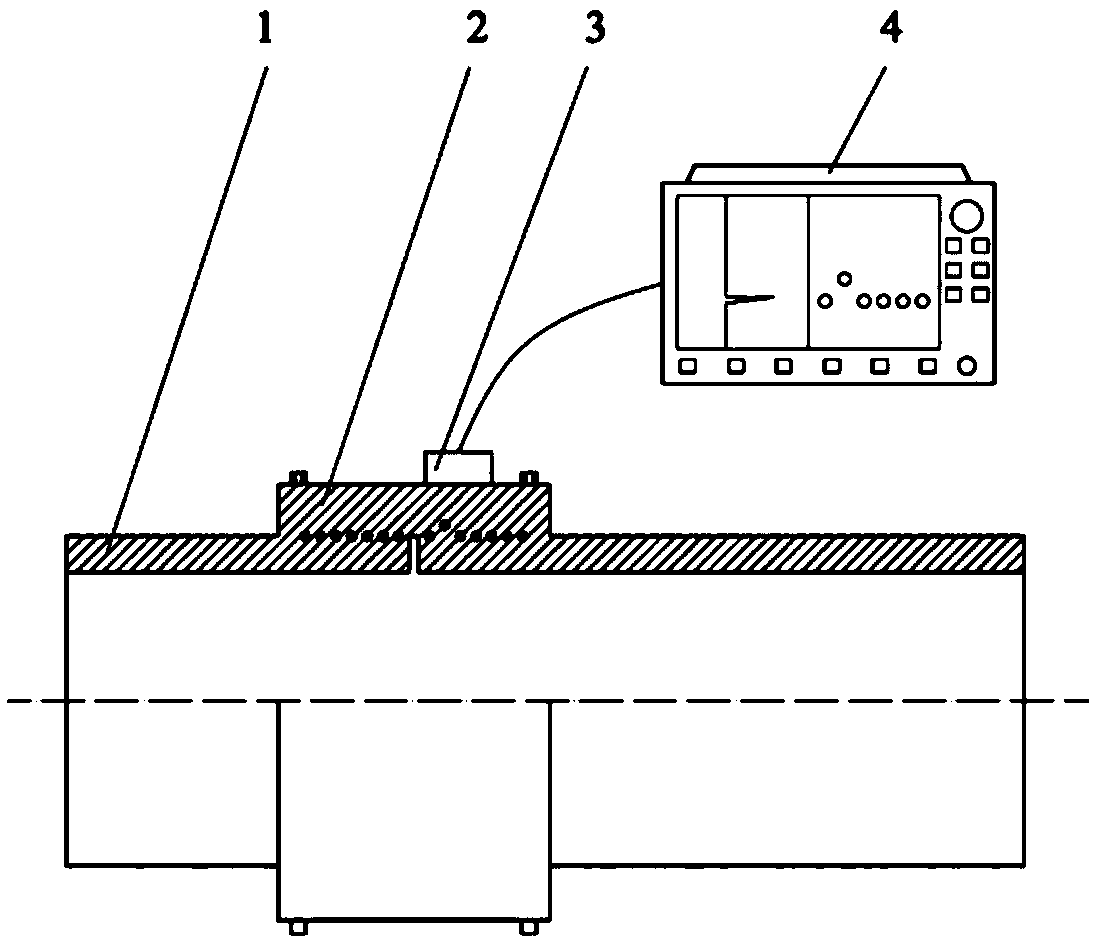

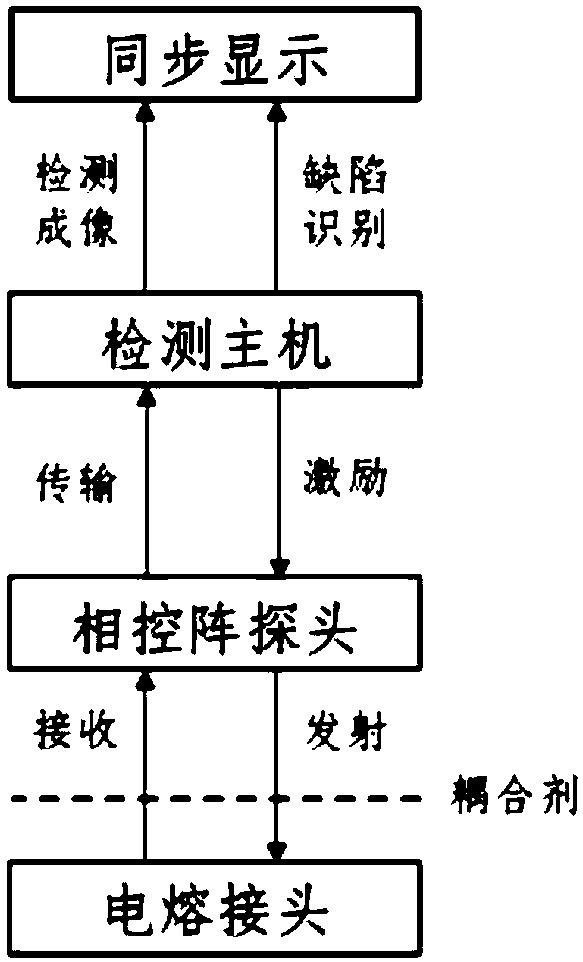

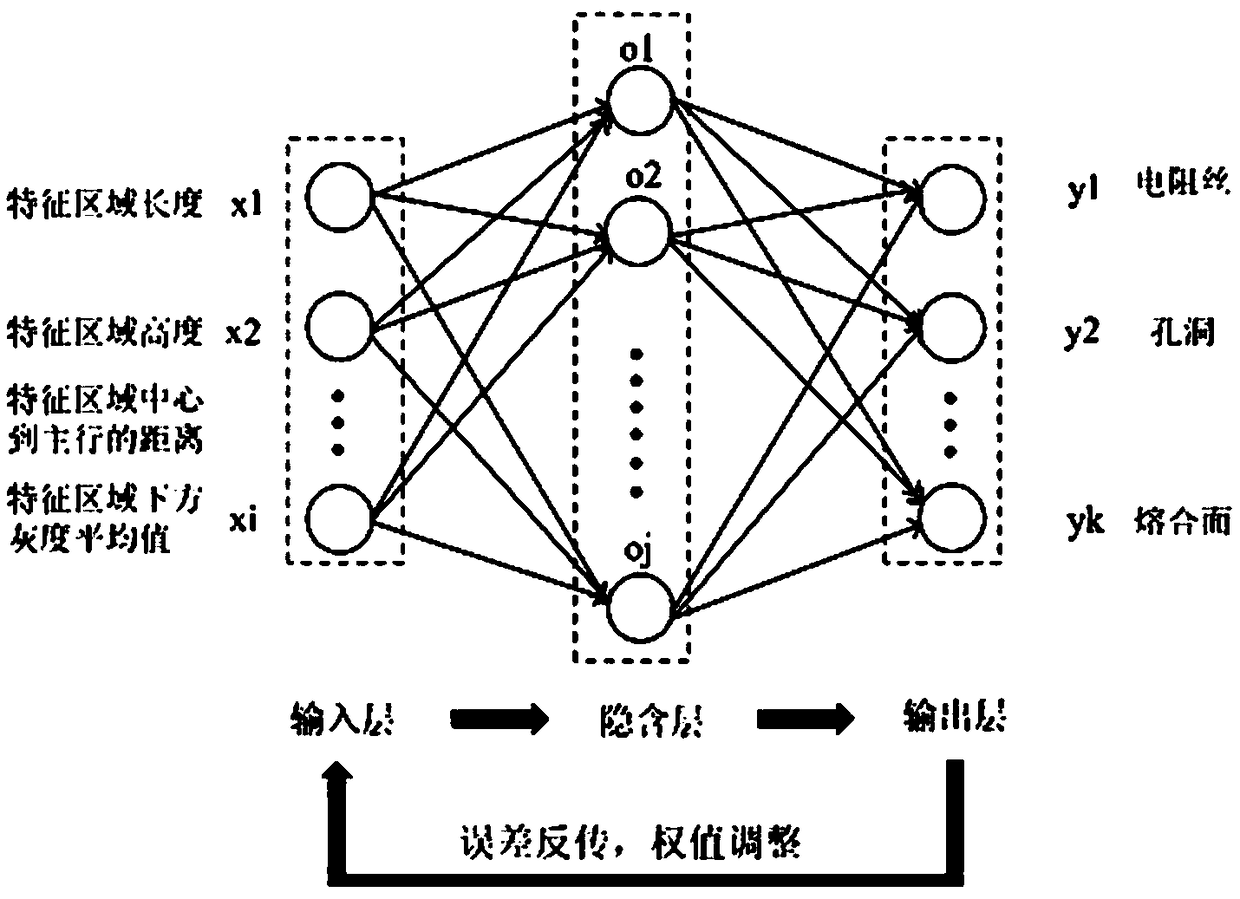

Ultrasonic detection method for defect automatic identification auxiliary electric melting joint smart phased array

ActiveCN109239206AOvercoming Dependence on QualificationAvoid dependenceAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalEngineeringWelding defect

The invention relates to the technology of plastic pipe electric melting joint detection and aims at providing an ultrasonic detection method for a defect automatic identification auxiliary electric melting joint smart phased array. The ultrasonic detection method comprises the steps of carrying out joint defect detection preparation, carrying out joint defect detection imaging and carrying out joint defect detection identification. Welding defect identification is realized through utilization of a defect automatic identification module based on a neural network algorithm. The welding defect identification comprises the content of preprocessing welding defect detection image data, carrying out classification identification on feature areas based on the neural network algorithm and carryingout safety assessment on typical defects. According to the method, typical defect automatic identification, real-time display and alarm prompt in a detection process are realized, dependence of a traditional phased array ultrasonic detection method on a qualification of a detector is overcome, and defect missing detection can be effectively avoided. According to a defect automatic identificationtechnology based on the neural network algorithm, operation speed is fast, complex defect identification accuracy is high, computing load of an ultrasonic detecting instrument can be reduced, and defect detection and identification are guaranteed to be displayed synchronously in real time.

Owner:诸暨市逍遥管道科技有限公司

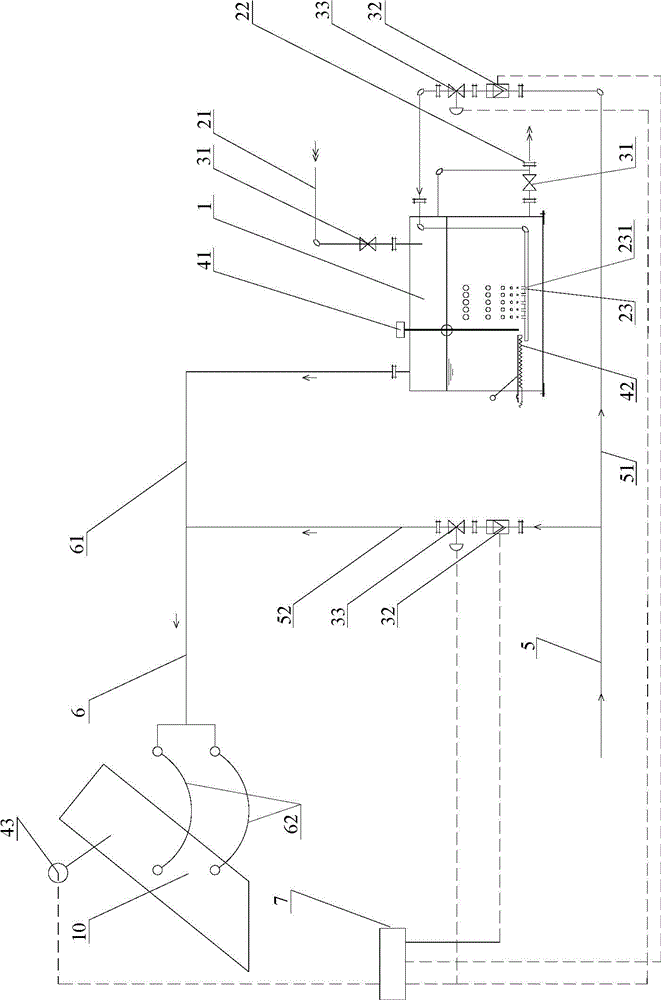

Dry and wet gas mixing and humidifying device for inhibiting zinc ash in hot galvanizing and use method thereof

PendingCN106480388ASuppress generationStop evaporationHot-dipping/immersion processesWater dischargeAlloy

The invention relates to the fields of hot-dip galvanizing alloy technology and auxiliary equipment used therefor, and specifically relates to a dry and wet gas mixing and humidifying device for inhibiting zinc ash in hot galvanizing and a use method thereof. The device comprises a furnace nose (10), and is characterized by also comprising a water tank (1), a water inlet pipe (21), a water discharge pipe (22), an air inlet pipe (23), a flow meter (33), a water level gauge (41), a heater (42), a dew-point instrument (43), a dry gas header pipe (5), a dry wet gas mixing pipe (6), and a control device (7). The use method comprises the following steps in sequence: (i) introducing dry gas; (ii) humidifying the dry gas; (iii) mixing dry gas and wet gas; and (iv) regulating the dew point. The device and method have the advantages that the zinc ash is well inhibited, the strip steel quality is high, the control is accurate, and the automation degree is high.

