A Manual Ultrasonic Flaw Detection Scanning Device Used for Defect Detection of Train Wheels

A defect detection and scanning device technology, applied in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Small detection sensitivity and other problems, to achieve the effect of stable detection effect, adjustable probe spacing, to avoid missed detection of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

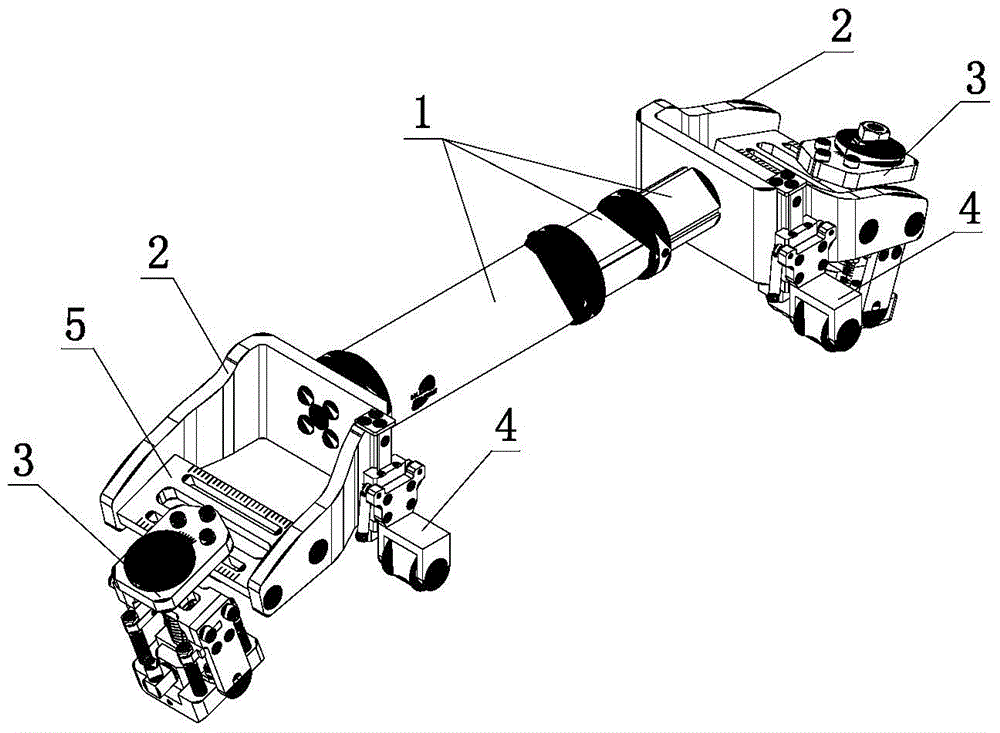

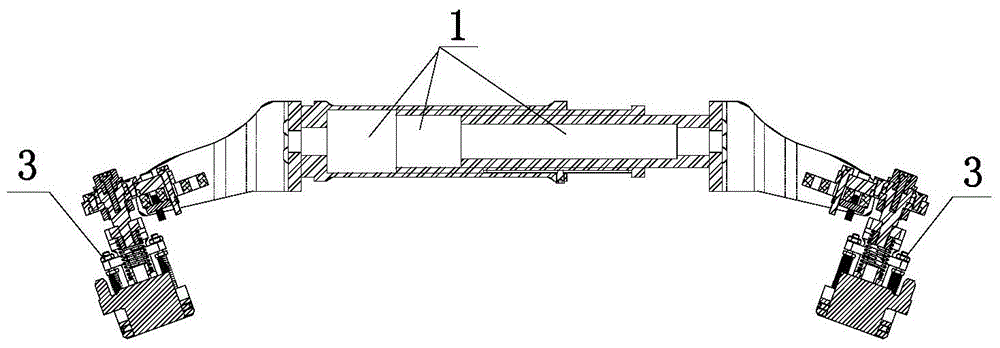

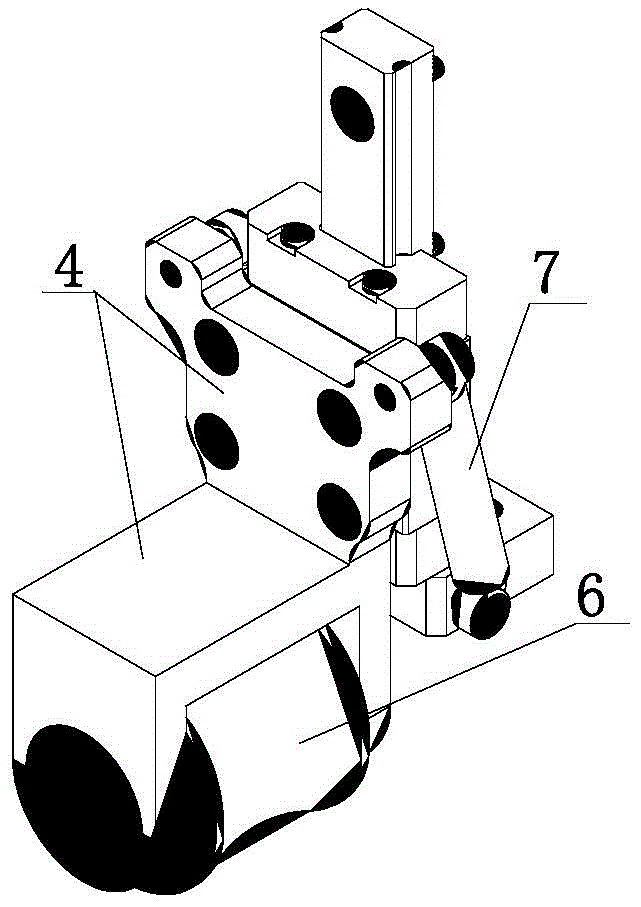

[0020] Such as Figures 1 to 4 As shown, the manual ultrasonic flaw detection scanning device used in the detection of train wheel defects provided by this embodiment includes a scanning arm 1, a carrier mounting frame 2, a probe fixture 3, and a scanning auxiliary positioning mechanism 4, etc. The scanning arm 1 is installed with a sleeve structure, and the length can be adjusted telescopically. The scale line is set on the sleeve, which is convenient to accurately set the overall length of the linear guide rail. The sleeves can be locked by a self-locking switch, and grooves are set on the outer surface of the sleeve. It is used to prevent the rotation between the inner and outer sleeves; the carrier mounting frame 2 is respectively installed at both ends of the scanning arm 1 and fixed by screws. The carrier mounting frame 2 can be a concave or U-shaped structure, etc. Fixture installation crossbeams 5 with scales are respectively arranged at the exit, and the fixture insta...

Embodiment 2

[0024] Compared with Embodiment 1, the telescopic mechanical structure of the scanning arm in this embodiment is the inner and outer tie rods, which are fixed together by bolts. The numbers of the inner and outer tie rods are even and symmetrical to each other. When the inner rod overlaps the outer rod, it shrinks. When the inner rod is pulled out of the outer rod, it is stretched to adjust the length of the scanning arm.

[0025] Compared with the existing technology, it makes up for the deficiency of the defect detection of the probe in the spontaneous and self-receiving mode during the manual operation of the traditional wheel defect. The detection sensitivity of crack defects is high, and at the same time realizes the two-way scanning of the radial and oblique cracks of the spokes, avoiding missed detection of defects. The scanning device has the advantages of convenient manual operation, adjustable probe spacing, fixed relative position, and stable detection effect. It pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com