A Quantitative Analysis Method for Low-Frequency Array Eddy Current Positioning

A quantitative analysis and array technology, applied in the analysis of materials, material analysis through electromagnetic means, and measurement devices, can solve problems such as boiler heating surface defects, improve detection accuracy and on-site work efficiency, avoid defect missed detection, and easily The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

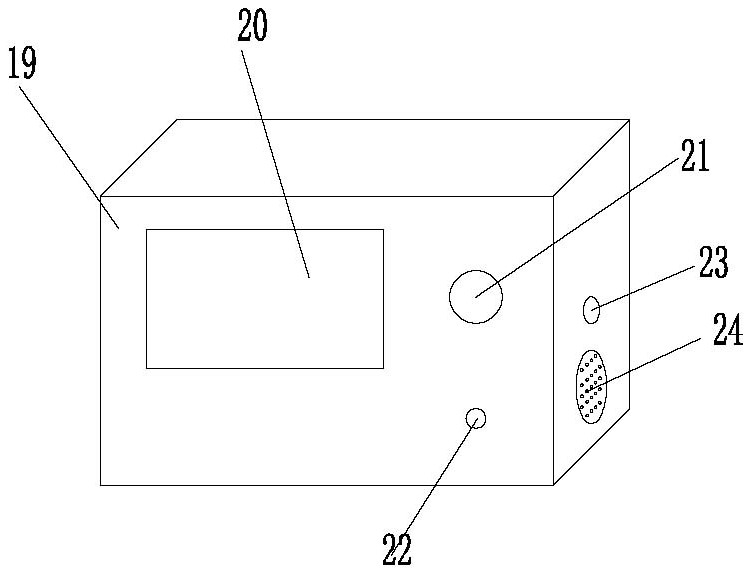

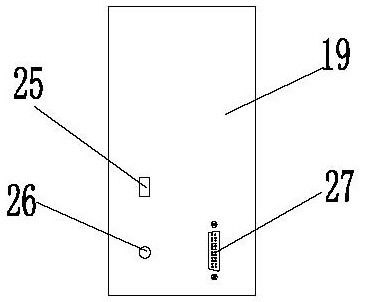

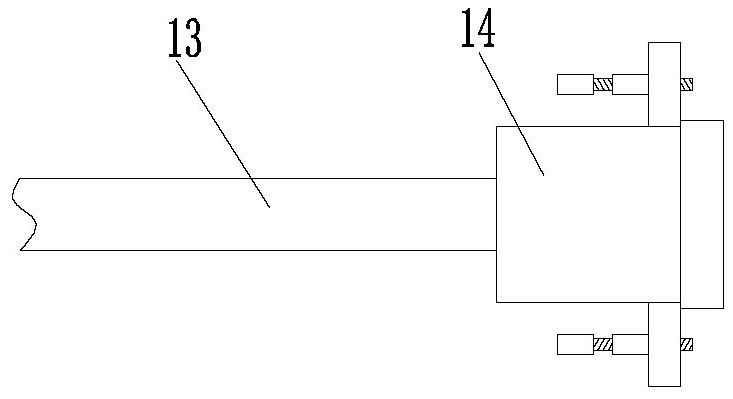

[0037] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] Depend on Figure 1-9 Given, a low-frequency array eddy current positioning quantitative analysis method of the present invention comprises the following steps:

[0039] A. To test and judge the standard of waste and to calibrate

[0040] DL / T 939-2016 "Technical Guidelines for Supervision of Boiler Heating Surface Tubes in Thermal Power Plants" stipulates that the wall thickness reduction of water-cooled walls, economizers, superheaters and reheaters in the low-temperature section should not exceed 30% of the design wall thickness. The wall thickness reduction of the superheater in the high temperature section is not easy to exceed 20% of the designed wall thickness. The amount of thinning is used as the standard for detection and rejection;

[0041]First process the test tubes for comparison of detection sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com