Owner:SHANGHAI DONGXIN METALLURGY TECH ENG

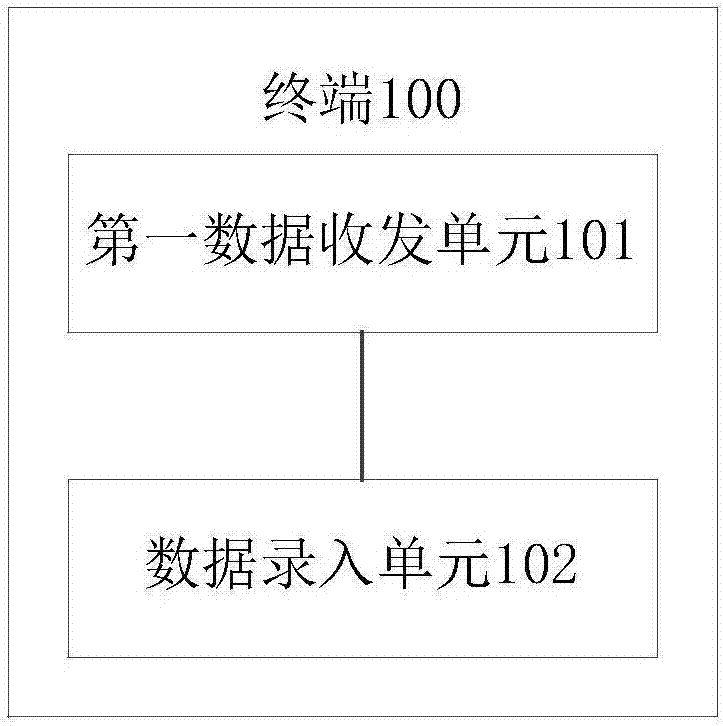

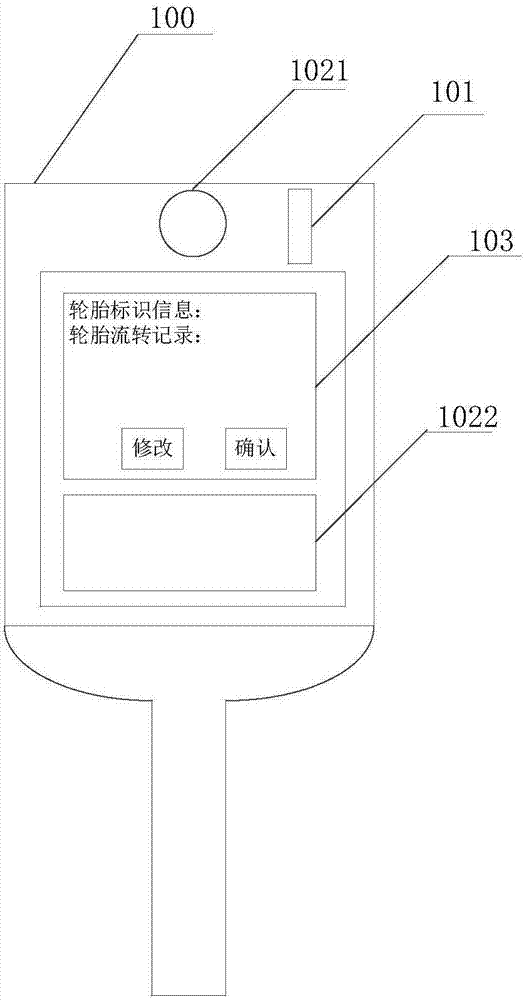

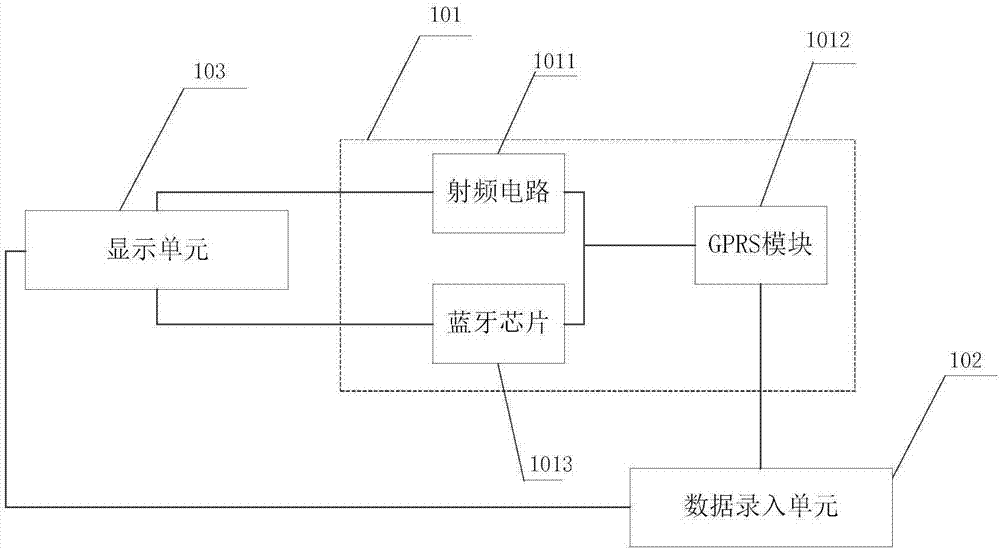

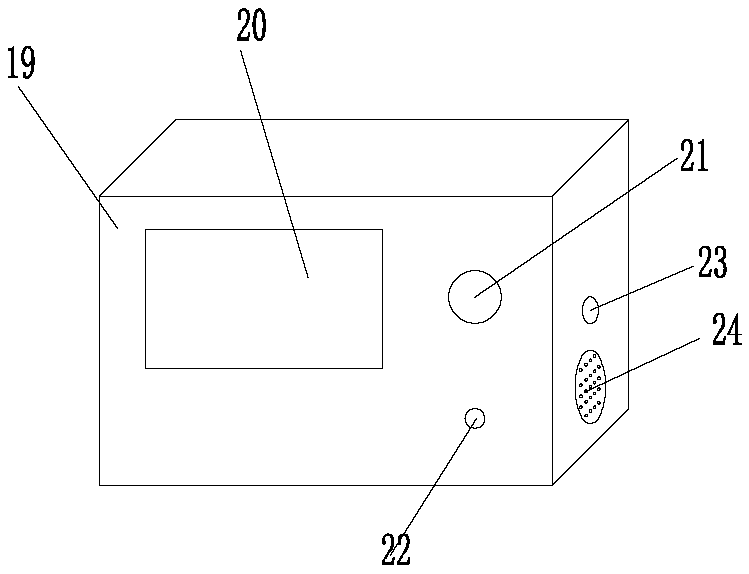

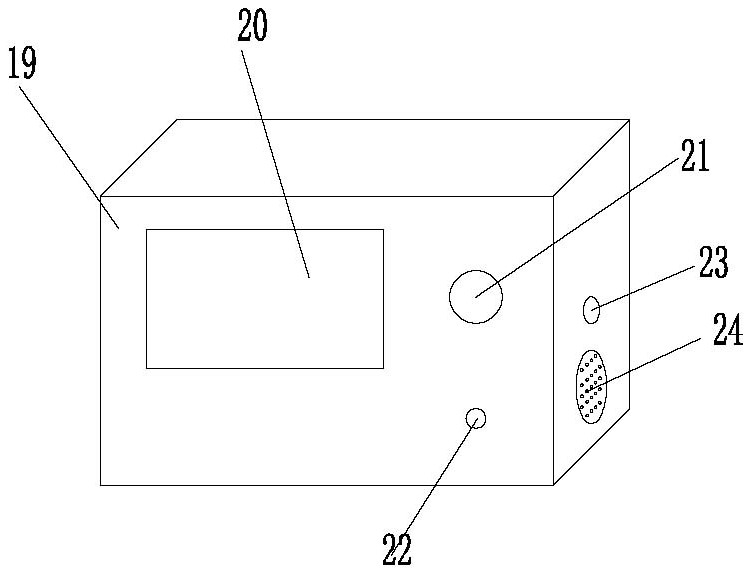

Data processing terminal for tire

PendingCN107221047AAvoid missing defectsSimplify the documentation processRegistering/indicating working of vehiclesVehicle tyre testingData exchangeData loss

The embodiment of the invention discloses a data processing terminal for a tire. The terminal comprises a first data receiving and transmitting unit and a data input unit; a worker can input a tire transfer record of some tire through the data input unit at any time, wherein the first data receiving and transmitting unit is capable of achieving data exchange with a data monitoring module arranged in the tire, a cloud server and a central control machine put in a vehicle, so that the worker can obtain identification information of some tire through the terminal, inputs the tire transfer record or other related data of the tire, and transmits the identification information and the input data to the cloud server, so that the recording process is simple and the problem of data loss easily caused in the manual recording process of the worker is avoided.

Owner:HAMATON AUTOMOTIVE TECH CO LTD +1

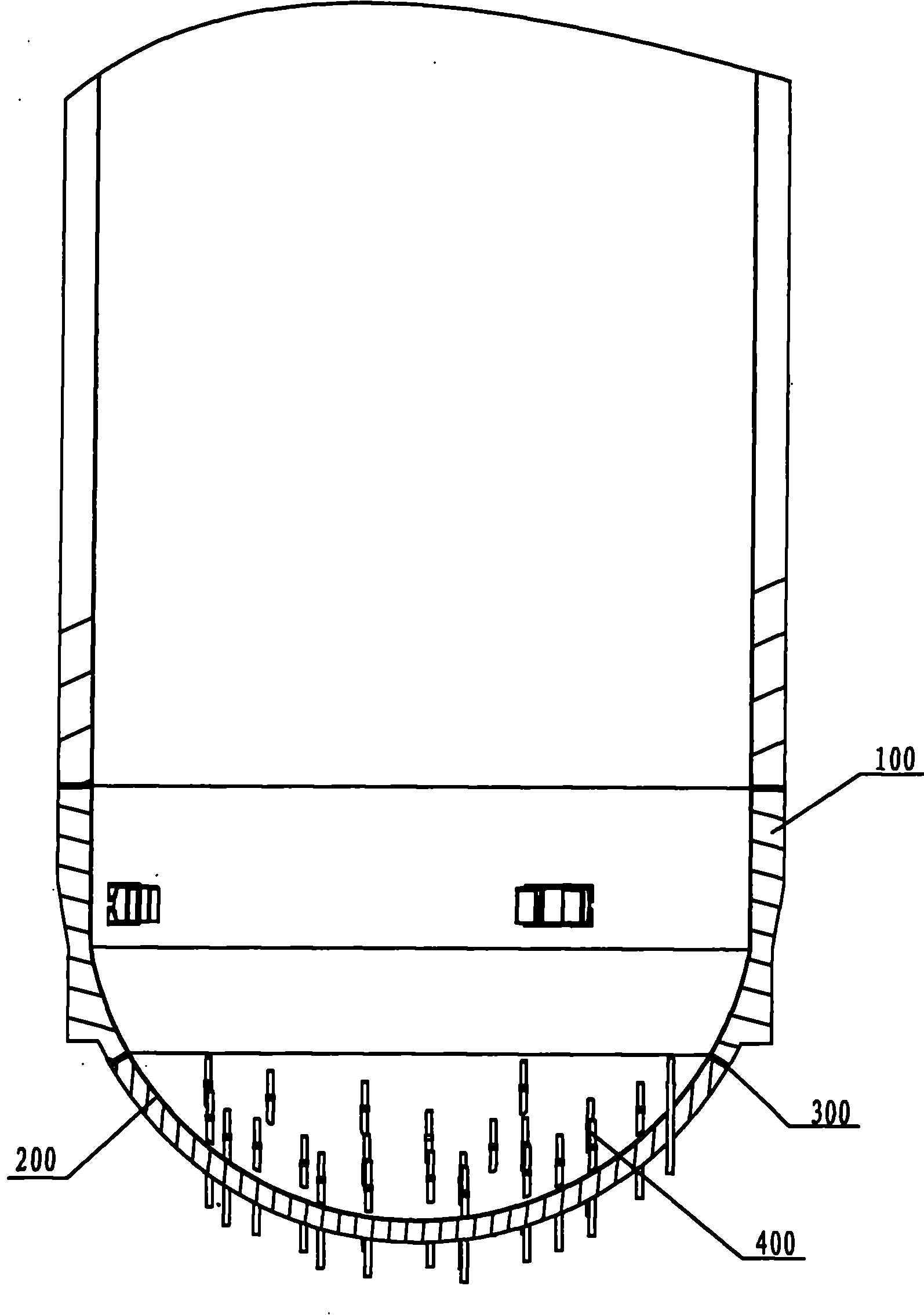

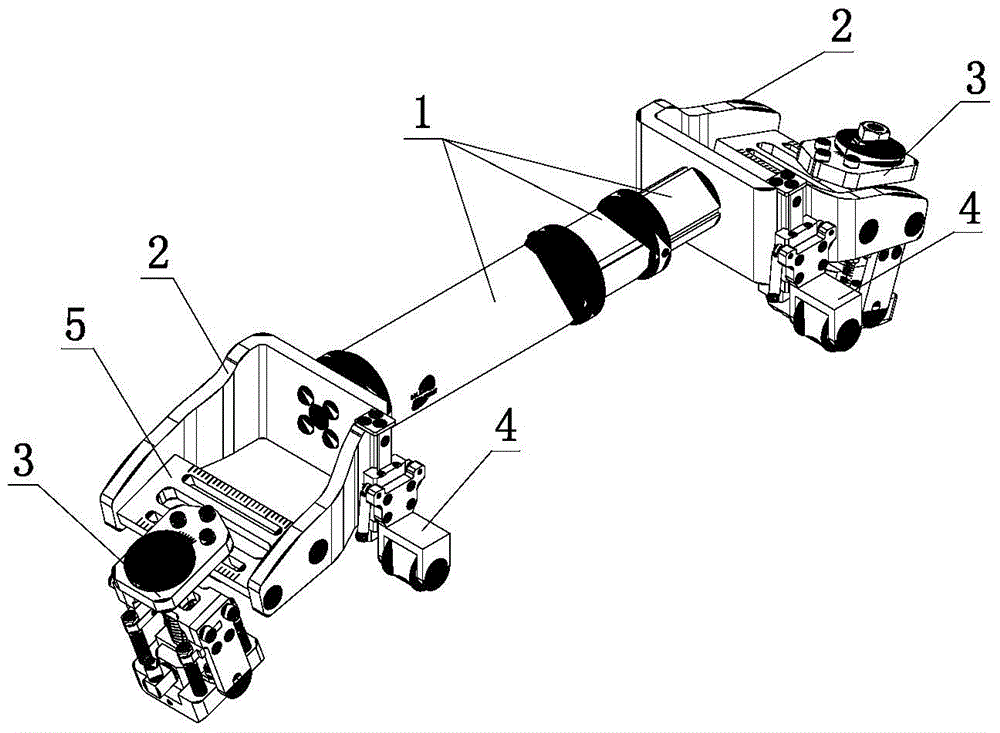

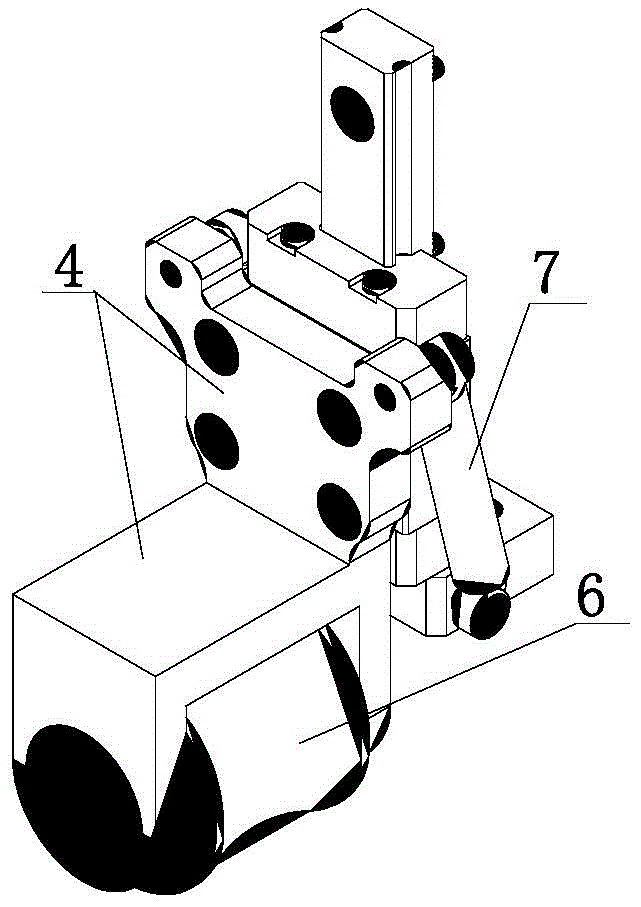

Front-end probe mechanism of reactor pressure vessel checking machine

InactiveCN101894592AAvoid missing defectsTightly coupledNuclear energy generationNuclear monitoringReactor pressure vesselNuclear power

The invention relates to a front-end probe mechanism of a reactor pressure vessel checking machine. The front-end probe mechanism comprises an ultrasonic probe body, a probe support framework framed outside the ultrasonic probe body, and a wall support frame in rotary connection with the probe support framework through a third rotating shaft; the probe support framework comprises an inner frame in rotary connection with two opposite sides of the ultrasonic probe body through a first rotating shaft respectively and an outer frame in rotary connection with two opposite sides of the inner frame through a second rotating shaft respectively; a torsion spring is also sleeved on the third rotating shaft; one end of the torsion spring is connected with the wall support frame, while the other end is connected with the outer frame; and the first rotating shaft, the second rotating shaft and the torsion spring provides a rotating freedom for the ultrasonic probe body on a spherical surface so that the ultrasonic probe body is tightly coupled with the spherical surface to be detected. The probe mechanism overcomes the defect of detection data loss due to poor coupling of the probe body and the spherical surface, and lays a foundation for safe operation of a nuclear power station.

Owner:CGNPC INSPECTION TECH +2

Image collecting system

ActiveCN103546672AHigh resolutionImprove the shooting effectTelevision system detailsColor television detailsComputer visionProtection system

The invention discloses an image collecting system which comprises a rigid helmet-shaped support and a plurality of camera shooting devices located on the inner side of the support. A to-be-shot object sample is placed at the optimal shooting position inside the support, the locating camera shooting devices are further selected, the to-be-shot object sample is placed nearby a focus plane, composed of the multiple camera shooting devices, inside the support, continuous shooting is carried out on the to-be-shot object sample through the locating camera shooting devices, after collected image information is analyzed, a locating point corresponding to the to-be-shot object sample is found in the image information, and therefore the practical position of the to-be-shot object sample in a support space formed by the support is determined. According to the image collecting system, the support and / or the to-be-shot object sample are / is moved to reduce the difference between the practical position and the optimal shooting position of the to-be-shot object sample, and then locating shooting is carried out. The image collecting system is particularly suitable for a police system or a security and protection system to shoot the head of a criminal suspect.

Owner:SUZHOU HB AI TECH RES&DEV CO LTD

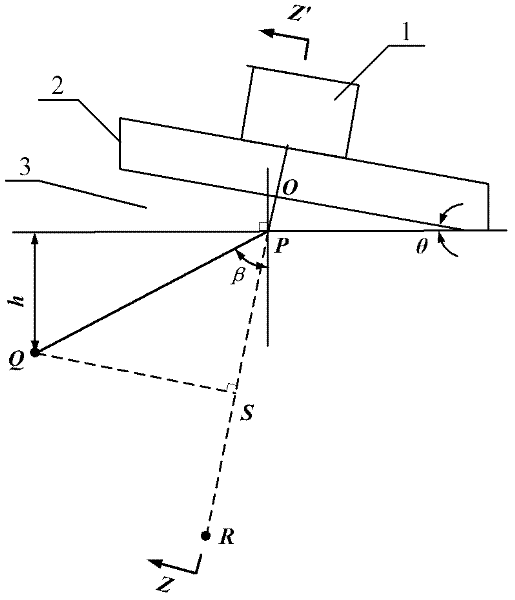

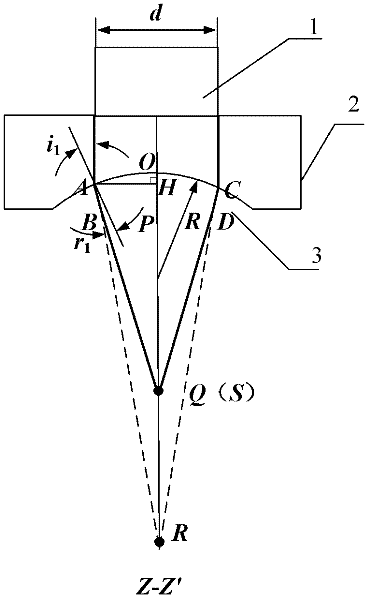

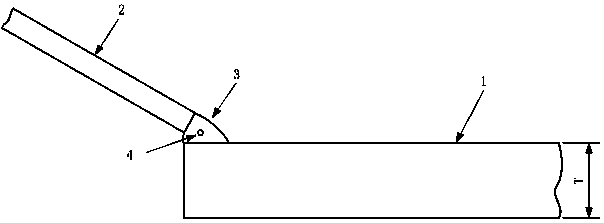

Ultrasonic time-of-flight diffraction method by cylinder focusing wedge

InactiveCN102507737AImprove identificationAvoid missing defectsAnalysing solids using sonic/ultrasonic/infrasonic wavesRefraction angleEnergy level

An ultrasonic time-of-flight diffraction method by a cylinder focusing wedge relates to the field of ultrasonic detection and solves the problem that an existing time-of-flight diffraction method for detection is low in energy level of defective diffraction signals and needs improvement of detecting sensitivity. The ultrasonic time-of-flight diffraction method includes the specific steps: firstly, determining known conditions including the diameter of a probe wafer, the longitudinal wave velocity of the wedge, the longitudinal wave velocity of a detected workpiece and the velocity of longitudinal waves in water; secondly, setting needed conditions including the water path of an acoustic beam of a spindle, the refraction angle of longitudinal waves in the detected workpiece and the focusing vertical depth of the acoustic beam of the spindle in the workpiece; and thirdly, computing the curvature radius of a cylinder of the wedge according to the conditions and detecting by the ultrasonic time-of-flight diffraction method through the manufactured cylinder focusing wedge. The ultrasonic time-of-flight diffraction method is used for ultrasonic detection.

Owner:HARBIN INST OF TECH

Quantitative analyzing method for positioning of low-frequency array eddy current

ActiveCN108152367ANovel structureEasy to operateMaterial magnetic variablesImaging processingPower station

The invention relates to a quantitative analyzing method for positioning of low-frequency array eddy current. According to the technical scheme, the quantitative analyzing method for positioning of low-frequency array eddy current comprises the following steps: A, detecting and calibrating a waste determining standard; B, carrying out defect positioning; and C, quantifying defects by using a three-dimensional C scanning image processing function. Interference of space scattered leakage magnetic flux is eliminated by a magnetic tank and a magnetic shielding technology of a shielding coil, defect resolving power is improved, in a detecting process, eight detecting coils can be used for imaging independently, detecting sensitivity can be always consistent, leak detection on defects is avoided, probe covered heated surface steel tube inner wall detects can be detected by one-time operation, repeated operations are not required, by the quantitative analyzing method for positioning of the low-frequency array eddy current, by a low-frequency array eddy current probe and imaging and displaying advantages of three-dimensional C scanned stereo images, the problems of positioning and quantifying of corrosion defects of the inner wall of a heated surface tube of a boiler of a power station is solved, the detection precision and field working efficiency are improved, and reliable and stablerunning of the heated surface tube of the boiler of the power station is ensured.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

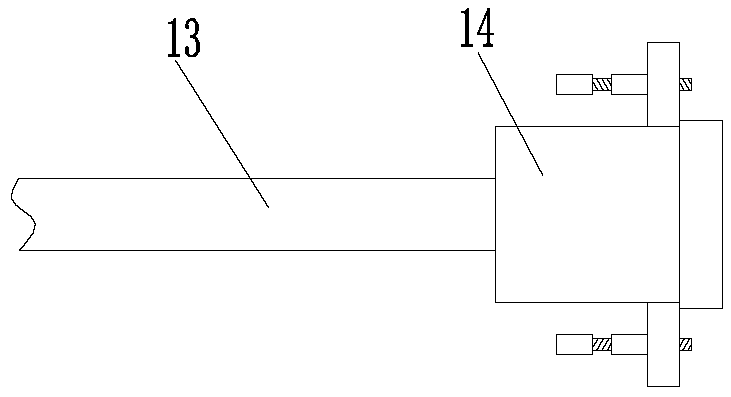

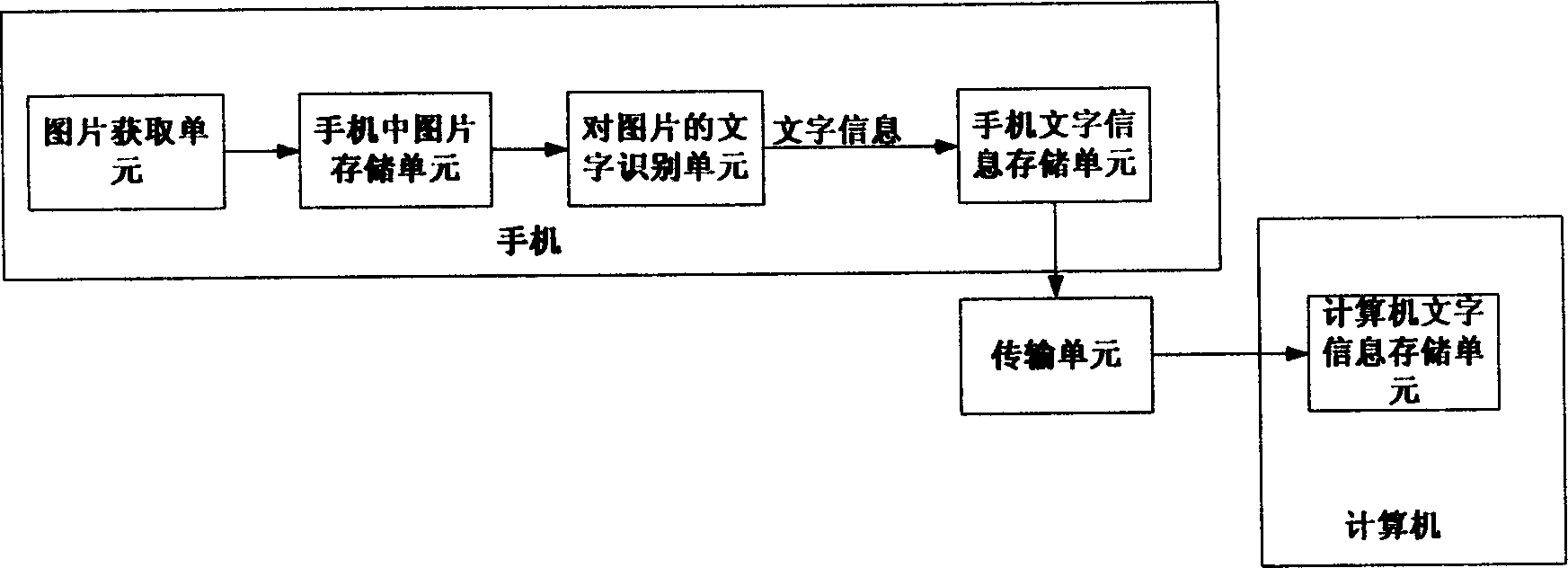

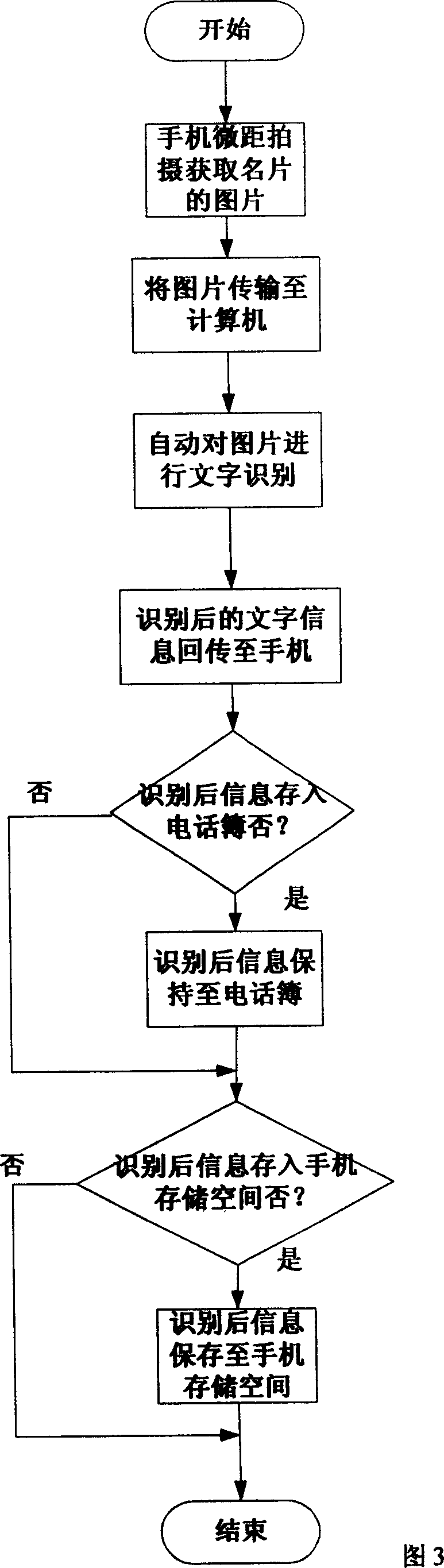

Method for converting namecards into telephone memo or electronic namecards by mobile telephone

InactiveCN1855951AFacilitate communicationFacilitate data exchangeCharacter and pattern recognitionSubscriber signalling identity devicesComputer hardwareBusiness card

A method of transform the calling card to the phone record or the electronic calling card by the mobile phone, the steps are: uses the camera on the mobile phone to shoot the calling card and get the image format file of the calling card, uses the identified software on the mobile phone to process the character identified processing, the system of the mobile phone writes the identified character information to the telephone record and adds into the phone book of the mobile phone, or the system of the mobile phone writes the identified character information to the electronic calling card record and adds into the electronic calling card book.

Owner:杭州波导软件有限公司

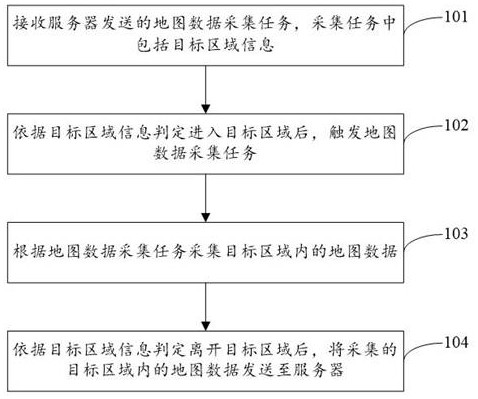

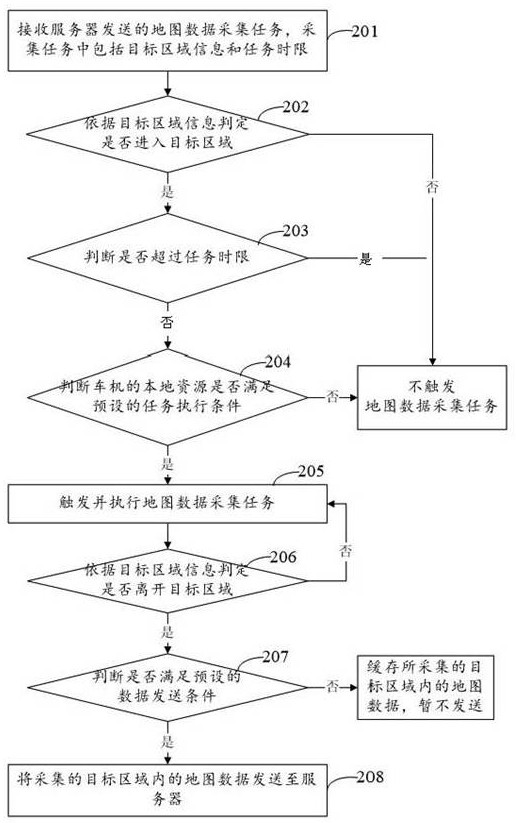

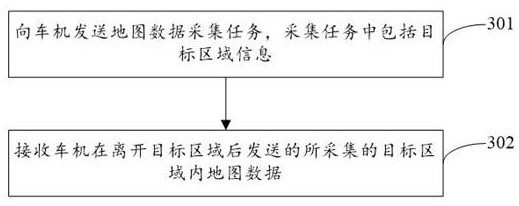

Data acquisition method and electronic equipment

InactiveCN111930874AAvoid missing defectsAvoid lossResource allocationGeographical information databasesData acquisitionEngineering

The invention relates to a data acquisition method and electronic equipment. The method comprises the following steps: receiving a map data acquisition task sent by a server, wherein the acquisition task comprises target area information; triggering the map data acquisition task after entering the target area is judged according to the target area information; acquiring map data in the target areaaccording to the map data acquisition task; and after it is judged that the user leaves the target area according to the target area information, sending the collected map data in the target area tothe server. According to the scheme provided by the invention, the integrity of map data reporting can be ensured.

Owner:蘑菇车联信息科技有限公司

Phased array ultrasonic detection method for welding buoy bottom plate and sampan

InactiveCN110988139ASolving defect detection challengesSolve signal interferenceAnalysing solids using sonic/ultrasonic/infrasonic wavesFillet weldEngineering

The invention relates to a phased array ultrasonic detection method for welding a buoy bottom plate and a sampan. The method is based on phased array ultrasonic angle gain compensation ACG and time gain compensation TCG. Sensitivity is set by utilizing an artificial transverse hole in a welding seam. An optimal scanning mode is determined through acoustic beam coverage simulation, detection is carried out in a vertical incident fan scanning mode and an oblique incident fan scanning mode, defects are visually displayed, quantified and accurately positioned, the key technical problem of internaldefect detection of the fillet weld of the bottom plate and the sampan is solved, and the detection sensitivity is not lower than phi 1 * 10 mm<-10>dB.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

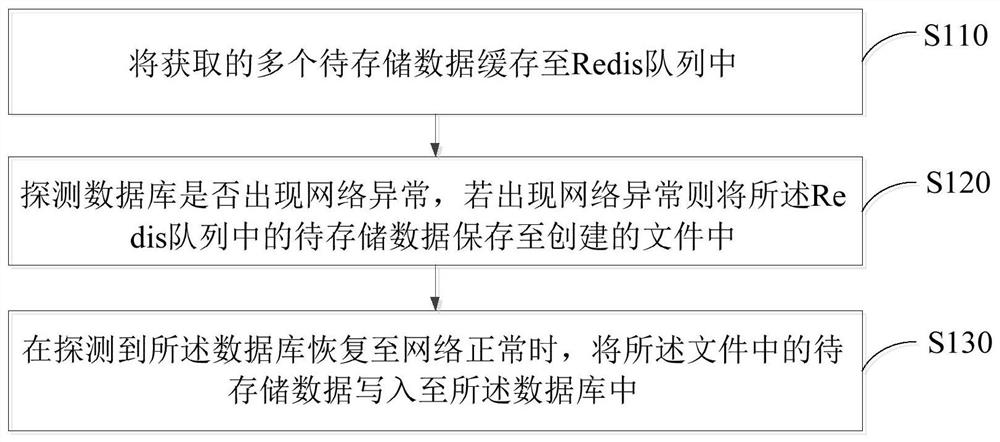

Data storage management method and device, electronic equipment and readable storage medium

PendingCN112650807AAvoid discardingAvoid missing defectsProgram initiation/switchingDatabase management systemsEngineeringStorage management

The embodiment of the invention provides a data storage management method and device, electronic equipment and a readable storage medium. The data storage management method comprises the steps: caching obtained to-be-stored data into a Redis queue, detecting whether there is a network abnormality in a database or not, storing the to-be-stored data cached in the Redis queue into a created file if there is the network abnormality, and storing the to-be-stored data in the Redis queue; and writing the to-be-stored data in the file into the database after detecting that the database recovers the network to be normal. Thus, when a network exception occurs, the data in the Redis queue is written into the file, so that the problem of data discarding caused by accumulation of subsequently received data in the Redis queue is avoided, and the defect of data loss during program crash can be avoided due to the fact that the data stored in the file is not lost during power failure.

Owner:成都知道创宇信息技术有限公司

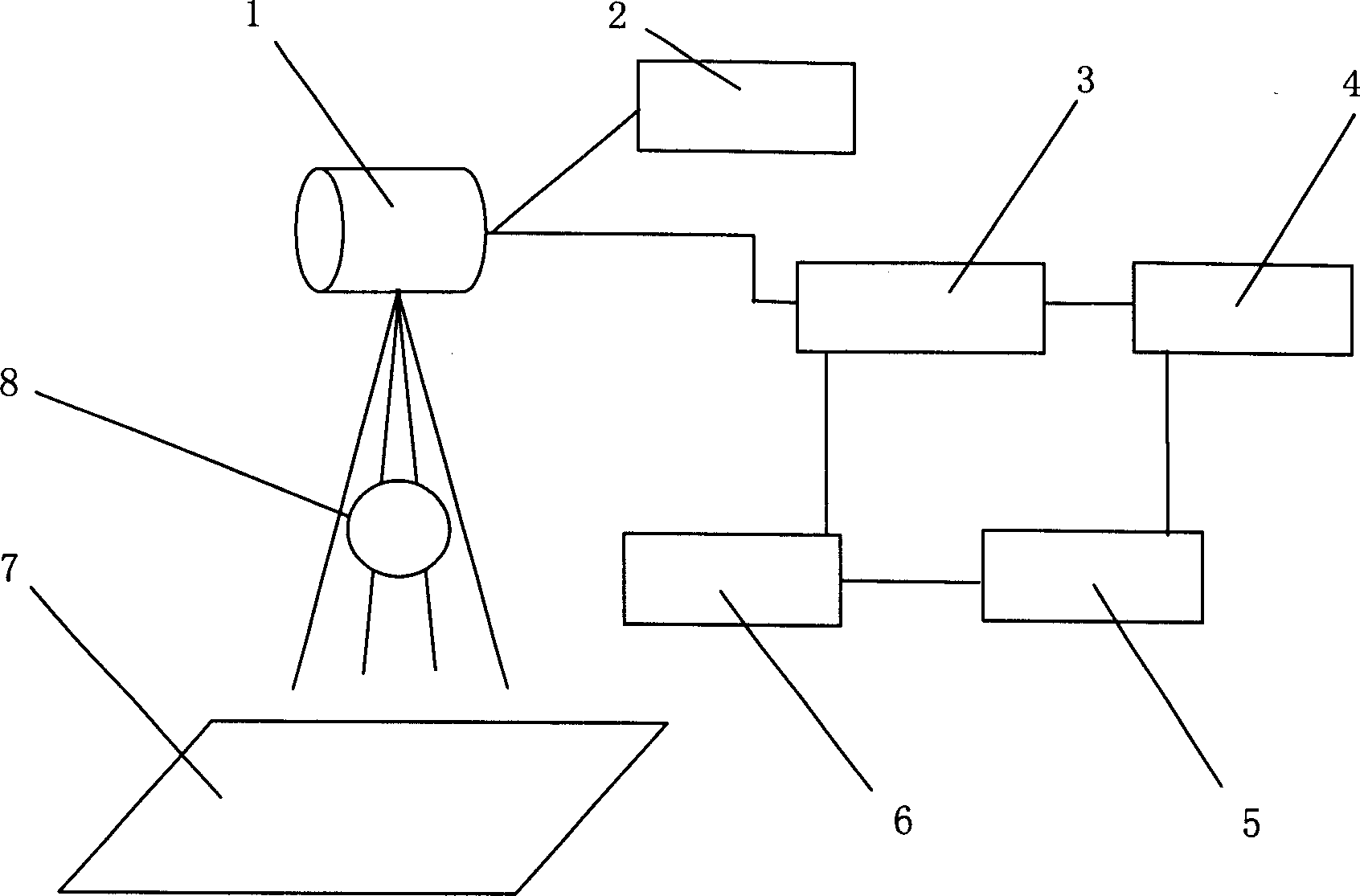

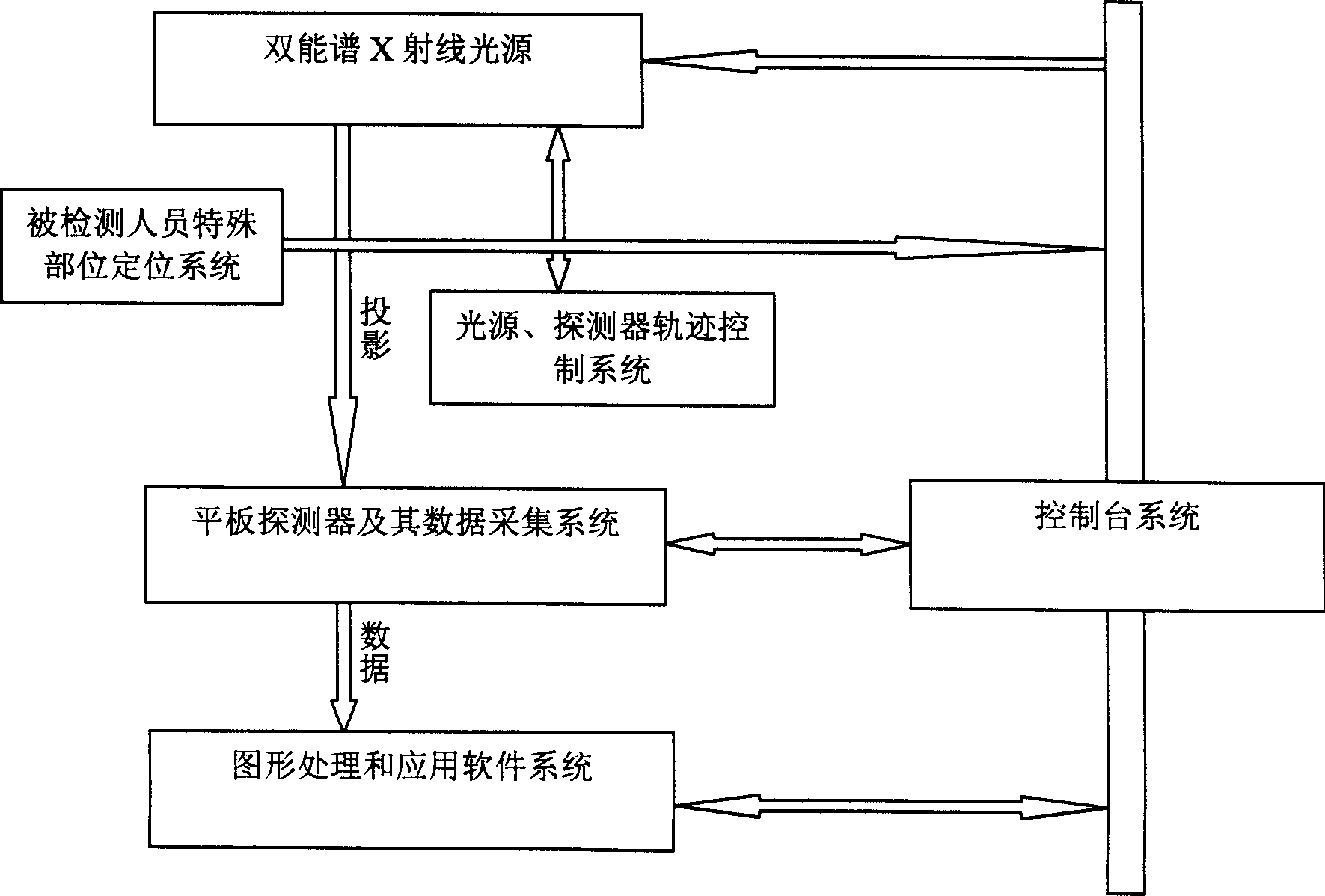

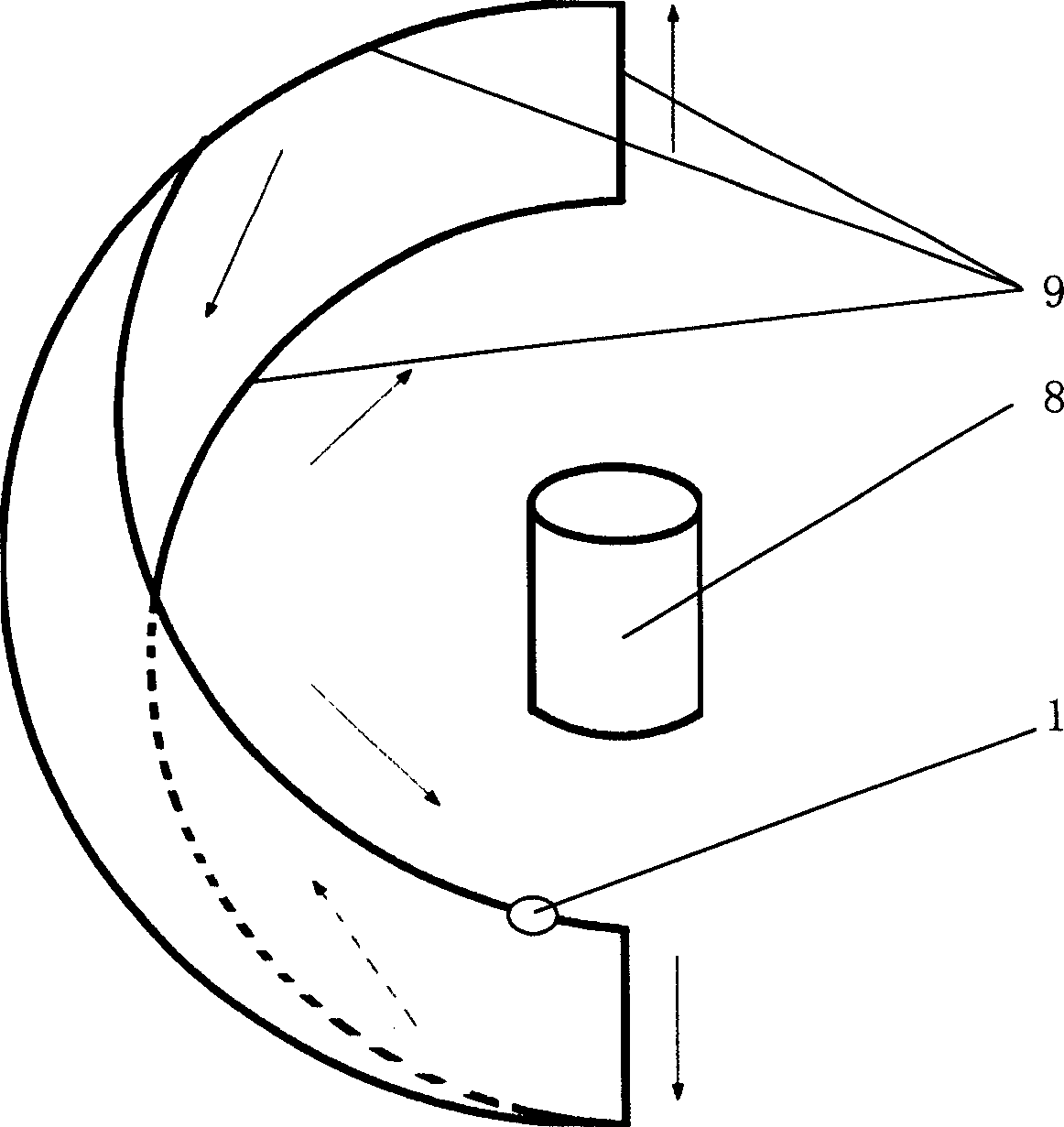

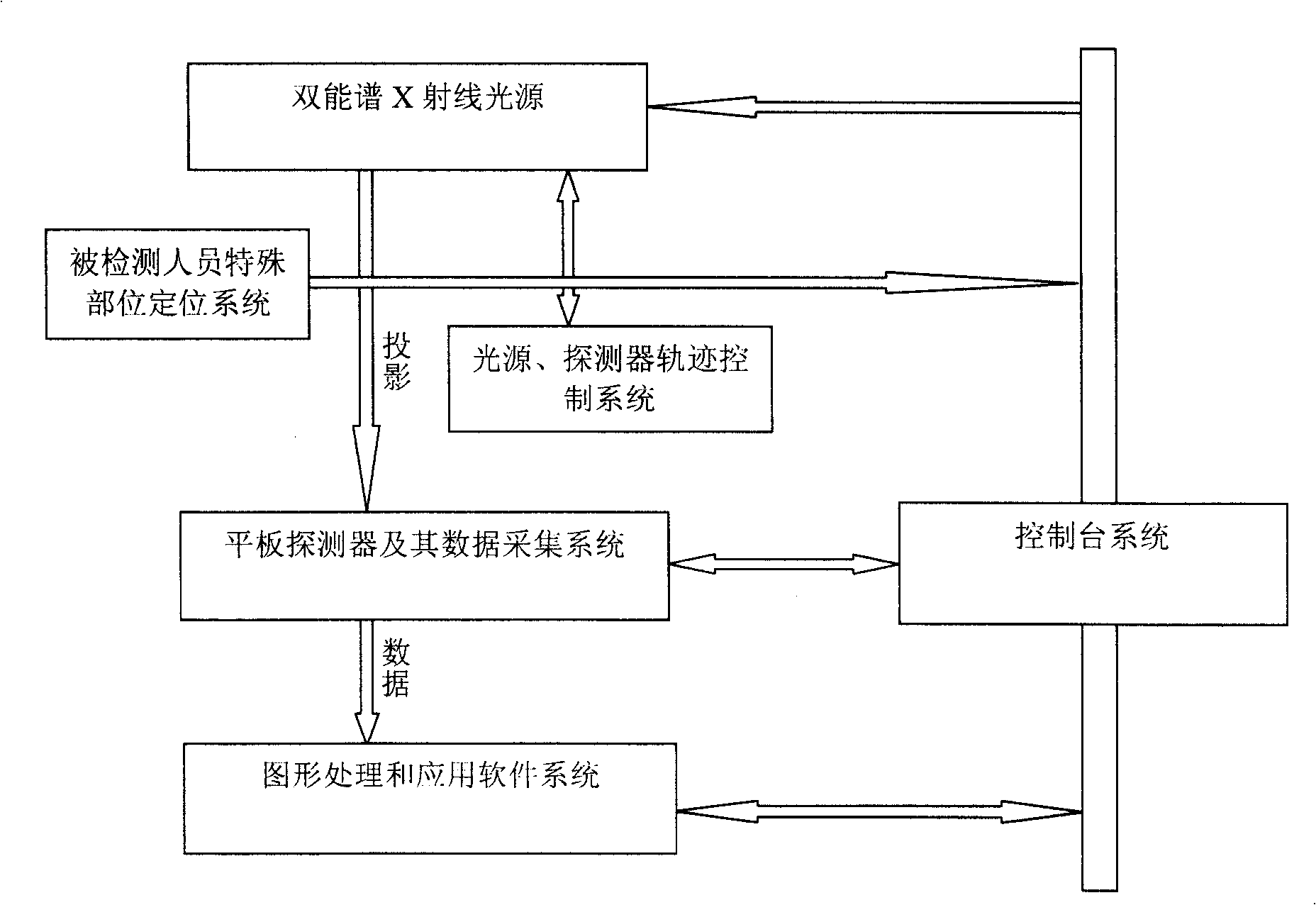

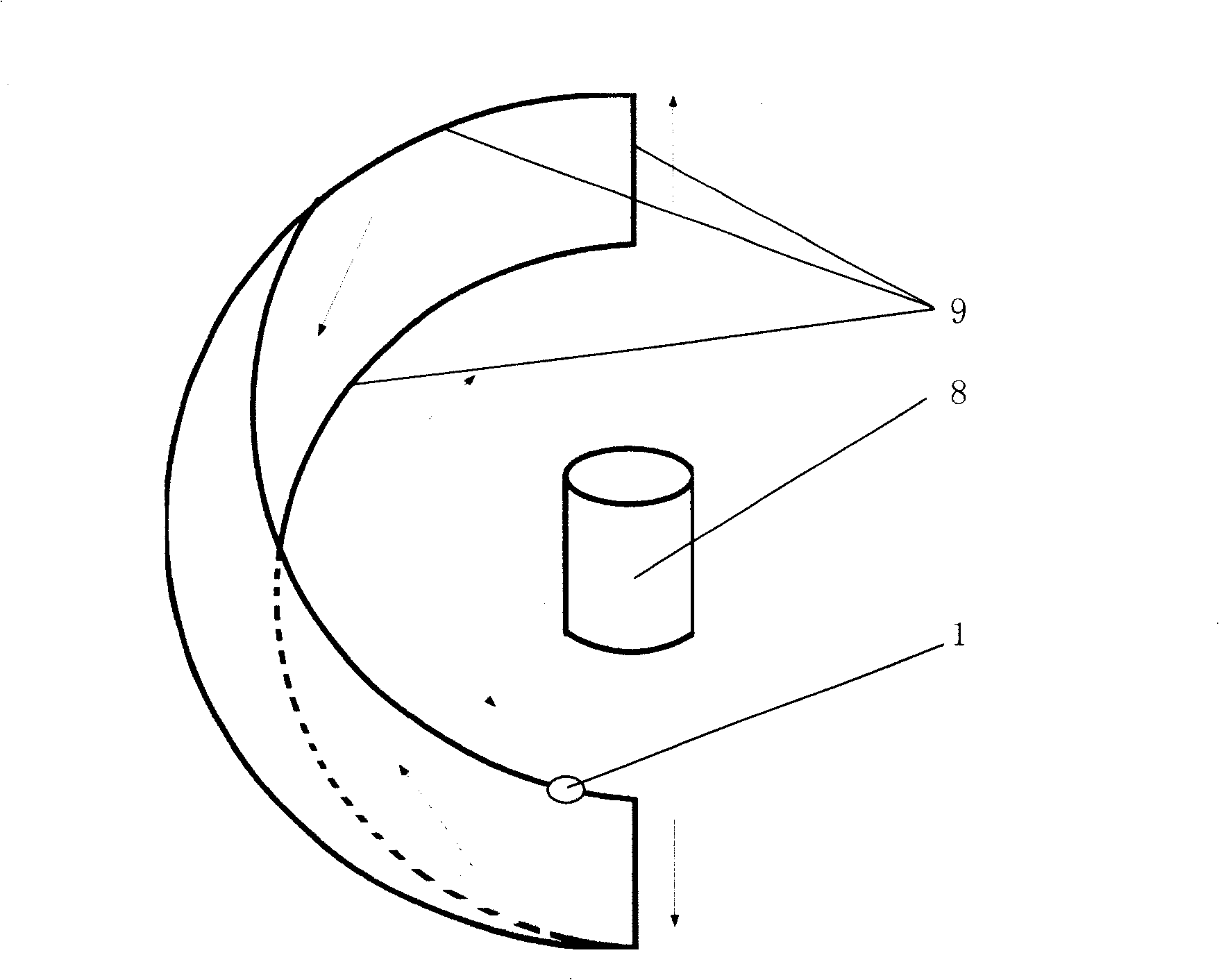

True three-dimensional volume imaging device with dual energy spectrum X-ray beam

This invention is about a dienergetic hard electron (whose energy range is 10-1400keV) three-dimension volume spectrum image-forming device, which contains removable dienergetic X-ray source orª†-radioisotope sources inside the system and the suited X-ray plate detector. The light source and the detector have a mobile linkage on a rotatable bracket, and between them there is a space for monitoring substance. The source move track can be a closed curve composed of two parallel arcs and two parallel beelines separately linking both ends of the two arcs. Its radial beam is a prick beam that always covers the whole monitoring substance, and faces to detecting side of the detector and forms monitoring substance projection on the detecting side. By using this invention, the high-resolution and isotropical three-dimension data set of soft and hard tissue on inspection personnelí»s unusual position can be obtained, and do image rebuilding image processing through computer system to form the three-dimension volume image. It can be used to physic examine flesh or inspect inner structure of industrial goods.

Owner:北京海思威科技有限公司

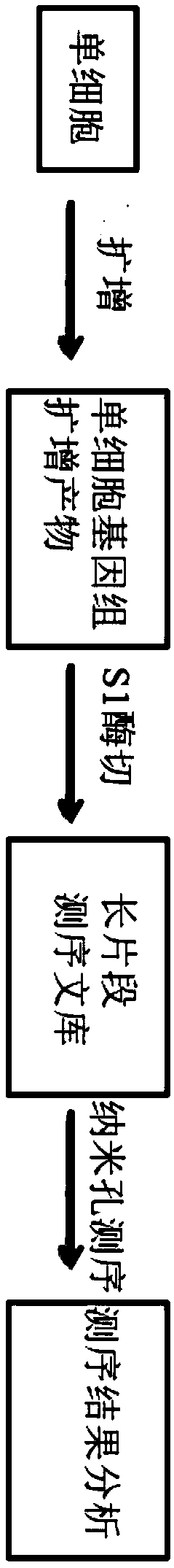

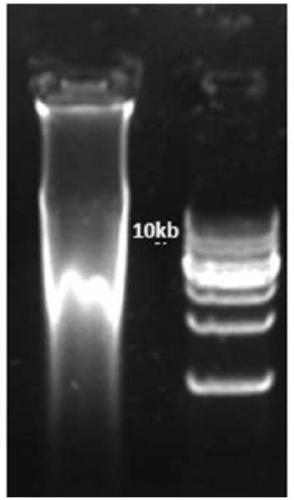

Single cell whole genome sequencing method

InactiveCN111363795AIncrease coverageAvoid heterogeneous amplificationMicrobiological testing/measurementGenomic sequencingWhole genome sequencing

The present invention provides a single cell whole genome sequencing method and an application of an amplification method in constructing a gene library and conducting single molecule sequencing. Theamplification method comprises step of contacting nucleic acid with nucleic acid polymerase and random primers to carry out multiple displacement amplification of the nucleic acid and strands.

Owner:TSINGHUA UNIV

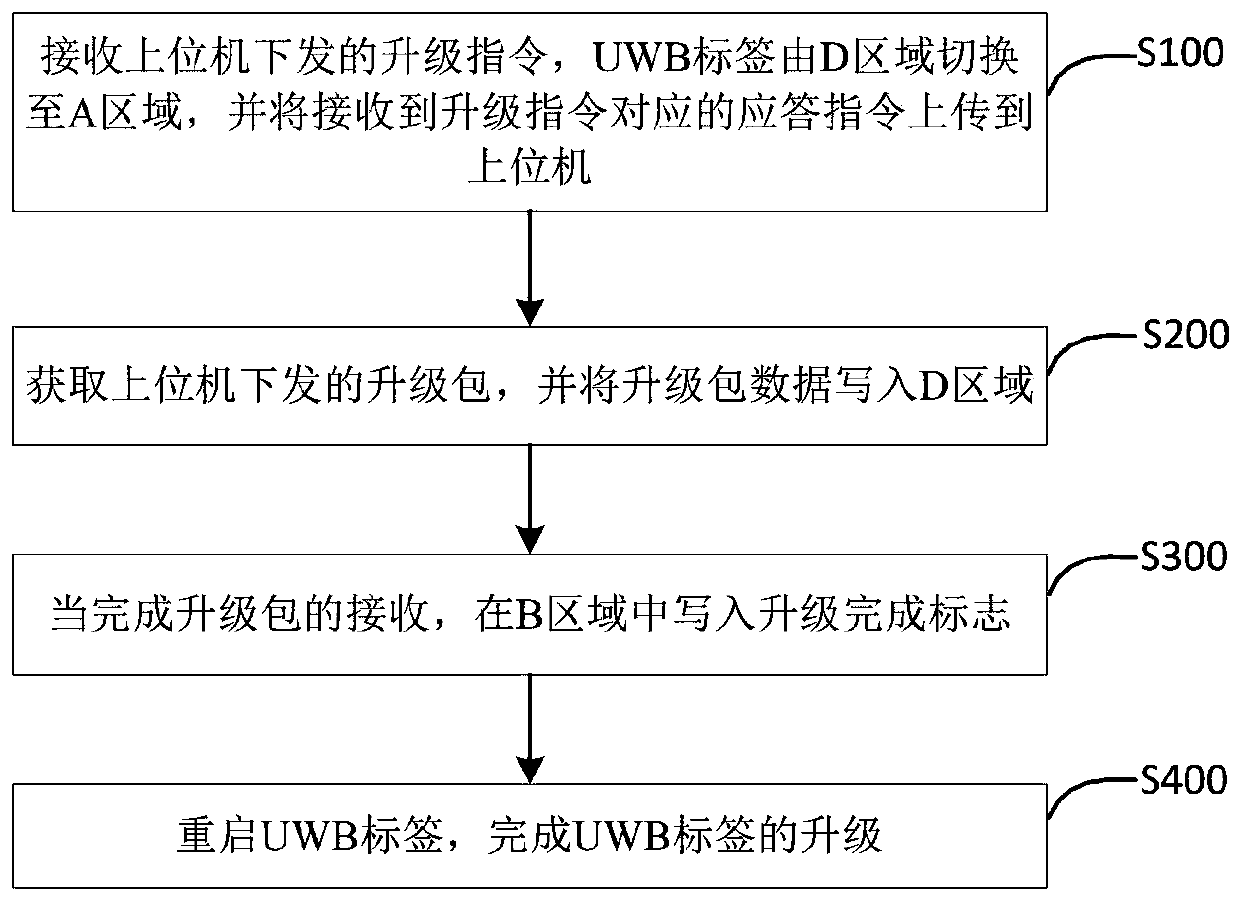

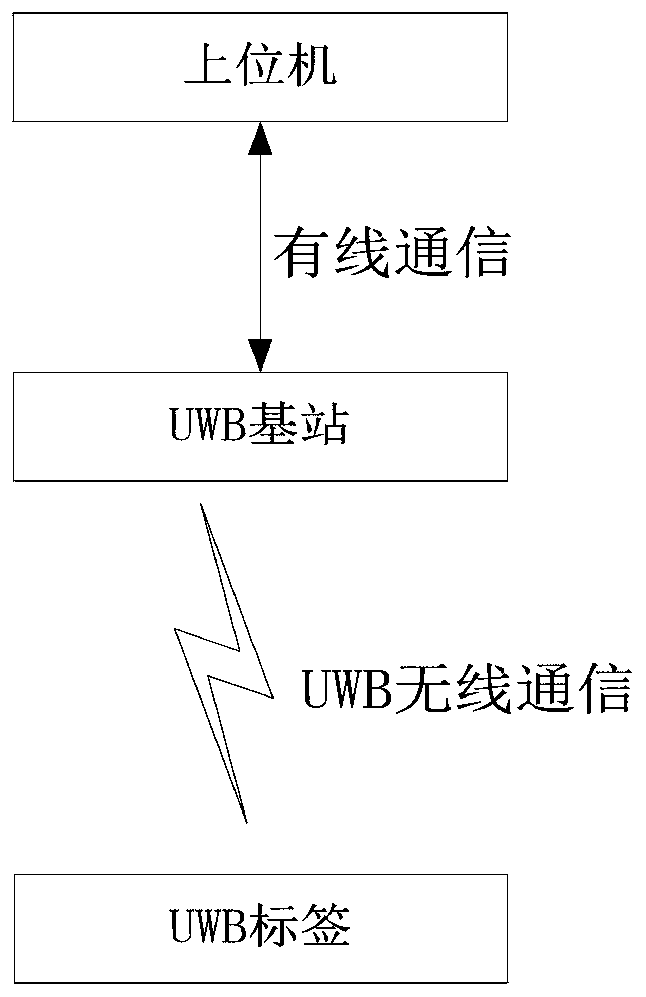

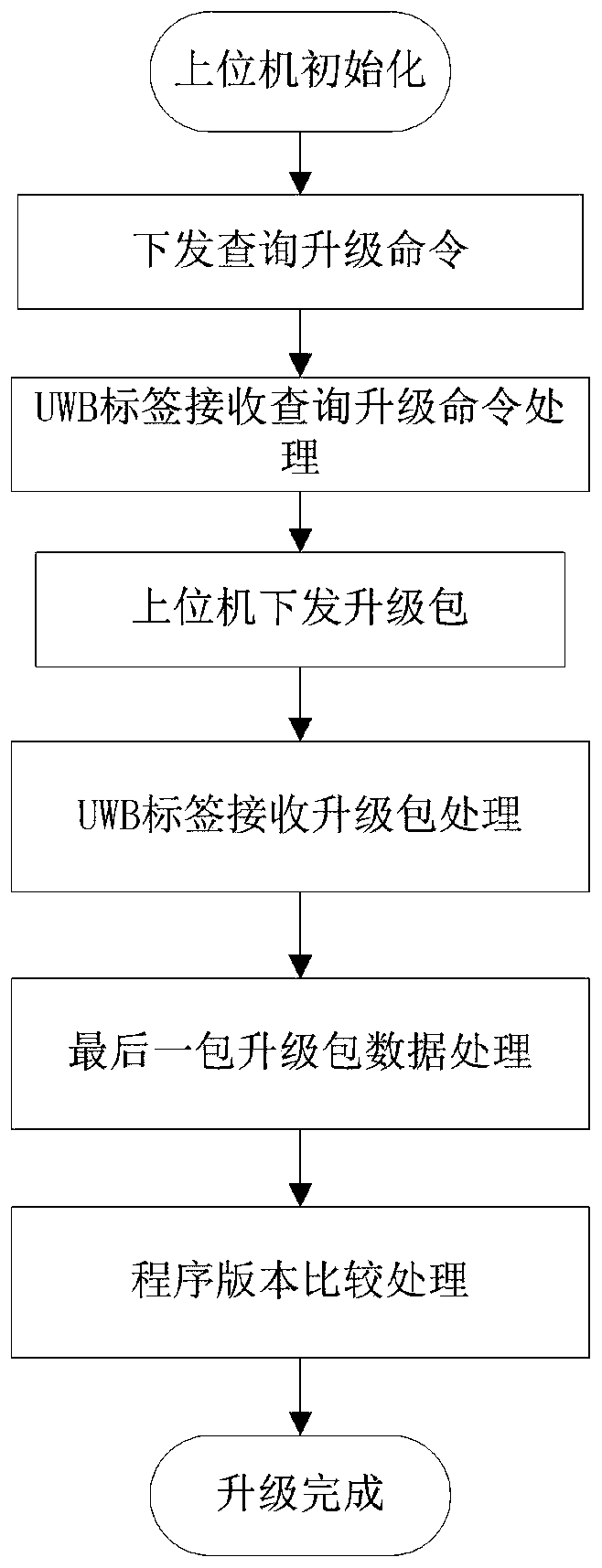

UWB label upgrading method and system based on ultra-wideband wireless communication

PendingCN111182506AImplement escalation controlAvoid missing defectsError prevention/detection by using return channelVersion controlComputer hardwareUltra-wideband

The invention discloses a UWB label upgrading method and system based on ultra wide band wireless communication. The UWB label comprises an area A used for storing BootLoader, an area B used for storing an upgrading mark, an area C used for configuring parameters and an area D used for storing a terminal program. UWB label upgrading comprises the following steps: receiving an upgrading instructionissued by an upper computer, and switching the UWB label from the area D to the area A; obtaining an upgrade package issued by the upper computer, and writing upgrade package data into the area D; when receiving of the upgrade package is completed, writing an upgrade completion mark into the area B; and restarting the UWB label, and completing upgrading of the UWB label. According to the UWB label upgrading method, online software upgrading of the UWB label is achieved on the premise that the cost is guaranteed, and the maintainability of the system is improved.

Owner:HEFEI GOCOM INFORMATION &TECH CO LTD

Steel tube supersonic flaw detecting longitudinal defect oil-dipping finger touch positioning method

InactiveCN101241109AImprove pass rateReduce generationAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringReference wave

The present invention provides a steel tube ultrasonic inspection longitudinal defect finger dunking oil touching orientation method including steps of: (1) finding highest echo of defect by probe to achieve reference wave height and keeping the probe fixed on the steel tube; (2) touching steel tube surface frontad around the circumference direction from the front of the probe by finger dipped oil, the range of defect wave will bob along with the moving time of finger touched along the surface of steel tube, touching in negative direction along with original touching path until the defect wave stop bobbing, confirming the last jumping point, namely the position of the defect on the steel tube. The method of present invention can direct detection personnel determining preliminarily the defect to employ efficient measure in detection process to avoid defect determination miss. In addition, the method of present invention can locate steel tube to be repaired and grinded to determine again to save expense of batch steel tubes reject to improve the qualified rate of steel tubes. And the method meets field needs and improves precision and speed of defect location.

Owner:TIANJIN PIPE (GROUP) CORP

Equipment for detecting foreign matter in bottles and bottle-gripping and rotary device thereof

ActiveCN101644658BAvoid missing defectsWill not block collectionMaterial analysis by optical meansForeign matterImaging processing

The invention discloses equipment for detecting foreign matter in bottles, comprising a bottle-gripping and rotary device, an image collector which is arranged at one side of a bottle and is used for collecting images of rotary liquid in the bottle, and an image processing device for judging whether foreign matter exists in the liquid in the bottle, wherein, the bottle-gripping and rotary device comprises a bottle rotating sleeve which is supported at a supporting seat and driven to rotate by a drive mechanism, a clamping jaw seat which is connected with the bottle rotating sleeve and can rotate with the bottle rotating sleeve, a clamping jaw in pin-jointed connection with the clamping jaw seat with the bottom end thereof being provided with a clamping block for clamping bottleneck and the top end thereof being in pin-jointed connection with one end of a connecting rod, a pull rod positioned in the bottle rotating sleeve with the bottom thereof being connected with the other end of the connecting rod, and a lifting mechanism arranged at the upper end of the pull rod for driving the pull rod to move in the bottle rotating sleeve. The invention has the advantages of avoiding the defect of missed detection due to foreign matter depositing at the bottom of the bottle when the foreign matter in the bottle rotates with the bottle and using the clamping jaw to only clamp the bottleneck which is in favor of collecting images of the foreign matter.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

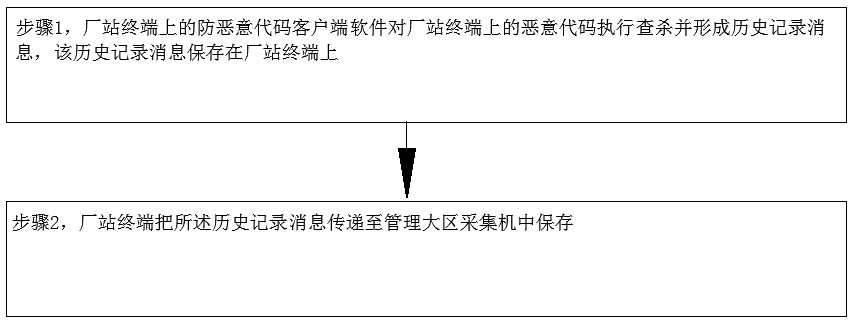

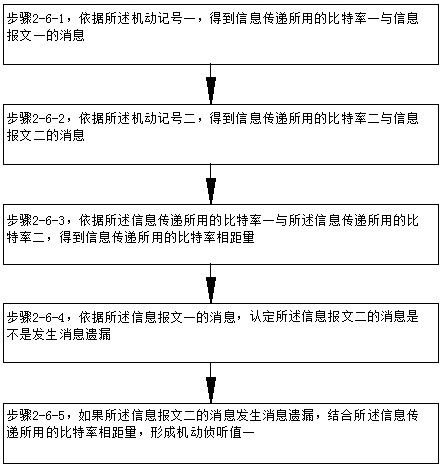

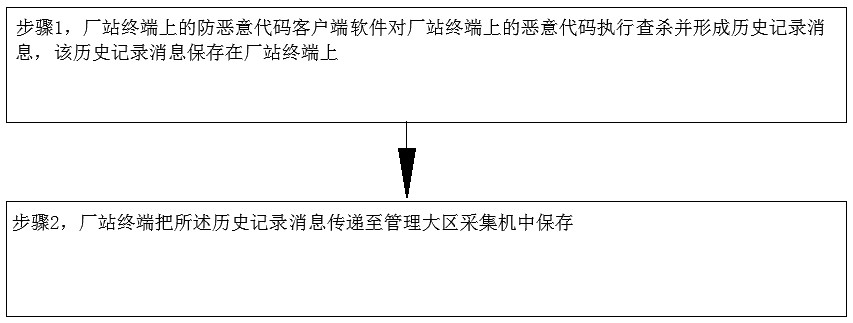

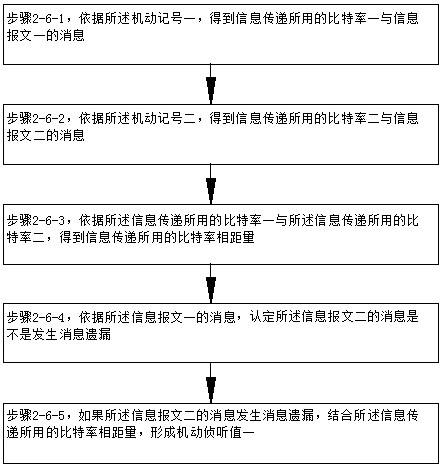

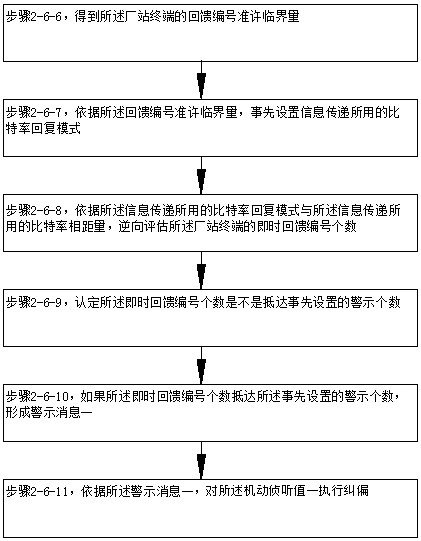

System and method for detecting comprehensive malicious codes in electric power production system

ActiveCN114266051ADelivered correctly and smoothlyImproved bitrate performanceData processing applicationsPlatform integrity maintainanceEngineeringElectric power

The invention discloses a comprehensive malicious code detection system and method in an electric power production system, and the method comprises the steps: setting anti-malicious code client software on a plant station terminal in a plant station, and enabling the anti-malicious code client software to be used for searching and killing malicious codes on the plant station terminal and forming a historical record message; a management large area acquisition machine is arranged in the production control large area; the plant station terminal is connected with the management large area acquisition machine; the plant station terminal and the management large area acquisition machine are connected with the attached server; the defects that in the prior art, historical record messages formed by malicious code prevention client software are only stored locally and are not transmitted to a management region acquisition machine, so that the messages acquired by the management region acquisition machine are not complete, and the historical record messages are omitted during transmission due to message congestion of the management region acquisition machine are effectively avoided.

Owner:江苏政采数据科技有限公司 +1

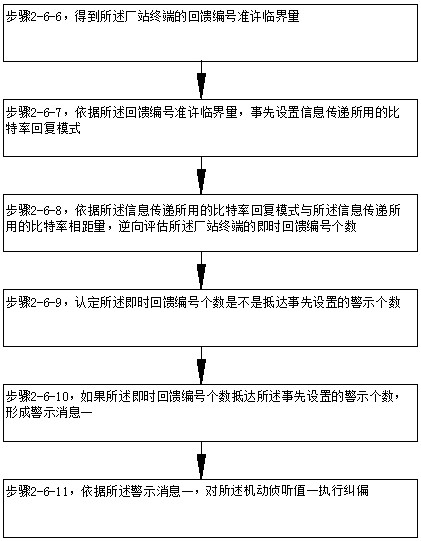

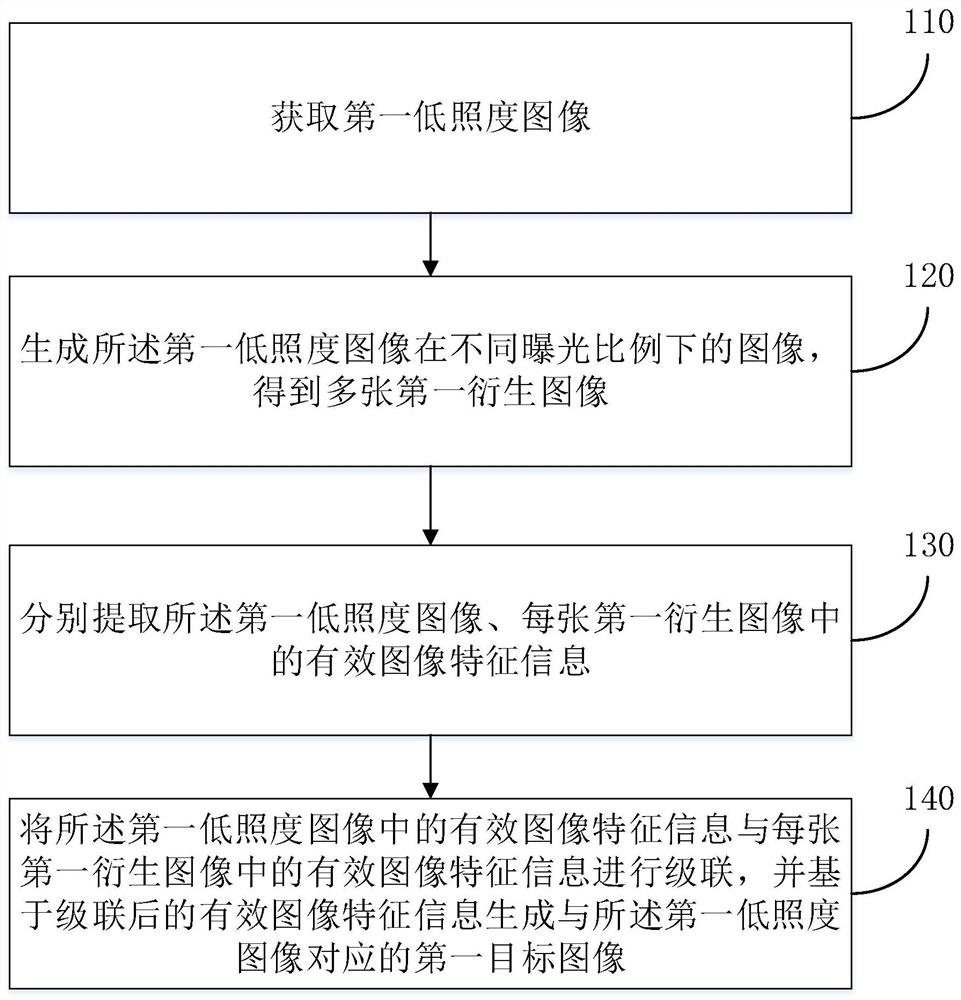

Image processing method and device

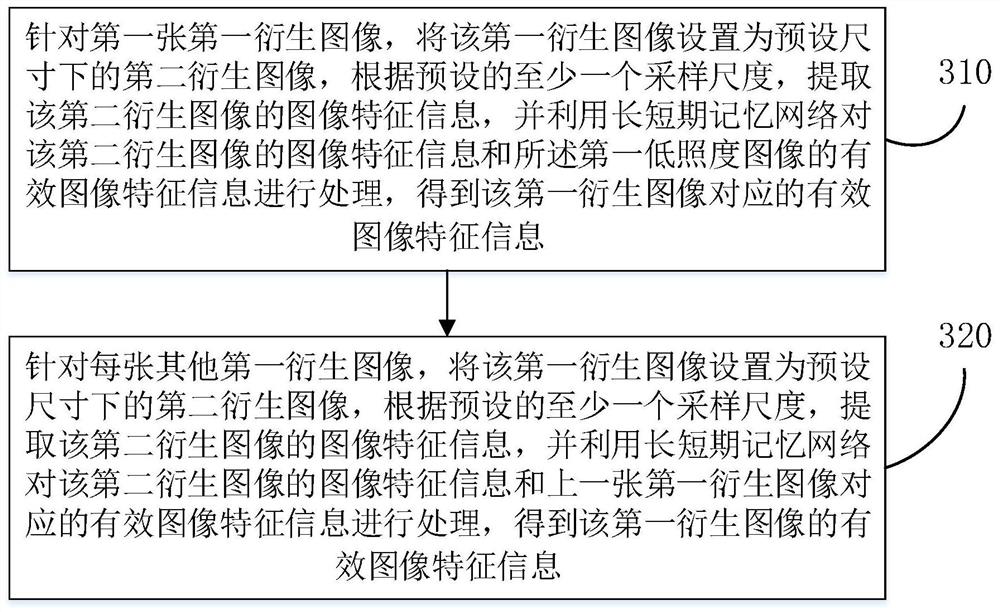

PendingCN111861897ASolve the defect of low exposure ratio sensitivityReduce processing timeImage enhancementImage analysisImaging FeatureExposure

The invention provides an image processing method and device. The method comprises the steps: firstly obtaining a first low-illumination image; then, images of the first low-illumination image under different exposure proportions are generated, and a plurality of first derivative images are obtained; then, respectively extracting effective image feature information in the first low-illumination image and each first derivative image; and finally, cascading the effective image feature information in the first low-illumination image with the effective image feature information in each first derivative image, and generating a first target image corresponding to the first low-illumination image based on the cascaded effective image feature information. According to the technical scheme, the clear target image is determined through the low-illumination image and the derivative images of the low-illumination image under different exposure proportions, so that the defect of low sensitivity tothe exposure proportion of the low-illumination image in the prior art is overcome, and the defect of loss of image details can be effectively avoided.

Owner:BEIJING DIDI INFINITY TECH & DEV

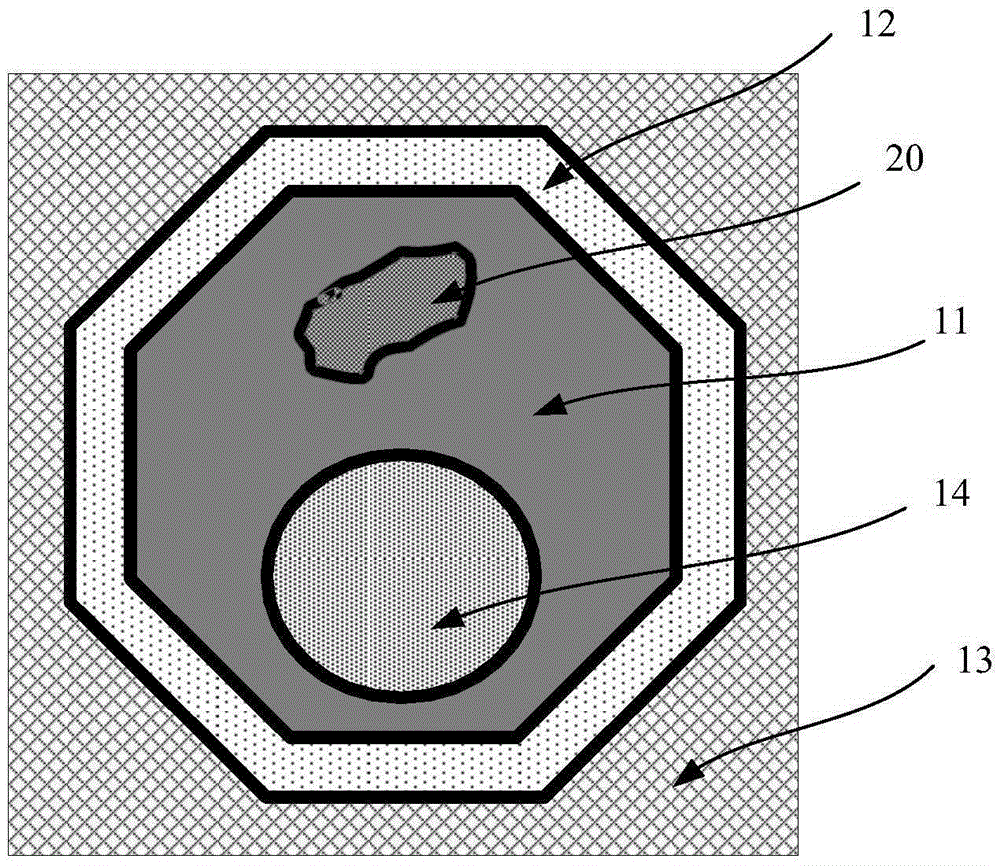

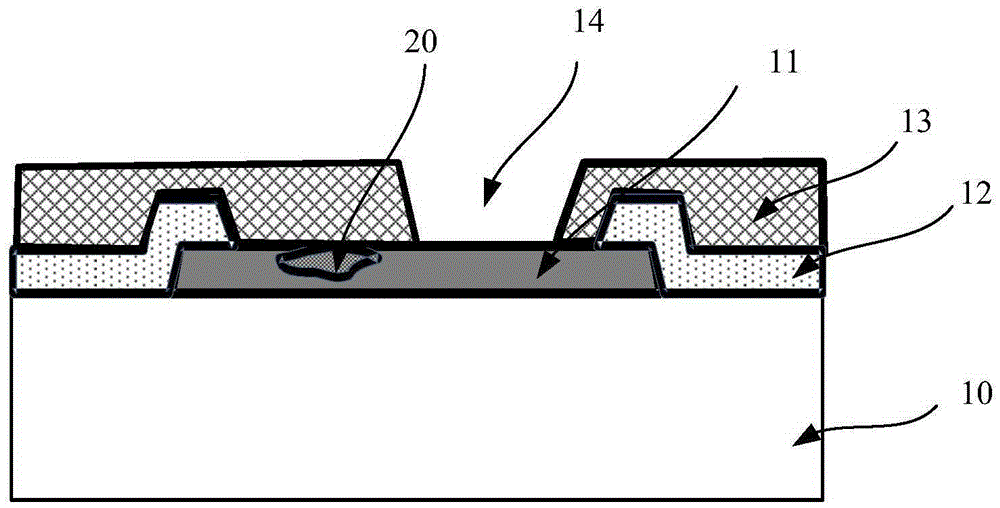

Semiconductor wafer test method, projection manufacturing method, semiconductor device and electronic device

InactiveCN106816394AAvoid missing defectsPreparation impactSemiconductor/solid-state device testing/measurementSolid-state devicesPower semiconductor deviceEngineering

The invention provides a semiconductor wafer test method, and a wafer projection manufacturing method, a semiconductor device and an electronic device and relates to the technical field of a semiconductor. The semiconductor wafer test method comprises a step that during a probe test, test probe mark is made to deviate from the center position of a welding pad. The wafer projection manufacturing method comprises steps that during the probe test, the test probe mark is made to deviate from the center position of the welding pad, is utilized at a welding pad opening forming a wafer projection and is arranged at a region not influenced by the test probe mark. The semiconductor wafer test method and the wafer projection manufacturing method are advantaged in that influence of the test probe mark on manufacturing a ball bottom metal layer in the projection process can be completely prevented, a defect of projection missing can be avoided, packaging reliability is improved, and the packaging yield is further improved. The semiconductor device and the electronic device employing the semiconductor wafer test method and the wafer projection manufacturing method have similar advantages.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

True three-dimensional volume imaging device with dual energy spectrum X-ray beam

This invention is about a dienergetic hard electron (whose energy range is 10-1400keV) three-dimension volume spectrum image-forming device, which contains removable dienergetic X-ray source or gamma-radioisotope sources inside the system and the suited X-ray plate detector. The light source and the detector have a mobile linkage on a rotatable bracket, and between them there is a space for monitoring substance. The source move track can be a closed curve composed of two parallel arcs and two parallel beelines separately linking both ends of the two arcs. Its radial beam is a prick beam that always covers the whole monitoring substance, and faces to detecting side of the detector and forms monitoring substance projection on the detecting side. By using this invention, the high-resolution and isotropical three-dimension data set of soft and hard tissue on inspection personnel's unusual position can be obtained, and do image rebuilding image processing through computer system to form the three-dimension volume image. It can be used to physic examine flesh or inspect inner structure of industrial goods.

Owner:北京海思威科技有限公司

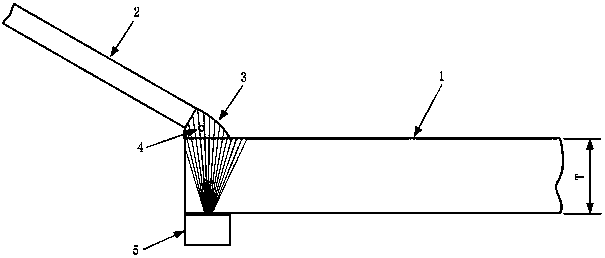

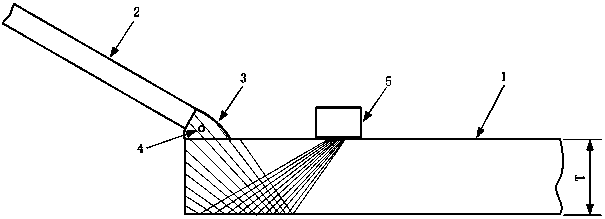

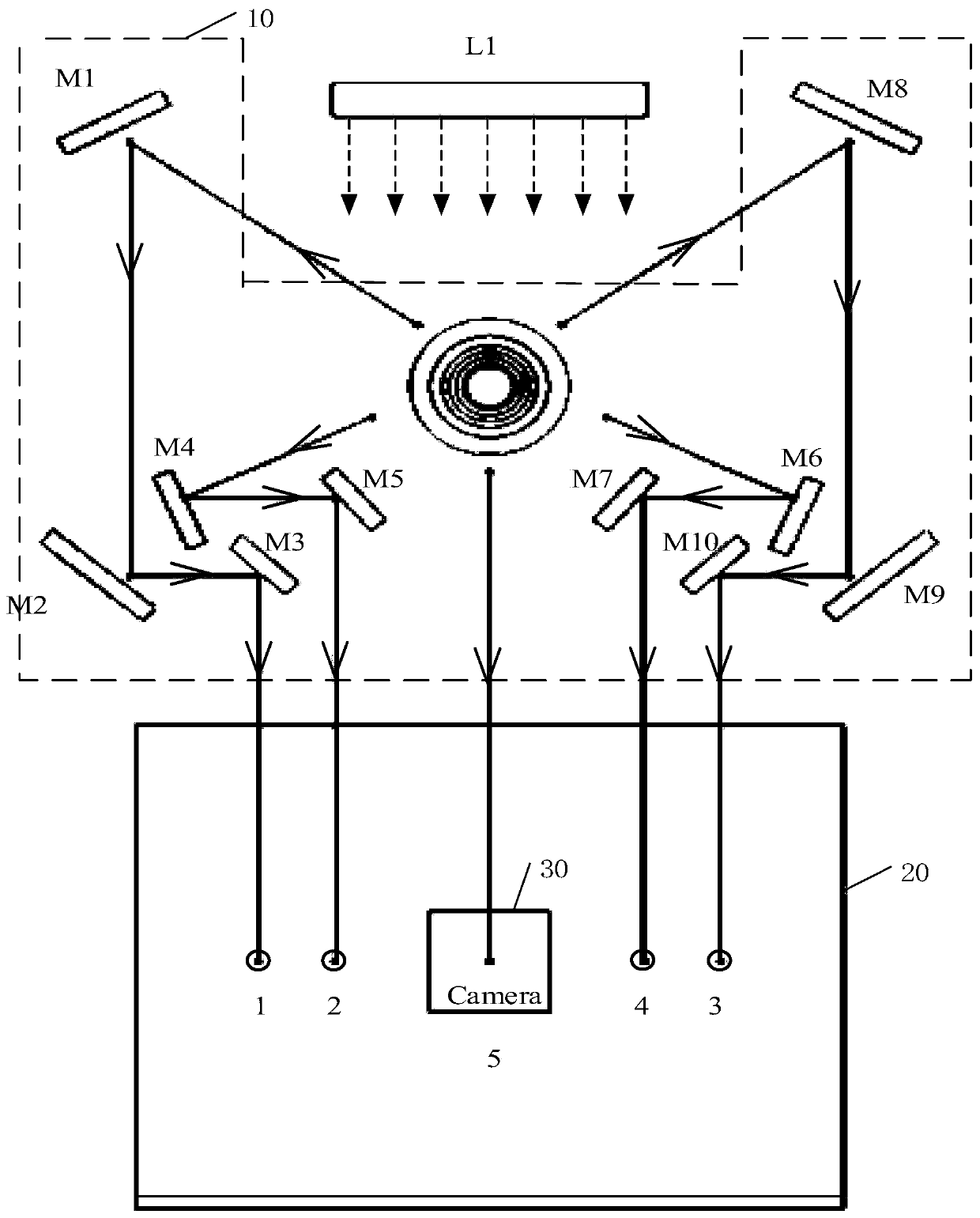

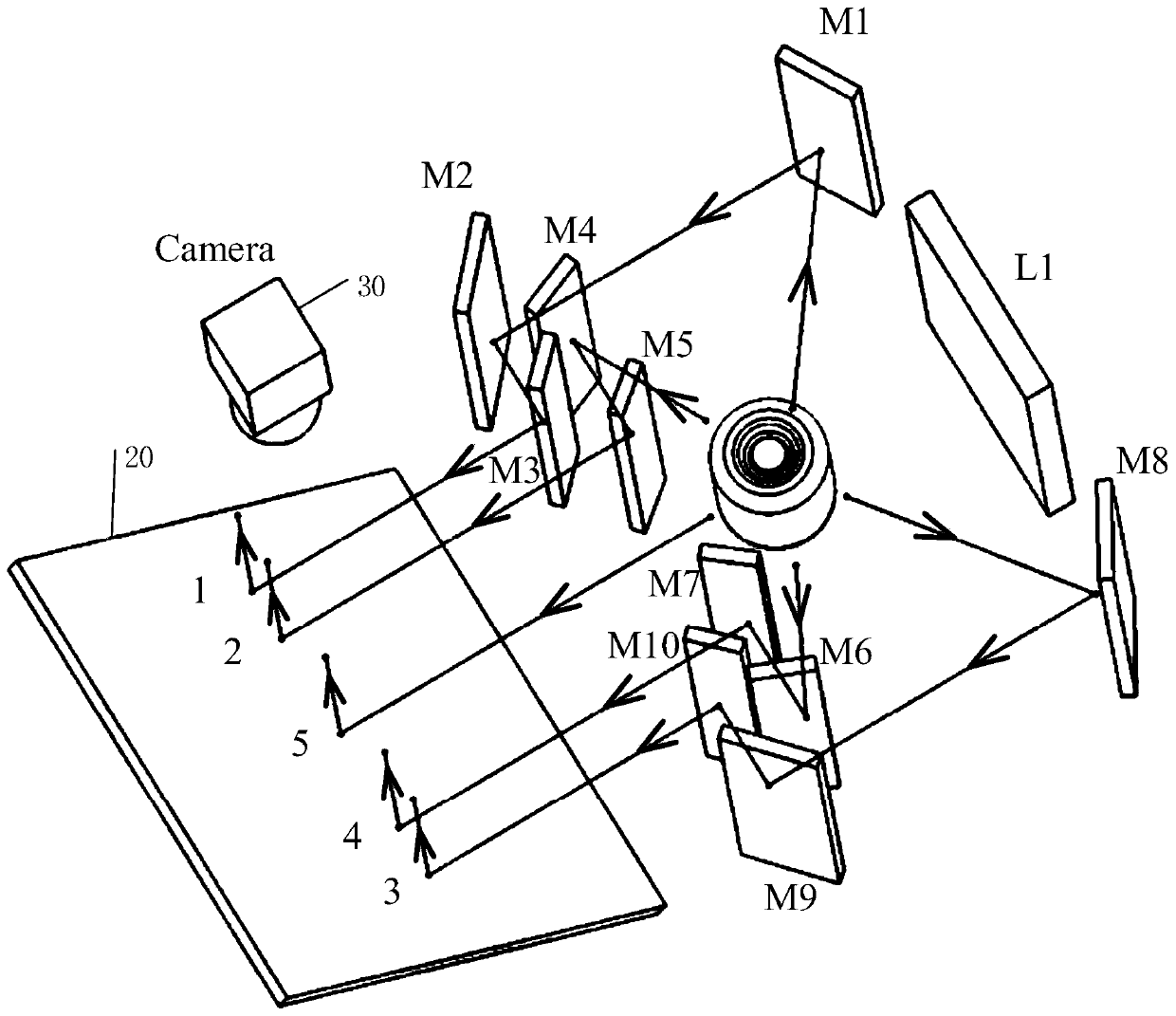

Bottle bottom defect detection system and method

PendingCN111351754ARealize the collectionAvoid blurOptically investigating flaws/contaminationEngineeringField of view

The invention provides a bottle bottom defect detection system and method. The system comprises a light source, a reflector array, a light collecting device, a shooting device and a control device; the light source irradiates the bottom of a to-be-detected product at a detection position; the reflector array receives a plurality of beams of return light carrying bottom information and reflected bya plurality of equally-divided areas at the bottom, and transmits the return light reflected by each equally-divided area to the light collecting device; the light collecting device reflects the plurality of beams of return light into the visual field range of the shooting device in a non-overlapping manner; the shooting device generates a bottom image comprising each equally-divided area according to the plurality of beams of collected return light, and sends the bottom image to the control device; and the control device identifies the bottom defects of the product according to the bottom image and outputs a result. The problems of low human eye visual detection speed, low detection precision and error proneness are overcome.

Owner:GUANGZHOU PANYU POLYTECHNIC

A comprehensive malicious code detection system and method in a power production system

ActiveCN114266051BDelivered correctly and smoothlyImproved bitrate performanceData processing applicationsPlatform integrity maintainanceEngineeringDatabase

A comprehensive malicious code detection system inside a power production system and a method thereof, comprising: anti-malicious code client software is installed on a station terminal in a factory station, and the anti-malicious code client software is used to check and kill the factory station terminal malicious code and form historical record messages; the production control area is equipped with a management area acquisition machine; the station terminal is connected to the management area acquisition machine; the plant station terminal and the management area acquisition machine are connected to the attached server Connected; effectively avoiding the historical record message formed by the anti-malicious code client software in the prior art, which is only stored locally and not transmitted to the management area acquisition machine, making the information collected by the management area acquisition machine not complete enough, and the management area acquisition The message congestion of the machine makes the defect of history record message omission during delivery.

Owner:江苏政采数据科技有限公司 +1

A Novel Dual Microphone Speech Detection and Enhancement Method

The invention relates to the field of speech information processing technology and microphone array signal processing and especially relates to the fields of voice activity detection, voice detectionand speech recognition and interaction and the like. The method can effectively detect time frame of a voice activity and can also carry out dynamic regulation on threshold according to noise transform through two dynamic threshold update policies, by taking variability of noise environment into full consideration and based on three groups of auditory features capable of reflecting the ratio of noise energy in the total energy. The detection result can be corrected again through a detection result buffer mode, thereby preventing the defect of detection miss between continuous active voice frames; a noise power spectral density matrix is subjected to adaptive update according to the speech detection result; and furthermore, speech enhancement can be carried out through a Weiner filter, so that the noise can be suppressed under the minimum mean square error criterion.

Owner:成都启英泰伦科技有限公司

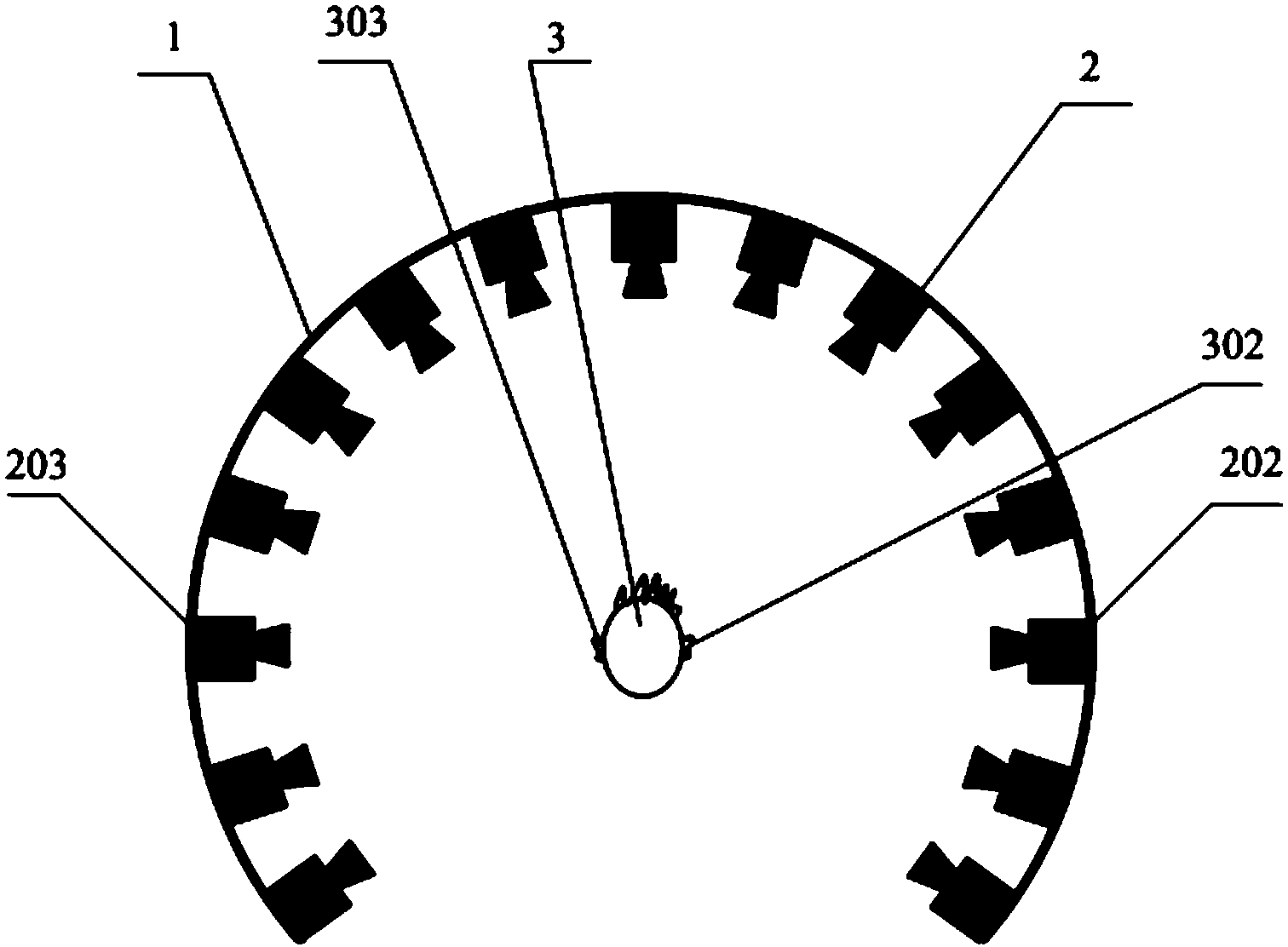

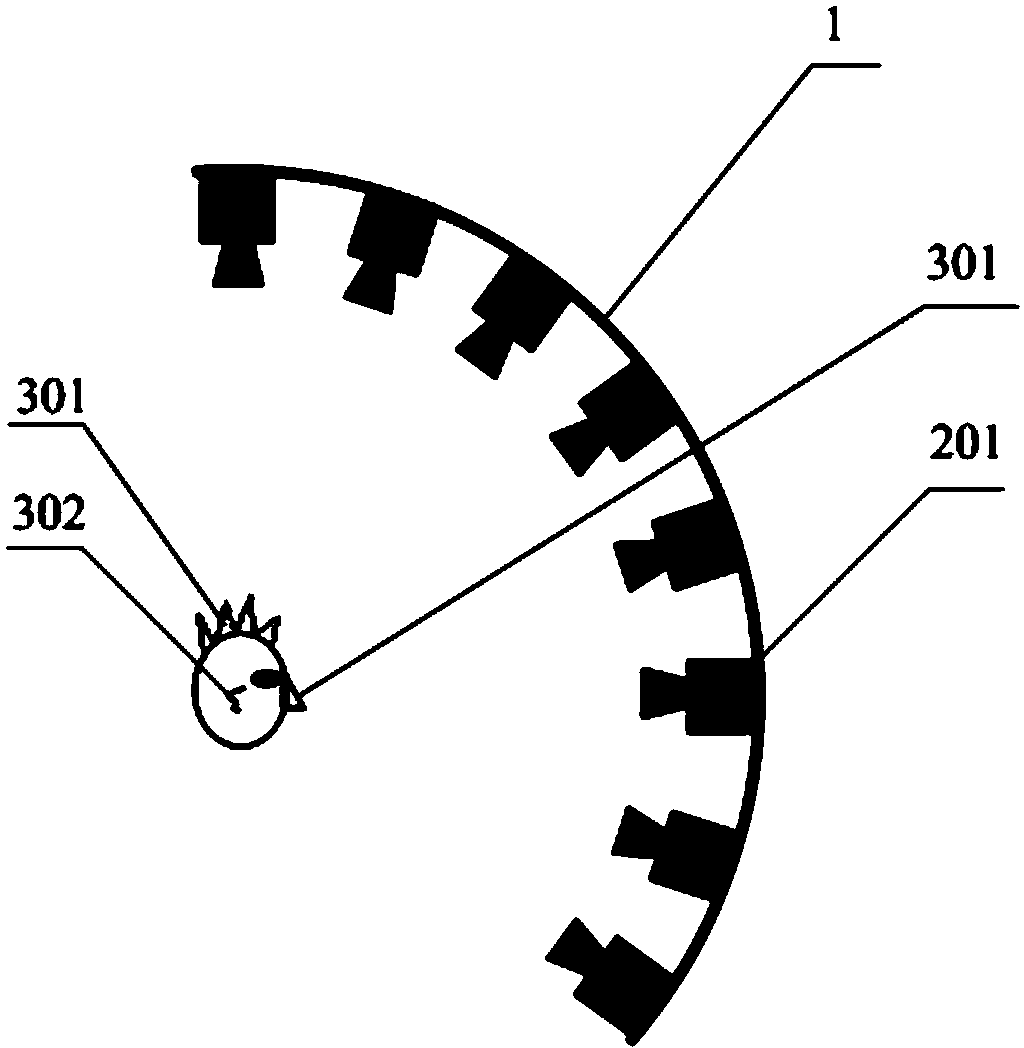

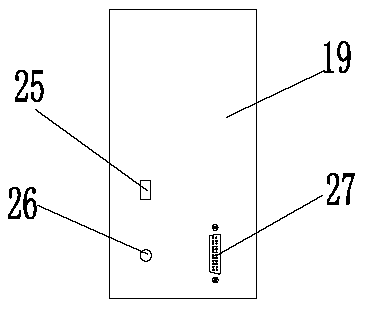

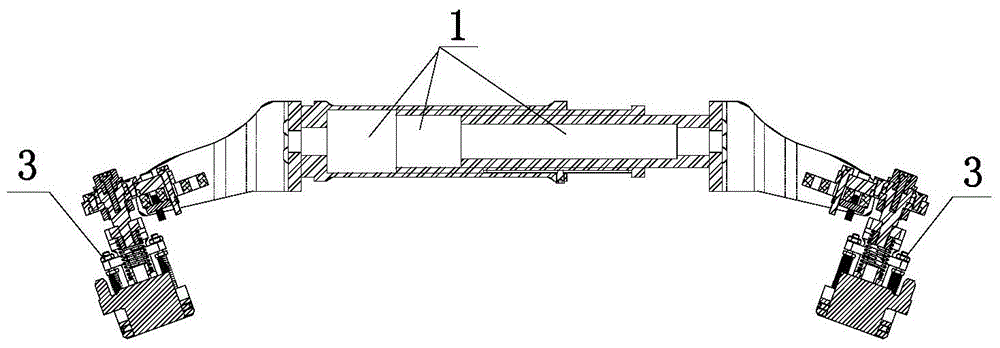

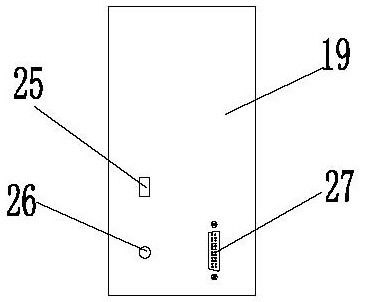

A Manual Ultrasonic Flaw Detection Scanning Device Used for Defect Detection of Train Wheels

ActiveCN103543204BEasy to operate manuallyEasy to detectAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic testingEngineering

The invention discloses a manual ultrasonic flaw detection scanning device for defect detection of train wheels, which comprises components such as a scanning arm, a carrier mounting frame, a probe fixture, and a scanning auxiliary positioning mechanism. The scanning arm adopts a retractable mechanical structure, its length can be adjusted, and it has an automatic locking function. The carrier mounting frames are respectively installed at both ends of the scanning arm, and the probe fixtures are respectively mounted on the carrier mounting frames The fixture is installed on the crossbeam, which can be moved and fixed on the fixture installation beam according to the detection needs. The scanning auxiliary positioning mechanism is installed on the inner side of the carrier mounting frame and rolls along the top of the rim during the detection process, which can scan stably device. The present invention can be used in the ultrasonic detection mode of sending and receiving and spontaneous receiving at the same time, and has the advantages of convenient manual operation, adjustable probe distance, fixed relative position, stable detection effect and the like.

Owner:BEIJING LEAD TIME SCI & TECH

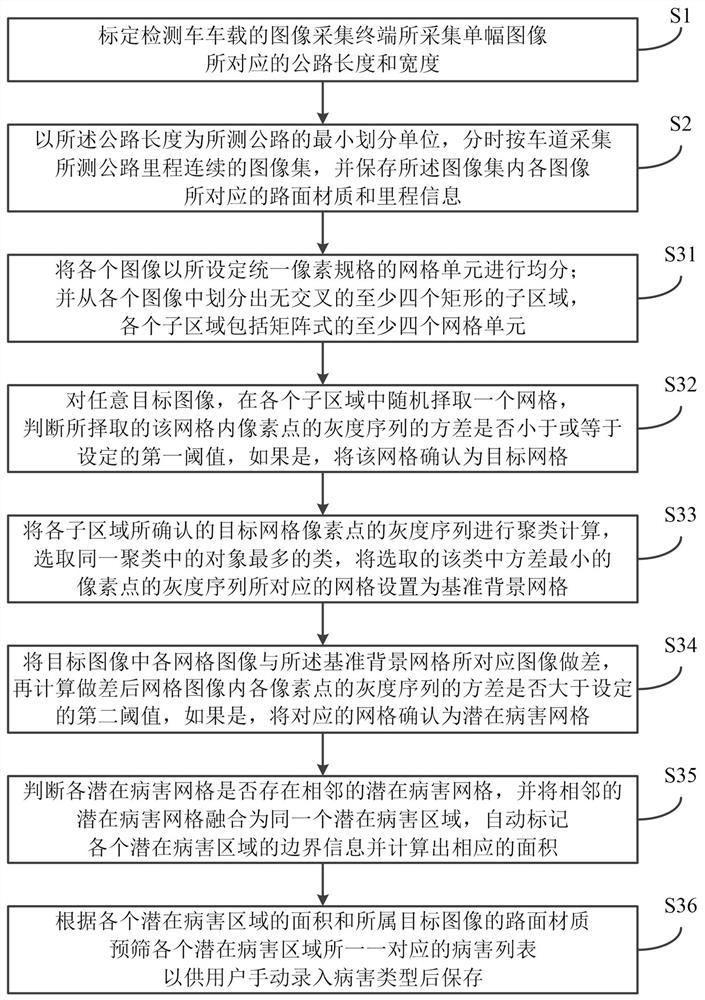

Image processing method and system in highway technical condition evaluation system

PendingCN114757887AAvoid misjudgmentSimplify complexityImage enhancementImage analysisDisease areaEngineering

The invention relates to the technical field of image processing, and discloses an image processing method and system in a highway technical condition evaluation system so as to improve efficiency and reliability. The method comprises the following steps: acquiring continuous image sets of measured highway mileages according to lanes in a time-sharing manner; determining a corresponding reference background grid for each target image; performing subtraction on each grid image in the target image and an image corresponding to the reference background grid, then calculating whether the variance of the gray sequence of each pixel point in the grid image after subtraction is greater than a set second threshold value, and if yes, determining the corresponding grid as a potential disease grid; fusing adjacent potential disease grids into the same potential disease area, automatically marking boundary information of each potential disease area, and calculating a corresponding area; and according to the area of each potential disease area and the pavement material of the target image, pre-screening a disease list corresponding to each potential disease area in a one-to-one manner for a user to manually input a disease type and then store the disease type.

Owner:HUNAN ZHONGDA CONSTR ENG TESTING TECH

A Quantitative Analysis Method for Low-Frequency Array Eddy Current Positioning

ActiveCN108152367BNovel structureEasy to operateMaterial analysis by electric/magnetic meansImaging processingPower station

The invention relates to a low-frequency array eddy current positioning and quantitative analysis method. The technical solution includes the following steps: A. calibrate the detection and judgment standard; B. locate the defect; C. quantify the defect by using the three-dimensional C scanning image processing function ; The present invention eliminates the interference of spatially scattered magnetic flux leakage through the magnetic shielding technology of the magnetic pot and the shielding coil, and improves the defect resolution. During the detection process, the 8 detection coils can be independently imaged, and the detection sensitivity is always consistent, avoiding the Defect missed detection, one operation can detect the inner wall defect of the heating surface steel pipe covered by the probe, without reciprocating operation, by adopting the low-frequency array eddy current positioning quantitative analysis method, taking advantage of the advantages of low-frequency array eddy current probe and three-dimensional C-scan stereo image imaging display, it can effectively solve the problem The positioning and quantification of corrosion defects on the inner wall of the heating surface tube of the utility boiler improves the detection accuracy and field work efficiency, and ensures the reliable and stable operation of the heating surface tube of the utility boiler.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com